Fishing equipment is built with precision, and each piece is essential for ensuring a smooth and effective experience. When it comes to maintaining or upgrading your gear, having a clear view of the internal elements is crucial for making informed decisions. Whether you’re looking to enhance performance or simply ensure longevity, being familiar with the individual sections is a valuable skill.

In this guide, we will explore the various mechanical elements that make up a high-quality reel. From the intricate internal mechanisms to the external features, each element plays a specific role in ensuring optimal functionality. Understanding how these components interact will give you a deeper appreciation of your fishing tools and allow for better upkeep and customization.

By examining the different sections of the reel, you can ensure that each part is well-maintained and functioning correctly. This knowledge is especially useful for repairs and adjustments, ensuring you can tackle any challenges that

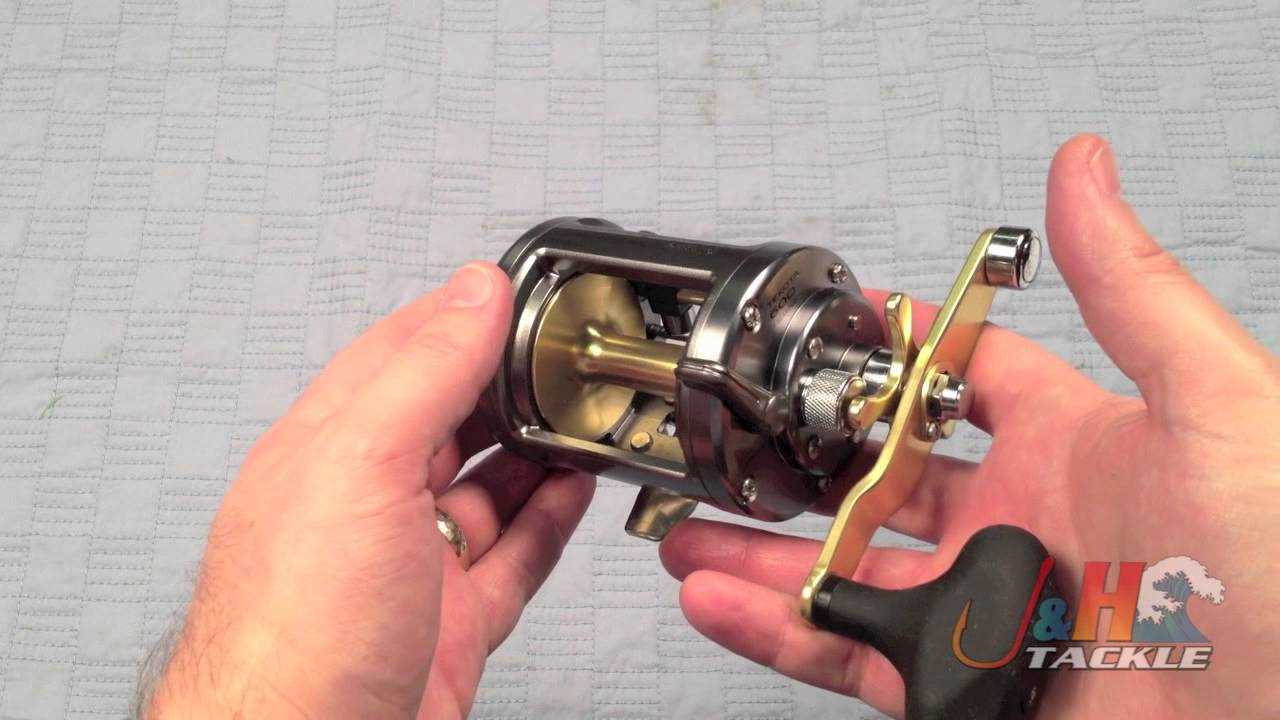

Shimano Tekota 600 Overview

This reel model stands out for its durability and performance, making it a popular choice for anglers seeking reliability in various fishing conditions. It offers precision, smooth handling, and is built to handle a range of environments, from freshwater to saltwater adventures.

Design and Build Quality

Crafted with high-quality materials, this reel is designed to withstand both time and harsh environments. Its construction provides strength without compromising on weight, offering a balanced feel that enhances control and maneuverability during use.

Performance and Usability

With advanced gear mechanisms and an ergonomic design, this reel delivers smooth and efficient operation. It is suitable for different fishing techniques and provides the angler with excellent drag power and line capacity, ensuring optimal performance even in challenging conditions.

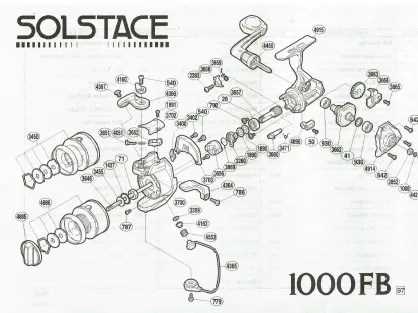

Main Components of Tekota 600 Reel

The structure of this fishing reel consists of several key elements that ensure its smooth operation and durability. Each component plays a vital role in providing seamless control and stability during fishing activities.

- Frame: The core of the reel, offering rigidity and support for the internal parts, ensuring the reel’s stability during intense use.

- Spool: The rotating part where the fishing line is wound, designed to manage line distribution smoothly and efficiently.

- Drag system: A crucial mechanism that allows the angler to apply pressure to the fish, providing resistance and control during retrieval.

- Gear system: This component is responsible for transferring power from the handle to the spool, allowing precise retrieval speed and power.

- Handle: Designed for comfort and leverage, the handle offers control over the reel, allowing efficient operation during fishing.

Each of these components is carefully designed to contribute to the reel’s overall performance, making it reliable for a variety of fishing conditions.

Understanding the Gear Mechanism

The gear mechanism plays a crucial role in ensuring the smooth operation of various mechanical systems. This section will explore how gear systems work, focusing on the interaction between different components that contribute to efficient power transfer. A clear understanding of the gears is essential for maintaining optimal performance and longevity of the equipment.

- Gear Ratio: The relationship between the number of teeth on two interacting gears determines how speed and torque are adjusted.

- Gear Alignment: Proper alignment ensures minimal wear and tear, reducing friction and enhancing the smooth transfer of motion.

- Materials: Gears are typically made from materials like steel or brass, chosen for durability and their ability to withstand different levels of stress.

By understanding these core elements of the gear system, users can better appreciate how the mechanism influences the overall performance of their equipment and make informed decisions when it comes to maintenance or repairs.

Drag System and Its Role

The drag system is a crucial component in any fishing reel, playing a significant role in the overall performance during a catch. It manages the resistance applied to the fishing line, helping to control the tension and prevent line breakage when reeling in larger fish. The way it is engineered and adjusted directly impacts how effectively an angler can handle varying sizes of fish without losing control or damaging equipment.

Drag adjustment allows the user to fine-tune the resistance, making sure it is suitable for different species and fishing environments. By adjusting this mechanism, anglers can increase or decrease the force exerted on the line, giving them the flexibility to match their tactics to the conditions they face.

The importance of a well-designed drag system cannot be overstated, as it provides both protection to the line and greater control to the fisherman, ensuring successful and enjoyable fishing experiences.

How to Replace Bearings

Replacing bearings is a crucial maintenance task to ensure smooth operation and extend the lifespan of any fishing reel. The process involves removing the worn components and installing new ones, ensuring optimal performance. It requires precision and the correct tools to avoid damaging other parts of the mechanism.

Follow these steps to replace the bearings effectively:

| Step | Description | |

|---|---|---|

| 1. Disassemble the reel | Carefully remove the screws and outer components, exposing the internal mechanisms. | |

| 2. Locate the bearings | Identify the position of the bearings within the reel’s structure, usually found near key moving parts. | |

| 3. Remove old bearings | Use specialized tools to gently extract the old bearings without damaging surrounding components. | |

| 4. Install new bearings | Place the new bearings into their designated spots, ensuring a snug and precise fit. |

| Component | Function |

|---|---|

| Spool | Holds the fishing line and facilitates smooth casting and retrieval. |

| Drag System | Controls the tension on the line during a fish’s fight, preventing breakage. |

| Gear Set | Transmits the rotation from the handle to the spool, enabling retrieval of the line. |

| Bearing | Reduces friction and ensures smooth rotation of the spool and other moving parts. |

| Handle | Allows the user to operate the reel, turning the gears for line retrieval. |

| Anti-Reverse Mechanism | Prevents the handle from spinning backwards, ensuring better control during retrieval. |

Upgrading Tekota 600 Components

Improving the performance of your fishing reel involves selecting the right upgrades for key components. By enhancing critical parts, you can achieve smoother operation, increased durability, and better casting precision. The process allows for customization based on your specific needs, ensuring the reel performs optimally in various fishing environments.

| Component | Upgrade Option | Benefit |

|---|---|---|

| Handle | Longer, ergonomic handle | Improved grip and torque for easier reeling |

| Drag System | Carbon fiber drag washers | Smoother drag performance under pressure |

| Gear Ratio | Higher gear ratio gears | Faster retrieval speed |

| Bearings | Stainless steel ball bearings | Enhanced smoothness and corrosion resistance |

| Spool | Lightweight aluminum spool | Reduced weight and increased casting distance |

How to Troubleshoot Reel Issues

When dealing with issues in fishing reels, it is essential to understand the basic components and their functions. Regular maintenance and quick identification of problems can help ensure smooth operation during use. Troubleshooting involves recognizing unusual behavior or performance and addressing it effectively to avoid potential malfunctions.

Common Signs of Trouble: Start by checking for any irregular sounds, stiffness, or slippage when reeling in. These may be indicators of internal wear or debris buildup. Often, the cause can be traced to issues like the line getting tangled, damaged gears, or improper lubrication.

Inspecting the Internal Mechanism: To diagnose internal problems, disassemble the reel carefully, making sure to note the placement of each part. Check for corrosion, broken components, or misalignment of moving parts. Cleaning and lubricating the internal parts can often solve the issue without the need for replacements.

Checking the Drag System: If the drag is not functioning as expected, it could be due to misalignment or wear in the friction components. Adjusting the drag settings and cleaning the drag washers may resolve the issue. In more severe cases, replacing the washers might be necessary.

Final Steps: After inspecting and addressing potential problems, reassemble the reel carefully. Test it by running the line through the spool and reeling in. If the reel operates smoothly without any issues, it is ready for use. Regular checks and maintenance can prevent future problems and prolong the lifespan of the equipment.