In the realm of energy solutions, having a clear comprehension of the structure and organization of vital elements is essential. This section delves into the intricacies of these essential systems, aiming to provide insight into their configurations and functionality. By examining the detailed arrangements, users can enhance their maintenance and operational efficiency.

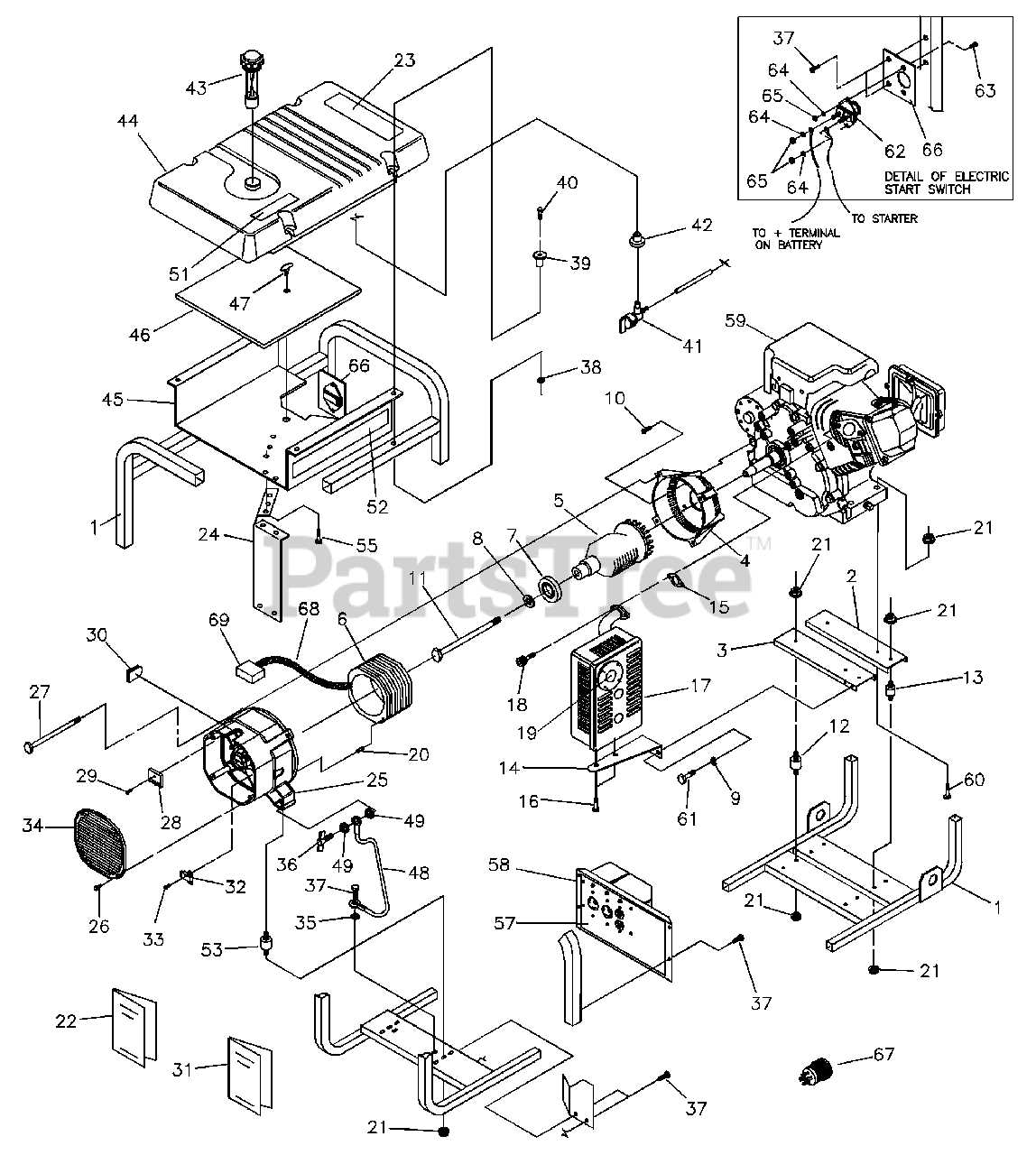

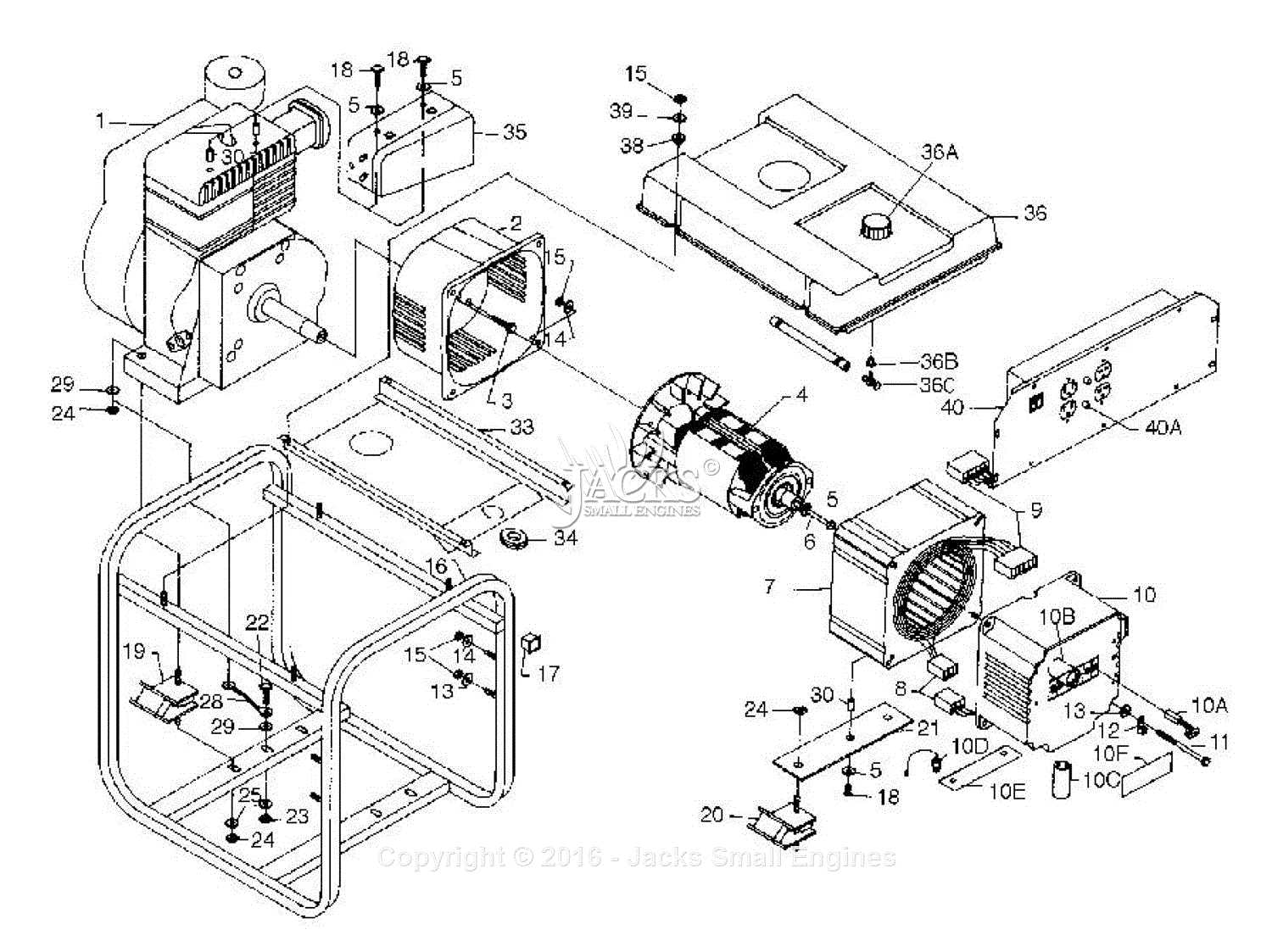

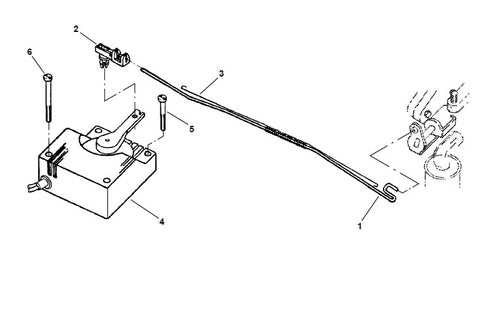

The availability of precise visual representations allows for easier identification of each element’s role within the larger framework. These illustrations serve as invaluable resources for both technicians and enthusiasts, facilitating a deeper understanding of how various components interact. Knowledge of these layouts can significantly simplify troubleshooting and repairs.

Furthermore, familiarity with the schematics not only aids in resolving immediate issues but also empowers users to optimize their setups for better performance. Whether for routine checks or major overhauls, these detailed guides are crucial for anyone involved in the upkeep of energy solutions. Embracing this knowledge ultimately leads to more reliable and efficient operation.

Understanding Onan 5000 Generators

This section explores the key features and functionalities of a specific class of portable power sources designed for reliability and efficiency. These units are essential for a variety of applications, providing electrical energy when conventional outlets are unavailable.

Key Features

High-quality power sources often come equipped with multiple capabilities, ensuring they can meet diverse user needs. These include robust output options, user-friendly interfaces, and safety mechanisms to protect both the unit and its users.

Maintenance Tips

Regular upkeep is crucial for optimal performance. Basic maintenance tasks can enhance longevity and efficiency, allowing users to maximize their investment in this technology.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 100 hours | Use recommended oil type. |

| Filter Replacement | Every 200 hours | Check for clogging. |

| Spark Plug Inspection | Every 50 hours | Replace if worn. |

Key Components of Onan 5000 Models

This section delves into the essential elements that make up a specific type of energy-producing machine. Understanding these critical components is vital for effective maintenance and troubleshooting. Each part plays a significant role in ensuring smooth operation and optimal performance, providing a reliable source of power for various applications.

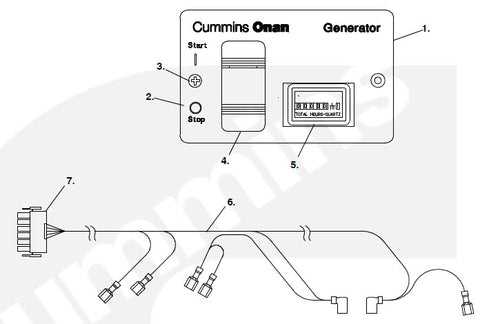

Core Elements

At the heart of the system lies the engine, responsible for converting fuel into mechanical energy. Its efficiency directly impacts overall performance. The alternator is another pivotal component, transforming mechanical energy into electrical power. Additionally, the control panel allows users to monitor and manage the unit’s operation, ensuring that it functions within safe parameters.

Supporting Features

Complementing the main elements are various supporting features such as the fuel system, which stores and supplies fuel to the engine. The cooling system maintains optimal operating temperatures, preventing overheating and extending the lifespan of the unit. Lastly, the exhaust system efficiently removes harmful gases, contributing to a safer and more environmentally friendly operation.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as invaluable tools for both novices and seasoned technicians, ensuring clarity in identifying and working with various elements.

Key benefits include:

- Enhanced comprehension of structure and function.

- Streamlined troubleshooting processes.

- Reduced risk of errors during assembly and disassembly.

- Improved inventory management for replacement components.

Utilizing these visual guides ultimately fosters efficiency and reliability, making them essential for anyone involved in upkeep and restoration tasks.

How to Read Diagrams Effectively

Understanding visual representations is crucial for efficient troubleshooting and maintenance. Familiarizing oneself with symbols, layouts, and connections can significantly enhance comprehension and facilitate problem-solving.

Identify Key Symbols

Start by recognizing the essential symbols used in the representation. Each symbol typically corresponds to a specific function or component, so a reference guide can be invaluable. Pay attention to legends and annotations that clarify these meanings.

Follow the Flow of Information

Next, observe the flow of information or energy within the schematic. This often dictates how various elements interact. Tracing the lines and connections can help you visualize the overall structure and pinpoint potential issues effectively.

Common Replacement Parts for Onan 5000

Maintaining optimal performance of your unit often requires timely substitutions of essential components. Understanding which elements frequently need replacing can enhance reliability and extend the lifespan of your equipment.

- Air Filter: Essential for clean airflow and efficient combustion.

- Oil Filter: Crucial for maintaining proper lubrication and preventing engine wear.

- Fuel Filter: Helps keep fuel lines clear, ensuring smooth operation.

- Spark Plug: Key for igniting the fuel-air mixture effectively.

- Belt: Important for power transmission within the system.

Regularly inspecting and replacing these items can significantly improve functionality and prevent unexpected breakdowns.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring longevity and efficiency of your equipment. By implementing a structured maintenance routine, you can prevent issues before they arise and enhance overall functionality.

Routine Checks

Performing systematic inspections is crucial. Here are key areas to focus on:

| Component | Recommended Frequency | Action |

|---|---|---|

| Oil Level | Weekly | Check and top up as needed |

| Air Filter | Monthly | Clean or replace as necessary |

| Fuel System | Every 6 Months | Inspect for leaks and blockages |

Seasonal Maintenance

During seasonal changes, additional tasks can optimize efficiency. Cleaning components and checking battery health can prevent performance drops in adverse conditions.

Troubleshooting Issues Using Diagrams

Identifying and resolving operational challenges can often be streamlined through visual aids. These illustrations serve as valuable tools, guiding users step-by-step to pinpoint and rectify faults in complex machinery. By utilizing these representations effectively, one can enhance the troubleshooting process significantly.

Key Benefits of Visual Aids

- Simplifies complex information

- Facilitates quicker identification of components

- Improves understanding of systems and their interactions

Steps for Effective Troubleshooting

- Identify the symptoms of the issue.

- Consult the visual representation for relevant sections.

- Trace the electrical or mechanical flow as indicated.

- Make necessary adjustments or repairs based on findings.

- Test the system to ensure proper functionality.

Where to Find Authentic Parts

Locating genuine components for your machinery can be a challenge, but it is essential for optimal performance and longevity. Authentic pieces ensure compatibility and reliability, reducing the risk of malfunctions. Understanding where to source these vital elements is crucial for maintaining your equipment’s functionality.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized distributors. These dealers are officially recognized and provide assurance that the items meet the necessary standards. Visiting their websites or physical locations can yield a range of products tailored for your specific model.

Online Marketplaces

Another viable option is exploring established online platforms. These websites often feature sections dedicated to original items, with customer reviews and ratings that can guide your selection process. Always verify the seller’s credibility to ensure the authenticity of the goods.

Investing time in finding authentic replacements will not only enhance performance but also extend the lifespan of your equipment. Prioritizing quality is key to successful maintenance.

Comparing Onan 5000 to Other Generators

When evaluating various power supply solutions, it’s essential to consider their unique characteristics, performance, and suitability for specific applications. Each model on the market has distinct features that cater to different user needs, from portability to power output. This comparison aims to highlight how one particular unit stands against its competitors in terms of reliability, efficiency, and overall functionality.

Performance is a crucial aspect when choosing a power source. Many alternatives may offer similar output, but differences in fuel consumption and runtime can greatly influence operational costs. Users often seek solutions that balance power and efficiency, minimizing the frequency of refueling and maximizing usage time.

Durability is another factor worth considering. Some units are designed for heavy-duty applications, providing enhanced resilience against wear and tear. This can be particularly beneficial for users who require a long-lasting solution for challenging environments, such as construction sites or remote locations.

In terms of noise levels, various models exhibit different sound profiles. Quieter options are often favored for residential use or during events, where minimal disturbance is desired. Comparatively, units designed for commercial use might prioritize power over noise reduction, leading to trade-offs in user experience.

Lastly, ease of maintenance should not be overlooked. Some alternatives are engineered with user-friendly designs that facilitate quick servicing, ensuring longevity and reliability. Users who prioritize hassle-free upkeep may find these features particularly appealing, making their choice more straightforward.

Overall, the landscape of power supply units is diverse, with each model offering unique advantages. By carefully examining these factors, users can make informed decisions that best suit their specific requirements and preferences.

Upgrades and Modifications for Efficiency

Enhancing performance and energy conservation can significantly improve the functionality of any portable power system. By implementing specific enhancements, users can optimize operation while reducing overall consumption.

- Fuel Efficiency Kits: These kits can help maximize energy output per unit of fuel, leading to longer operational periods.

- Improved Exhaust Systems: Upgrading the exhaust can enhance airflow, reducing back pressure and improving performance.

- Advanced Control Modules: Modern controllers provide better regulation and monitoring, increasing efficiency through smart management.

- High-Performance Filters: Utilizing superior air and fuel filters ensures cleaner operation, allowing for more efficient combustion.

By considering these upgrades, users can delve deeper into the potential of their systems, achieving ultimate efficiency and reliability in diverse applications.

Safety Precautions While Repairing

When undertaking repairs on any machinery, ensuring safety is paramount. Proper precautions can prevent accidents and injuries, allowing for a smoother and more efficient repair process.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and steel-toed boots. These items provide essential protection against potential hazards like sharp edges and flying debris.

Work Environment

Maintain a clean and organized workspace to minimize risks. Ensure good ventilation and adequate lighting. Additionally, keep flammable materials away from the area to avoid fire hazards.

Resources for Further Learning

Expanding your knowledge on maintenance and repair techniques can greatly enhance your understanding and capabilities. This section provides a curated list of valuable resources to help you dive deeper into the subject matter.

-

Online Forums:

- Join communities where enthusiasts share tips and experiences.

- Participate in discussions to ask questions and gain insights.

-

Instructional Videos:

- Explore platforms like YouTube for visual guides.

- Look for channels dedicated to technical education.

-

Technical Manuals:

- Obtain manuals specific to your equipment for detailed instructions.

- Use them as a reference for troubleshooting and maintenance procedures.

-

Workshops and Classes:

- Find local workshops that offer hands-on training.

- Enroll in classes focusing on repair and maintenance skills.

-

Online Courses:

- Look for accredited courses that cover relevant technical topics.

- Access platforms that provide comprehensive learning experiences.

Utilizing these resources will empower you with the knowledge needed to tackle various challenges and enhance your technical skills effectively.