In the realm of garage functionality, an intricate assembly of elements plays a pivotal role in ensuring smooth operation and durability. Each component, whether mechanical or structural, contributes significantly to the overall performance and safety of the system.

Recognizing the interplay between these elements allows homeowners and technicians alike to better appreciate the engineering behind seamless functionality. From lifting mechanisms to support structures, the harmony of these parts is crucial for effective usage.

As we delve into the specifics of this assembly, the ultimate goal is to provide clarity on how each section interacts within the entire framework. Understanding these connections not only enhances maintenance practices but also aids in troubleshooting potential issues.

Understanding Overhead Door Components

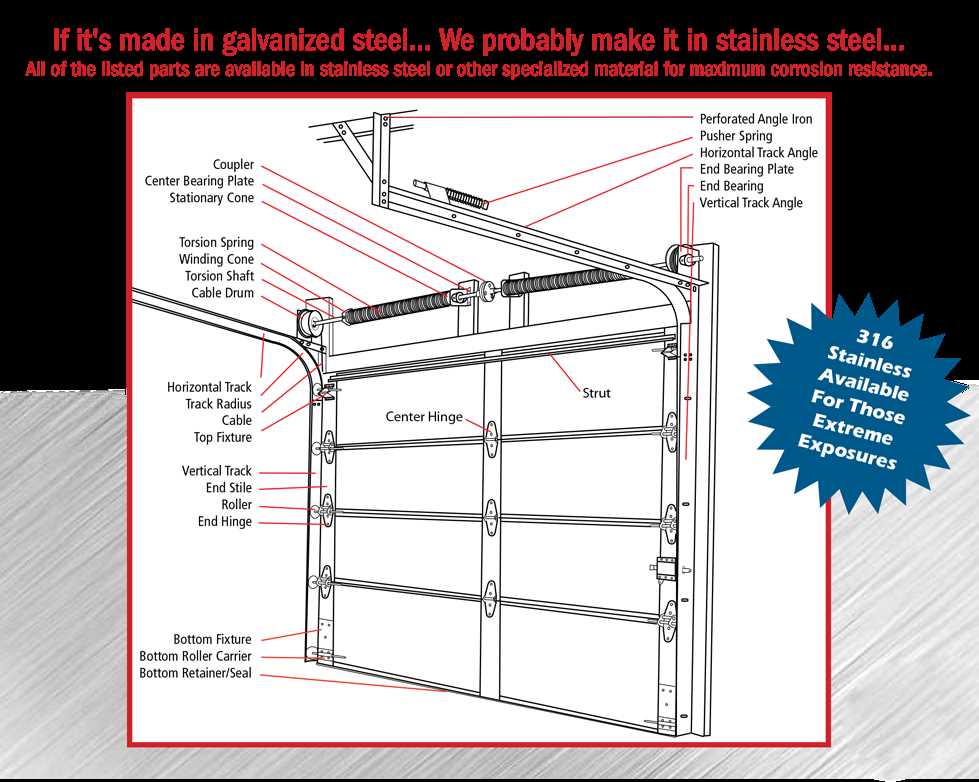

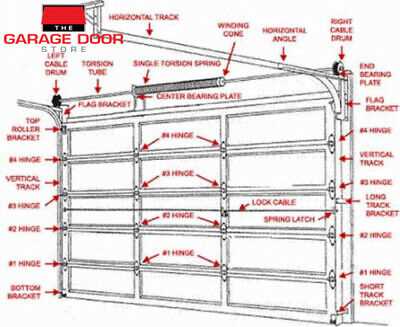

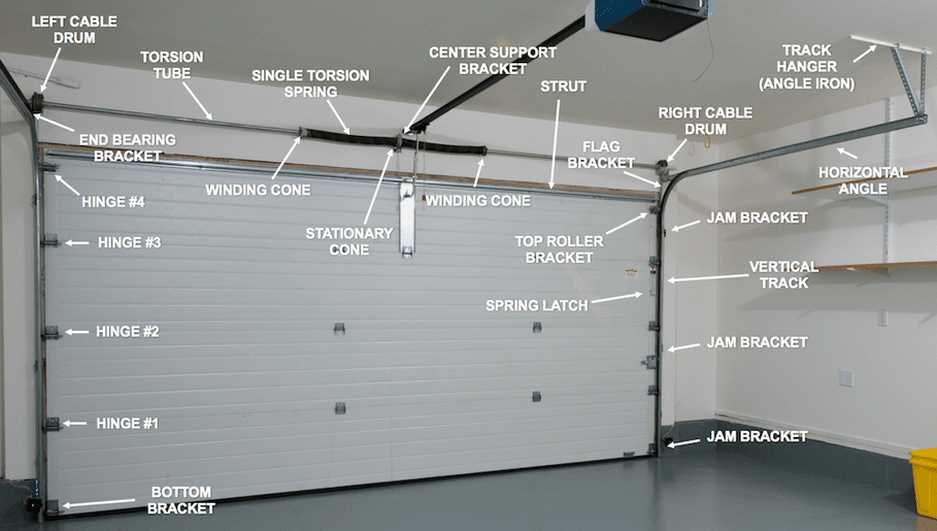

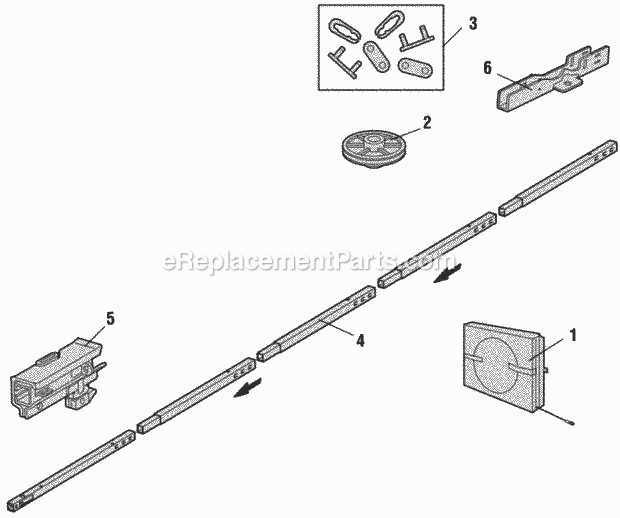

Exploring the elements that make up a typical lifting mechanism reveals the complexity and functionality inherent in these systems. Each component plays a critical role, contributing to the efficiency and safety of the entire assembly.

Key Elements

Among the vital components, a few stand out due to their importance in operation and maintenance. Understanding these will enhance your appreciation of how the system functions seamlessly.

| Component | Function |

|---|---|

| Spring | Provides the necessary lift and balance. |

| Track | Guides the movement of the mechanism. |

| Rollers | Facilitate smooth operation along the track. |

| Operator | Controls the opening and closing actions. |

Importance of Maintenance

Regular inspection and care of these elements are essential for longevity and safe use. Understanding their function allows for more effective upkeep and troubleshooting when issues arise.

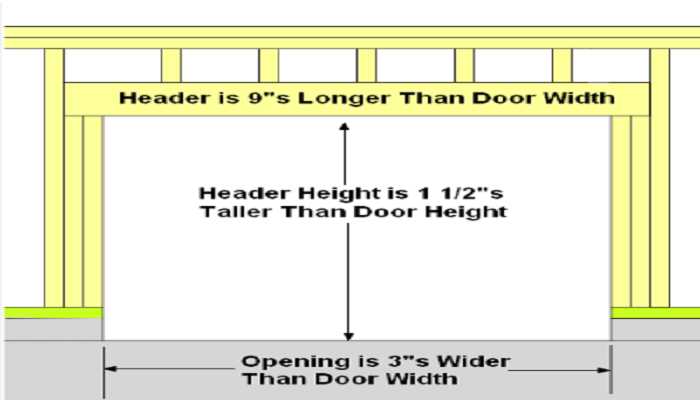

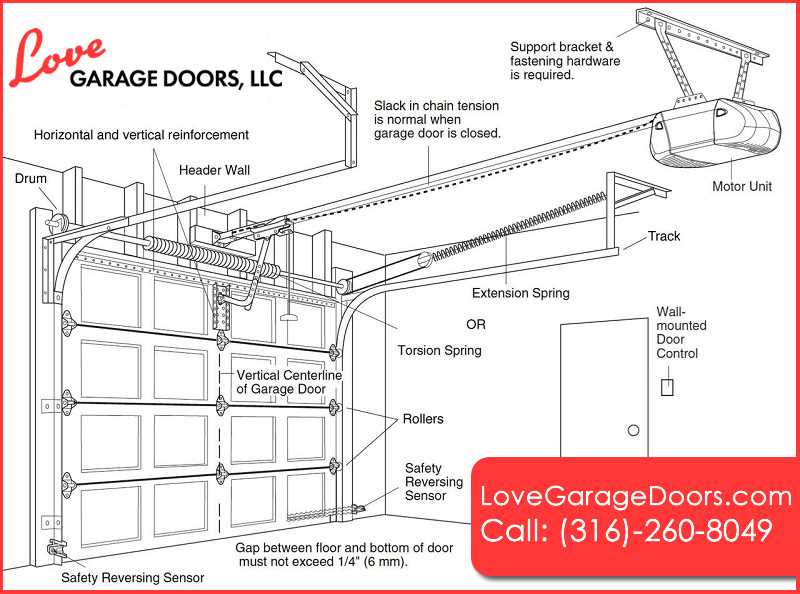

Essential Parts of Overhead Doors

Understanding the crucial components of these systems is vital for maintenance and functionality. Each element plays a significant role in ensuring smooth operation and longevity, making familiarity with them essential for any owner or technician.

Key Components

Several main elements contribute to the overall performance. These include the support framework, operating mechanism, and safety features, each working together to achieve seamless functionality.

| Component | Description |

|---|---|

| Track | Guides the movement, allowing for vertical ascent and descent. |

| Spring | Balances the weight, making lifting easier and reducing strain. |

| Hinges | Connects sections, enabling flexibility during operation. |

| Motor | Powers the mechanism for automated functions. |

Importance of Maintenance

Regular upkeep of these elements is crucial to prevent malfunctions and ensure safety. Recognizing each component’s function aids in timely repairs and prolongs the lifespan of the entire system.

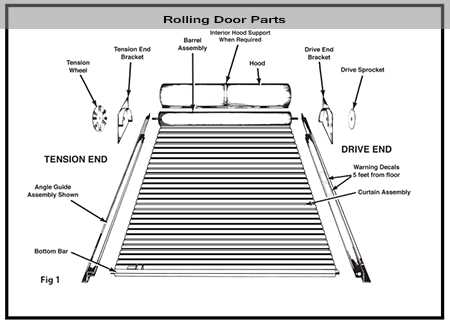

Functionality of Each Component

This section explores the essential roles played by various elements within the system, highlighting their contributions to overall operation and efficiency. Understanding how each segment works is crucial for optimal performance and maintenance.

Primary Elements

The main components serve as the foundation, enabling seamless movement and stability. Tracks guide the mechanism, while rollers facilitate smooth transitions. Each part is designed for durability, ensuring longevity under repeated use.

Supportive Features

Additional features enhance functionality. Springs provide counterbalance, reducing strain on other components, while sensors ensure safety by detecting obstacles. Each feature complements others, contributing to the ultimate efficiency of the entire system.

Types of Overhead Doors Explained

This section explores various styles of elevating entrances commonly used in residential and commercial spaces. Each variant offers unique functionalities and aesthetic qualities, catering to diverse needs and preferences. Understanding these differences can help in selecting the most suitable option for any specific application.

One popular type is the sectional model, which consists of several panels hinged together, allowing for smooth vertical movement. This design is highly versatile and often seen in garages and warehouses due to its efficient use of space.

Another option is the roll-up design, featuring a single sheet that coils around a drum. This style is favored in commercial settings where quick access and durability are essential, as it can withstand frequent use without compromising performance.

For a more traditional appearance, swing-style mechanisms are available, swinging outward or inward. These provide an elegant touch but require more space to operate effectively.

Lastly, there are tilt-up models, which consist of a single solid panel that tilts upwards. This type is appreciated for its simplicity and ease of installation, making it a popular choice for residential applications.

Common Issues with Door Mechanisms

Mechanisms that facilitate the opening and closing of entryways can encounter various complications over time. Understanding these frequent problems can aid in effective troubleshooting and maintenance, ensuring smooth operation and longevity.

| Issue | Description | Possible Solutions |

|---|---|---|

| Misalignment | Components may become misaligned, causing difficulty in operation. | Realign tracks and adjust mounting brackets. |

| Noisy Operation | Unusual sounds during use can indicate wear or lack of lubrication. | Lubricate moving parts and replace worn components. |

| Sticking | Friction between surfaces can lead to sticking or jamming. | Clean tracks and ensure proper alignment. |

| Unresponsive Mechanism | Failure to respond to control commands may signal electrical issues. | Check power supply and inspect wiring connections. |

| Worn Springs | Springs can lose tension, impacting the balance and functionality. | Replace springs as needed and check for proper tension. |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficient operation of your entry system. By following a few key practices, you can extend its lifespan and enhance performance. Here are some effective strategies to keep in mind.

| Tip | Description |

|---|---|

| Lubrication | Apply a suitable lubricant to moving components periodically to reduce friction and wear. |

| Inspection | Conduct routine checks for signs of wear or damage, ensuring all elements are functioning properly. |

| Alignment | Verify that tracks and components are correctly aligned to prevent operational issues. |

| Cleanliness | Keep the system free from debris and dirt to maintain smooth functionality and prevent corrosion. |

| Professional Servicing | Schedule annual inspections by a qualified technician to address potential concerns before they escalate. |

How to Identify Faulty Parts

Understanding the components of a mechanical system is crucial for effective maintenance and troubleshooting. Recognizing signs of wear or malfunction can prevent larger issues and ensure smooth operation. This section provides guidance on how to spot potential failures in various elements of the mechanism.

Common Signs of Malfunction

Several indicators can suggest that a specific component is not functioning properly. Unusual noises during operation, such as grinding or squeaking, often signal that something is amiss. Additionally, irregular movement or failure to respond can be a clear warning of underlying problems. Pay close attention to these symptoms to facilitate timely repairs.

Visual Inspection Techniques

Conducting a thorough visual check is an essential step in identifying faulty components. Look for cracks, rust, or wear on visible surfaces, as these can compromise functionality. Moreover, check for loose connections or signs of misalignment that may hinder performance. Keeping a keen eye on these details will aid in early detection and help maintain the integrity of the entire system.

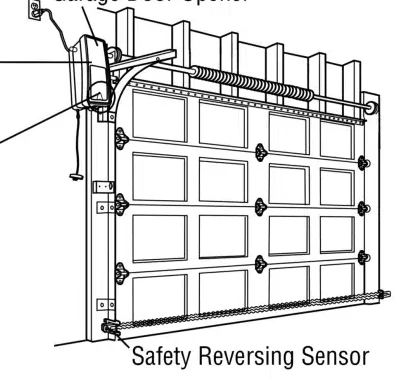

Safety Features in Overhead Doors

Ensuring security and protection is crucial in any mechanism that operates in a home or commercial setting. Various innovations have been integrated to enhance safety and mitigate potential hazards associated with these structures. Understanding these features can significantly improve user experience and overall reliability.

Emergency Reversal Mechanism

A key component designed to prevent accidents is the emergency reversal mechanism. This feature detects obstacles in the path of the moving panel. If an object is encountered, the system automatically reverses direction, thereby preventing injury or damage. This technology is vital for maintaining a safe environment, particularly in high-traffic areas.

Manual Release System

In situations where power is lost or the automated system malfunctions, a manual release option is essential. This allows for safe operation and enables users to open or close the structure manually without risking injury. A properly functioning manual release system ensures that users can maintain control and safety at all times.

Investing in these advanced safety features not only complies with regulations but also provides peace of mind for users and their families. Regular maintenance and awareness of these functionalities are key to ensuring long-term safety and reliability.

Tools Needed for Repairs

When tackling repairs for any system involving elevated access, having the right equipment is crucial for efficiency and safety. A well-equipped toolkit not only simplifies the task but also ensures that any issues can be addressed promptly and effectively.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for removing and securing screws. |

| Pliers | Used for gripping, twisting, and cutting wires or other materials. |

| Level | Ensures components are aligned correctly during installation. |

| Measuring Tape | For precise measurements of components and spaces. |

| Safety Goggles | Protects eyes from debris and hazards. |

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues related to lifting mechanisms. By following a systematic method, you can effectively troubleshoot and restore functionality to your equipment.

- Identify the Problem:

- Observe the mechanism for unusual noises or movements.

- Check for any visible damage or misalignment.

- Gather Tools and Materials:

- Screwdriver set

- Wrench set

- Lubricant

- Replacement components as needed

- Perform Preliminary Checks:

- Ensure power is disconnected for safety.

- Inspect cables and pulleys for wear.

- Disassemble Components:

- Carefully remove any damaged pieces.

- Keep track of all screws and small parts.

- Replace Damaged Items:

- Install new components according to manufacturer specifications.

- Ensure proper alignment and secure fastening.

- Reassemble and Test:

- Put all parts back together carefully.

- Reconnect power and test the mechanism.

Following these steps will help ensure your lifting apparatus operates smoothly and efficiently. Always prioritize safety and consult a professional if necessary.

Upgrading Your Overhead Door System

Enhancing your entry system can significantly improve both functionality and security. Whether it’s for residential or commercial use, modernizing these structures can lead to better performance and efficiency. This section will explore key aspects to consider when looking to upgrade your existing setup.

Benefits of Modernization

Investing in a new mechanism can offer numerous advantages. For instance, advanced models typically feature enhanced safety protocols and energy efficiency. Additionally, contemporary designs often come equipped with smart technology, allowing for remote access and monitoring. Increased durability is another crucial factor, as newer options tend to withstand wear and tear much better than older versions.

Key Components to Consider

When upgrading, focus on critical elements such as the lifting mechanism, tracks, and sensors. Each component plays a vital role in the overall functionality. For example, switching to a stronger lifting system can facilitate smoother operations and extend the lifespan of the installation. Furthermore, upgrading sensors enhances safety by preventing accidents and ensuring proper operation under various conditions.

Resources for Further Learning

Expanding your knowledge on mechanisms and their components can greatly enhance your understanding and skills. This section offers various resources to help you delve deeper into the subject and master the intricacies involved.

Books and Guides

- “The Complete Guide to Mechanisms” by John Smith

- “Fundamentals of Mechanical Systems” by Jane Doe

- “Understanding Mechanisms: A Practical Approach” by Alex Johnson

Online Courses and Tutorials

- Coursera: Mechanical Engineering Basics

- Udemy: Understanding Mechanical Systems

- Khan Academy: Engineering Concepts

Utilizing these resources will provide you with the ultimate foundation and advanced insights necessary for proficiency in the field.