In the world of lawn maintenance, having a comprehensive understanding of your machinery’s internal structure is crucial. This knowledge not only enhances the efficiency of your equipment but also extends its lifespan. By familiarizing yourself with how different elements interact, you can make informed decisions regarding repairs and upgrades.

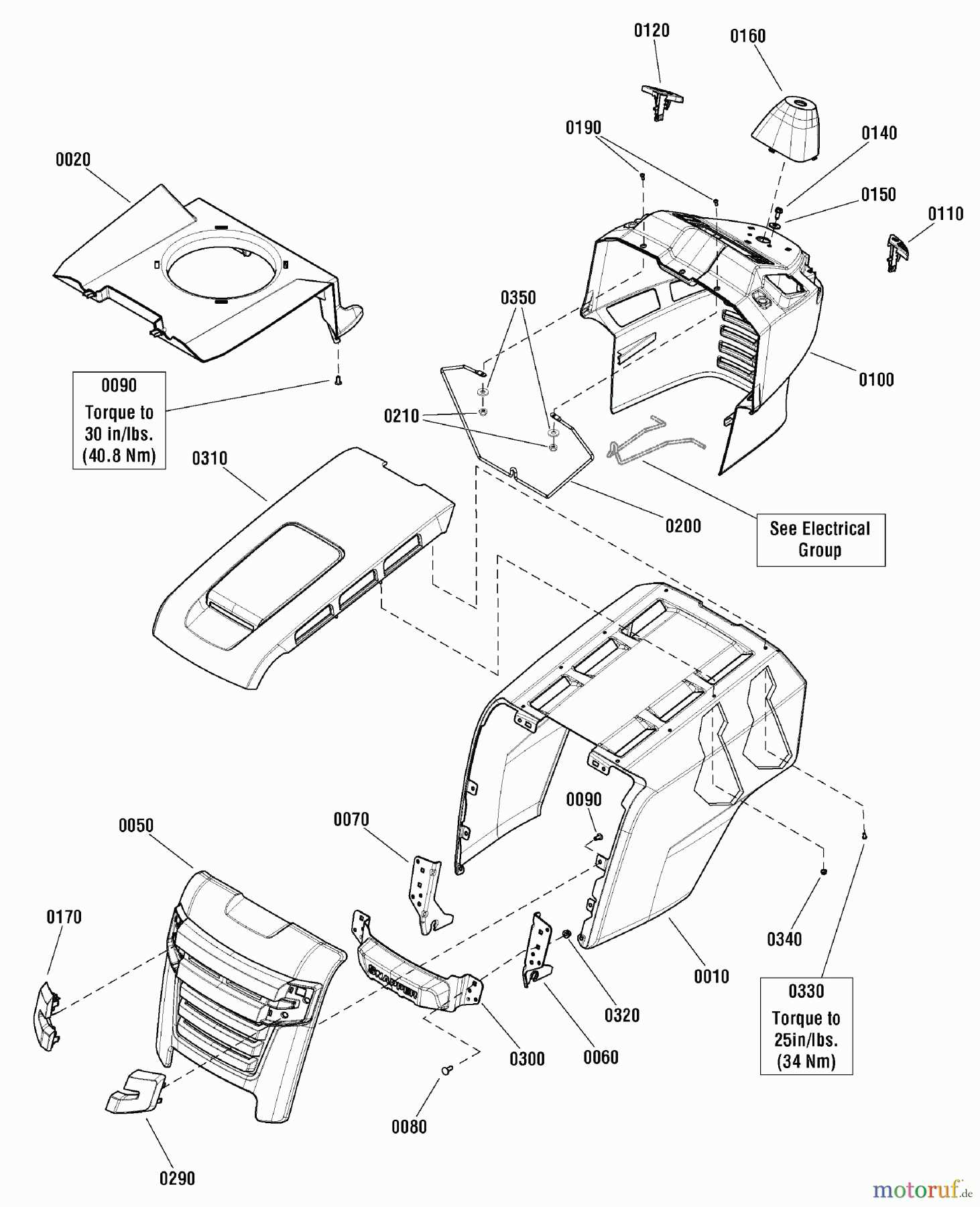

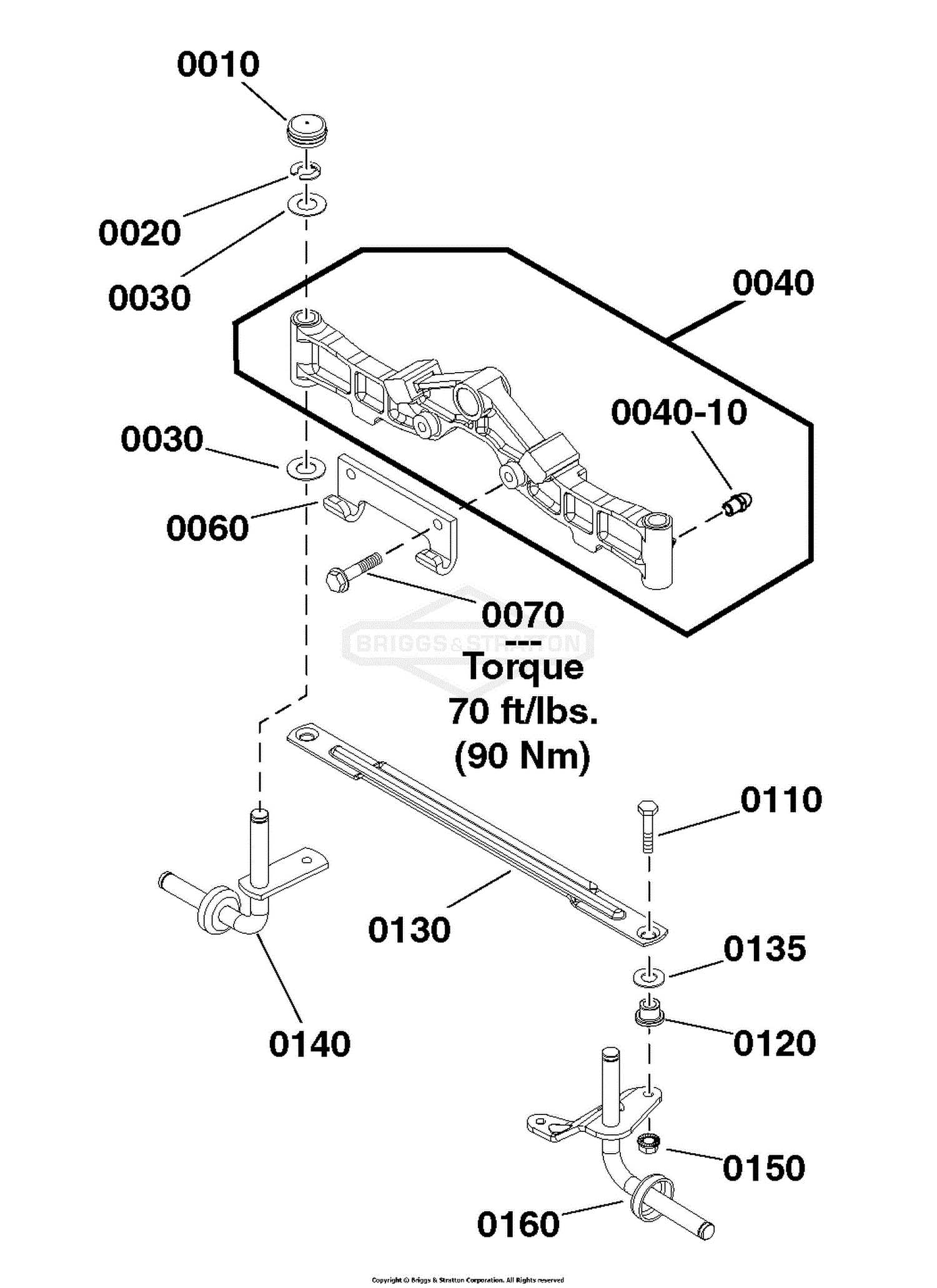

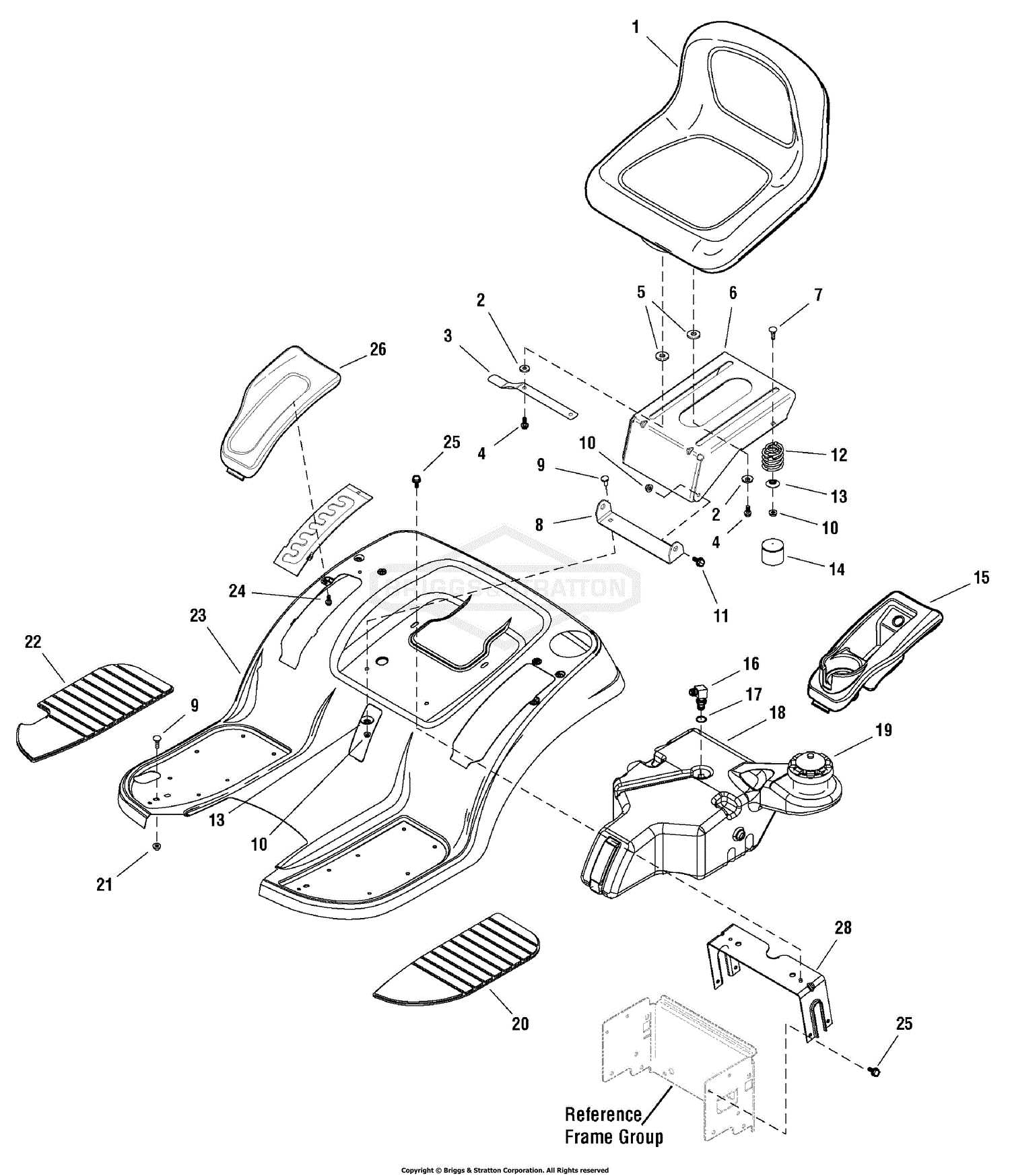

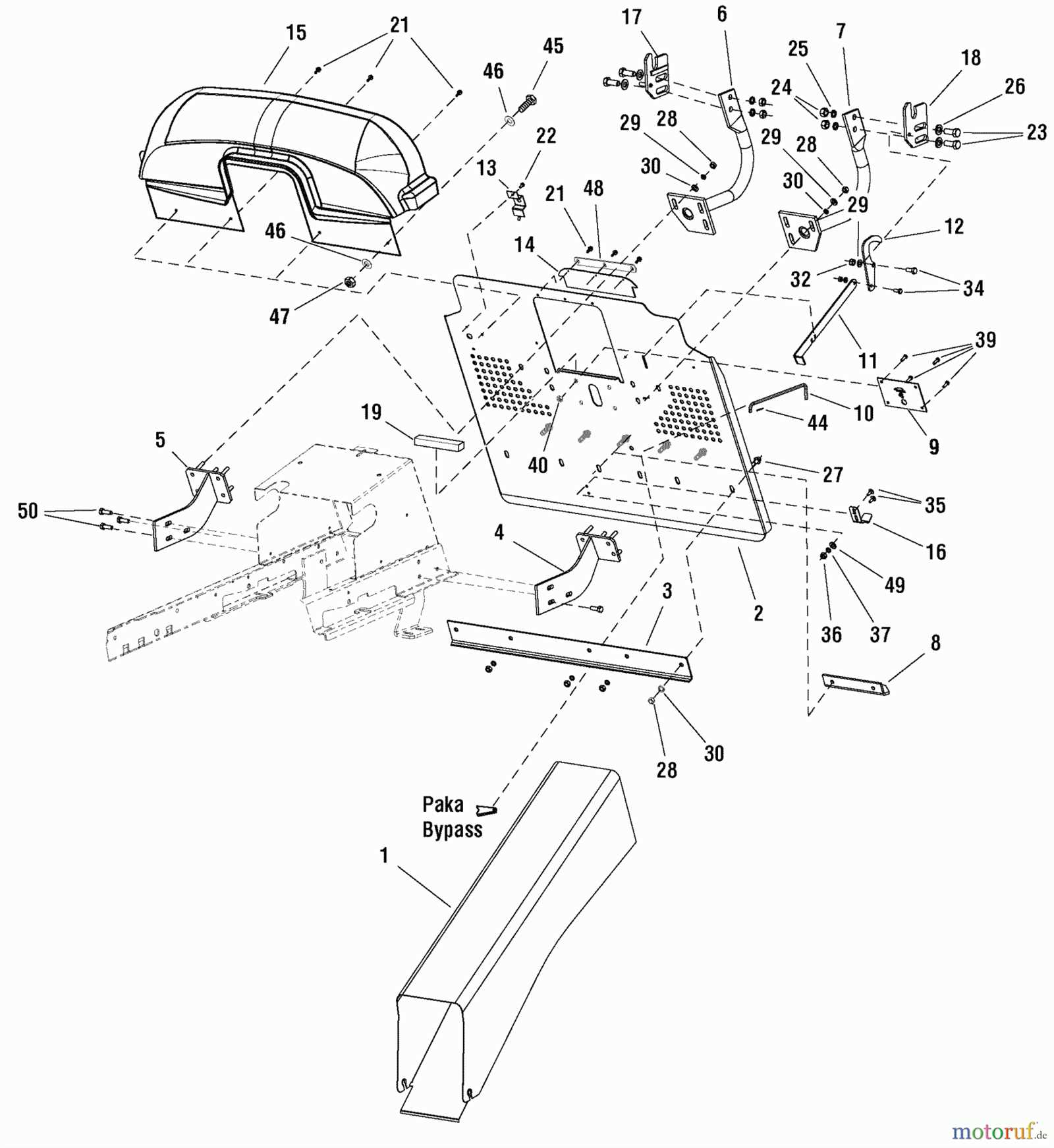

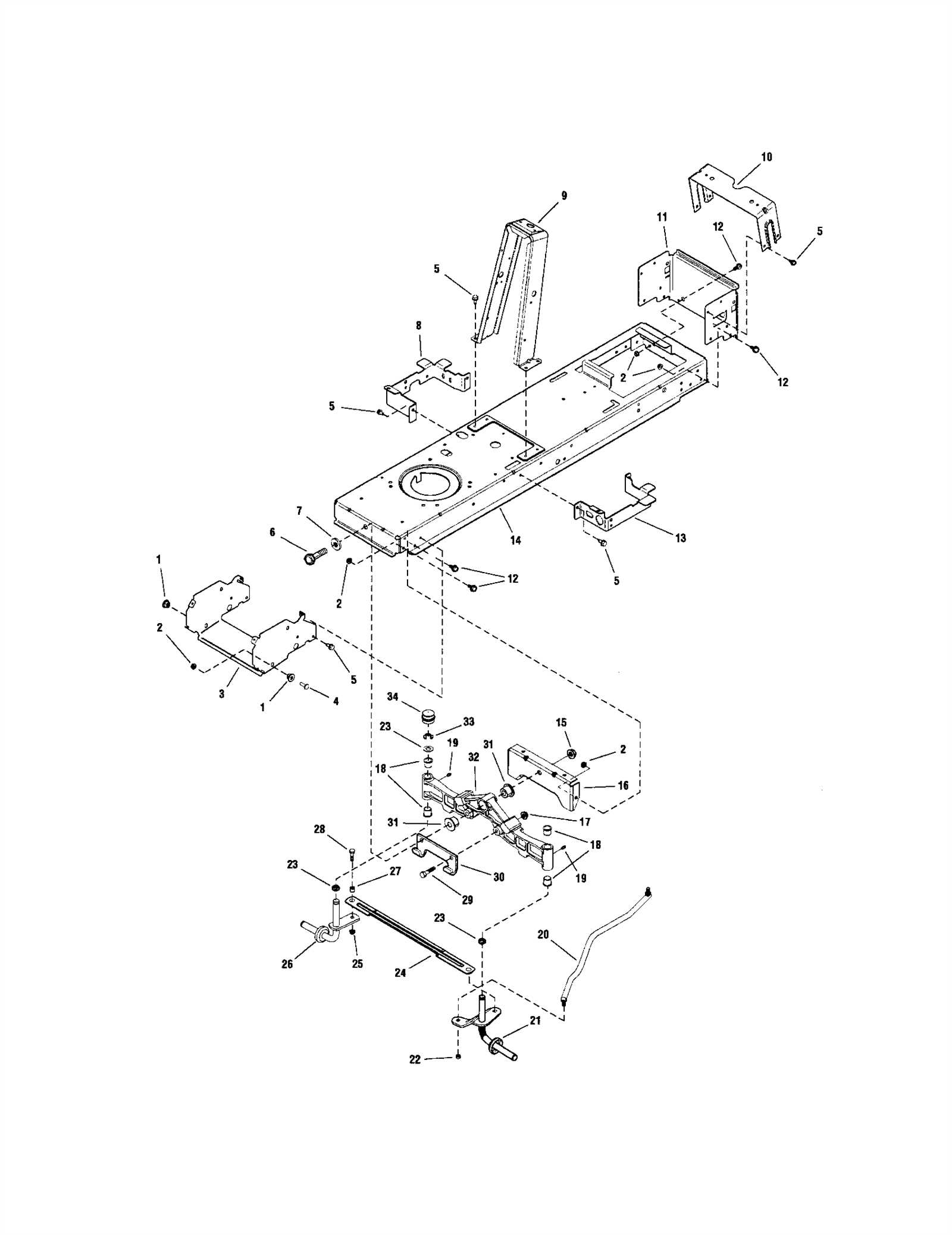

Visual representations of machinery components serve as invaluable tools for both novice and experienced users. These illustrations highlight the intricate relationships between various parts, allowing for easier identification and troubleshooting. When equipped with this information, operators can swiftly pinpoint issues, ensuring that their devices remain in optimal working condition.

Moreover, detailed layouts facilitate smoother maintenance routines. By understanding where each element fits within the larger assembly, individuals can carry out replacements or adjustments with confidence. This proactive approach not only saves time but also minimizes potential frustrations during the upkeep process.

Understanding Snapper LT200 Components

In the realm of lawn care machinery, a comprehensive grasp of the various elements that contribute to the overall functionality is essential. Each component plays a pivotal role, influencing performance and durability. By exploring these individual parts, users can enhance maintenance practices and optimize machine operation.

Key Elements of the System

The following table outlines crucial components, their functions, and potential issues that may arise:

| Component | Function | Common Issues |

|---|---|---|

| Engine | Powers the entire unit | Overheating, poor performance |

| Transmission | Transfers power to the wheels | Slipping, unusual noises |

| Deck | Houses cutting blades | Corrosion, damage |

Maintaining Optimal Functionality

Regular checks and maintenance of each element are vital to prolonging the lifespan of the machinery. Understanding these components not only aids in effective troubleshooting but also empowers users to take proactive measures in equipment care.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations of these elements offer significant advantages for both professionals and enthusiasts. They serve as essential tools for identifying specific pieces, ensuring proper assembly, and simplifying troubleshooting processes.

Benefits of Visual Representations

- Enhanced clarity in identifying components

- Streamlined repair processes

- Improved efficiency in ordering replacements

- Reduction in assembly errors

Conclusion

Utilizing these visual aids ultimately leads to better performance and longevity of equipment. By familiarizing oneself with the layout and functions of various elements, users can ensure their machinery operates smoothly and efficiently.

Common Issues with Snapper LT200

Understanding typical problems that arise with this lawn maintenance equipment can help users maintain optimal performance and extend its lifespan. Many users encounter a range of issues, from mechanical failures to operational inconsistencies.

Mechanical Failures

- Engine Starting Difficulties: Issues may stem from a faulty battery or ignition system.

- Blade Malfunctions: Dull or damaged blades can affect cutting efficiency.

- Transmission Problems: Difficulty in shifting gears can indicate transmission wear.

Operational Inconsistencies

- Uneven Cutting: This can result from improper wheel alignment or uneven blade height.

- Excessive Vibration: Often caused by loose components or unbalanced blades.

- Fuel Inefficiency: Issues may arise from clogged fuel filters or incorrect fuel mixtures.

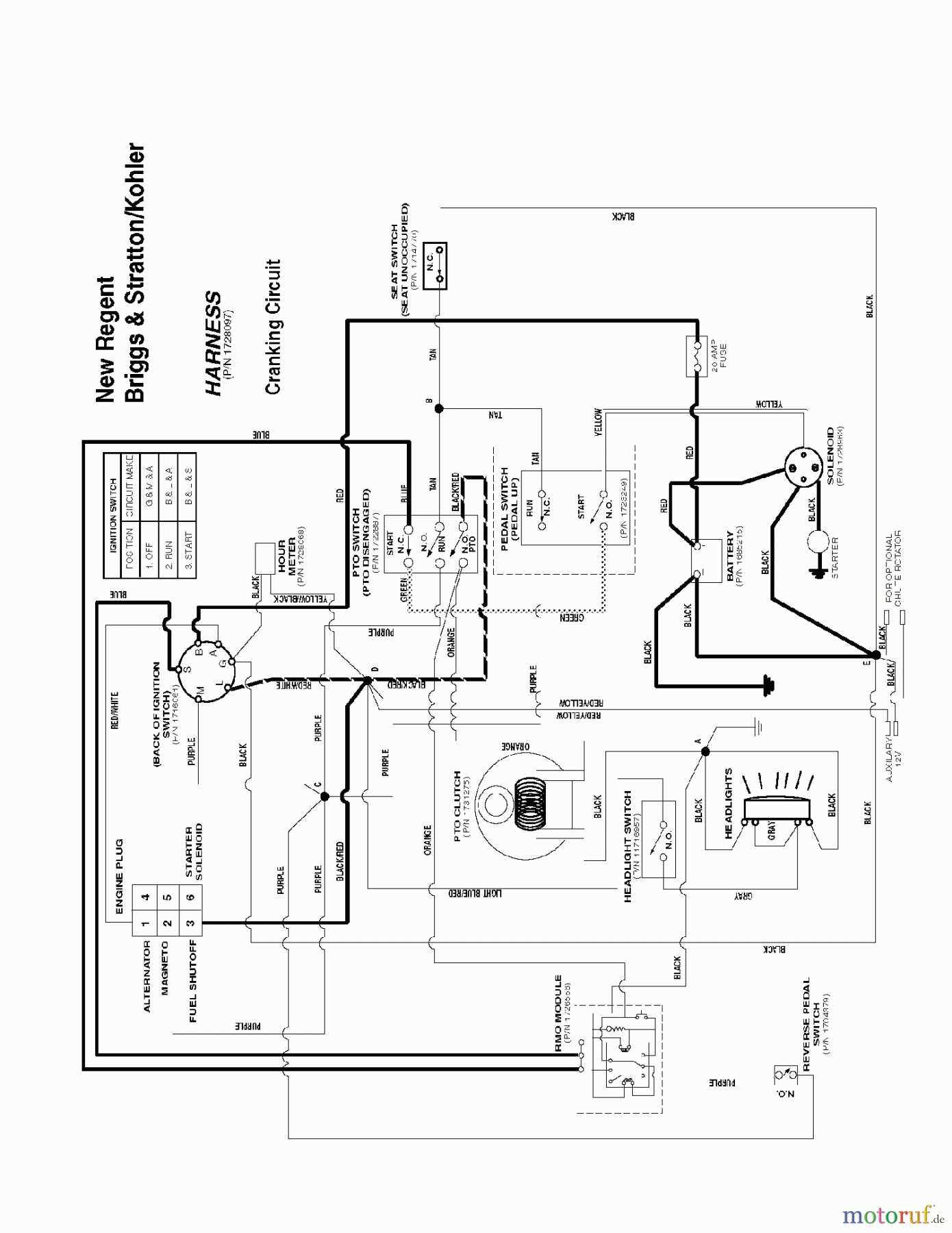

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide insights into the relationships between different elements, helping users identify what is necessary for specific tasks.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Learn the common symbols used to represent various elements.

- Identify Key Sections: Break down the illustration into sections to understand their function.

- Follow the Flow: Observe how parts connect and interact with each other.

- Refer to Annotations: Pay attention to any labels or notes that provide additional context.

By following these guidelines, you can navigate complex visuals with confidence and ensure successful repairs or upgrades.

Identifying Key Components

Understanding the essential elements of any machinery is crucial for effective maintenance and troubleshooting. Recognizing each part’s function allows users to address issues efficiently and ensure the longevity of their equipment. This section highlights significant components commonly found in such machines, aiding in the identification process for better management and repair.

Main Elements Overview

Every piece of equipment is made up of various integral parts, each serving a specific role. Familiarity with these components not only streamlines the maintenance process but also enhances operational safety. Below is a breakdown of key elements that you should be aware of:

| Component | Description |

|---|---|

| Engine | The powerhouse of the machine, responsible for generating the necessary energy for operation. |

| Transmission | Transfers power from the engine to the wheels, influencing speed and torque. |

| Chassis | The framework that supports all other components, providing stability and structure. |

| Blade Assembly | Essential for cutting, this part directly interacts with the ground and is vital for performance. |

| Control System | Includes all the levers and buttons that allow the operator to control the machine’s functions. |

Understanding Functions

Each component plays a pivotal role in the overall operation. By learning how these elements work together, operators can diagnose problems more effectively and perform necessary adjustments or repairs. Mastery of these details not only enhances efficiency but also contributes to the safety and effectiveness of the machinery.

Maintenance Tips for Snapper LT200

Proper upkeep of your lawn equipment ensures longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns, allowing for a seamless mowing experience. Here are some essential guidelines to keep your machine in top shape.

1. Regular Inspection: Periodically check the various components for wear and tear. Look for any loose bolts, frayed belts, or damaged blades. Addressing these issues early can prevent further damage.

2. Cleanliness is Key: After each use, clean the undercarriage and blades to remove grass clippings and debris. This practice helps to maintain performance and reduces rust and corrosion.

3. Oil Changes: Just like a car, your equipment requires regular oil changes. Follow the manufacturer’s recommendations for oil type and change intervals to ensure smooth operation.

4. Air Filter Maintenance: A clean air filter is crucial for efficient engine performance. Inspect and replace the filter as needed, especially in dusty environments, to maintain airflow.

5. Sharpen the Blades: Dull blades tear the grass rather than cut it, leading to a stressed lawn. Regularly sharpening the blades ensures a clean cut and promotes healthy growth.

6. Battery Care: For electric models, check the battery regularly. Keep it charged and inspect connections to prevent starting issues.

7. Seasonal Storage: At the end of the mowing season, store your machine in a dry, sheltered area. Consider draining fuel or adding a fuel stabilizer to prevent engine issues in the spring.

By following these maintenance tips, you can extend the life of your lawn equipment and ensure it operates at its best. Regular attention to these areas will make your mowing tasks easier and more efficient.

Where to Find Replacement Parts

When it comes to maintaining and restoring your equipment, sourcing the right components is essential for optimal performance. There are various avenues to explore, each offering a unique selection of options to meet your needs.

Online Resources

- Manufacturer’s Website: Often the most reliable source for authentic components.

- E-commerce Platforms: Websites like Amazon or eBay can have a wide variety of aftermarket options.

- Specialty Retailers: Look for sites dedicated to outdoor equipment, as they may carry specific items.

Local Stores and Workshops

- Home Improvement Stores: Many carry a selection of general equipment parts.

- Local Repair Shops: Professionals can often order specific components for you.

- Salvage Yards: A treasure trove for used parts at a fraction of the cost.

Comparing OEM vs. Aftermarket Parts

When maintaining equipment, the choice between original components and alternative options often arises. Each type offers distinct advantages and drawbacks that can significantly influence performance and longevity.

Original equipment manufacturers (OEM) provide components that match the specifications of the original design. These parts are typically:

- Guaranteed to fit and function as intended.

- Backed by warranties from the manufacturer.

- Often higher in price due to brand reputation.

On the other hand, aftermarket alternatives can vary widely in quality and pricing. Benefits of these options may include:

- Lower costs, making them appealing for budget-conscious users.

- A broader range of choices, including upgraded features.

- Potentially shorter wait times for availability.

Ultimately, the decision between these two paths requires careful consideration of factors such as budget, performance expectations, and reliability needs.

Step-by-Step Repair Guide

This guide provides a structured approach to troubleshoot and fix common issues that may arise with your outdoor machinery. By following each step methodically, you can ensure a thorough examination and effective resolution of problems.

Start by gathering necessary tools and safety equipment. Ensure you have a clean workspace, as this will help in organizing components and maintaining focus during the repair process.

Next, identify the specific issue you’re facing. Refer to the user manual for guidance on common problems and potential solutions. If you have access to a detailed breakdown of components, use it to familiarize yourself with the assembly and function of each part.

Once the problem is identified, begin disassembling the equipment carefully, noting the order and orientation of each part. Keep small components in labeled containers to avoid misplacement.

After disassembly, inspect each part for wear and damage. Replace any faulty components with quality replacements to ensure optimal performance. When ready, reassemble the machinery, following the reverse order of disassembly.

Finally, conduct a thorough test of the equipment after reassembly. Monitor its operation closely to confirm that the repair has been successful and the issues have been resolved. This systematic approach will help you achieve the best results in maintaining your machinery.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, ensuring safety is paramount. Adhering to specific guidelines not only protects the individual performing the work but also preserves the integrity of the equipment. Following are key measures to enhance safety during repair activities.

- Wear Appropriate Gear: Always don safety goggles, gloves, and sturdy footwear to minimize the risk of injury.

- Disconnect Power Sources: Before beginning any repair, ensure that all power supplies are disconnected to prevent accidental startups.

- Use Proper Tools: Utilize the correct tools for the job to avoid damage and ensure efficient repairs.

In addition to these basic precautions, further steps can be taken to foster a safe working environment.

- Work in a Well-Lit Area: Good visibility reduces the likelihood of accidents and mistakes.

- Maintain a Clean Workspace: Keep tools organized and remove any hazards that could cause trips or falls.

- Follow Manufacturer Guidelines: Always consult the user manual for specific safety instructions related to the equipment.

By adhering to these precautions, individuals can significantly reduce the risk of accidents and injuries while performing essential maintenance tasks.

Upgrading Snapper LT200 Features

Enhancing the capabilities of your lawn care equipment can significantly improve performance and user experience. By focusing on specific upgrades, you can tailor your machine to better suit your gardening needs and preferences.

- Engine Performance:

- Consider upgrading to a more powerful engine for improved cutting efficiency.

- Regular maintenance and tuning can optimize existing engine performance.

- Cutting Deck:

- Installing a larger or more efficient cutting deck can reduce mowing time.

- Adding mulching capabilities enhances grass management.

- Wheels and Tires:

- Opt for wider tires for better traction and stability on uneven terrain.

- Consider upgraded wheels to improve maneuverability.

- Comfort Features:

- Adding ergonomic seating can enhance comfort during long mowing sessions.

- Implementing better controls and handles improves ease of use.

By carefully selecting enhancements, users can create a machine that meets their ultimate lawn care needs and preferences, leading to a more efficient and enjoyable mowing experience.

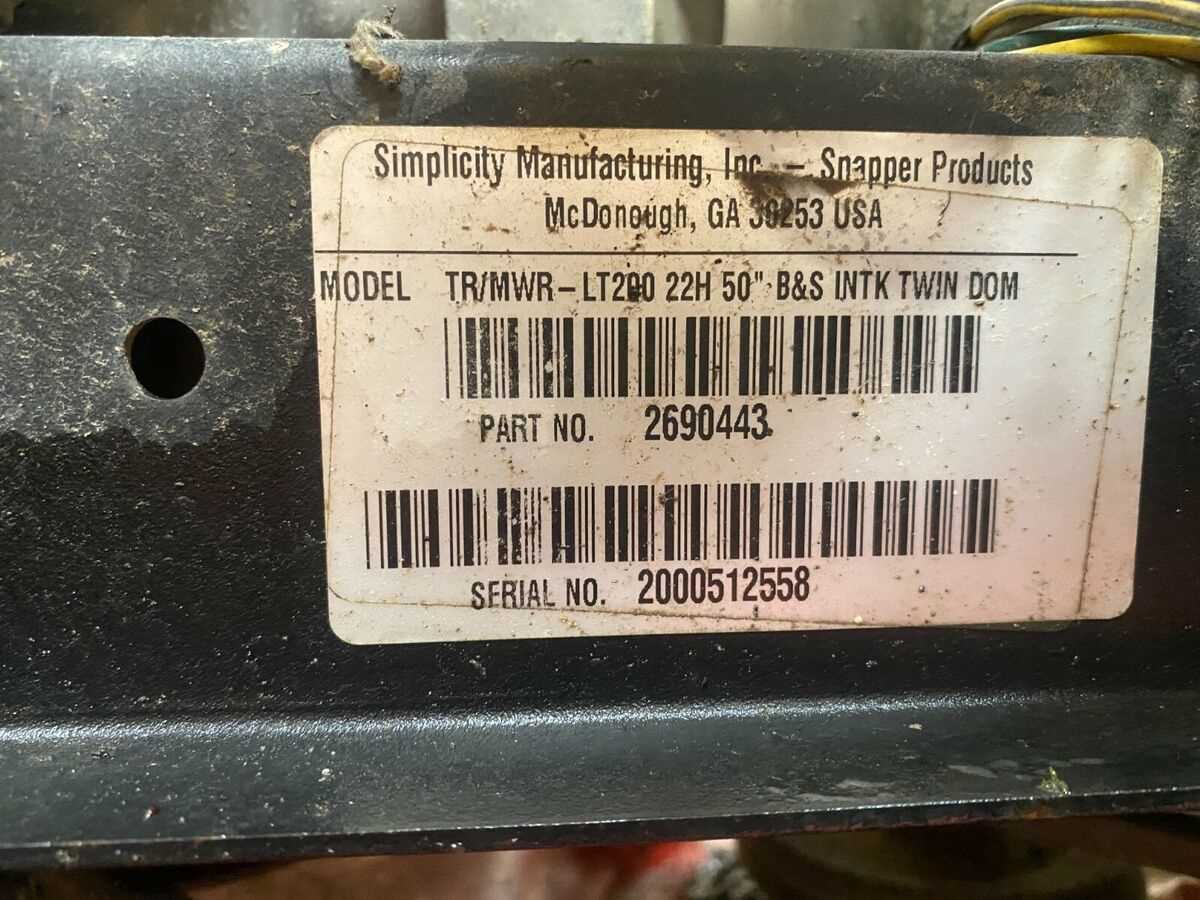

Frequently Asked Questions

This section aims to address common inquiries regarding maintenance and component identification for lawn equipment. Here, we provide clarity on various aspects to assist users in their understanding and troubleshooting processes.

- What should I do if I can’t find a specific component?

- Check the manufacturer’s website for additional resources.

- Consult user manuals for part numbers and specifications.

- Visit local dealers for personalized assistance.

- How can I ensure I’m purchasing the correct replacement?

- Always refer to the model number and serial number.

- Cross-reference with online catalogs or databases.

- Seek advice from knowledgeable staff at retail outlets.

- What are the common signs of wear in machinery?

- Unusual noises during operation.

- Decreased performance or efficiency.

- Visible damage or irregularities on parts.

- How often should maintenance be performed?

- Follow the manufacturer’s recommended schedule.

- Inspect equipment before and after use.

- Adjust frequency based on usage conditions.

Resources for Snapper Owners

Maintaining your equipment can be a rewarding experience, ensuring optimal performance and longevity. A variety of tools and information are available to assist enthusiasts in keeping their machinery in top condition. Whether you are looking for troubleshooting tips, replacement components, or expert advice, these resources can enhance your ownership experience.

Online Communities: Joining forums and social media groups dedicated to enthusiasts can provide invaluable insights. Members often share their experiences, tips, and solutions to common issues.

Manufacturer’s Website: The official site typically offers manuals, FAQs, and other essential documents that can guide you through maintenance and repairs.

Retailers and Suppliers: Local and online stores specializing in outdoor equipment often carry a wide range of accessories and replacements, making it easier to find what you need.

Videos and Tutorials: Platforms like YouTube feature numerous how-to videos, providing visual guidance for repairs and upgrades.

Local Mechanics: Finding a qualified technician in your area can be beneficial for more complex tasks or routine maintenance that requires expert attention.