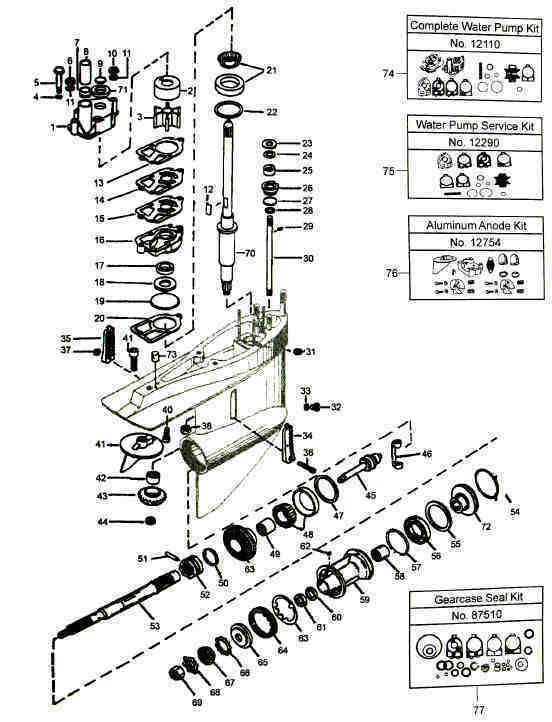

When it comes to keeping your vessel in top condition, knowing where to find and how to interpret detailed illustrations of various components is crucial. Such visuals offer clarity, guiding you through the intricacies of your watercraft’s structure. From the engine to the electrical systems, these references are valuable for ensuring that each piece functions seamlessly.

Detailed visual references can assist in the upkeep and servicing of your boat, making it easier to identify specific mechanisms and their configurations. With this knowledge, it becomes possible to handle tasks with greater precision, whether you are addressing routine upkeep or tackling more complex issues.

For enthusiasts and seasoned mariners alike, having a reliable guide for all technical aspects is invaluable. It helps in navigating through the assembly, pinpointing potential issues, and enhancing the overall efficiency of maintenance efforts. These resources serve as an essential tool for maintaining smooth operations, ensuring every adventure on the water remains worry-free.

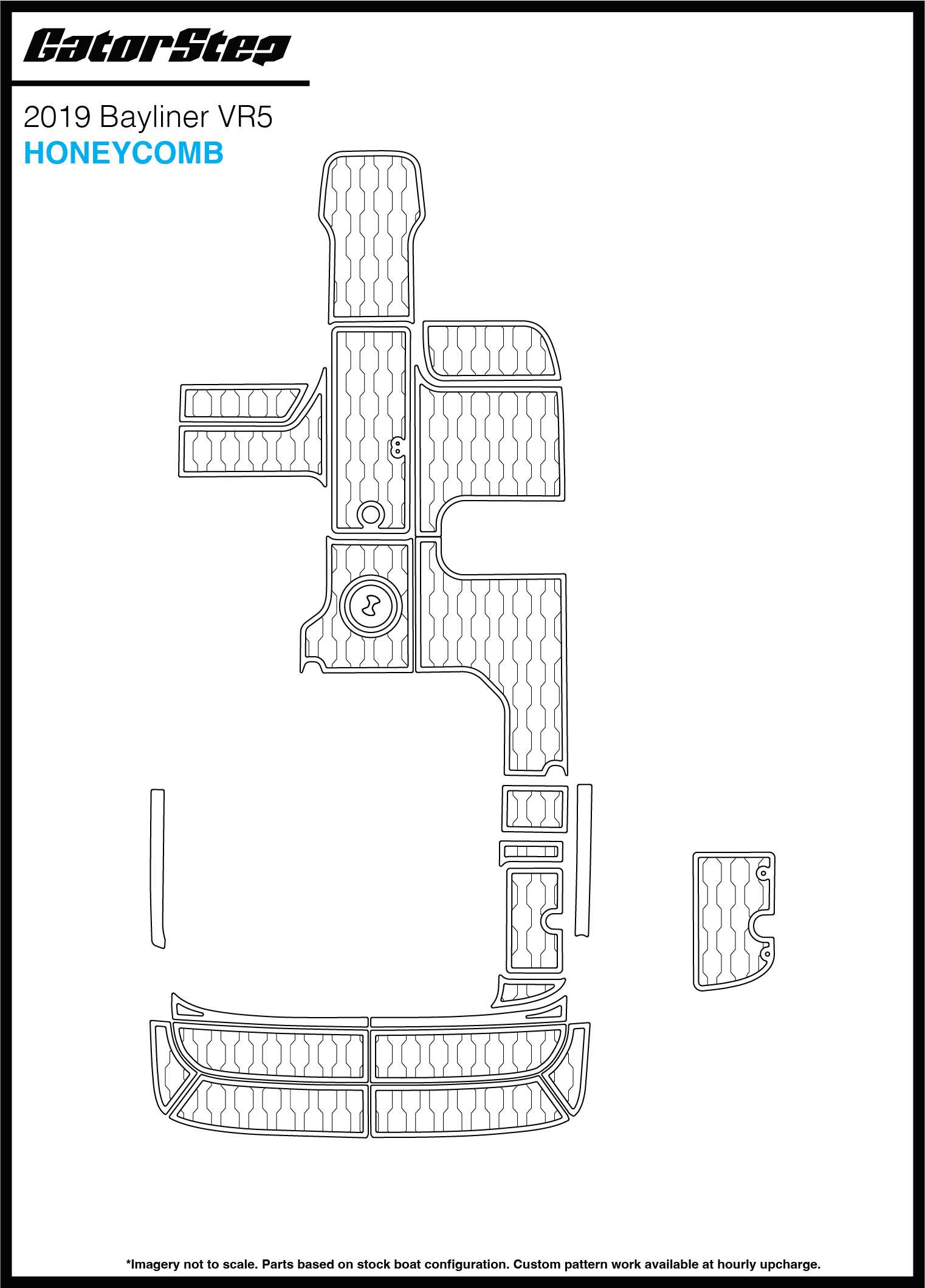

Understanding Various Components in Bayliner Boats

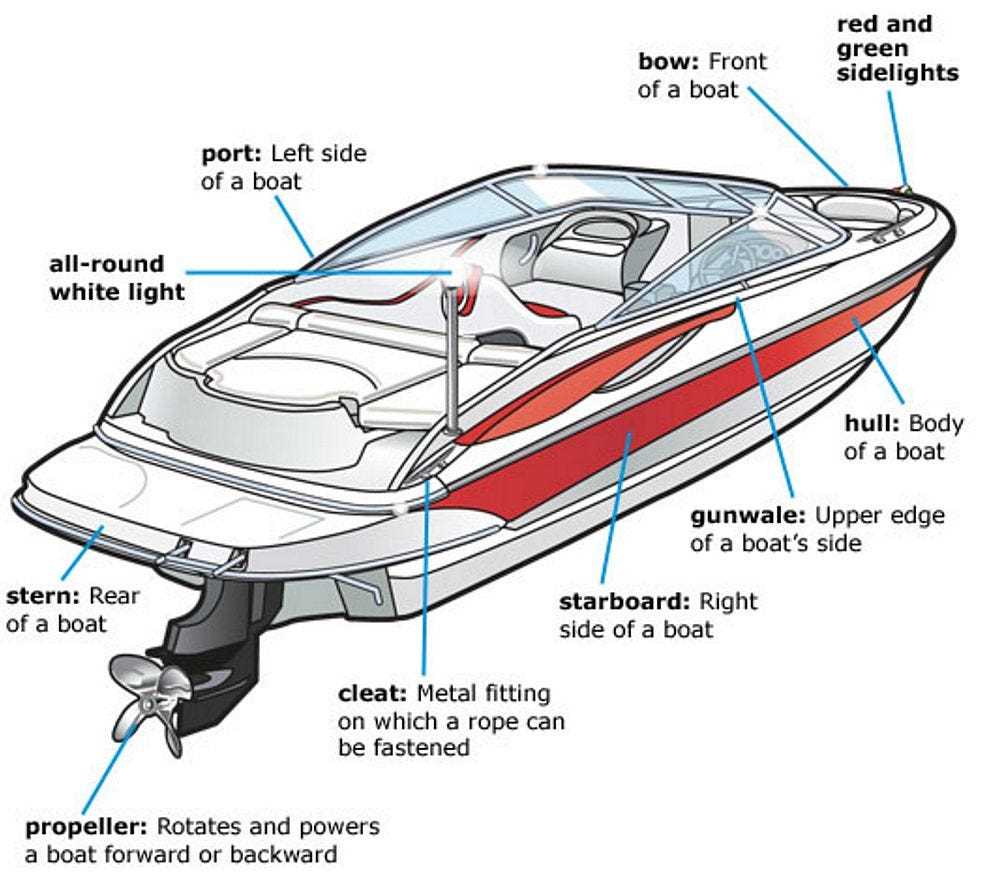

Watercraft of this type are designed with a range of specialized systems that ensure smooth sailing and user comfort. From the navigation elements to power management, each piece plays a crucial role in the overall operation and user experience. Exploring these details helps in better understanding how different elements work together to maintain performance and safety on the water.

Navigation and Steering Mechanisms

The guiding systems include elements like rudders, control cables, and steering wheels, which work in harmony to provide precise control over the vessel’s direction. These mechanisms ensure responsive handling, whether navigating through calm waters or maneuvering in a crowded marina. Additionally, advanced electronic aids may be present, offering GPS tracking and course plotting for enhanced direction control.

Power and Electrical Systems

The energy framework includes a network of wiring, switches, and batteries that distribute power to various onboard equipment. This system supports functions like lighting, communication devices, and auxiliary features, ensuring all components operate efficiently during excursions. The proper configuration of these elements is vital to avoid power disruptions and maintain safe operation.

| Component | Function | Key Considerations | |||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steering Wheel | Controls direction | Regular lubrication and inspection |

| Component | Description | Common Purpose | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Assembly | The primary source of power for navigation, including mechanisms for fuel injection and cooling. | Propelling the vessel forward and ensuring efficient energy use. | ||||||||||||||||||||||||||

| Steering Mechanism | Includes the wheel

How to Source Specific Replacement PartsFinding the right components for your project can seem daunting, but with the right approach, it becomes a manageable task. This section will guide you through the best practices for locating items that match your needs and ensure that your equipment stays in optimal condition. Identify Your Needs ClearlyBefore searching, it’s crucial to understand the exact specifications of the item you need. This involves checking model numbers, dimensions, and other details that will help narrow down your options. Such clarity will prevent compatibility issues and ensure a smooth selection process. Explore Reliable Sources and VendorsThere are various places where you can obtain the necessary components, from online marketplaces to local dealerships. Researching the most reputable vendors will help you find high-quality items, often accompanied by reviews from other customers. Don’t forget to compare prices and shipping terms to find the best deal. Tips for Installing Boat Engine PartsProperly fitting new components in a vessel’s motor is crucial for ensuring smooth performance and longevity. Understanding the correct approach to setup and alignment can prevent potential issues and maintain optimal operation. Here are some key suggestions to follow during this process to make sure everything functions seamlessly. Before starting, thoroughly review the specifications of the new elements and compare them with the existing ones. This helps in confirming compatibility and prevents mismatches that could lead to complications. Preparing all necessary tools beforehand can streamline the procedure and minimize interruptions. When handling various mechanisms, ensure secure attachment by using appropriate fasteners. Double-check the positioning of hoses, cables, and connectors to avoid leaks or disconnections. It’s essential to follow the recommended tightening torque values to prevent overtightening, which can cause damage. After installation, testing the engine under low load conditions allows you to identify any irregularities. Pay attention to unusual sounds or vibrations, as these can indicate alignment problems or loose connections. Make adjustments as needed before using the motor for extended periods. Regular maintenance checks after the initial setup ensure the new elements continue to operate as intended. Keeping a close eye on performance can help detect minor issues before they escalate, maintaining the reliability of your vessel’s propulsion system. Diagram Overview for Steering SystemThe section focuses on the fundamental structure and layout of the guidance mechanism, which is crucial for maintaining smooth navigation. It aims to simplify the understanding of how the system is arranged, ensuring that each element works together efficiently to deliver precise control. Key Components and Their Roles

Flow of Motion and ResponseThe layout allows for coordinated movement from the helm to the directional components, ensuring immediate feedback. This interaction between parts helps achieve a steady and precise path in the water. Understanding this flow can aid in identifying the origin of any operational issues, as each component plays a crucial role in the overall system’s performance.

|