When it comes to maintaining outdoor equipment, having a clear visual representation of its elements can significantly enhance the understanding of its functionality. Such illustrations serve as essential tools for both enthusiasts and professionals, simplifying the identification and replacement of worn or damaged components.

Whether you are performing routine maintenance or tackling a more complex repair, a detailed schematic can provide invaluable insight. By breaking down the machinery into its individual pieces, users can easily pinpoint areas that require attention, ensuring optimal performance and longevity.

In this section, we will explore the intricate layout of a specific model’s inner workings. By examining each segment, you will gain a comprehensive understanding of how these elements interact, empowering you to handle your equipment with confidence and precision.

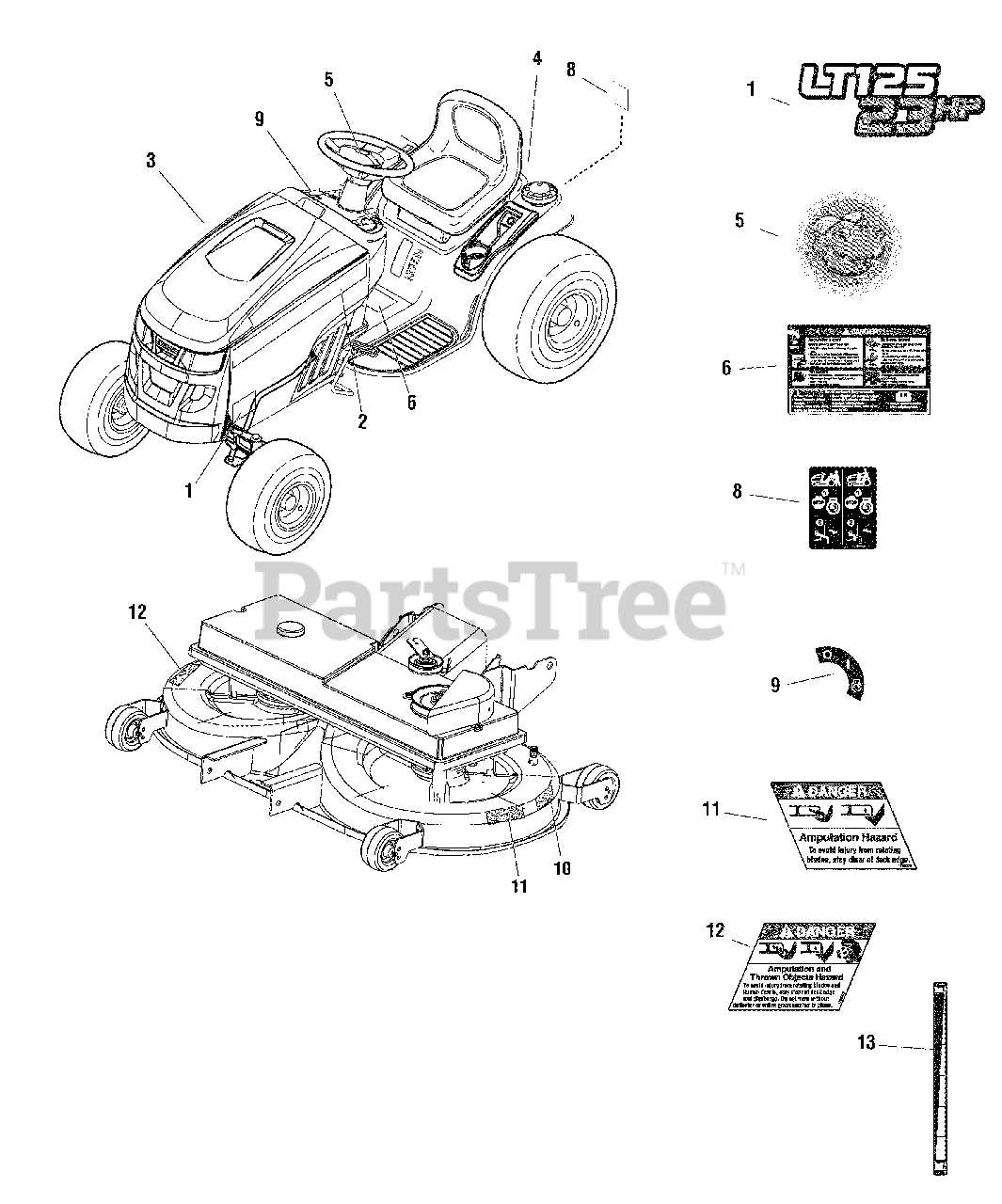

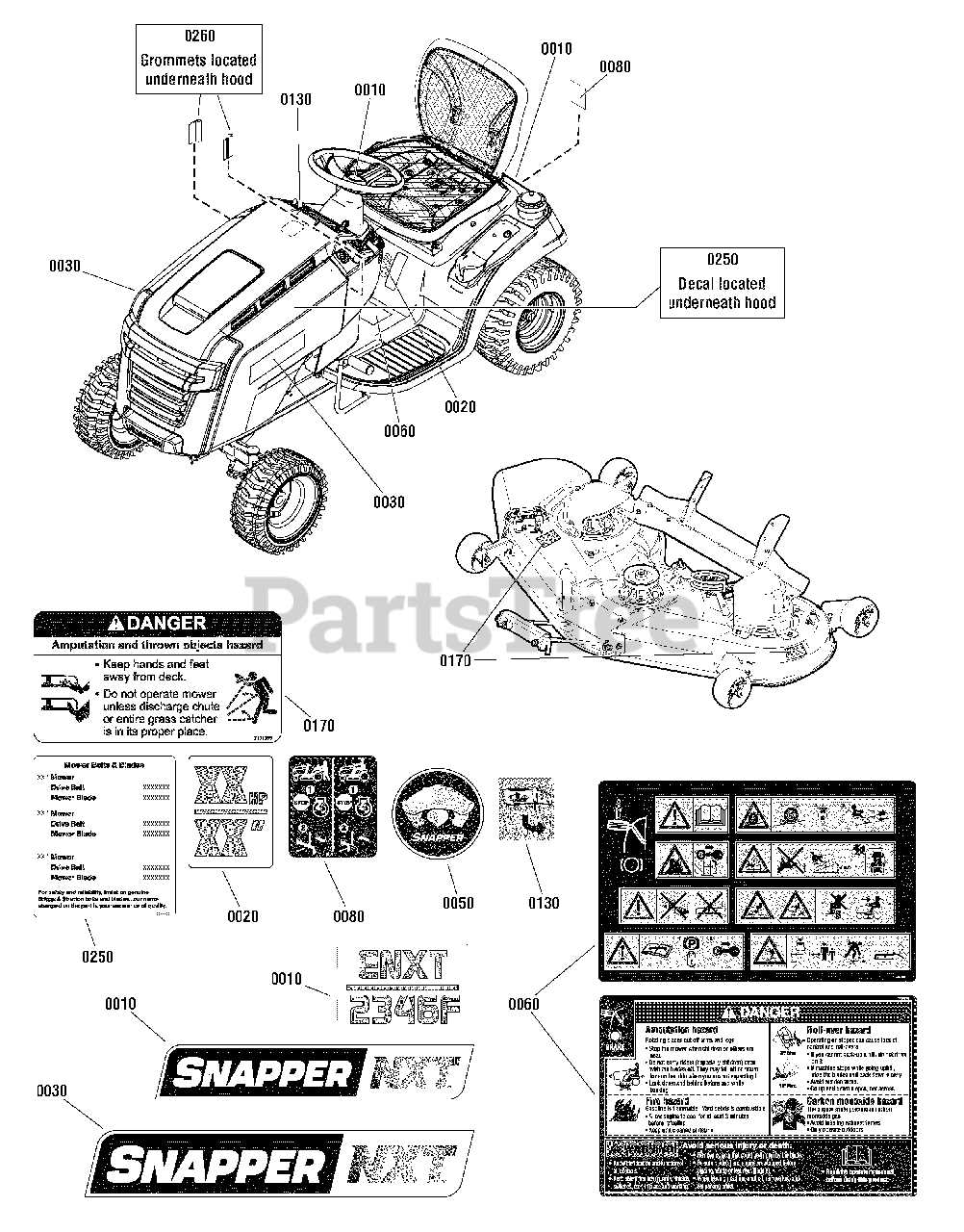

Understanding Snapper LT125 Components

The inner workings of a lawn care machine are crucial for its efficiency and performance. Each element plays a significant role in the overall functionality, ensuring that the device operates smoothly and effectively. By exploring these various components, users can gain insight into how to maintain and troubleshoot their equipment.

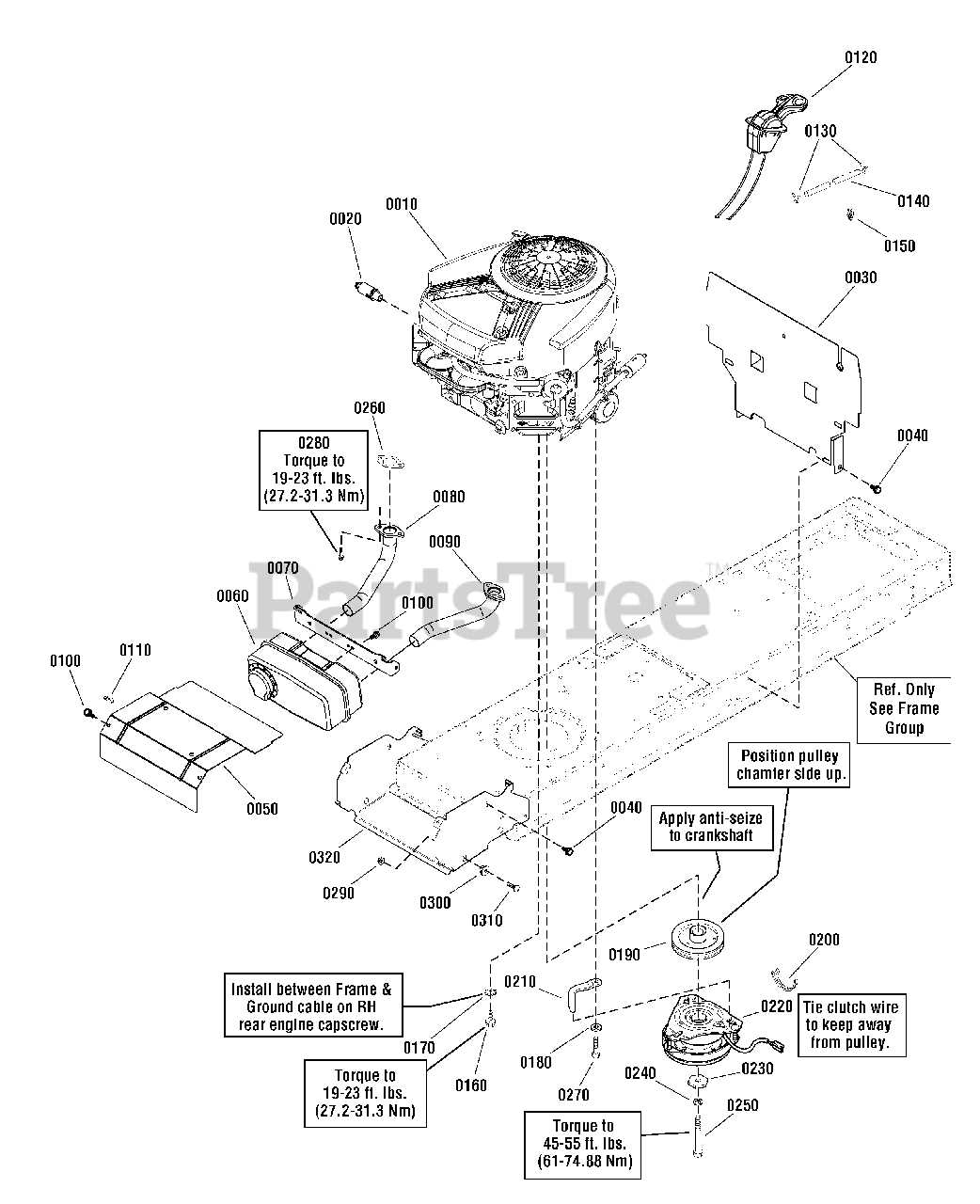

Engine: The power source is vital, providing the necessary energy for operation. Understanding its specifications and maintenance requirements can enhance longevity.

Transmission: This system is responsible for transferring power to the wheels, affecting speed and maneuverability. Knowledge of the transmission’s design can assist in identifying potential issues.

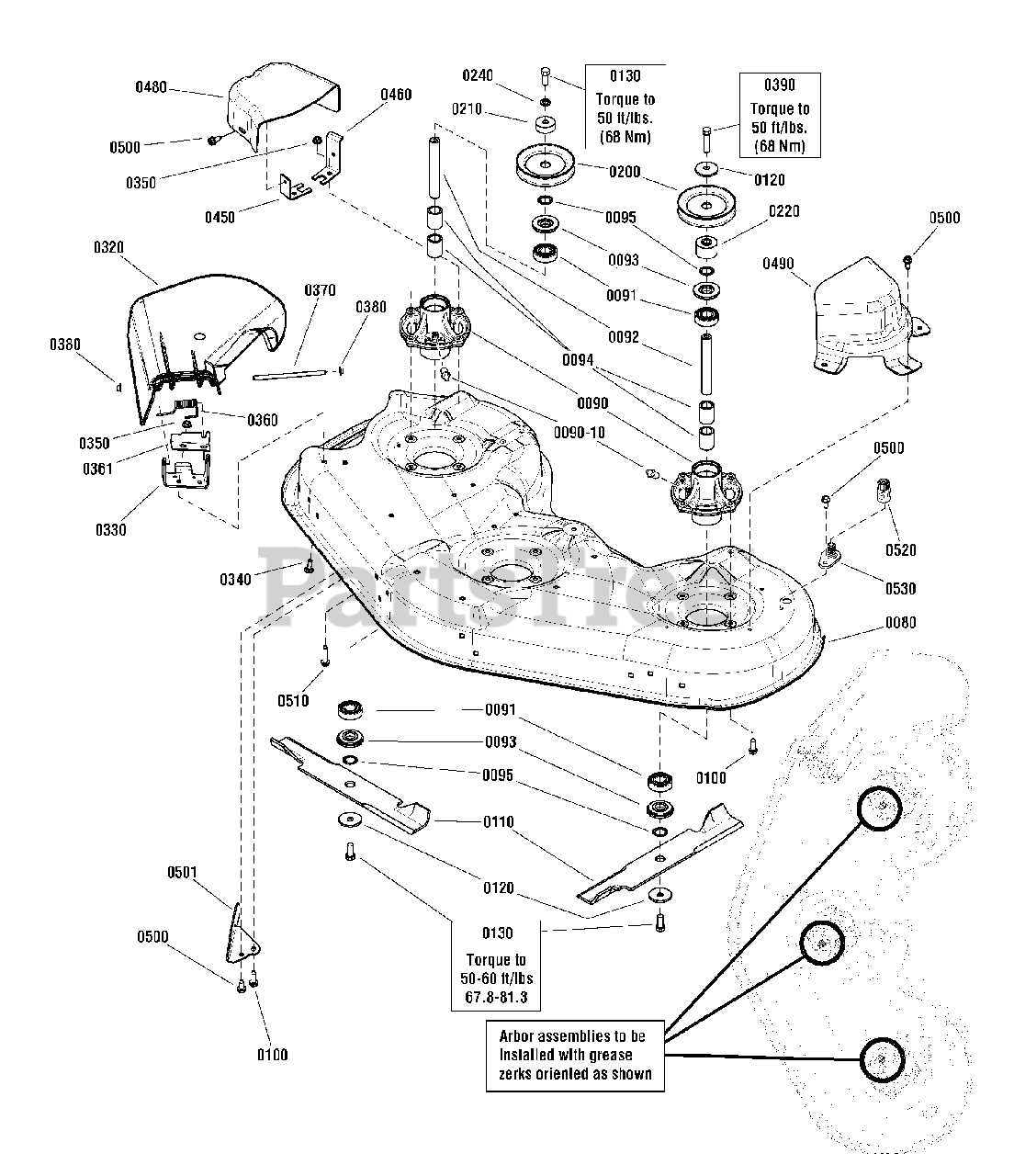

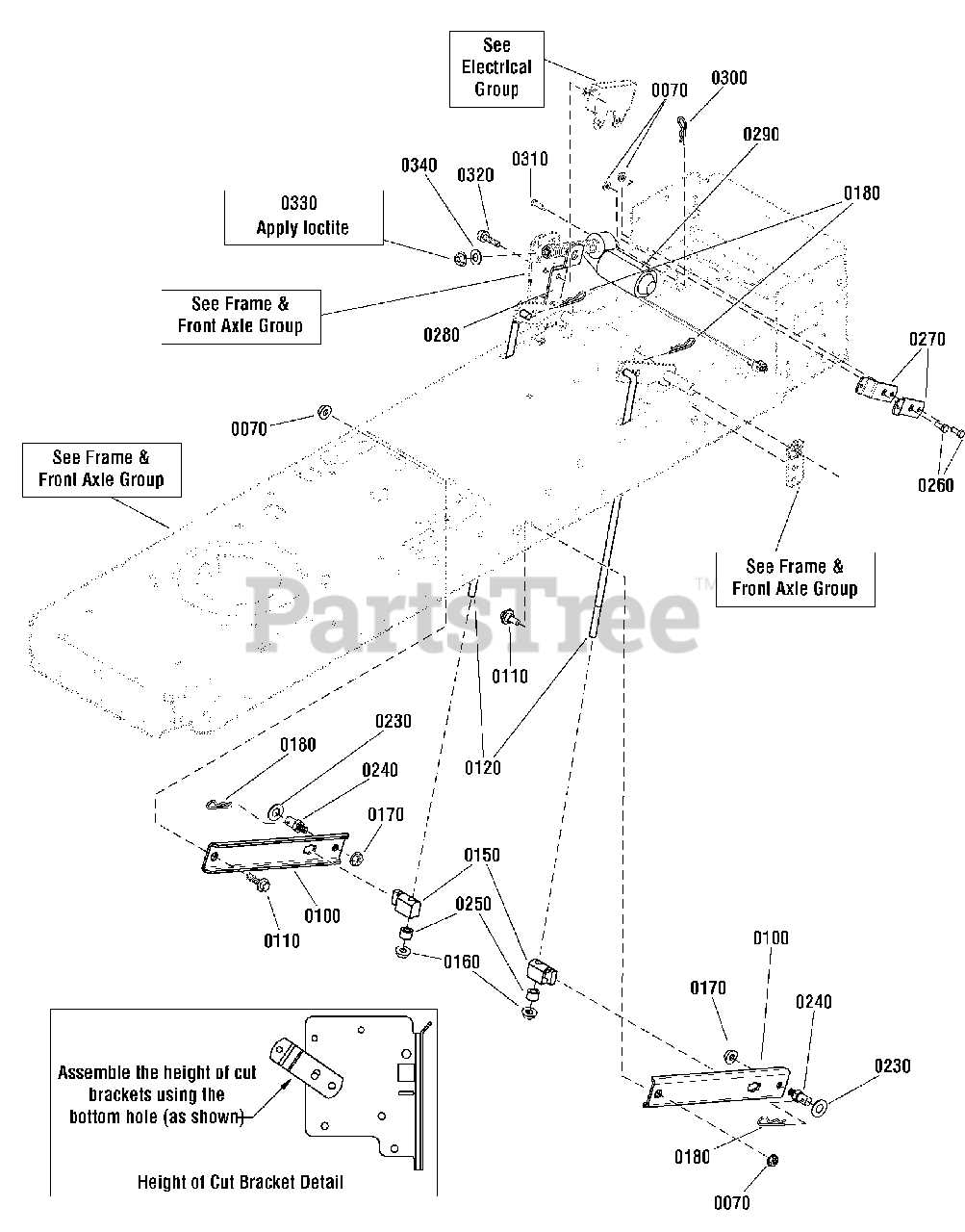

Cutting Deck: This part directly impacts the quality of the cut. Familiarity with its structure and maintenance can lead to improved mowing results.

Controls: The operator’s interface allows for adjustments and commands, making it essential to understand its layout and functionality for optimal use.

In essence, a comprehensive understanding of these elements not only aids in effective operation but also empowers users to tackle maintenance tasks with confidence.

Parts Breakdown for Snapper LT125

This section provides an in-depth overview of the various components essential for optimal functioning of the machine. Understanding these elements is crucial for maintenance and troubleshooting.

- Engine: The powerhouse that drives the entire system.

- Transmission: Responsible for transferring power effectively.

- Chassis: The structural frame that supports all other components.

Each category encompasses specific items that contribute to overall performance:

- Power System

- Fuel tank

- Battery

- Starter motor

- Mobility Mechanism

- Wheels

- Axles

- Brakes

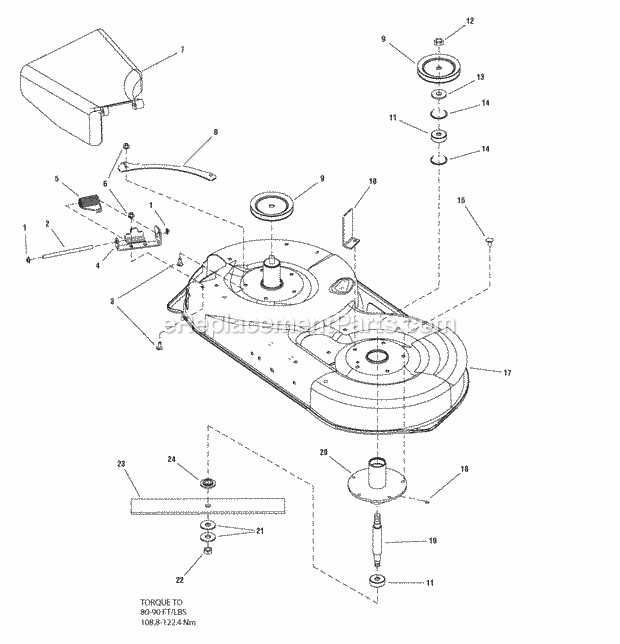

- Cutting Assembly

- Blades

- Deck

- Spindles

Familiarizing yourself with these components will ultimately enhance your ability to maintain and repair the machinery effectively.

Importance of Accurate Diagrams

Clear and precise visual representations are essential in understanding complex systems and components. They serve as invaluable tools for both professionals and enthusiasts, facilitating effective communication and ensuring that all parties are on the same page. Without such illustrations, identifying and addressing issues becomes significantly more challenging.

Moreover, accurate visual guides enhance efficiency by providing step-by-step instructions that can prevent errors during assembly or repairs. When individuals can easily reference these visuals, they are less likely to make mistakes, ultimately saving time and resources. This is particularly crucial in maintenance and troubleshooting tasks.

Additionally, well-crafted visual aids can aid in education and training, allowing learners to delve into the intricacies of machinery and components with greater ease. They transform complex information into digestible segments, promoting better comprehension and retention. In the end, the importance of reliable visual references cannot be overstated, as they are fundamental to achieving optimal performance and longevity of equipment.

Common Repairs for LT125 Model

Maintaining outdoor machinery is essential for optimal performance and longevity. Various issues may arise during regular use, necessitating timely repairs. This section focuses on typical fixes that owners might encounter, ensuring the equipment remains in excellent working condition.

Engine Troubleshooting

One of the most frequent concerns is engine-related problems. These can range from starting difficulties to unusual noises during operation. Regular inspection of the ignition system and fuel lines can prevent major failures.

Deck Maintenance

Another common area requiring attention is the cutting deck. Over time, wear and tear can lead to reduced cutting efficiency. Ensuring the blades are sharp and free of debris is crucial for achieving a clean cut.

| Issue | Common Solution |

|---|---|

| Engine won’t start | Check spark plug and fuel supply |

| Noisy operation | Inspect for loose components |

| Inefficient cutting | Sharpen or replace blades |

Finding Replacement Parts Efficiently

Locating the right components for your equipment can be a daunting task, but with the right approach, it can be streamlined. Understanding where to look and how to evaluate options is key to ensuring you acquire the necessary items without unnecessary delays or expenses.

Key Strategies for Efficient Searches

- Utilize Online Resources: Explore manufacturer websites, online retailers, and forums dedicated to equipment maintenance.

- Consult User Manuals: Reference manuals for detailed information on specifications and compatible components.

- Leverage Community Knowledge: Join online groups or local clubs to tap into the experience of fellow enthusiasts.

Evaluating Your Options

- Check Compatibility: Always verify that the item matches your equipment’s model and specifications.

- Compare Prices: Research various suppliers to find the best deals while considering shipping costs.

- Assess Quality: Read reviews and choose reputable brands to ensure longevity and performance.

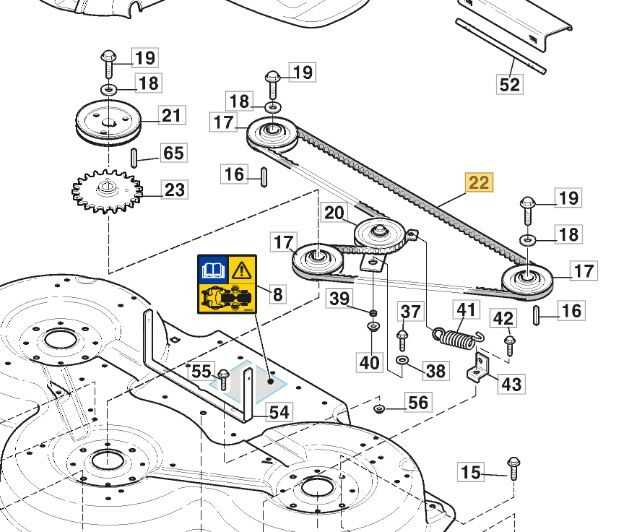

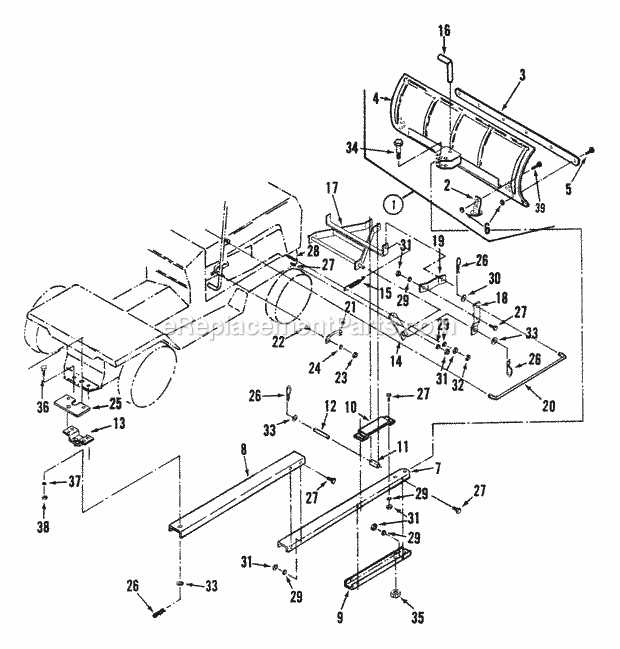

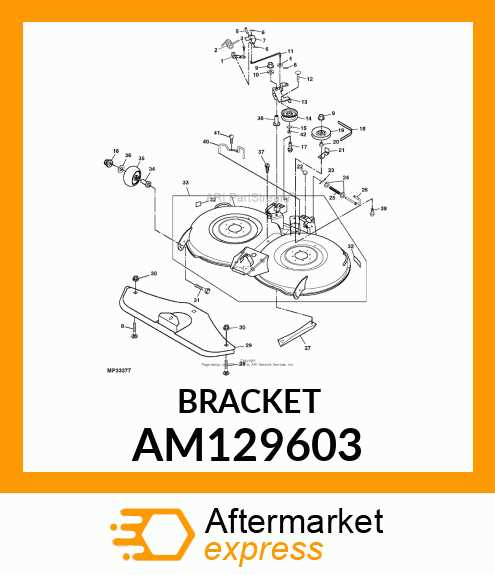

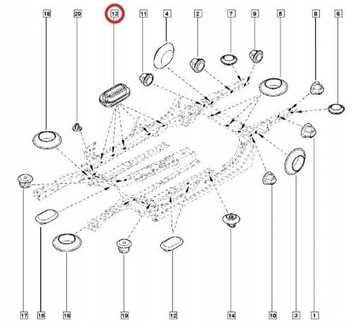

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repair of machinery. These visual representations help you identify components and their relationships within the system, ensuring you can navigate repairs efficiently.

Familiarize yourself with the layout: Each illustration typically follows a standardized format, with labels indicating various elements. Recognizing this structure will streamline your interpretation.

Identify key symbols: Different shapes and lines convey specific meanings, such as connections and types of components. Learning these symbols will enhance your comprehension of the overall design.

Follow the numbering system: Most visuals will include a reference list that corresponds with the elements shown. Use this list to locate and understand each part’s function and specifications.

Practice makes perfect: The more you engage with these visuals, the easier it becomes to read them quickly and accurately. Over time, you’ll develop an intuitive sense for identifying and addressing issues.

Maintenance Tips for Snapper Equipment

Regular upkeep is essential to ensure the longevity and efficiency of your outdoor machinery. By following a few straightforward practices, you can keep your equipment running smoothly, minimizing downtime and repair costs. This section provides guidance on how to maintain your tools effectively.

Routine Checks

Conducting frequent inspections helps identify potential issues before they escalate. Focus on the following components during your checks:

| Component | Recommended Action |

|---|---|

| Blades | Sharpen and inspect for damage. |

| Air Filter | Clean or replace as needed. |

| Oil Level | Check and change according to the schedule. |

| Fuel System | Inspect for leaks and use fresh fuel. |

Seasonal Maintenance

At the start of each season, it’s beneficial to perform comprehensive maintenance. This may include deep cleaning, replacing worn parts, and ensuring all safety features are functional. Addressing these areas will enhance performance and extend the lifespan of your machinery.

Identifying Wear and Tear

Understanding the signs of deterioration is crucial for maintaining the performance and longevity of your equipment. Regular inspections can help identify issues early, preventing costly repairs and ensuring optimal functionality.

Key indicators of wear and tear include:

- Visual Inspection: Look for cracks, corrosion, or signs of damage on components.

- Unusual Noises: Listen for any abnormal sounds during operation, which may signal mechanical issues.

- Performance Issues: Notice any decline in efficiency or power output, which could indicate underlying problems.

Regular maintenance checks should focus on:

- Inspecting belts and cables for fraying or excessive wear.

- Checking fluid levels and looking for leaks.

- Examining moving parts for signs of friction or irregular movement.

By staying vigilant and proactive in monitoring these elements, you can effectively extend the life of your machinery and maintain its performance standards.

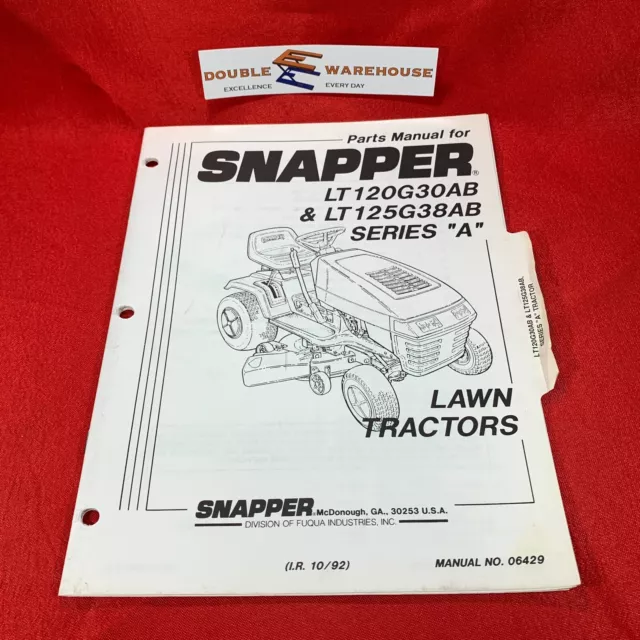

Resources for Parts and Manuals

When it comes to maintaining outdoor equipment, having access to the right resources is essential. Reliable manuals and component guides can significantly enhance your understanding of machinery, ensuring that repairs and upkeep are carried out efficiently. Various platforms offer valuable information, enabling users to identify and order necessary components with ease.

One of the primary sources for manuals is the official manufacturer’s website. Here, you can often find downloadable versions of user guides and service documents. These materials typically include detailed instructions and schematics, making it easier to comprehend assembly and disassembly processes.

Additionally, numerous online retailers specialize in selling equipment accessories. These sites often provide exploded views of machinery, allowing customers to visualize each component. Many of them also feature customer service representatives who can assist in identifying specific items or providing guidance on usage.

For those seeking community support, forums and discussion boards can be invaluable. Users often share insights, troubleshooting tips, and recommendations for sourcing parts. Engaging with fellow enthusiasts can provide unique perspectives and solutions to common challenges.

Lastly, consider checking local repair shops or authorized service centers. They not only have access to genuine components but can also offer expert advice on maintenance practices and product care.

Tools Required for Repairs

When undertaking maintenance or repair tasks, having the right equipment is essential for efficiency and effectiveness. Proper tools not only facilitate the job but also ensure safety and precision during the process. Whether you’re tackling a minor adjustment or a major overhaul, being prepared with the necessary instruments can make a significant difference.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are crucial for disassembling components and accessing internal mechanisms. A reliable socket set can also simplify tasks, allowing for quick and easy adjustments to various fittings.

Power Tools for Efficiency

In more extensive repair scenarios, power tools like drills and impact wrenches can greatly reduce the time and effort required. These tools enhance your ability to handle tough bolts and fasteners, making the overall repair process smoother and more efficient.

Safety Precautions During Repairs

When undertaking maintenance or repair work on machinery, adhering to safety measures is paramount. These precautions help prevent accidents and ensure a smooth process, protecting both the individual performing the work and the equipment itself. Awareness and preparation can significantly reduce risks associated with mechanical tasks.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, safety goggles, and steel-toed boots.

- Ensure the equipment is turned off and disconnected from any power source before starting any repairs.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep your workspace clean and organized to minimize hazards and distractions.

Handling Tools and Equipment

- Inspect tools for damage before use, ensuring they are in good working condition.

- Use tools for their intended purpose to avoid accidents.

- Store tools properly after use to prevent tripping hazards.

- Be cautious of sharp edges and moving parts while handling machinery components.

By following these safety precautions, individuals can create a safer working environment and effectively reduce the likelihood of injury during repairs.

Frequently Asked Questions about LT125

This section addresses common inquiries regarding a popular model known for its reliability and efficiency. Users often seek clarity on maintenance, components, and troubleshooting tips to enhance their experience with this equipment.

What are the best maintenance practices for this model?

Regular upkeep is essential for optimal performance. Ensure you check the oil levels frequently, replace filters as needed, and keep the blades sharp. Additionally, inspecting belts and tires can prevent issues and extend the lifespan of the machine.

Where can I find replacement components?

Replacement items can be sourced from authorized dealers, online marketplaces, or specialty shops that cater to outdoor power equipment. It’s advisable to consult the user manual for specific part numbers to ensure compatibility and quality.