When it comes to maintaining watercraft propulsion systems, a comprehensive grasp of their inner workings is essential. Each component plays a vital role in ensuring optimal performance and reliability. Familiarity with the various elements not only aids in efficient repairs but also enhances overall user experience.

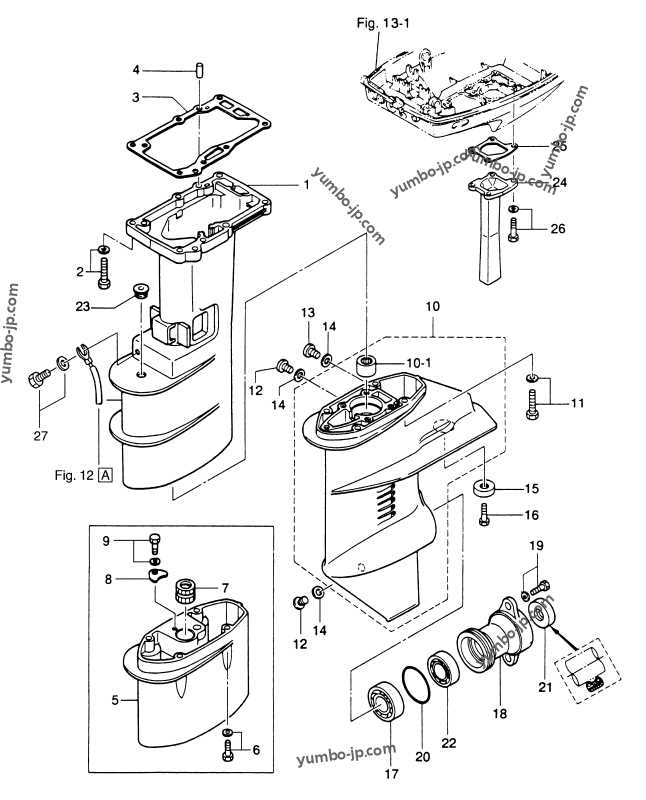

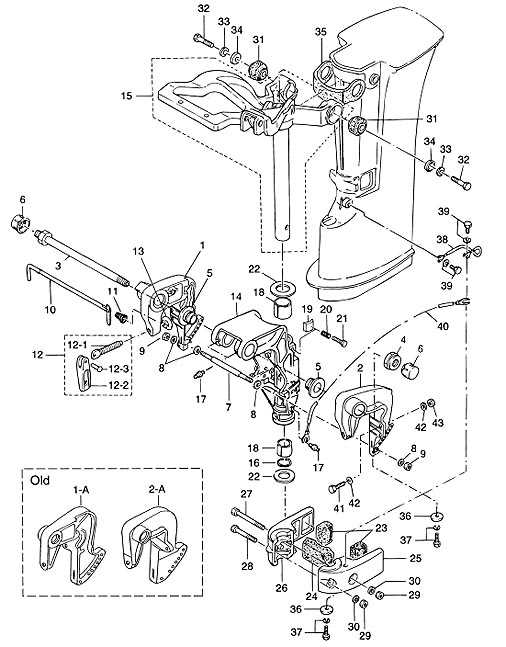

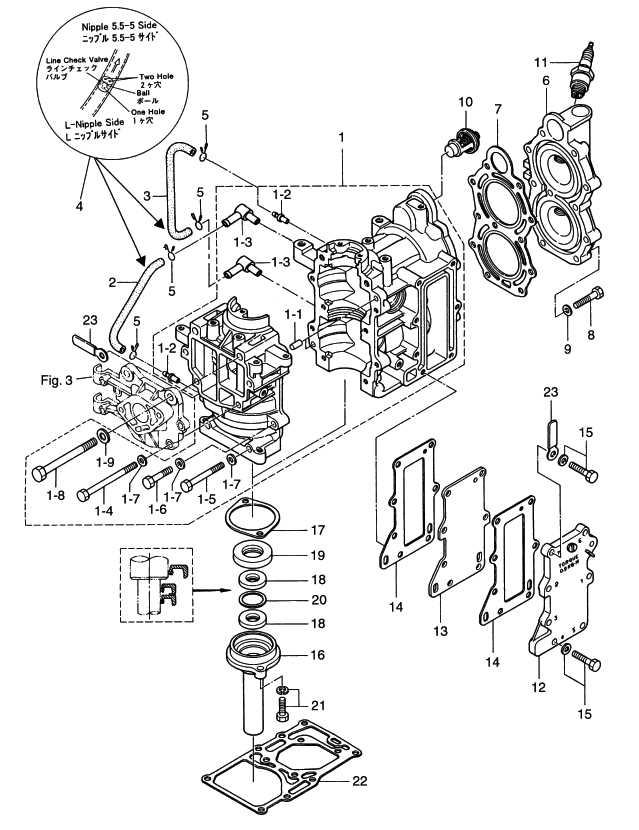

Visual representations serve as invaluable tools for both seasoned mechanics and novices alike. They allow for a clearer understanding of how different pieces interact and contribute to the engine’s functionality. By studying these illustrations, one can pinpoint specific areas that may require attention or replacement, ultimately leading to a smoother operation.

Moreover, exploring these graphical guides promotes better decision-making during maintenance routines. Recognizing the layout and connections of essential components empowers users to approach repairs with confidence. In turn, this knowledge can significantly extend the lifespan of the machinery, ensuring enjoyable and trouble-free excursions on the water.

Understanding Tohatsu 9.8 Engine Parts

Grasping the intricacies of an outboard motor’s components is essential for effective maintenance and troubleshooting. A comprehensive overview of each element contributes to improved performance and longevity of the unit. This knowledge empowers users to identify issues promptly and ensure their marine experiences are both safe and enjoyable.

Key Components and Their Functions

Each element within the engine plays a vital role in its overall operation. The powerhead, responsible for generating thrust, is often the most recognized part, yet it operates in harmony with others, such as the cooling system and fuel delivery mechanisms. Understanding how these systems interact helps in diagnosing problems and enhancing efficiency.

Maintenance Tips for Longevity

Regular upkeep is crucial for sustaining optimal function. Pay attention to the condition of seals and gaskets, as well as the integrity of the cooling passages. Utilizing quality lubricants and conducting periodic inspections can prevent minor issues from escalating into major repairs. Knowledge of individual components allows for targeted maintenance strategies, ultimately extending the lifespan of the motor.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. These illustrations serve as essential tools for both novice and experienced users, facilitating a clear comprehension of how each element fits together and operates within the whole system.

Enhanced Understanding

Having a visual reference allows individuals to identify each element’s location and purpose more easily. This clarity helps in diagnosing issues, making repairs, or performing maintenance. By providing an organized layout, these visual aids simplify complex mechanisms, ensuring that users can grasp intricate details without ambiguity.

Streamlined Maintenance and Repair

When it comes to upkeep and fixing machinery, accurate visual guides are invaluable. They enable users to locate specific components quickly, reducing downtime and enhancing efficiency. Furthermore, they assist in ensuring that replacements are precise, ultimately leading to better performance and longevity of the equipment.

In conclusion, having access to detailed visual guides significantly contributes to effective management and repair of machinery, making them indispensable for anyone working with mechanical systems.

Components of Tohatsu 9.8 Motor

The efficient functioning of a small outboard engine relies on a variety of integral components that work in harmony. Understanding these elements is essential for maintenance and optimal performance.

- Powerhead: The central unit housing the combustion chamber and essential mechanisms for energy generation.

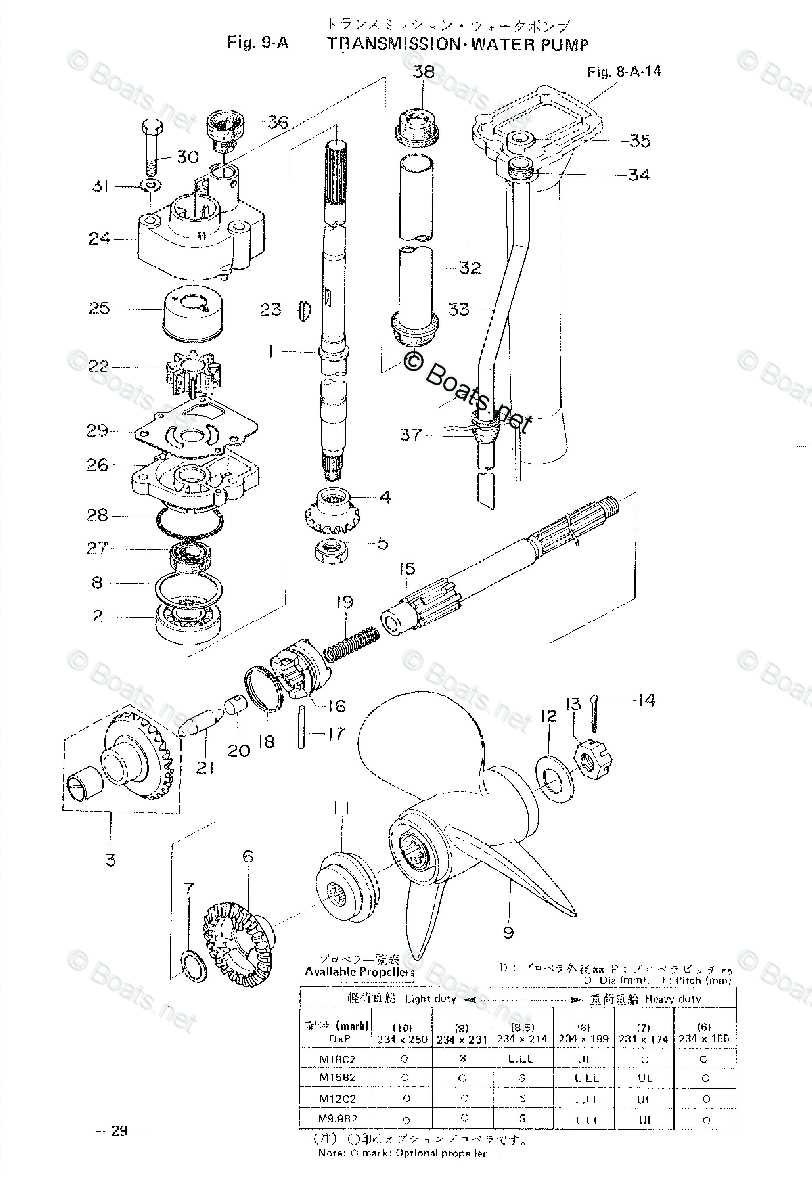

- Lower Unit: Contains the gearing system and propeller, facilitating movement through water.

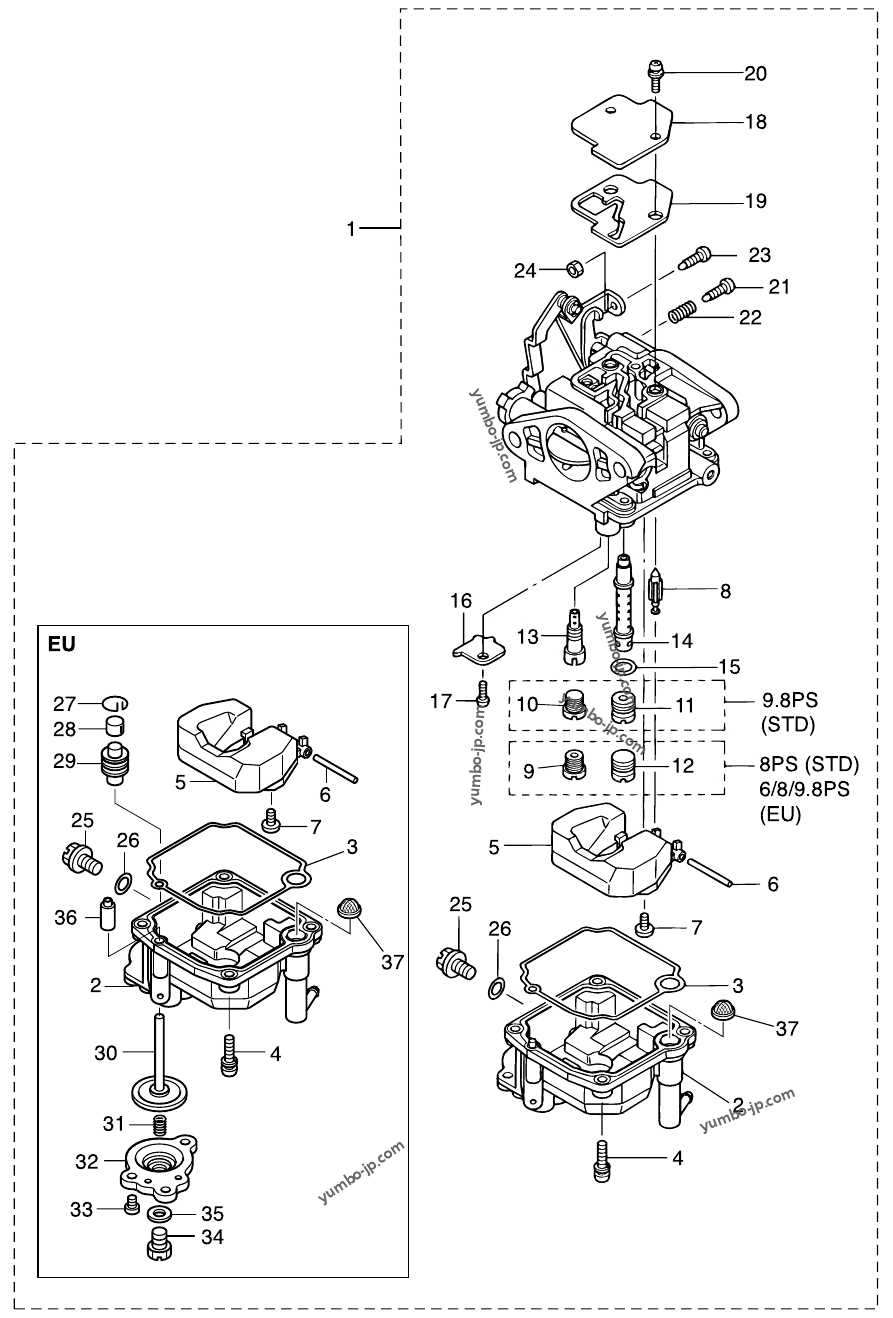

- Fuel System: Comprises the tank, lines, and carburetor, ensuring proper fuel delivery.

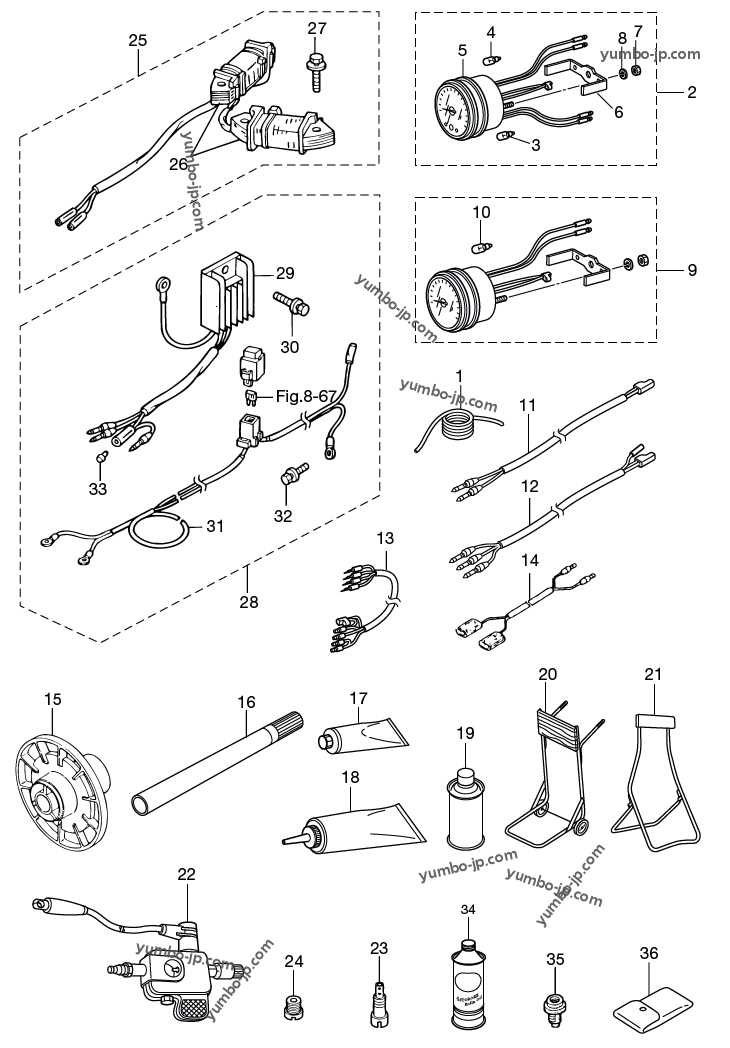

- Ignition System: Generates the spark necessary for combustion, including components like the spark plug and coil.

- Cooling System: Maintains optimal operating temperatures through circulation of water or coolant.

Each of these parts plays a critical role in ensuring the engine operates smoothly and efficiently. Regular inspection and maintenance of these components can prolong the lifespan of the motor and enhance its performance.

- Regularly check the fuel lines for leaks.

- Inspect the spark plug for wear and replace as necessary.

- Ensure the cooling system is free of obstructions.

- Examine the propeller for damage and proper attachment.

By understanding and caring for these key components, users can enjoy reliable operation and extend the longevity of their marine equipment.

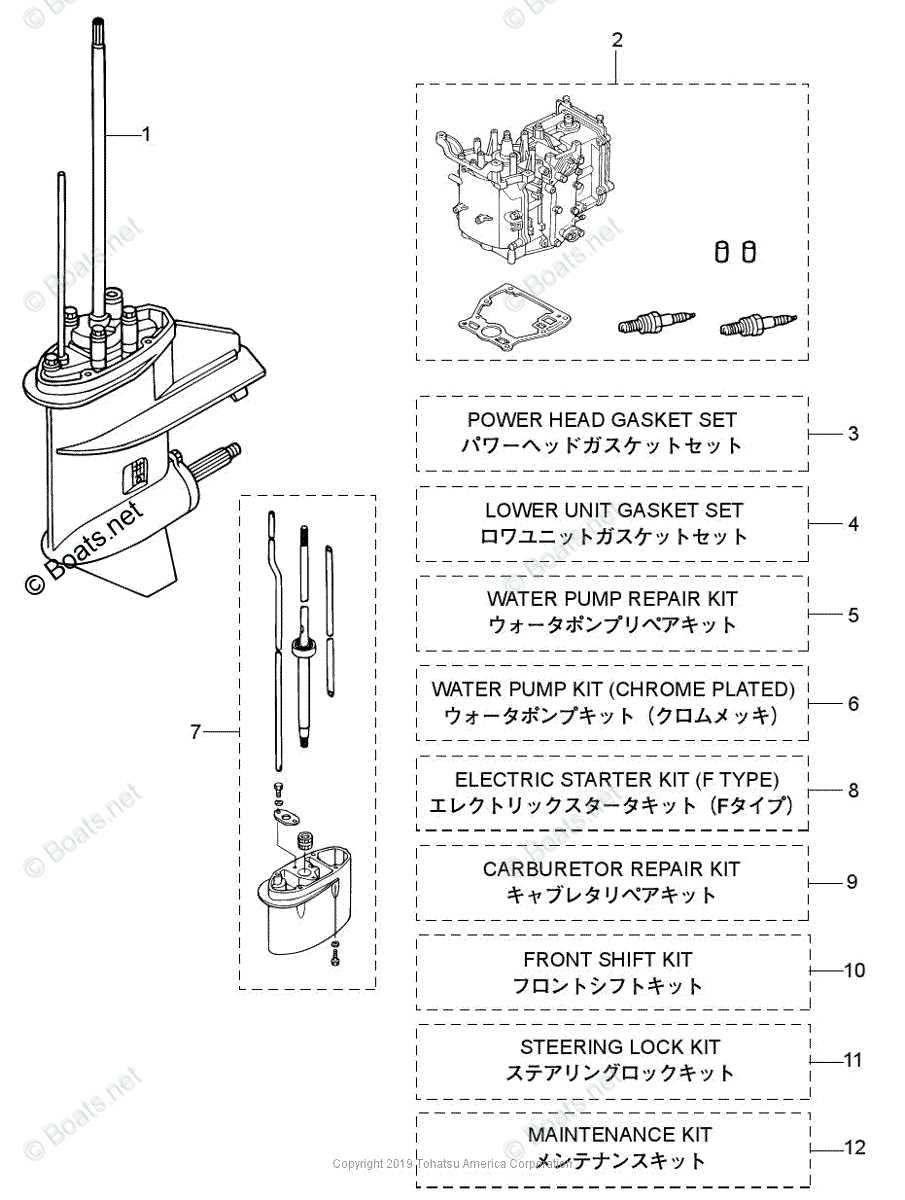

How to Read Parts Diagrams

Understanding the visual representation of components is essential for effective maintenance and repair. These illustrations provide a clear overview of various elements and their relationships, allowing users to identify and locate necessary items efficiently. By mastering how to interpret these visuals, you can streamline your repair process and ensure all components are accounted for.

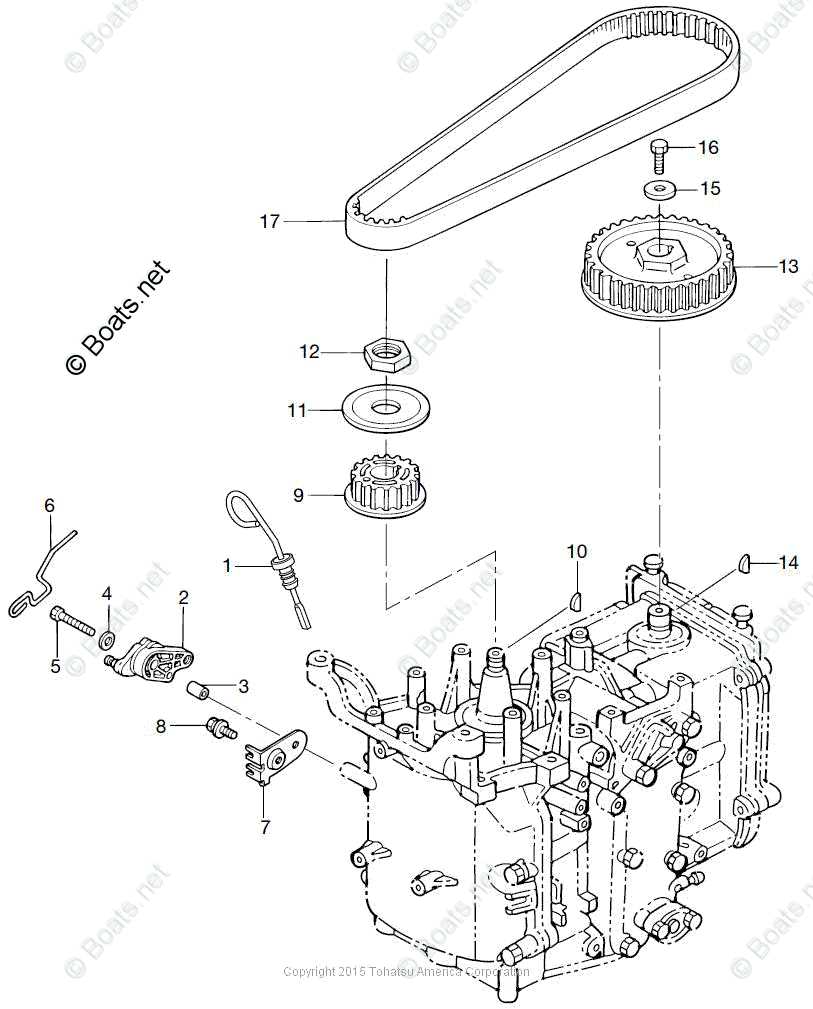

Breaking Down the Visuals

Start by familiarizing yourself with the key symbols and notations used in the illustrations. Each symbol represents a specific part, and often, these visuals are accompanied by a numbered list or legend that provides additional context. Pay close attention to the arrangement, as it typically reflects the assembly sequence, guiding you on how components fit together.

Identifying Key Components

As you study the illustration, look for distinct sections that highlight various groups of components. Focus on the major assemblies, as these usually contain the most critical parts. Take notes of any connecting elements, as understanding how they interlink can aid in troubleshooting and repairs. Always refer to the accompanying documentation for detailed descriptions, ensuring that you grasp the function and importance of each element.

Common Replacement Parts for Tohatsu

When maintaining small marine engines, certain components frequently require replacement to ensure optimal performance and longevity. Understanding which items are commonly replaced can help users keep their engines running smoothly and efficiently.

Essential Components

- Fuel Filters

- Spark Plugs

- Oil Seals

- Propellers

- Cooling Hoses

Maintenance Accessories

- Maintenance Kits

- Gaskets

- Battery Cables

- Throttle Cables

- Water Pump Impellers

Regularly inspecting and replacing these essential components can significantly enhance the performance and reliability of your marine engine, ensuring a better experience on the water.

Identifying Engine Issues through Diagrams

Visual representations of mechanical components serve as invaluable tools for diagnosing operational problems within an engine. By examining these schematics, one can pinpoint discrepancies, track down malfunctioning parts, and understand the intricate relationships between various elements. This method not only simplifies the troubleshooting process but also enhances the technician’s ability to restore functionality effectively.

Common Symptoms and Their Visual Indicators

Understanding the typical signs of engine distress and correlating them with specific components in the illustrations is crucial for efficient repair. Below is a summary of prevalent issues and their corresponding visual cues:

| Symptom | Visual Indicator |

|---|---|

| Overheating | Discolored cooling system components |

| Loss of Power | Worn or damaged intake components |

| Unusual Noises | Loosened bolts or misaligned parts |

| Excessive Vibration | Worn mounts or unbalanced elements |

Utilizing Illustrations for Effective Diagnosis

When tackling engine challenges, referring to detailed visual guides can significantly streamline the assessment process. These illustrations not only display the layout but also highlight critical areas prone to wear and tear. Technicians can leverage these resources to enhance their diagnostic accuracy, ensuring a more effective repair strategy and ultimately prolonging the life of the engine.

Maintenance Tips for Tohatsu 9.8

Regular upkeep is essential for ensuring optimal performance and longevity of your outboard motor. By adhering to a systematic maintenance routine, you can prevent common issues and enhance the efficiency of your engine. This guide provides key recommendations to keep your equipment running smoothly.

Start by checking the oil levels and replacing it as necessary. Fresh oil helps lubricate internal components, reducing wear and tear. Additionally, inspect the fuel system for any leaks or blockages. Using high-quality fuel and adding a stabilizer can prevent contamination and ensure proper combustion.

Examine the cooling system regularly. Make sure the water intake is free of debris, and check the impeller for wear. A well-functioning cooling system prevents overheating and prolongs engine life.

Inspect all electrical connections for corrosion and ensure that the battery is charged. Regular cleaning of terminals and connections can prevent electrical issues that may arise during operation.

Lastly, perform routine checks on the propeller and lower unit. Look for any signs of damage or wear, and make adjustments or replacements as needed. Keeping these components in top condition is vital for maintaining performance and safety while on the water.

Where to Find Parts Diagrams

Locating visual references for components can significantly enhance your repair and maintenance efforts. These resources provide clear illustrations and detailed breakdowns, enabling you to identify each piece and understand how they fit together. Whether you are a seasoned technician or a novice enthusiast, having access to these guides is essential for effective troubleshooting and part replacement.

Online Resources: Numerous websites specialize in providing comprehensive visual aids for various machinery. Manufacturer websites often have sections dedicated to documentation, where you can find digital copies of schematics. Additionally, dedicated forums and community pages may offer user-generated content, including high-quality images and discussions related to specific models.

Retail and Repair Shops: Local dealers and repair shops can be invaluable sources for printed materials. Many establishments keep catalogs and reference guides that showcase parts and their configurations. Engaging with knowledgeable staff can also lead to insights and recommendations tailored to your specific needs.

Service Manuals: Investing in a service manual is another effective way to access detailed illustrations. These manuals typically contain extensive information on assembly, disassembly, and troubleshooting, along with clear visuals that aid in understanding complex setups. They can often be purchased online or through specialty retailers.

Utilizing these resources can simplify the process of finding and identifying essential components, ensuring that your repair and maintenance tasks are executed with precision.

Ordering Genuine Tohatsu Components

When it comes to maintaining your marine engine, sourcing authentic components is essential for optimal performance and longevity. Genuine replacements ensure compatibility, reliability, and adherence to manufacturer specifications. Here’s how to navigate the process of obtaining these essential items.

Follow these guidelines to make your ordering experience seamless:

- Identify the Required Component:

- Consult your user manual for specific part numbers.

- Check for compatibility with your engine model.

- Choose a Reputable Supplier:

- Look for authorized dealers or certified retailers.

- Verify customer reviews and feedback on the supplier’s service.

- Place Your Order:

- Provide accurate information regarding the component.

- Confirm your shipping and payment details.

- Follow Up:

- Track your order for timely delivery.

- Inspect the item upon arrival to ensure it meets expectations.

By following these steps, you can confidently acquire the necessary components to keep your engine running smoothly and efficiently.

Aftermarket vs. OEM Parts

When it comes to replacing components in mechanical systems, the choice often comes down to two primary categories: those produced by the original manufacturer and those created by third-party companies. Each option presents its own set of advantages and challenges, influencing both performance and cost. Understanding these differences is crucial for making informed decisions about maintenance and repairs.

Quality and Reliability

Original manufacturer offerings typically adhere to stringent quality control standards, ensuring a high level of reliability and compatibility with the equipment. In contrast, aftermarket options can vary significantly in quality, as they are produced by numerous independent entities. While some aftermarket products match or even exceed OEM specifications, others may fall short, leading to potential issues in functionality or durability.

Cost Considerations

Budget constraints often drive the decision between the two types of components. Generally, aftermarket options are more affordable, making them appealing for those looking to save money. However, lower initial costs can sometimes lead to higher long-term expenses if these alternatives require more frequent replacements or lead to additional repairs. Weighing the upfront savings against potential future costs is essential for a well-rounded decision.

Tools for Tohatsu 9.8 Repairs

Proper maintenance and repair of marine engines require a specific set of instruments to ensure effective service and longevity. Utilizing the right tools not only facilitates efficient repairs but also minimizes the risk of damage to components. Understanding which equipment is essential can greatly enhance the repair experience.

Wrenches and Sockets: A variety of sizes is crucial for loosening and tightening bolts and nuts. A socket set can provide better torque and reach, especially in tight spaces.

Screwdrivers: Both flathead and Phillips screwdrivers are necessary for accessing various parts. A magnetic tip can be particularly useful for retrieving screws that may fall into hard-to-reach areas.

Pliers: Needle-nose and regular pliers are invaluable for gripping and manipulating small components. They can also help in removing stubborn fasteners.

Torque Wrench: Ensuring that bolts are tightened to the manufacturer’s specifications is vital. A torque wrench allows for precise tightening, preventing over-tightening that could lead to damage.

Multi-tool: A versatile tool can be handy for quick fixes, combining several functions into one device, which is especially useful in confined spaces.

Cleaning Supplies: Proper maintenance often involves cleaning parts. Brushes, rags, and degreasers are essential for maintaining optimal engine performance and longevity.

Diagnostic Tools: Depending on the complexity of the repairs, diagnostic equipment may be necessary to troubleshoot issues effectively. This can include compression testers and digital multimeters.

Equipping yourself with the right tools not only simplifies the repair process but also ensures that your marine engine remains in top condition for years to come. Regular inspections and timely maintenance using these instruments can prevent larger issues down the line.

Benefits of Regular Maintenance

Routine upkeep of machinery is essential for ensuring optimal performance and longevity. Neglecting maintenance can lead to significant issues that may not only affect efficiency but also increase repair costs over time.

Here are some key advantages of adhering to a regular maintenance schedule:

- Enhanced Performance: Regular checks and adjustments ensure that the equipment operates at peak efficiency, resulting in better fuel economy and reduced emissions.

- Extended Lifespan: Consistent care prevents wear and tear, allowing machinery to function effectively for many years.

- Cost Savings: Early detection of potential problems can lead to less expensive repairs compared to addressing major issues that arise from neglect.

- Increased Safety: Regular inspections help identify safety hazards, reducing the risk of accidents or malfunctions during operation.

- Better Resale Value: Well-maintained equipment typically has a higher market value, making it more appealing to potential buyers.

By prioritizing routine maintenance, operators can enjoy a smoother, safer, and more economical experience with their machinery.

FAQs about Tohatsu 9.8 Parts

This section addresses common inquiries regarding components of the marine engine, focusing on maintenance, replacement, and compatibility. Understanding these elements is essential for optimal performance and longevity of your equipment.

- What is the best way to maintain the engine’s components?

- Regular cleaning to remove debris and salt buildup.

- Routine inspections for wear and tear.

- Proper lubrication of moving parts to ensure smooth operation.

- How can I identify compatible replacements for damaged components?

- Refer to the manufacturer’s specifications for part numbers.

- Consult a knowledgeable dealer or repair service for guidance.

- Check user manuals for detailed compatibility information.

- What should I do if I cannot find a specific component?

- Explore online marketplaces for availability.

- Contact customer service for assistance in locating hard-to-find items.

- Consider alternative brands that offer similar functionality.

- Are there common issues associated with engine components?

- Corrosion from exposure to water and salt.

- Fuel line clogs leading to performance drops.

- Electrical issues causing starting difficulties.

- How often should components be replaced?

- Follow manufacturer guidelines for specific intervals.

- Replace items showing signs of damage or decreased performance immediately.

- Regularly assess wear items, such as gaskets and seals, during routine checks.