In the realm of power tools, having a clear understanding of the various elements and their configurations is essential for optimal performance and maintenance. This section delves into the intricate details of a specific tool’s construction, offering insights into how each part contributes to its overall functionality. By comprehending the relationships between these components, users can enhance their ability to troubleshoot and ensure effective operation.

Additionally, visual representations of these elements serve as valuable references for both novices and experienced users. They facilitate a deeper appreciation of the design and engineering behind the equipment, promoting informed decisions during repairs or upgrades. With this knowledge, users can confidently navigate the complexities of their tools, maximizing efficiency and longevity.

The assembly of precision-driven devices requires attention to detail and knowledge of each component’s role within the overall structure. This process involves careful alignment, securing elements in place, and ensuring that all components function harmoniously. By understanding the core steps in the assembly process, one can efficiently restore or maintain the equipment, ensuring long-lasting performance and reliability.

To aid in the understanding of the assembly, the table below outlines the key steps involved and their respective tools and considerations:

| Step | Action | Tools Needed |

|---|---|---|

| 1 | Identify and organize all components | Sorting tray, labeling tags |

| 2 | Align the primary structure | Wrench set, alignment tool |

| 3 | Secure the internal mechanisms | Screwdriver, locking pins |

| 4 | Test functionality of the assembled unit | Calibration gauge, test board |

Key Features of Senco FinishPro 35

The tool is designed for precision work, offering a blend of durability and efficiency. Its construction allows for seamless handling, making it ideal for various tasks where accuracy is crucial. Professionals appreciate the combination of power and control, which enhances productivity in different applications.

Compact Design for Versatile Use

This tool’s ergonomic build enables it to be used in tight spaces without compromising performance. Its compact structure makes it both easy to maneuver and comfortable to operate for extended periods. The well-balanced weight distribution further adds to the user-friendly experience.

High Efficiency and Reliability

Equipped with an advanced mechanism, the tool ensures consistent operation under varying conditions. It is engineered to provide a reliable and powerful output, ensuring that tasks are completed efficiently with minimal downtime. This makes it a preferred choice for those seeking long-term performance.

Common Issues with Nail Gun Parts

When working with fastening tools, problems may arise that affect their efficiency and durability. Understanding the frequent complications and their causes can help avoid downtime and improve performance during projects.

| Issue | Possible Cause | Solution |

|---|---|---|

| Misfiring | Worn trigger or misaligned mechanism | Check for wear and replace the faulty component |

| Jamming | Debris buildup or damaged internals | Clean the tool and inspect for any damaged elements |

| Air leaks | Worn seals or O-rings | Replace seals or O-rings to restore airtight performance |

| Weak firing | Low air pressure or spring tension | Check the air pressure or adjust/replace the spring |

Maintenance Tips for Optimal Performance

To ensure reliable operation and prolong the lifespan of your equipment, regular upkeep is essential. Proper care not only enhances functionality but also minimizes the need for costly repairs. Following a consistent maintenance routine can prevent common issues and help your tool perform efficiently over time.

Start by inspecting all components for wear and tear. Cleaning moving parts and ensuring they are free of debris can significantly reduce strain and improve smoothness in operation. Lubricate key areas according to manufacturer recommendations to avoid friction that can lead to damage.

Periodically check for loose screws or fasteners, tightening them as necessary. Regularly replace worn seals or gaskets to prevent leaks and ensure airtight functionality. Paying attention to air filters or power supplies is also crucial in maintaining consistent power output.

Finally, storing the tool in a clean, dry place helps protect it from environmental damage. Following these guidelines can keep your equipment running at its best and extend its service life.

Identifying Replacement Parts Easily

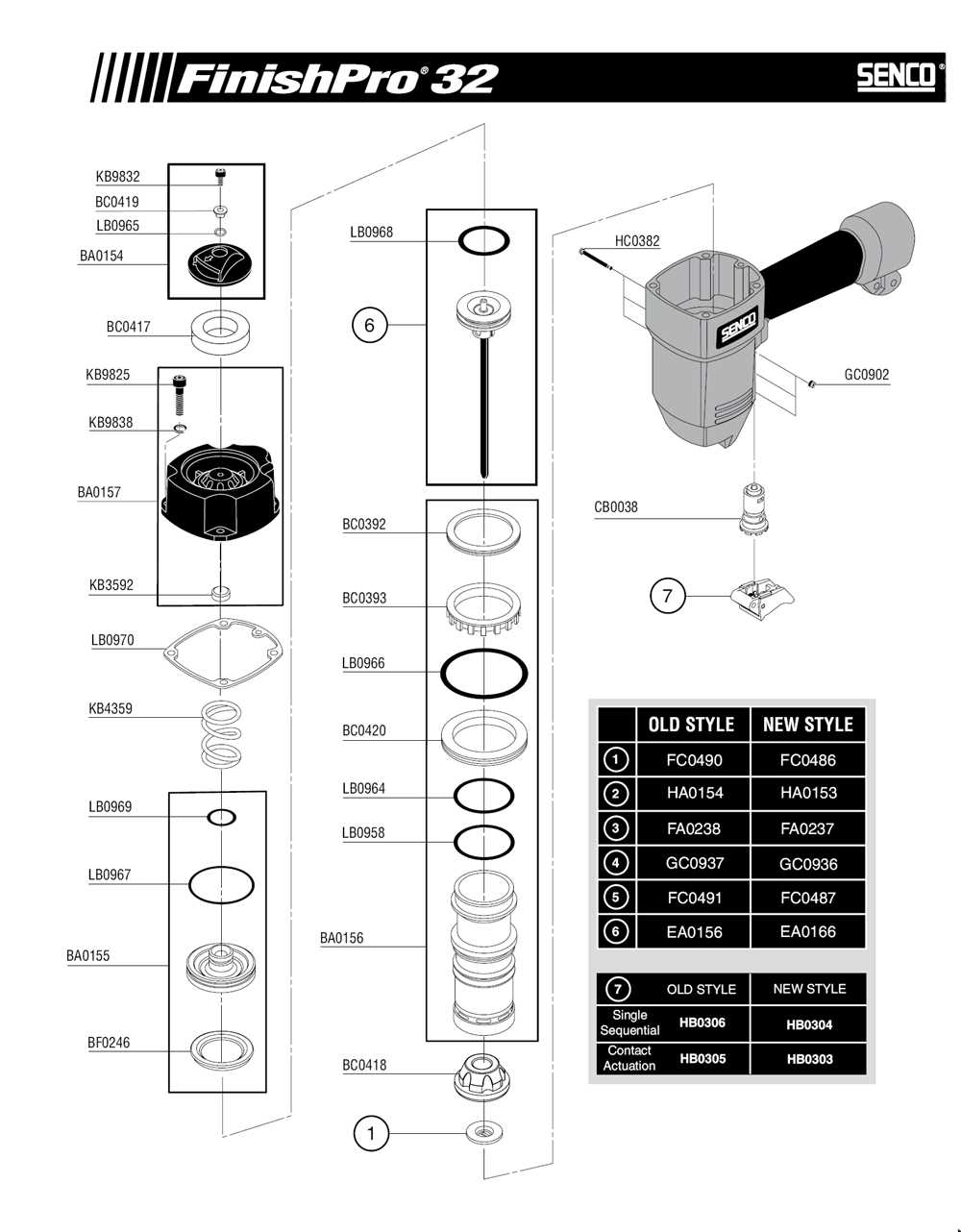

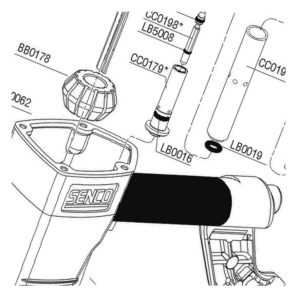

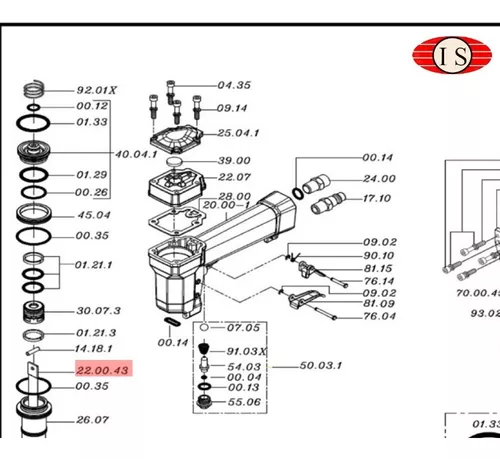

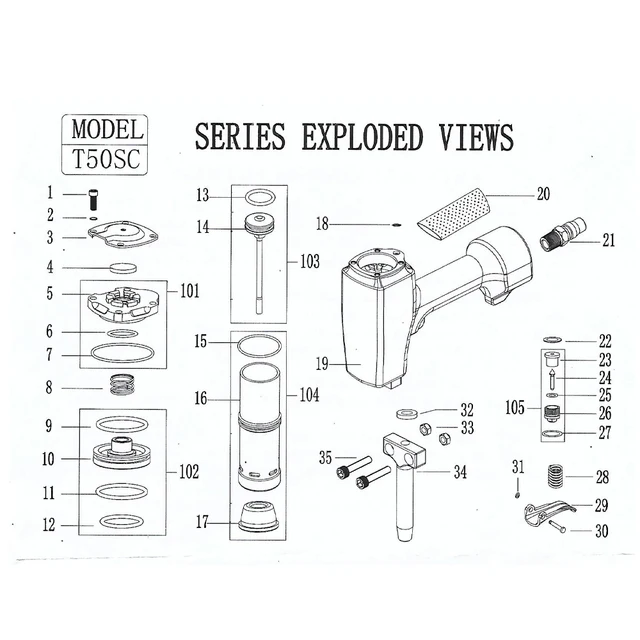

When a tool begins to show signs of wear, knowing how to quickly recognize the necessary components for restoration is key to ensuring smooth operation. Understanding the internal layout and the role of each element within the device can simplify the process of finding exactly what needs to be swapped or repaired.

To streamline the identification process, follow these steps:

- Examine the tool thoroughly to determine which component is malfunctioning or missing.

- Consult the manual for details on how the various elements are assembled and function together.

- Utilize an online search by entering relevant descriptions to locate the specific item required.

- Keep a record of model numbers and specifications for future reference.

By following these steps, you will be able to identify what needs replacing with ease, ensuring the tool remains in optimal condition for ongoing use.

Tools Required for Repairs

When handling maintenance or restoration tasks, it’s important to have the right set of equipment at your disposal. A well-prepared toolkit ensures that you can approach the task with confidence, efficiently addressing any issues that arise. Choosing the correct instruments for different stages of the work can save time and reduce the chance of mistakes.

Basic Hand Tools

To begin, having essential hand tools like a screwdriver set and pliers will be invaluable. These will help with disassembling various components and securing elements during reassembly. A sturdy hammer may also be needed for more intensive adjustments.

Specialized Equipment

In addition to basic tools, certain repairs may require more specialized instruments. Items such as a calibration gauge or a precision wrench ensure that you can fine-tune mechanisms and restore functionality effectively. Always ensure that these tools are readily available before starting any repair work.

Step-by-Step Disassembly Guide

In this section, you will be guided through the careful process of taking apart the tool for maintenance or repair. Following these steps will help ensure that the device is disassembled safely and efficiently. Each step should be followed in sequence to avoid any damage or misplacement of essential components.

Required Tools

Before starting, make sure you have the necessary instruments to disassemble the equipment properly. You will need basic hand tools, such as screwdrivers and pliers, along with any specialized instruments that may be required.

Disassembly Steps

| Step | Description |

|---|---|

| 1 | Disconnect the device from any power source to avoid accidental activation. This is a crucial safety precaution. |

| 2 | Begin by removing any external fasteners or covers. These are typically secured with screws that must be carefully unscrewed. |

| 3 | Once external panels are removed, identify and loosen internal components, paying attention to the arrangement for reassembly. |

| 4 | Carefully detach the main mechanisms from the frame, making sure to note the position of each part. |

| 5 | Organize all removed parts systematically to prevent confusion when

How to Properly Clean ComponentsRegular maintenance of mechanical components is essential to ensure smooth operation and prolong their lifespan. Proper cleaning helps to prevent debris buildup and wear, keeping the system running efficiently. In this section, we will cover a step-by-step approach to effectively cleaning individual parts, focusing on safety and precision. Essential Tools and Materials

Step-by-Step Cleaning Process

By following these steps, you can maintain optimal performance and Understanding Pneumatic Systems Basics

Pneumatic systems operate by utilizing compressed air to generate mechanical motion. These systems are widely used in various industries due to their simplicity, efficiency, and reliability. The core principle involves transforming air pressure into kinetic energy, which is then harnessed to drive tools, machinery, or other mechanical devices. Air Compression is a fundamental aspect of such systems, where atmospheric air is compressed to increase its pressure. This stored energy can be released in a controlled manner to perform work, such as powering actuators or motors. Valves play a crucial role in regulating the flow of compressed air, directing it to specific components as needed. This ensures precise control over the movement and operation of the equipment, allowing for versatile applications in automated processes or manual operations. Maintaining consistent air pressure and proper flow control is essential for optimal performance. Adequate lubrication and regular inspection of system components help prevent wear and ensure a long operational life. Safety Precautions When RepairingWhen working on any mechanical device, it is crucial to follow safety guidelines to prevent injuries and ensure a smooth repair process. This section highlights essential measures to consider before starting any maintenance or replacement work. Protective GearAlways wear appropriate protective gear, including safety glasses and gloves. These will protect you from accidental debris or sharp components. In addition, using ear protection is advised when dealing with noisy environments or power tools. Disconnect Power SourcesBefore initiating any repair, disconnect all power sources to prevent accidental activation of the equipment. This step is critical for preventing electrical hazards or unintended motion of moving parts. Always double-check that the device is powered off and unplugged. Where to Find Authentic PartsFinding genuine components for your tools is essential to maintain their performance and longevity. Authentic items ensure compatibility and reliability, enhancing the overall functionality of your equipment. To locate these reliable resources, it’s important to consider various options that cater to your needs. 1. Authorized Retailers

One of the most dependable methods is to purchase from official dealers. These retailers often provide:

2. Online MarketplacesAnother option is to explore e-commerce platforms that specialize in tools and accessories. When using these platforms, look for:

By utilizing these sources, you can confidently secure the necessary components to keep your equipment running smoothly. |