In the world of aquatic maintenance, having a comprehensive grasp of the essential elements that contribute to optimal performance is crucial. Each piece plays a significant role in ensuring functionality and longevity, making it imperative to familiarize oneself with their interconnections and arrangements. Knowledge of these components not only aids in effective troubleshooting but also enhances the overall efficiency of the system.

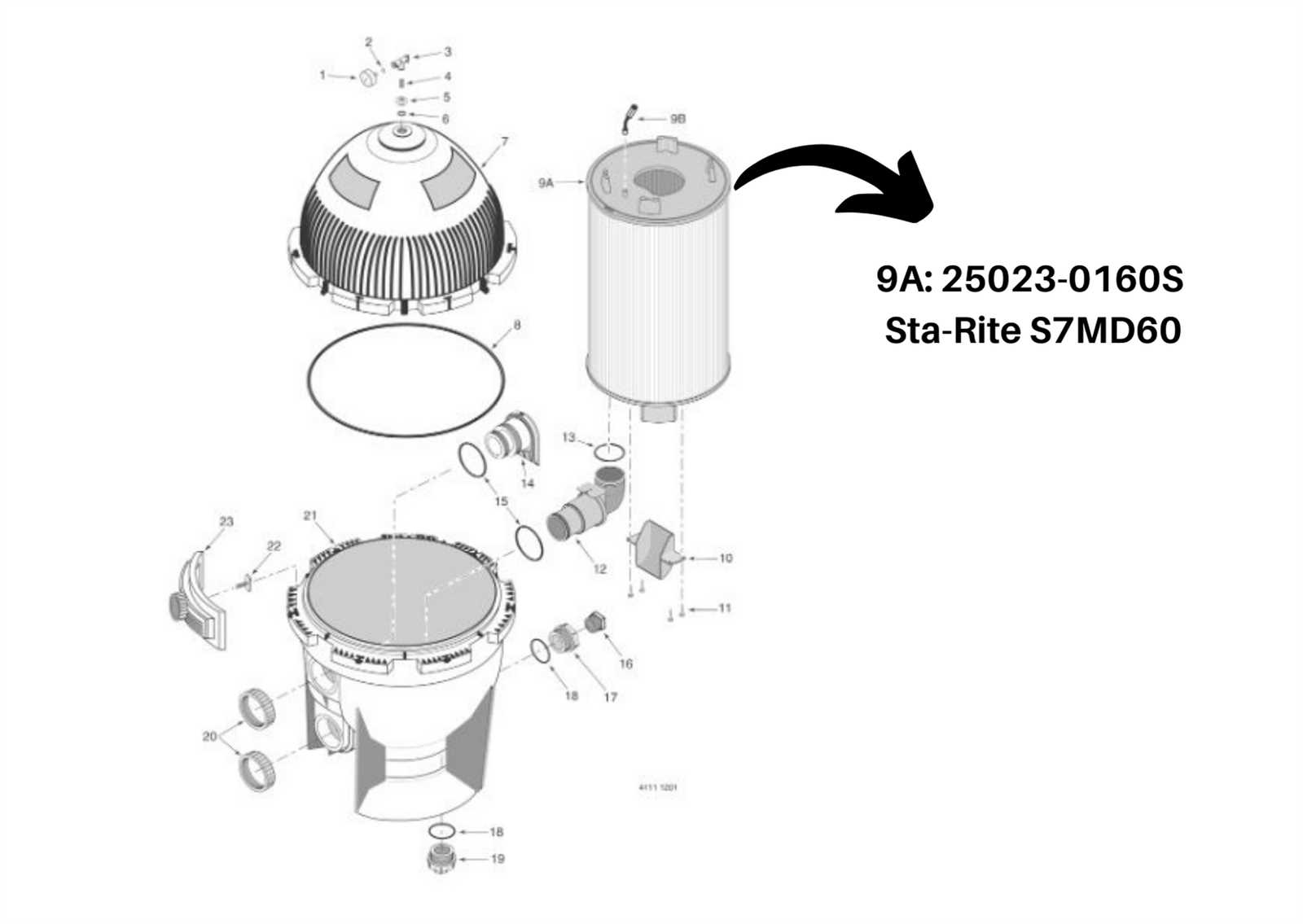

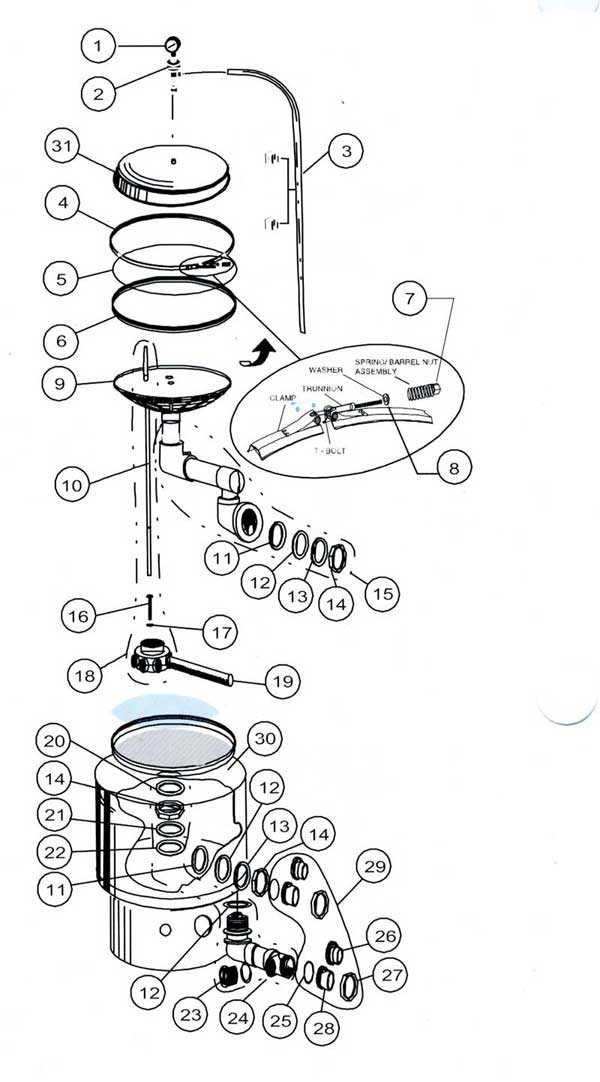

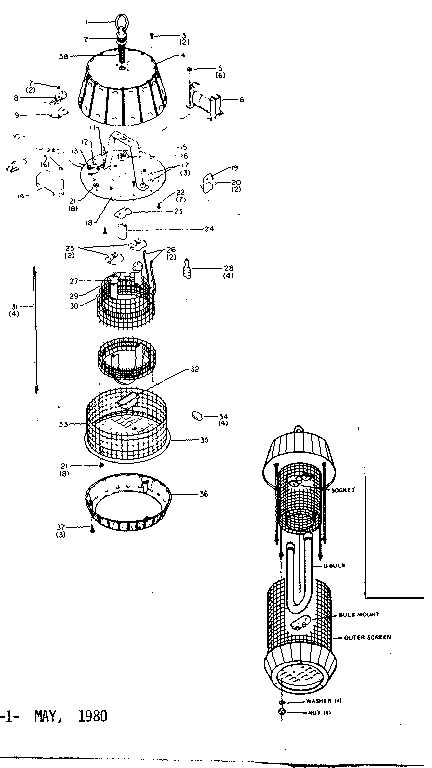

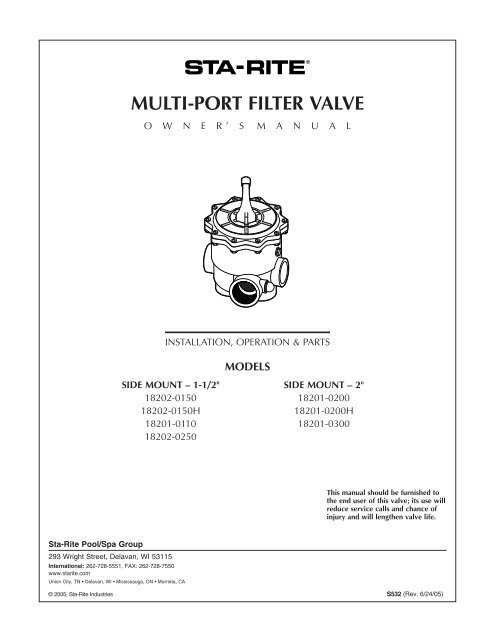

Visual representations serve as invaluable tools for technicians and enthusiasts alike, providing clarity and facilitating a deeper understanding of how various elements interact. By examining these illustrations, one can quickly identify individual parts, their respective functions, and the assembly process required for repairs or upgrades. This insight can dramatically reduce downtime and improve serviceability.

Moreover, grasping the layout of the equipment can empower users to make informed decisions when it comes to maintenance and replacements. By recognizing the significance of each component, individuals can enhance their problem-solving skills and ensure that their aquatic systems operate at peak performance. Ultimately, this knowledge lays the foundation for a more enjoyable and efficient pool experience.

Understanding Sta-Rite S7M120 Components

In the realm of pool maintenance, comprehending the various elements that contribute to a system’s functionality is essential. Each component plays a crucial role in ensuring optimal performance and efficiency, which ultimately affects the overall health of the aquatic environment. This section delves into the key constituents of a specific filtration unit, providing insight into their functions and interrelations.

Main Elements of the Filtration Unit

Every filtration system comprises several integral parts, each designed to fulfill a specific purpose. Understanding these elements helps users troubleshoot issues and maintain their systems effectively.

| Component | Function |

|---|---|

| Filter Cartridge | Captures debris and contaminants from the water, ensuring cleanliness. |

| Pump | Circulates water through the system, maintaining flow and pressure. |

| Multiport Valve | Controls water flow direction, allowing for various operational modes such as backwashing. |

| Drain Plug | Facilitates the removal of water from the system for maintenance purposes. |

Importance of Proper Maintenance

Regular inspection and upkeep of these components are vital for ensuring longevity and efficiency. Neglecting any part can lead to reduced performance or even system failure. Familiarity with these elements empowers users to maintain their systems proactively, ultimately leading to a more enjoyable pool experience.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricacies of various systems. These illustrations provide an organized view that simplifies the complexities involved in maintenance, assembly, and troubleshooting. By offering clarity, they enable users to identify individual elements and their interconnections, fostering a deeper comprehension of the overall structure.

Enhancing Communication

Clear communication is essential when dealing with mechanical systems. Visual guides serve as a universal language, bridging the gap between technicians, engineers, and users. They allow for efficient dialogue regarding specific pieces, ensuring that everyone involved has a shared understanding of the subject matter.

Facilitating Maintenance and Repair

Having a detailed visual reference significantly aids in the maintenance and repair process. Service professionals can quickly locate parts that require attention, making the workflow more efficient. This not only saves time but also reduces the risk of errors during disassembly or reassembly, ultimately leading to improved performance and longevity of the equipment.

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repair. These visuals provide a comprehensive overview of components, their arrangements, and interconnections. By familiarizing yourself with this information, you can streamline troubleshooting and ensure the correct assembly of parts.

Key elements to focus on include symbols representing different components, numbers indicating specific items, and lines showing relationships between parts. Pay attention to the legend or key, which often explains the meaning of various markings used in the illustration.

Furthermore, cross-referencing the illustration with a list of components can enhance your comprehension and assist in identifying any necessary replacements. With practice, interpreting these visuals becomes an invaluable skill in maintaining equipment efficiently.

Common Issues with Sta-Rite S7M120

When dealing with pool equipment, several common challenges can arise that may affect performance and efficiency. Understanding these issues can help users troubleshoot and maintain their systems effectively.

- Clogged Filters: Debris accumulation can hinder water flow, leading to decreased filtration efficiency.

- Leakage: Seals and gaskets may wear out over time, causing water leaks that require immediate attention.

- Noisy Operation: Unusual sounds during operation often indicate mechanical problems or misalignment.

- Electrical Issues: Faulty wiring or blown fuses can disrupt functionality, necessitating electrical checks.

- Pump Performance: Insufficient water circulation can stem from worn impellers or blockage in the system.

Regular maintenance and timely repairs can mitigate these issues, ensuring the longevity and ultimate efficiency of your equipment.

Replacement Parts Availability

Ensuring the longevity and optimal performance of equipment often requires the timely replacement of components. Availability of these essential elements can significantly influence maintenance schedules and overall operational efficiency. Understanding where to source these items is crucial for both professionals and DIY enthusiasts.

Local Suppliers: Many regional distributors specialize in various equipment parts, offering convenience and quick access. These vendors often provide not only the components themselves but also valuable expertise in selection and installation.

Online Retailers: The digital marketplace has expanded options for obtaining necessary elements. Numerous websites cater specifically to equipment needs, providing detailed descriptions and user reviews to assist in informed purchasing decisions. Be sure to check the return policy and warranty options.

Manufacturer Direct: Purchasing directly from the original producer can ensure authenticity and compatibility. This route often comes with the added benefit of customer support, guiding users through the installation process and troubleshooting common issues.

Aftermarket Options: Alternative suppliers offer a wide range of components, often at competitive prices. While these may provide a cost-effective solution, it is essential to verify quality and compatibility to avoid performance issues.

In conclusion, various avenues exist for obtaining replacement components, each with its own advantages. Assessing individual needs and considering the sources available can lead to successful maintenance and uninterrupted operation.

Maintenance Tips for Longevity

To ensure the extended lifespan of your equipment, regular upkeep is essential. Adopting a systematic approach to maintenance not only enhances performance but also prevents costly repairs.

1. Regular Inspections: Schedule routine checks to identify any wear and tear early. Look for signs of damage or unusual performance issues.

2. Clean Components: Keep all parts free from debris and contaminants. This reduces the risk of malfunctions and maintains optimal efficiency.

3. Lubrication: Apply appropriate lubricants to moving parts as recommended. This minimizes friction and extends operational life.

4. Monitor Operating Conditions: Be mindful of environmental factors such as temperature and humidity. Extreme conditions can impact performance and longevity.

5. Follow Manufacturer Guidelines: Adhere to suggested maintenance schedules and procedures. This ensures that your equipment operates as intended.

6. Train Personnel: Equip users with knowledge on proper operation and care. Well-informed operators can significantly reduce wear and enhance reliability.

By implementing these strategies, you can greatly increase the durability and efficiency of your machinery.

Assembly Instructions for S7M120

Proper assembly of the unit is crucial for its efficient operation and longevity. Following systematic guidelines will ensure that each component fits seamlessly and functions optimally. This section provides a step-by-step approach to assembling the device effectively.

Step 1: Begin by gathering all necessary components and tools. A clean and organized workspace will facilitate a smoother assembly process.

Step 2: Review the provided instructions thoroughly. Familiarize yourself with each part and its intended location within the assembly.

Step 3: Start with the base, ensuring that it is stable and secure. Attach the initial components carefully, aligning them according to the specified guidelines.

Step 4: Progressively add subsequent pieces, making sure to fasten each part tightly. Double-check connections to prevent any potential issues during operation.

Step 5: Once all components are assembled, conduct a thorough inspection. Verify that everything is correctly positioned and securely attached before proceeding to the testing phase.

By following these detailed steps, you can achieve a successful assembly that promotes reliable performance and extends the lifespan of your equipment.

Identifying Wear and Tear

Recognizing signs of deterioration in equipment is crucial for maintaining efficiency and extending its lifespan. Regular inspections can reveal potential issues before they lead to significant problems. Understanding common indicators of wear can help in making informed decisions about repairs and replacements.

Key signs to look for include unusual noises, leaks, and visible damage. Monitoring performance changes over time is essential, as gradual declines can signal underlying issues. Proper maintenance routines should incorporate checks for these indicators to ensure optimal functioning.

| Indicator | Description | Possible Action |

|---|---|---|

| Unusual Noises | Sounds that are different from normal operation. | Inspect components for damage or misalignment. |

| Leaks | Fluid escaping from seals or connections. | Replace seals or tighten connections as necessary. |

| Visible Damage | Cracks, corrosion, or wear on surfaces. | Assess the extent of damage and consider replacement. |

| Performance Decline | Reduced efficiency or effectiveness in operation. | Conduct a thorough inspection and maintenance. |

By being vigilant and proactive, operators can significantly reduce downtime and avoid costly repairs, ensuring smooth and reliable performance in the long run.

Comparative Analysis with Other Models

This section explores the differences and similarities among various pool equipment systems, focusing on their design features, operational efficiency, and user experiences. By examining alternative models, we can gain insights into performance variations and technological advancements that distinguish each option.

When analyzing different systems, one of the primary aspects to consider is the ease of maintenance. Some models may offer more accessible components, facilitating quicker repairs and reducing downtime. Additionally, variations in materials and construction techniques can significantly impact longevity and reliability, which are crucial for pool owners seeking long-term solutions.

Another critical factor is energy efficiency. Different systems utilize various technologies to optimize performance while minimizing energy consumption. A comparative look at energy ratings and operational costs can provide valuable information for users aiming to manage their expenses effectively.

Finally, user feedback plays an essential role in understanding the practical implications of each model. Experiences shared by users often highlight strengths and weaknesses that may not be evident through technical specifications alone. This qualitative data can guide potential buyers in making informed decisions tailored to their specific needs.

Upgrading Parts for Efficiency

Enhancing components within a system can significantly improve overall performance and reliability. By carefully selecting and replacing outdated elements, users can achieve optimal functionality while minimizing energy consumption and maintenance costs.

Benefits of Upgrading

- Increased efficiency in operation

- Reduced energy usage

- Longer lifespan of the equipment

- Lower maintenance requirements

Considerations for Upgrading

- Assess current performance and identify weak areas

- Research compatible alternatives that enhance capabilities

- Evaluate the cost-effectiveness of upgrades

- Consult professionals if necessary for optimal choices

Where to Find Expert Help

When tackling complex equipment, seeking knowledgeable assistance can be crucial for optimal performance and longevity. Experts can offer insights into troubleshooting, maintenance, and efficient operation, ensuring you get the most out of your investment.

One effective way to find qualified professionals is through specialized forums and online communities dedicated to equipment enthusiasts. These platforms often feature experienced users who can share advice and resources tailored to specific models.

Local service providers and repair shops often employ technicians with extensive expertise. Reaching out to these businesses can lead to personalized support and access to specialized tools that may not be readily available to the average user.

Additionally, manufacturers frequently provide resources, including customer support lines and technical guides. Utilizing these channels can connect you with individuals who possess in-depth knowledge about your specific machinery.

Lastly, consider consulting with industry experts at workshops or trade shows. These events provide opportunities to learn from seasoned professionals and to network with others who share similar interests.