In the world of woodworking, the efficiency and precision of a specific instrument play a crucial role in achieving optimal results. Grasping the intricate relationship between each element of the device allows users to maximize its potential. By exploring the arrangement of these key elements, enthusiasts can enhance their skills and improve their craftsmanship.

Every piece of a woodworking apparatus serves a unique purpose, contributing to its overall functionality. Identifying how these components interact not only aids in maintenance but also empowers users to troubleshoot issues effectively. With a clearer understanding, both novices and seasoned craftsmen can delve into their projects with confidence.

Ultimately, a comprehensive grasp of the essential features can transform the way individuals approach their woodworking endeavors. By familiarizing oneself with the layout and roles of each segment, one can ensure a more productive and enjoyable experience in the workshop.

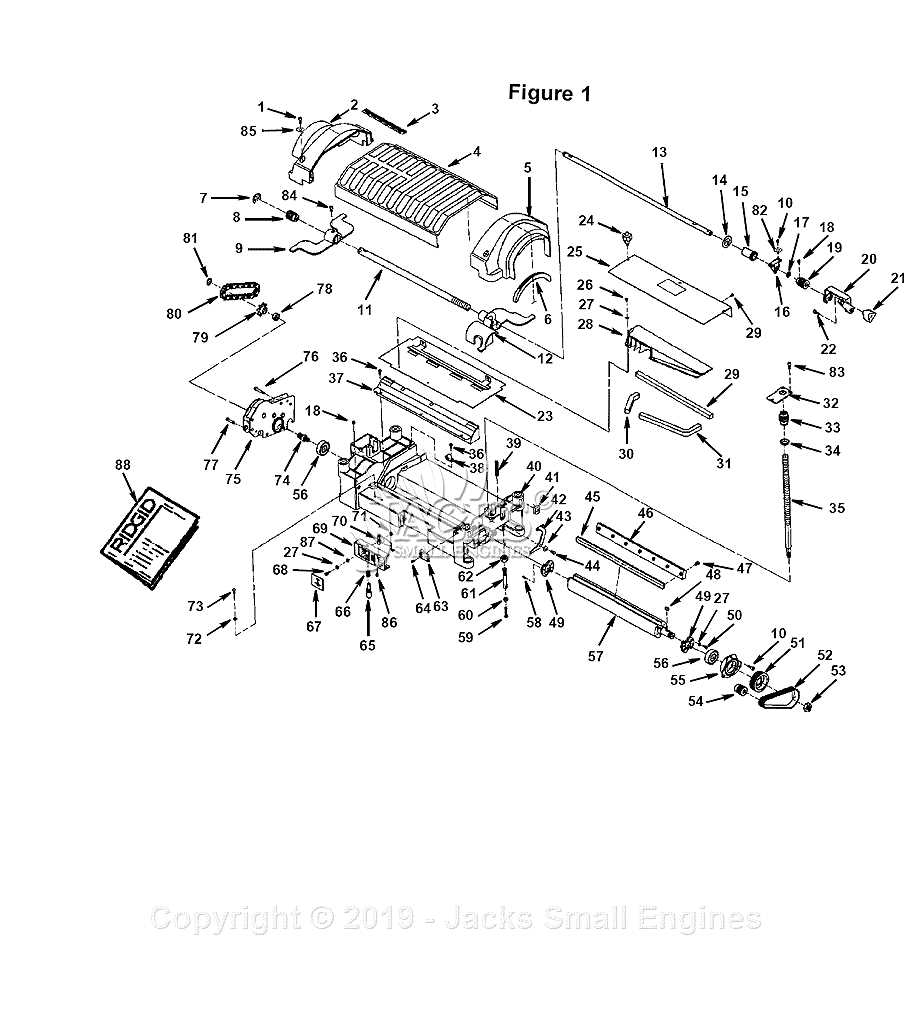

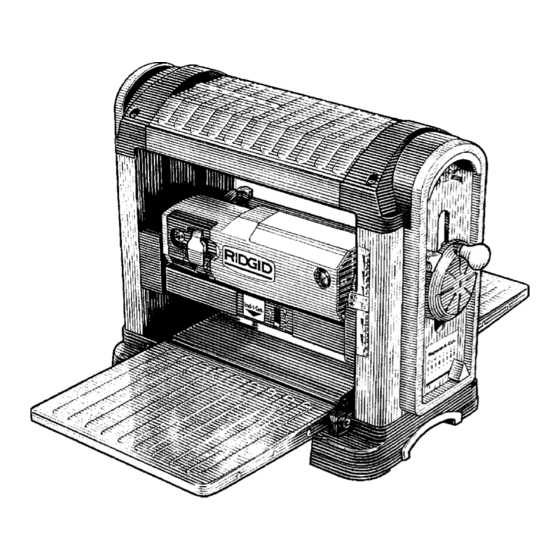

Understanding Ridgid Planer Components

Grasping the essential elements of a woodworking machine is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring smooth operation and achieving the desired finish on materials. Familiarity with these parts not only enhances user experience but also extends the longevity of the equipment.

The cutting mechanism is at the heart of the device, responsible for shaping and refining surfaces with precision. This element works in conjunction with feed rollers, which guide the material through the cutting area, ensuring consistent results.

Another critical aspect is the depth adjustment feature, allowing users to control how much material is removed in each pass. Understanding this mechanism helps achieve the ultimate finish without overworking the material.

Additionally, dust collection systems are essential for maintaining a clean workspace. These components minimize debris, improving visibility and safety during operation. Familiarity with the arrangement and functionality of these elements promotes effective use and maintenance of the machine.

Key Parts of a Ridgid Planer

Understanding the essential components of this woodworking tool is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring the effectiveness and longevity of the machine, enabling users to achieve precise finishes on their materials.

Cutting Mechanism

The cutting mechanism is fundamental to the tool’s operation. It consists of sharp blades that slice through wood, providing smooth surfaces. Regular inspection and sharpening of these blades are vital to maintain cutting efficiency and prevent wear and tear.

Feed System

The feed system is responsible for moving the material through the machine. This component ensures that the wood is fed at a consistent speed, allowing for uniform thickness and reducing the risk of snipe. Proper alignment and functionality of the feed rollers are essential for achieving the desired results.

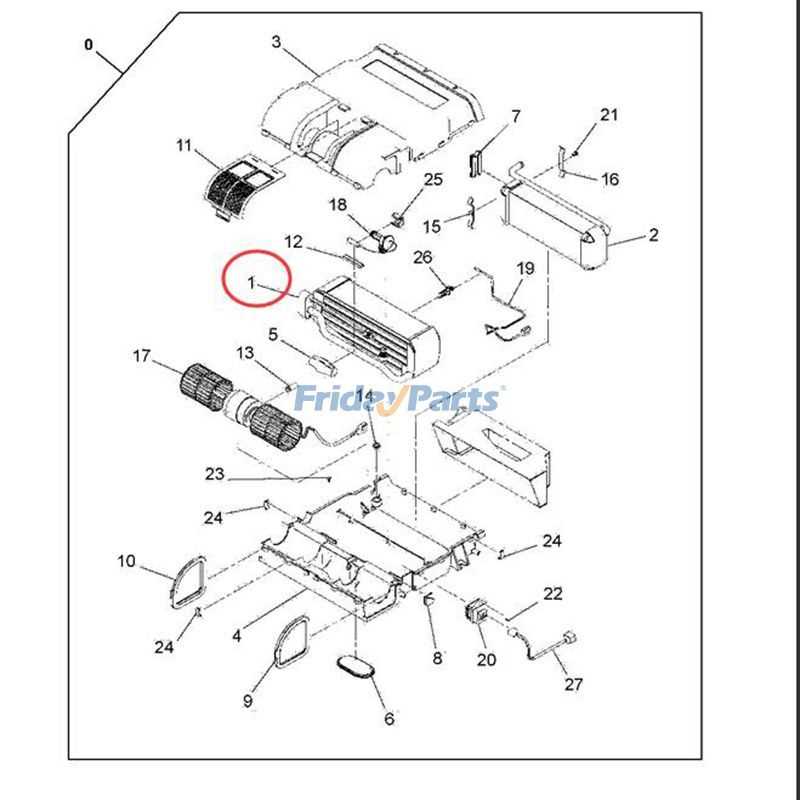

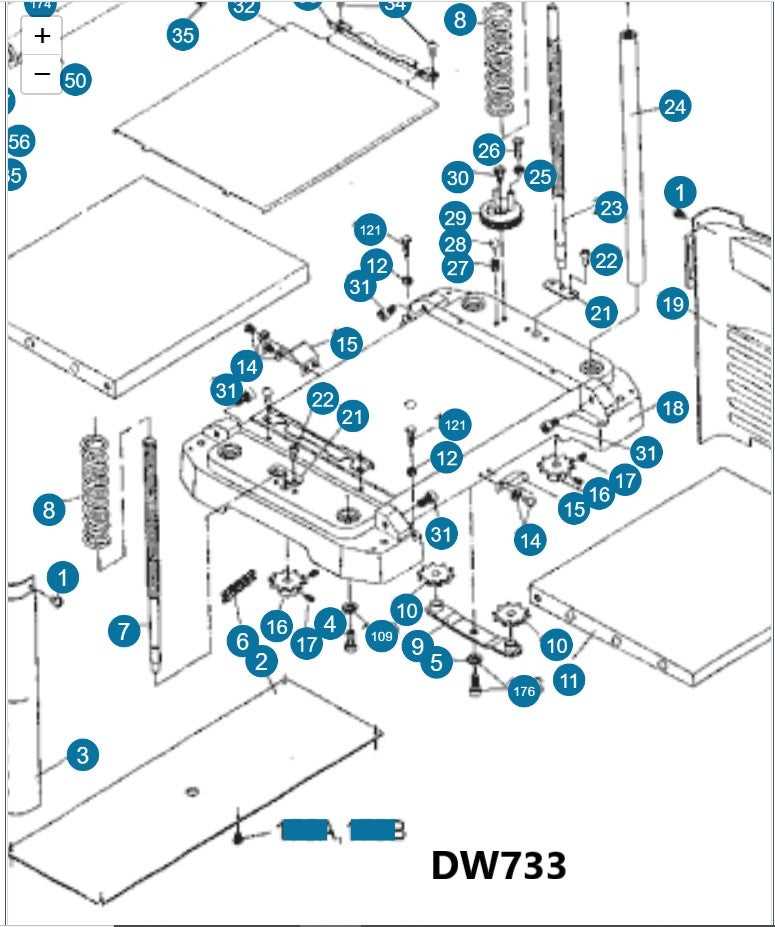

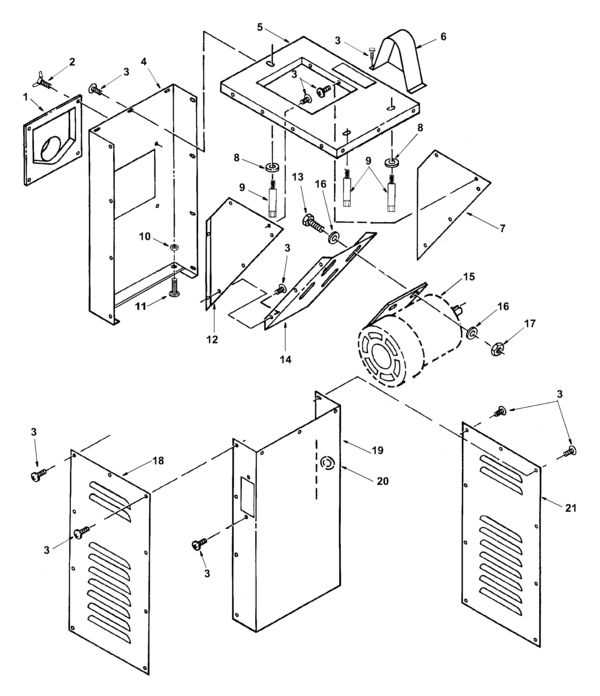

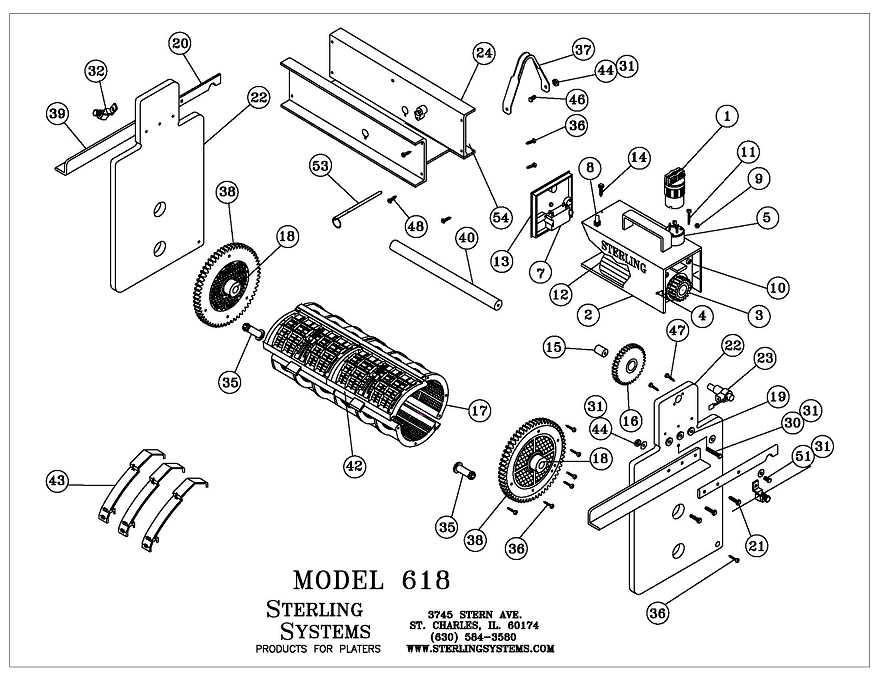

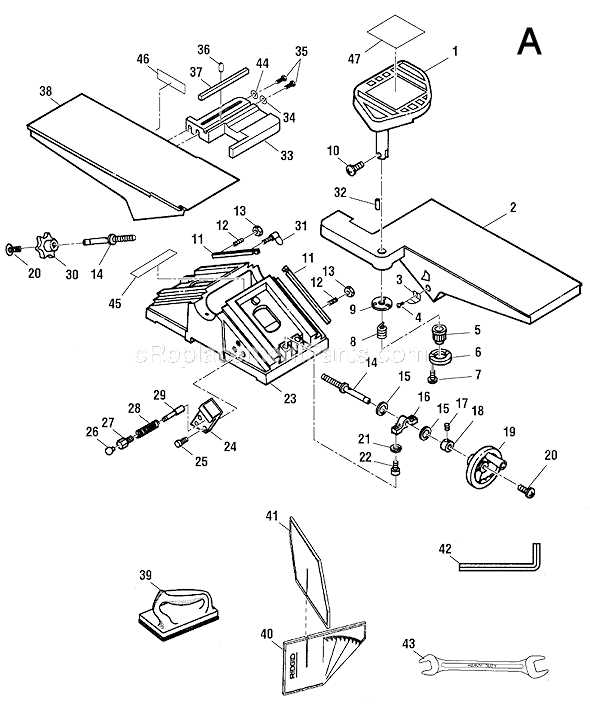

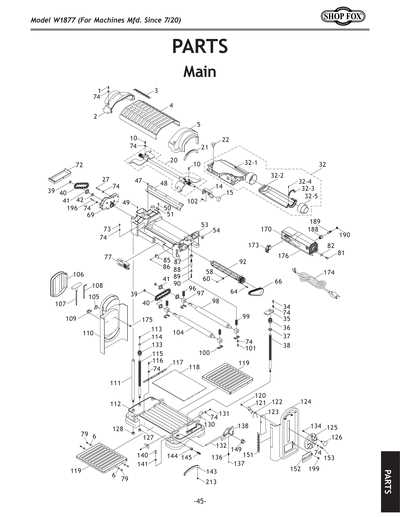

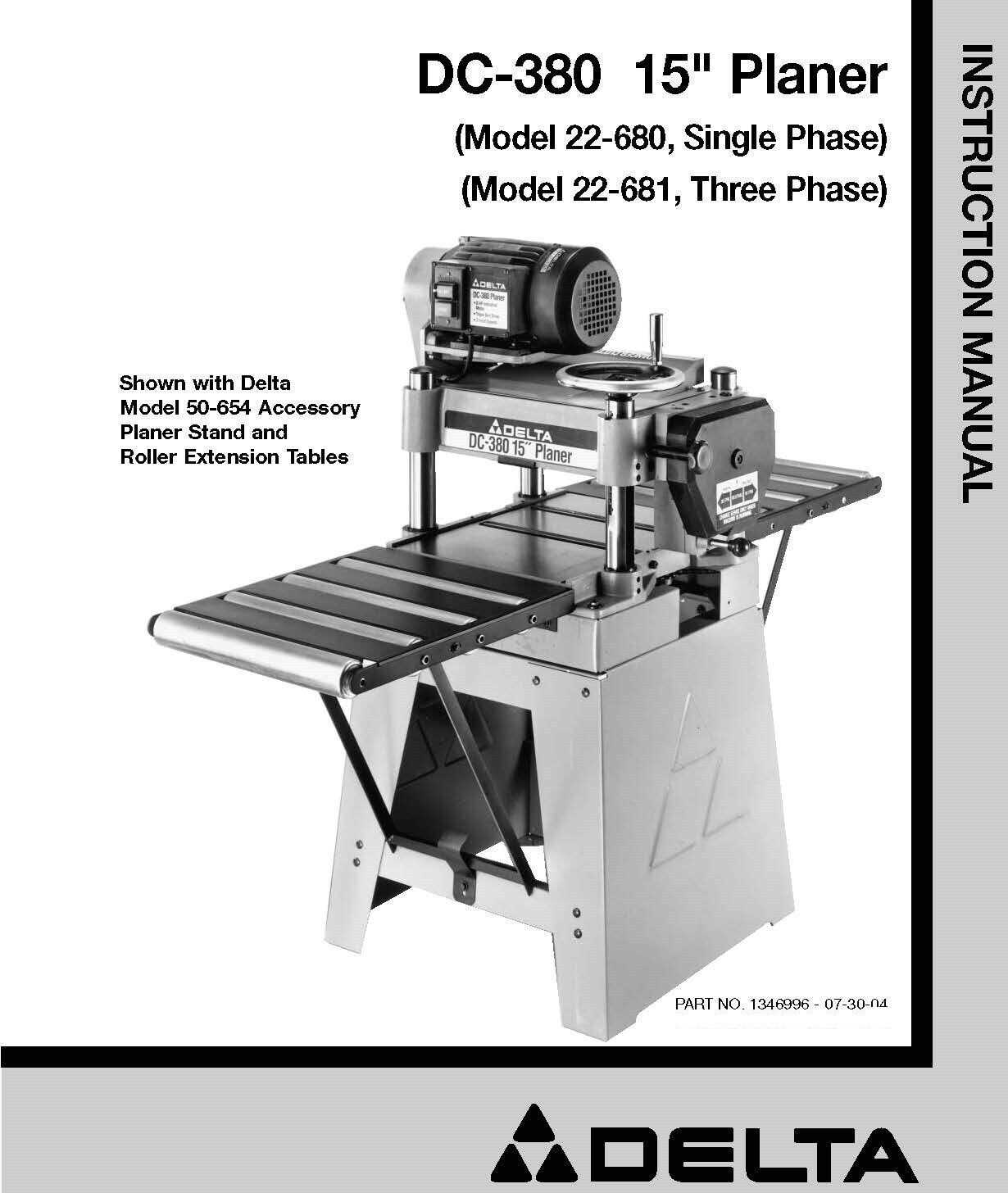

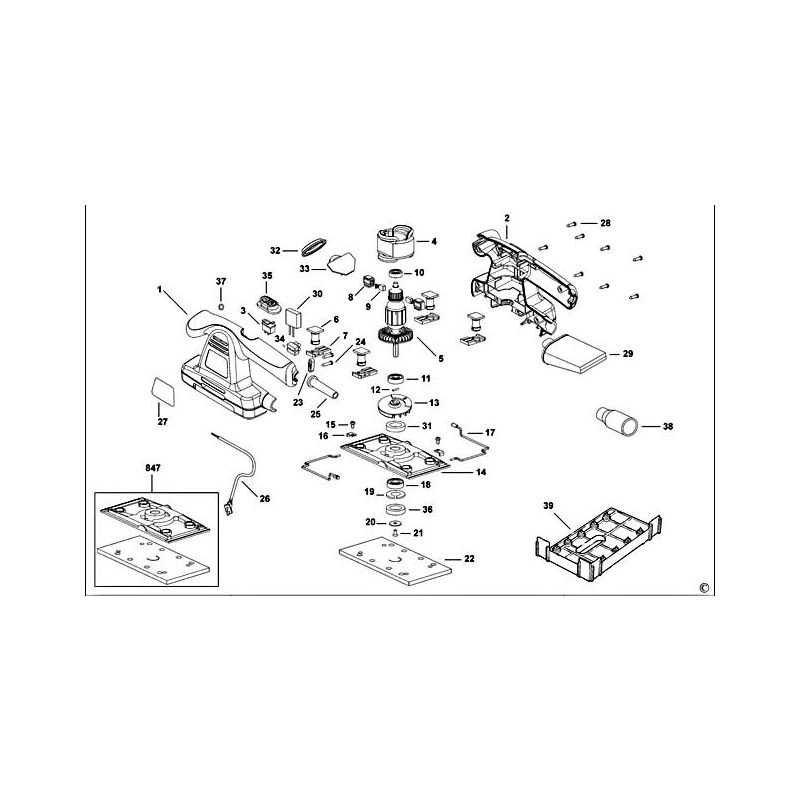

How to Read the Parts Diagram

Understanding a component layout is crucial for effective maintenance and repairs. These visual representations provide an organized view of the individual elements within a machine, allowing users to identify each section and its function clearly.

To begin, familiarize yourself with the overall layout. Each segment is typically numbered or labeled, which corresponds to a specific item in the accompanying list. This list usually includes descriptions, part numbers, and sometimes even suggested quantities needed for replacement. Pay close attention to any notes or symbols that might indicate compatibility or special instructions.

Next, focus on the relationships between components. Many layouts illustrate how parts interact with one another, showing connections that are not immediately obvious. This can be particularly helpful when troubleshooting issues or planning upgrades, as it highlights dependencies and potential areas of concern.

Lastly, take your time to cross-reference any unfamiliar terms. It may be beneficial to look up definitions or illustrations of specific items to ensure a complete understanding. This knowledge not only aids in repairs but also enhances your overall familiarity with the machinery, empowering you to work more confidently and effectively.

Common Issues with Ridgid Planers

When working with woodworking tools designed for surface leveling and smoothing, users may encounter several common challenges. These can range from performance inconsistencies to mechanical failures, impacting both efficiency and quality of work. Understanding these issues is essential for effective troubleshooting and maintenance.

Frequent Mechanical Failures

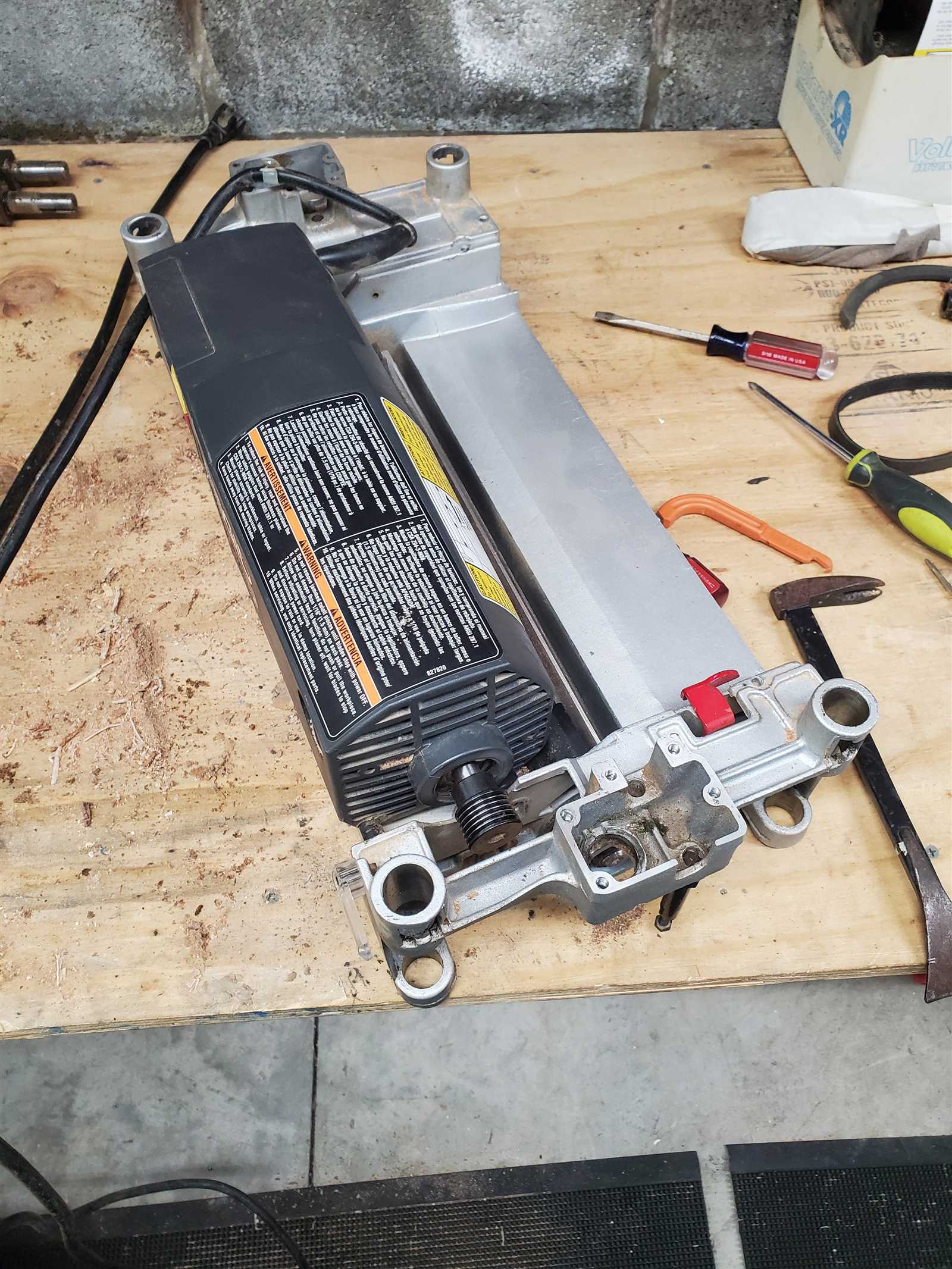

One of the most prevalent problems involves motor malfunctions, which can lead to reduced power or complete shutdown. Additionally, wear and tear on the cutting blades often results in poor finish quality, requiring timely replacement. Regular inspection can help prevent these issues from escalating.

Adjustment and Calibration Problems

Improper alignment and calibration can lead to uneven cuts and material tear-out. Users frequently face challenges with depth adjustment mechanisms, which may become stiff or unresponsive over time. Ensuring that all components are correctly set and regularly maintained can significantly enhance performance and longevity.

Maintenance Tips for Longevity

Ensuring the durability of your woodworking equipment is essential for achieving optimal performance over time. Regular upkeep not only enhances efficiency but also minimizes the risk of unexpected failures. By following a few straightforward practices, you can significantly extend the life of your tools and maintain their functionality.

Routine Cleaning

Regular cleaning is crucial for preventing dust and debris buildup. After each use, wipe down the surfaces with a soft cloth to remove shavings and residue. Pay special attention to the blades and feed rollers, as they are prone to accumulation. Using a gentle brush can help dislodge any stubborn particles.

Proper Lubrication

Maintaining optimal performance requires adequate lubrication of moving parts. Consult the user manual to identify the specific points that need attention. Using the recommended lubricant ensures smooth operation and reduces wear. Additionally, check for any signs of rust or corrosion, and address them promptly to prevent further damage.

Implementing these maintenance tips will contribute to the longevity of your equipment, allowing you to achieve consistent results in your woodworking projects.

Replacing Worn-Out Components

Over time, machinery can suffer from wear and tear, leading to diminished performance. Identifying and replacing these outdated elements is crucial for maintaining efficiency and extending the lifespan of your tools.

Common signs that components may need replacement include:

- Unusual noises during operation

- Decreased performance or output

- Visible damage or wear on key parts

When considering replacements, follow these steps:

- Inspect the tool thoroughly to identify affected areas.

- Consult the user manual for specifications of replacement items.

- Purchase high-quality replacements to ensure longevity.

- Carefully disassemble the tool, taking note of each component’s placement.

- Install the new elements and reassemble the tool securely.

Regular maintenance and timely replacements will ultimately enhance the functionality of your equipment, ensuring it operates smoothly for years to come.

Tools Required for Repairs

When undertaking maintenance or restoration of any machinery, having the right instruments at your disposal is crucial. Proper tools not only facilitate effective repairs but also ensure safety and precision throughout the process. Below is a list of essential equipment you may need.

| Tool | Purpose |

|---|---|

| Wrenches | For loosening and tightening bolts and nuts. |

| Screwdrivers | To remove or secure screws of various sizes. |

| Measuring Tape | For accurate measurements during adjustments. |

| Safety Glasses | To protect eyes from debris and dust. |

| Cleaning Supplies | For removing dust and residue from components. |

Safety Precautions During Repairs

When undertaking maintenance on power tools, ensuring safety is paramount. Proper precautions help prevent accidents and injuries, allowing for a smooth and effective repair process. Familiarity with the equipment and awareness of potential hazards are essential for a successful outcome.

Here are some key safety measures to consider:

| Precaution | Description |

|---|---|

| Disconnect Power | Always unplug the device or remove the battery before starting any repair work to eliminate the risk of accidental activation. |

| Use Protective Gear | Wear safety goggles, gloves, and ear protection to shield yourself from debris and loud noises during repairs. |

| Work in a Well-Lit Area | Ensure your workspace is adequately illuminated to see all components clearly and reduce the likelihood of mistakes. |

| Keep Workspace Organized | Maintain a clean and clutter-free area to prevent accidents and easily locate tools and parts when needed. |

| Read the Manual | Consult the manufacturer’s instructions for specific safety tips and guidelines related to the equipment. |

By adhering to these precautions, you can create a safer environment while performing repairs, minimizing risks and ensuring a successful maintenance experience.

Comparing Models of Ridgid Planers

When selecting a wood smoothing tool, understanding the distinctions between various models is crucial for making an informed decision. Each variation offers unique features and capabilities, catering to different user needs and preferences. By evaluating specifications, performance metrics, and user experiences, one can find the ideal solution for both professional and hobbyist applications.

Power and Performance: Different models provide varying power levels, which significantly affect their ability to handle different types of wood and thicknesses. Higher wattage typically translates to better performance, especially when working with dense materials.

Portability: For users who prioritize mobility, some designs are lighter and more compact, making them easier to transport and store. This is particularly beneficial for those who work on-site or in various locations.

Adjustability and Features: Many tools offer adjustable settings that enhance precision and control. Features like depth adjustment and feed rate can dramatically influence the quality of the finish and the ease of use, making them essential considerations during comparison.

Price Point: Budget constraints are always a factor. Evaluating the cost in relation to the features and benefits offered by each model can help determine the best value for your investment.

In conclusion, a thorough comparison of these machines can empower users to choose the best model that aligns with their specific woodworking needs and project requirements.

Upgrading Parts for Enhanced Performance

Improving the components of your woodworking tool can significantly boost its efficiency and precision. By selecting high-quality replacements and enhancements, users can achieve smoother finishes, increased durability, and better overall functionality. This section explores key upgrades that can elevate your equipment to the next level, ensuring optimal performance in every project.

Choosing High-Quality Components

Investing in premium materials is crucial for enhancing tool performance. Durable blades made from advanced steel or carbide can extend cutting life and provide cleaner edges. Additionally, precision bearings can minimize friction, leading to smoother operation and reduced wear over time.

Adjustable Features for Customization

Incorporating adjustable settings allows for greater versatility. Upgrading to variable speed controls gives users the ability to adapt to different tasks, from fine detailing to heavy-duty work. Furthermore, adding ergonomic handles can improve comfort during extended use, enhancing overall productivity.

Where to Purchase Genuine Parts

Finding authentic components for your tools is crucial for maintaining their performance and longevity. This section will guide you through reliable sources to acquire original elements, ensuring you get the best quality for your equipment.

Authorized Dealers

- Check the manufacturer’s official website for a list of authorized sellers.

- Visit local hardware stores that are certified to sell original components.

Online Marketplaces

- Amazon and eBay often feature listings for genuine items, but verify the seller’s reputation.

- Specialty online retailers focus on providing authentic products for various tools.

Exploring Aftermarket Part Options

When maintaining and enhancing the performance of your equipment, considering alternative components can be beneficial. Aftermarket selections often provide a cost-effective solution without sacrificing quality.

These alternatives can offer various advantages:

- Cost savings compared to original items

- Potential for improved performance or features

- Greater availability in some cases

However, it’s essential to keep certain factors in mind:

- Ensure compatibility with your device.

- Research the manufacturer’s reputation and reviews.

- Check warranty implications of using non-original components.

By carefully evaluating these options, you can make informed decisions that enhance your equipment’s longevity and functionality.

Customer Support and Resources Available

Access to reliable customer support and resources is essential for anyone utilizing tools and equipment. This section outlines the various avenues available for assistance, ensuring users can find the information and help they need efficiently.

Support Channels

- Online Help Center: A comprehensive platform offering articles, FAQs, and troubleshooting guides.

- Phone Support: Reach trained representatives for direct assistance with your queries.

- Email Assistance: Send your questions via email for detailed responses tailored to your needs.

Additional Resources

- Community Forums: Join discussions with fellow users to share experiences and solutions.

- Video Tutorials: Access step-by-step guides that visually demonstrate how to use equipment effectively.

- Instruction Manuals: Downloadable guides that provide in-depth information about functionality and maintenance.