This section aims to provide a comprehensive overview of the essential elements that make up a specific machine model. By delving into the structure and arrangement of these crucial parts, users can gain valuable insights into the overall functionality and maintenance of the equipment. Understanding how each component interacts can lead to better performance and longevity.

In addition, this guide serves as a reference for anyone looking to enhance their knowledge about the intricate workings of this particular device. By exploring the configuration of its various sections, readers will be better equipped to troubleshoot issues and perform necessary repairs or upgrades.

Moreover, a clear representation of the assembly allows users to identify individual elements more easily, ensuring that any replacements or adjustments can be carried out with precision. With a focus on clarity and accessibility, this information is designed to empower users in their operational and maintenance tasks.

Understanding Ts800 Parts Diagram

This section aims to provide a comprehensive overview of the components involved in the Ts800 model, offering insights into their functions and interactions. By exploring these elements, users can gain a clearer understanding of how each piece contributes to the overall operation.

- Components play crucial roles in ensuring efficient performance.

- Understanding each segment helps in troubleshooting and maintenance.

- Familiarity with the layout enhances repair processes.

Focusing on specific elements can clarify how they work together:

- Motor: The powerhouse that drives the entire system.

- Control Unit: Central hub for managing operations and commands.

- Structural Frame: Provides stability and support for all components.

Having knowledge of these segments allows users to perform more effective diagnostics and repairs, ultimately leading to better upkeep of the device.

Overview of Ts800 Components

This section provides a comprehensive insight into the various elements that make up the system. Understanding these components is essential for effective operation and maintenance, ensuring that each part functions harmoniously within the entire assembly.

The following key elements play crucial roles in the overall performance:

- Power Source: Supplies the necessary energy for operation.

- Control Unit: Manages the functioning of the device, coordinating the different components.

- Transmission System: Facilitates the movement and flow of data or energy throughout the apparatus.

- Mechanical Parts: Include various gears and levers that assist in physical operations.

- Safety Mechanisms: Ensure secure operation by preventing potential hazards.

Each of these elements contributes to the efficiency and reliability of the system, highlighting the importance of regular inspection and maintenance to ensure optimal performance.

Importance of Parts Identification

Recognizing individual components is crucial for effective maintenance and repair processes. A thorough understanding of each element within a system allows users to ensure optimal performance and longevity of the equipment. When each piece is accurately identified, troubleshooting becomes more efficient, reducing downtime and preventing potential damage.

Moreover, knowing the specific characteristics of each element aids in sourcing replacements when necessary. This knowledge not only streamlines repairs but also enhances safety by minimizing the risk of using incorrect or incompatible components. By prioritizing accurate identification, operators can maintain high standards of functionality and reliability.

Additionally, clear identification facilitates effective communication among technicians and support teams. It fosters a common language, ensuring that all parties are aligned on issues and solutions. This collaborative approach ultimately leads to more informed decision-making and improved overall service quality.

Common Parts in Ts800 Model

The components of this model play a crucial role in its functionality and performance. Each element contributes to the overall efficiency and reliability of the device, ensuring that it operates smoothly under various conditions. Understanding these elements is essential for effective maintenance and repair.

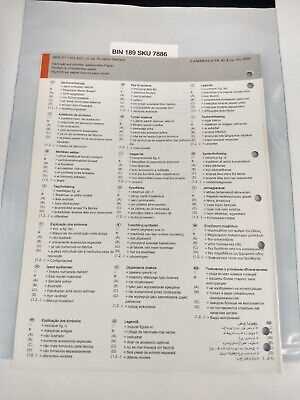

How to Read the Diagram

Understanding an assembly guide is essential for anyone looking to repair or maintain machinery. These guides provide crucial visual information, helping users identify components and their relationships within the system. By familiarizing yourself with the layout and symbols used, you can efficiently navigate the content and ensure accurate assembly or disassembly.

Familiarize Yourself with the Symbols

Most visual aids employ standard symbols to represent different elements. Recognizing these can significantly enhance your comprehension. Pay attention to legend keys, as they explain the meaning of each icon, helping you connect the dots more effectively.

Follow the Flow of Connections

Observe how different elements are interconnected. Lines often indicate relationships or pathways, showing how one component interacts with another. By following these links, you can better understand the overall structure and functionality, enabling a smoother repair process.

Benefits of Using the Diagram

Utilizing a visual representation of components can significantly enhance understanding and efficiency in maintenance and repair tasks. Such illustrations provide a clear overview of individual elements and their relationships, making it easier to identify and resolve issues promptly.

Improved Clarity and Understanding

A graphical outline simplifies complex structures, allowing users to grasp the layout and function of various elements at a glance. This clarity aids in both training new technicians and supporting experienced professionals in troubleshooting situations.

Enhanced Efficiency in Repairs

Having access to a visual guide streamlines the repair process. Technicians can quickly locate the necessary components, reducing downtime and expediting repairs. Furthermore, this approach minimizes the likelihood of errors, as users can confirm they are addressing the correct parts without confusion.

Identifying Replacement Parts Easily

Understanding how to locate and identify necessary components can greatly simplify maintenance and repairs. This process ensures that the right items are acquired swiftly, minimizing downtime and enhancing efficiency.

Here are some key strategies to facilitate the identification of components:

- Consult the User Manual: This document often contains valuable information regarding components and specifications.

- Utilize Online Resources: Websites and forums dedicated to equipment can provide diagrams and discussions that aid in recognition.

- Check Manufacturer’s Website: Many manufacturers offer detailed resources, including part numbers and descriptions.

- Join Community Groups: Engaging with others who share similar interests can provide insights and tips.

- Take Photos: Documenting existing components can assist in finding exact matches when shopping for replacements.

Implementing these methods will streamline the identification process, making it easier to find what is needed for effective repairs or upgrades.

Maintenance Tips for Ts800

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a few key practices, you can keep your machine running smoothly and avoid common issues.

Regular Inspections

- Check all components for wear and tear.

- Inspect the electrical connections for corrosion or damage.

- Look for any signs of leaks or unusual noises during operation.

Routine Cleaning

- Clean the exterior regularly to prevent dirt buildup.

- Remove debris from ventilation areas to ensure proper airflow.

- Use appropriate cleaning agents for different surfaces to avoid damage.

By adhering to these guidelines, you can significantly enhance the efficiency and lifespan of your machinery, minimizing the need for repairs and replacements.

Common Issues and Solutions

When working with complex machinery, various challenges may arise that hinder performance or functionality. Identifying these problems quickly is crucial for maintaining efficiency and ensuring smooth operation. Here are some frequent difficulties encountered along with effective resolutions.

-

Inconsistent Performance:

Inconsistent operation may stem from various factors such as wear and tear or improper settings. Regular maintenance checks and timely adjustments can help restore optimal functioning.

-

Frequent Breakdowns:

If breakdowns occur frequently, it may indicate underlying issues with specific components. Conducting a thorough inspection and replacing worn parts can prevent future malfunctions.

-

Unusual Noises:

Strange sounds can signal mechanical problems. Investigating the source of the noise and addressing any loose or damaged elements is essential to avoid further complications.

-

Overheating:

Excessive heat buildup often results from inadequate lubrication or airflow. Ensuring proper lubrication and checking ventilation pathways can mitigate overheating issues.

By proactively addressing these common issues, users can enhance the longevity and reliability of their equipment, minimizing downtime and ensuring optimal performance.

Finding Authentic Parts Suppliers

Locating reliable sources for components is crucial for maintaining equipment functionality. Authentic suppliers ensure quality and compatibility, which can significantly enhance performance and longevity. This section outlines key strategies for identifying trustworthy vendors in the market.

| Criteria | Description |

|---|---|

| Reputation | Check reviews and ratings from previous customers to gauge reliability. |

| Certifications | Verify that suppliers have relevant certifications indicating quality standards. |

| Warranty | Look for suppliers offering warranties on their products, which indicates confidence in quality. |

| Customer Service | Assess the responsiveness and support provided, which can be crucial in resolving issues. |

Using these criteria will guide you in selecting trustworthy suppliers that offer high-quality components essential for optimal operation.

Parts Compatibility with Other Models

Understanding the interchangeability of components among different models is crucial for maintaining efficiency and ensuring optimal performance. Certain elements may share similarities across various units, allowing for seamless replacements and upgrades. This flexibility can significantly enhance the longevity and functionality of equipment.

Shared Components Across Models

Many units incorporate similar mechanisms, which facilitates the use of specific components interchangeably. For instance, several models may utilize identical motors or electronic circuits, enabling users to source replacements without being limited to a single unit type. This compatibility not only simplifies maintenance but also reduces costs associated with acquiring unique components.

Considerations for Compatibility

While several components may appear compatible, it is essential to verify specific details such as dimensions, voltage ratings, and design features. Before proceeding with replacements, consulting manufacturer specifications or expert resources can prevent potential issues and ensure the chosen elements perform effectively. Ultimately, thorough research enhances reliability and reduces downtime.

Visual Aids for Better Understanding

Utilizing visual resources significantly enhances comprehension and retention of complex information. By representing intricate components and their relationships visually, individuals can grasp concepts more intuitively. This approach not only clarifies functionality but also aids in troubleshooting and assembly processes.

Types of Visual Resources

Various forms of visual aids can be employed to facilitate understanding. These include illustrations, charts, and 3D models, each serving distinct purposes in conveying information effectively.

Benefits of Visual Representation

Employing graphical representations allows for quicker identification of elements and fosters a deeper understanding of their interconnections. This can lead to more efficient learning and application in practical scenarios.

| Type | Description | Use Cases |

|---|---|---|

| Illustrations | Detailed drawings that showcase individual elements. | Assembly guides, manuals |

| Charts | Graphical representations of data relationships. | Performance analysis, comparisons |

| 3D Models | Interactive models providing a comprehensive view. | Training, simulations |

Resources for Further Information

For those seeking to deepen their understanding and knowledge, a variety of valuable resources are available. These materials can enhance your grasp of the subject and provide essential insights, whether you’re a novice or an experienced user. Utilizing these resources can help clarify complex concepts and guide you through various processes.

Online Platforms and Communities

Engaging with online forums and communities is an excellent way to connect with others who share your interests. These platforms often feature discussions, troubleshooting tips, and shared experiences that can prove invaluable. Websites dedicated to technical knowledge and user experiences can be particularly enlightening.

Instructional Manuals and Guides

Accessing comprehensive manuals and guides is crucial for acquiring detailed information. These documents typically cover fundamental aspects and advanced techniques, ensuring you have a thorough understanding. Many manufacturers and educational sites offer downloadable resources that are easy to navigate and reference.