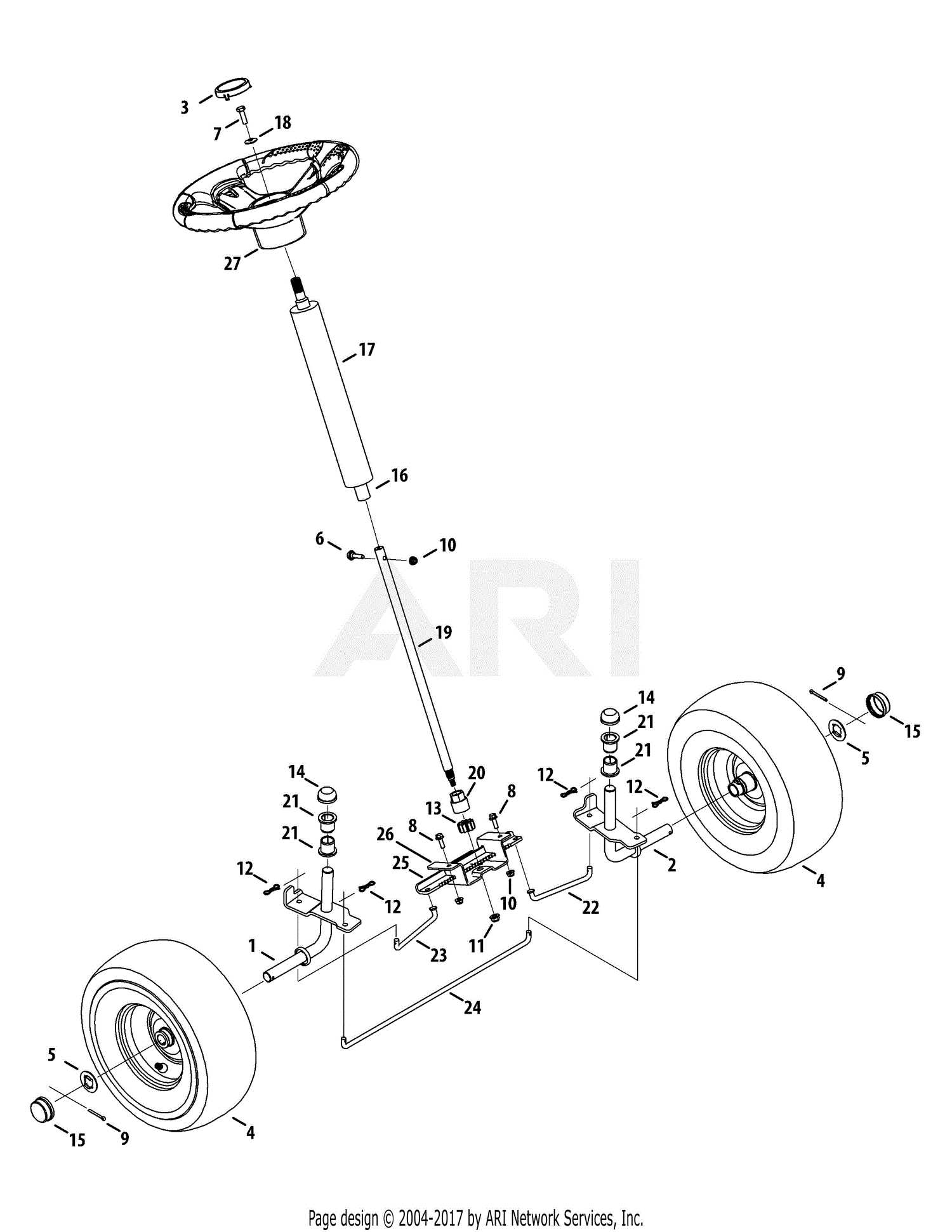

Steering Mechanism Explained

The steering system plays a critical role in ensuring smooth and precise control over the vehicle’s movement. Its design allows the operator to easily guide the machine in the desired direction, enhancing both safety and efficiency. This section provides a closer look at the essential components involved in the steering process and how they work together to deliver optimal performance.

- Steering Wheel: The primary interface for the user to control direction. Turning it adjusts the position of the wheels.

- Steering Linkages: These components connect the steering wheel to the wheels, transferring motion efficiently.

- Front Axle: Supports the steering mechanism, ensuring stability during direction changes.

- Tie Rods: Essential for transferring movement from the steering system to the wheels, maintaining alignment.

- Steering Gear: Converts the rotational motion of the steering wheel into linear motion to move the wheels.

A well-functioning steering

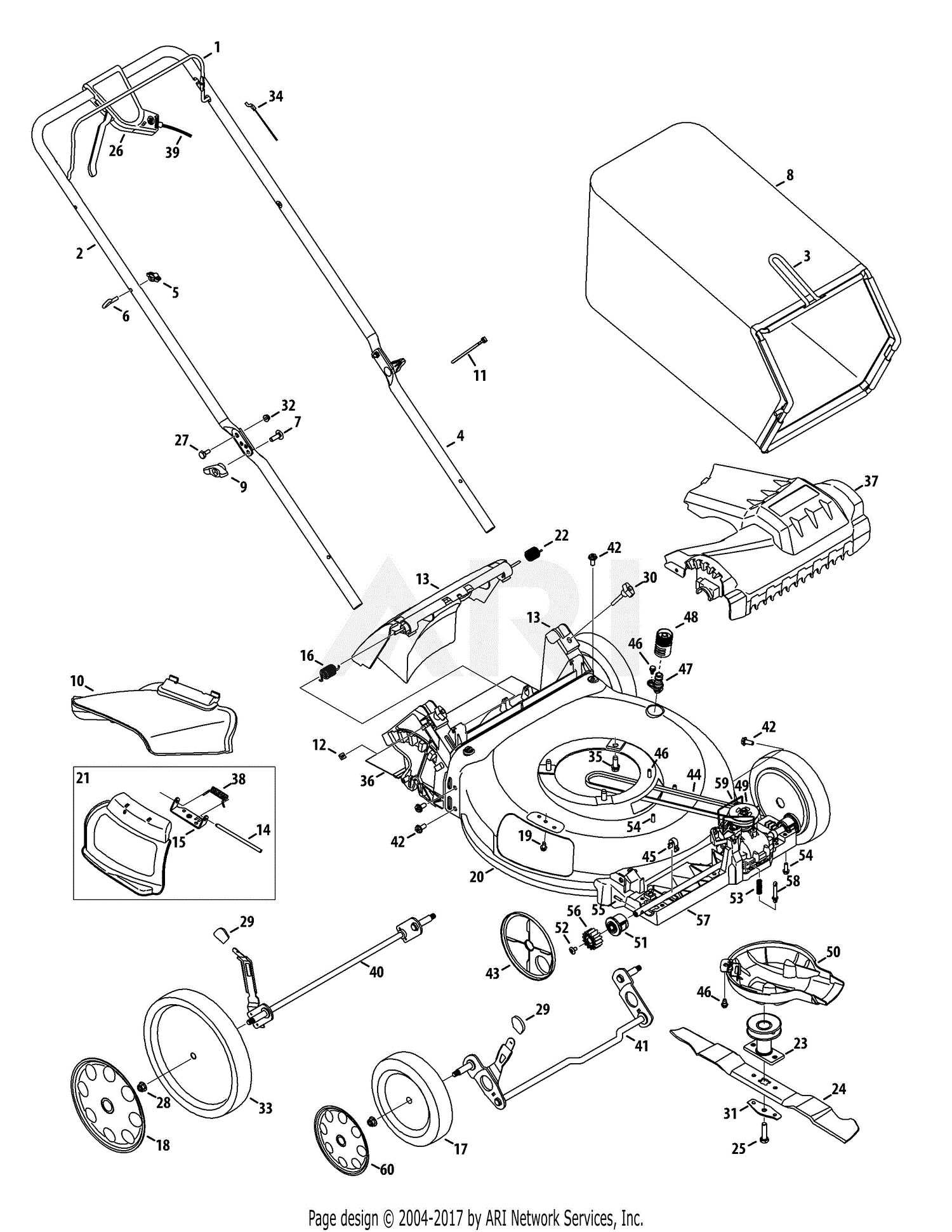

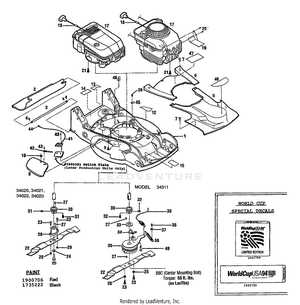

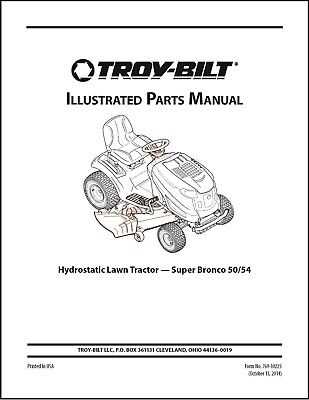

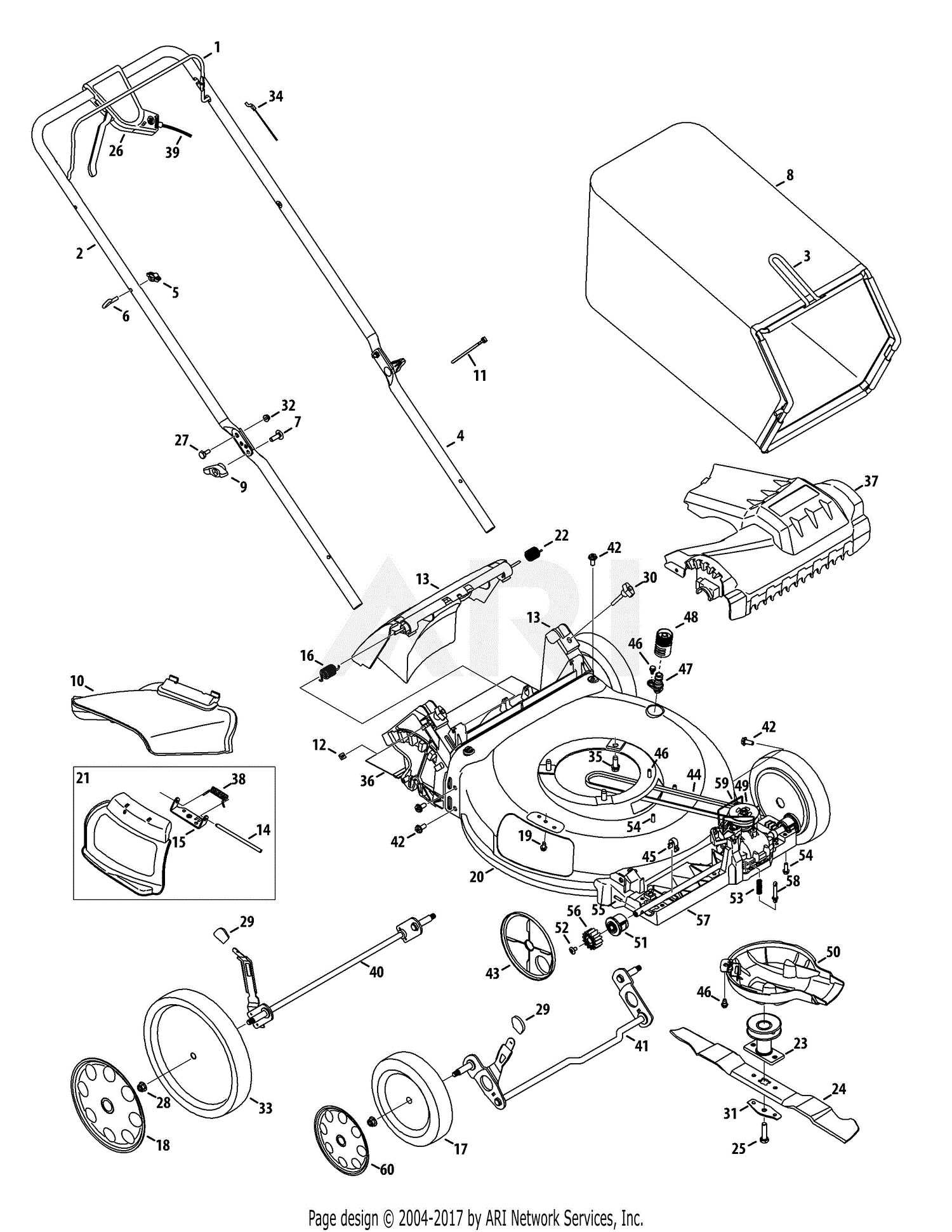

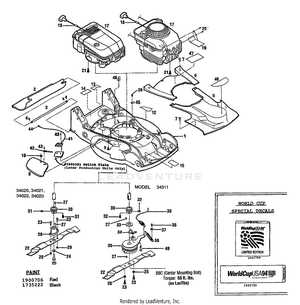

Cutting Deck Layout and Parts

The cutting platform is an essential component responsible for efficient grass trimming. It consists of multiple elements working together to ensure even cutting and smooth operation. Understanding the arrangement of these components is key to maintaining performance and durability.

Blades and Spindles form the heart of the cutting platform, slicing through grass with precision. These blades are mounted on rotating spindles, ensuring uniform cuts across the yard.

Belt Systems drive the movement of the blades, transferring power from the engine to the cutting area. Proper alignment and tension of these belts are crucial for smooth functioning.

Additionally, pulleys and wheels play a role in stabilizing the platform, allowing it to glide effortlessly across the terrain, while supporting the overall structure.

Electrical System Overview

The electrical system of a lawn care machine plays a vital role in its overall functionality. This intricate network is responsible for powering various components, ensuring smooth operation and optimal performance. Understanding the key elements of this system is essential for effective maintenance and troubleshooting.

Power Source is the heart of the electrical system, providing the necessary energy to operate the machine. Typically, this is supplied by a battery that stores energy and delivers it when needed. Regular inspection of the battery’s condition is crucial for preventing unexpected failures.

Wiring Harness connects different electrical components, facilitating the flow of electricity throughout the system. Ensuring that the wiring is intact and free from damage helps maintain efficient operations. Corrosion and frayed wires can lead to malfunctioning parts and should be addressed promptly.

Ignition System is responsible for starting the engine. It relies on the battery and various electrical components to create the necessary spark for combustion. Regular maintenance of this system can enhance reliability and prolong the life of the machine.

Overall, a thorough understanding of the electrical setup can significantly contribute to effective care and maintenance, helping to avoid common issues that can arise from neglect.

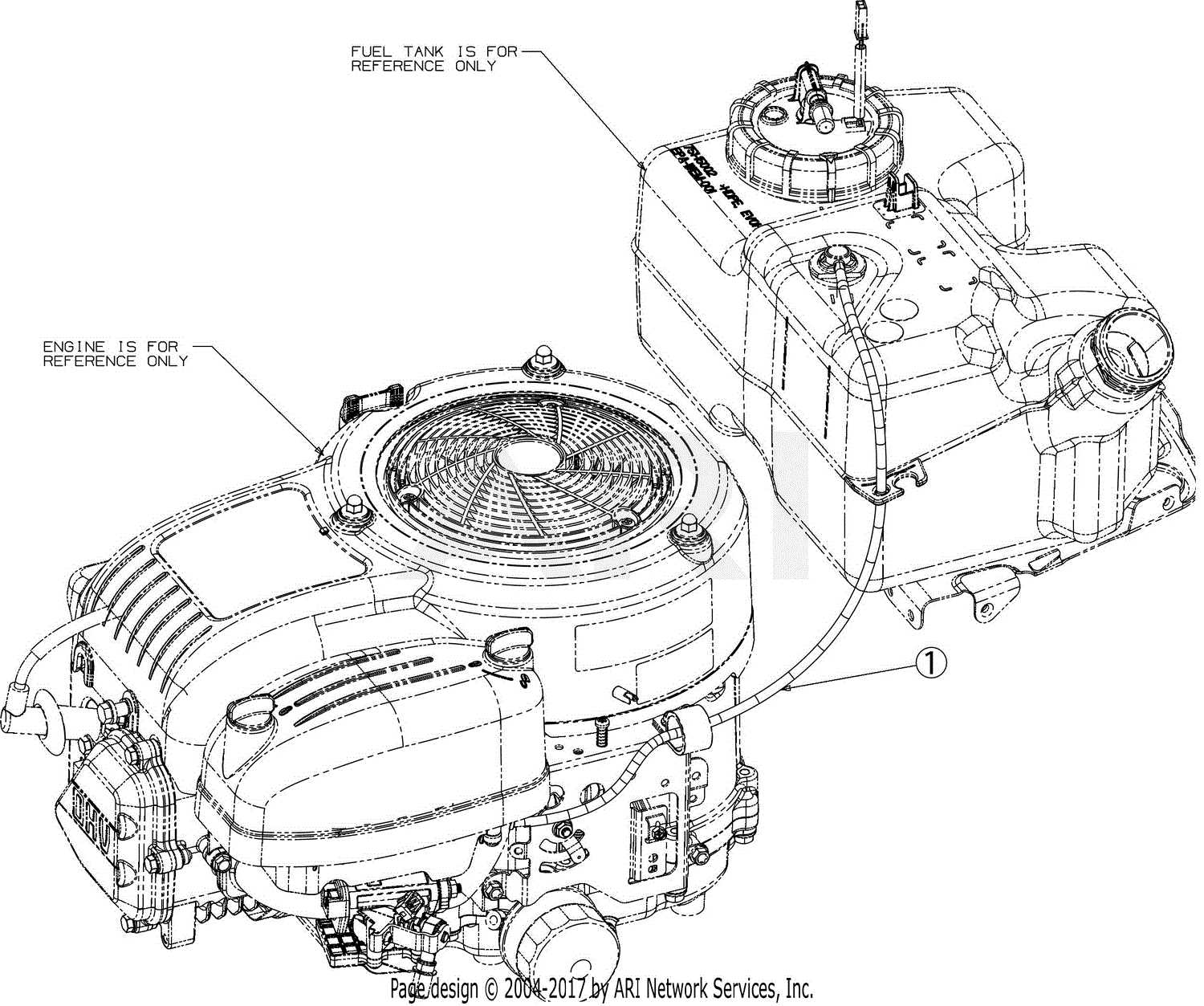

Fuel System and Related Components

The fuel system plays a crucial role in the overall performance and efficiency of outdoor power equipment. It is responsible for delivering the necessary energy source to the engine, ensuring smooth operation and optimal power output. Understanding the various elements within this system can aid in troubleshooting and maintenance, ultimately extending the lifespan of the machinery.

Key Elements of the Fuel System

Essential components of the fuel delivery system include the fuel tank, fuel lines, and filters. The fuel tank stores the liquid energy source, while the lines transport it to the engine. Filters are vital in removing impurities, preventing potential damage to internal engine parts. Regular inspection of these elements is recommended to ensure proper functionality.

Maintenance Tips

To maintain the efficiency of the fuel system, it is important to regularly check for leaks and ensure that all connections are secure. Replacing fuel filters at recommended intervals helps to maintain clean fuel flow. Additionally, using high-quality fuel can contribute to better engine performance and reduce the risk of buildup in the system.

Seat Assembly and Adjustment Options

The proper assembly and adjustment of the seating structure are crucial for ensuring optimal comfort and control during operation. This section explores the components involved in the seating setup and the various methods to customize its position to suit individual preferences.

Understanding the Assembly involves recognizing the key elements that contribute to a secure and stable seat. The main components typically include the seat cushion, mounting brackets, and support frame. Each part plays a significant role in providing a reliable seating experience, enhancing both safety and ease of use.

Adjustment Mechanisms are essential for tailoring the seat to the operator’s specific needs. Various options, such as sliding tracks and height-adjustable mechanisms, allow for quick and straightforward modifications. By utilizing these features, users can achieve a personalized fit that promotes comfort and reduces fatigue during extended use.

In summary, understanding the assembly and adjustment options available for the seating structure enhances the overall functionality of the equipment, leading to a more enjoyable and efficient experience.

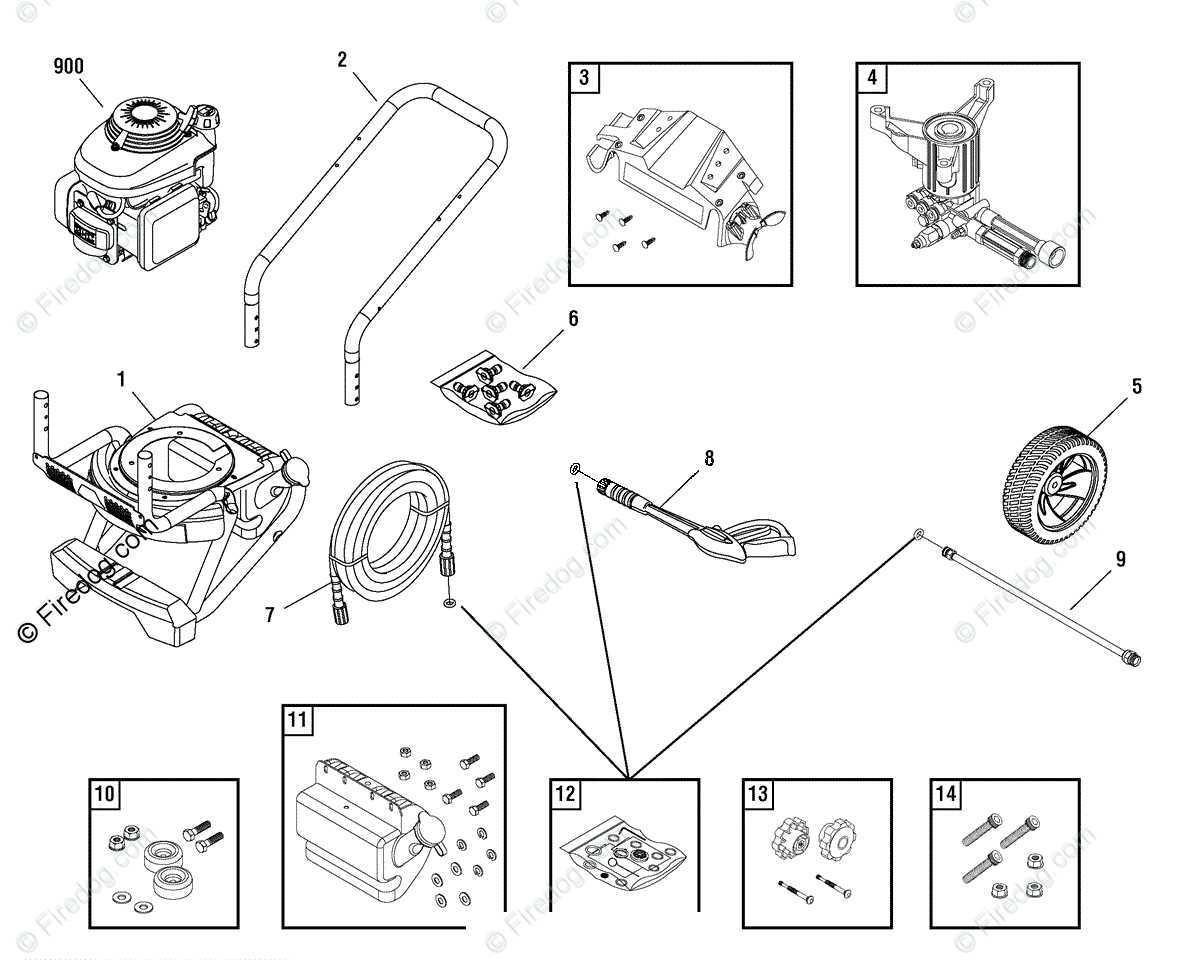

Tire and Wheel Replacement Guide

Proper maintenance of the wheels and tires is essential for the optimal performance of your outdoor equipment. Understanding how to replace these components can enhance maneuverability and extend the lifespan of the machine. This guide provides a step-by-step approach to ensure a smooth and efficient replacement process.

Before starting the replacement, gather the necessary tools and materials:

- Wrench set

- Jack or lifting equipment

- New tires and wheels

- Lubricant

Follow these steps for an effective replacement:

- Prepare the Equipment: Park the machine on a flat, stable surface and engage the parking brake.

- Lift the Machine: Use a jack to elevate the equipment, ensuring it is secure before proceeding.

- Remove Old Tires and Wheels: Use the appropriate wrench to loosen and remove the bolts securing the wheels.

- Inspect Components: Check the wheel hubs and axles for any signs of damage or wear that may require attention.

- Install New Tires and Wheels: Position the new tires and wheels, securing them with bolts. Ensure they are tightened according to the manufacturer’s specifications.

- Lower the Equipment: Carefully remove the jack and lower the machine back to the ground.

- Test the Setup: Start the equipment and test the new tires and wheels for any irregularities in movement.

Regularly checking and replacing the tires and wheels will help maintain the performance of your outdoor machinery, ensuring that it operates smoothly for years to come.

Chassis Frame Structure Details

The chassis frame is a fundamental component that supports various elements of the machine, providing stability and strength during operation. Understanding its construction and features is essential for maintenance and repair.

Key aspects of the chassis frame include:

- Material Composition: Typically made from robust steel or high-grade composite materials, ensuring durability and resistance to wear.

- Design Features: The design often includes reinforcements at critical points to enhance structural integrity and minimize flexing under load.

- Attachment Points: Various mounting locations are integrated into the frame to secure the engine, transmission, and other components effectively.

Regular inspection of the chassis frame is crucial to ensure longevity and optimal performance. Potential issues such as corrosion or deformation should be addressed promptly to maintain safety and functionality.

Safety Features and Associated Parts

Ensuring user protection during operation is a crucial aspect of lawn care machinery. Various safety elements contribute to minimizing risks, enhancing the overall functionality and efficiency of these machines. Understanding these components is essential for proper maintenance and operation.

Key safety features include:

- Emergency Stop Switch: Instantly halts operation when activated, preventing potential accidents.

- Safety Belts: Secures the operator, ensuring stability and reducing the risk of falls.

- Blade Brake: Stops the cutting mechanism quickly when the operator leaves the seat, avoiding unintended injuries.

- Operator Presence Control: Ensures that the machinery will not operate if the operator is not seated.

- Guarding Systems: Protects users from moving parts, reducing the likelihood of injury during maintenance or operation.

Regular inspection of these features is vital to maintain their effectiveness. It is recommended to consult the user manual for guidance on specific checks and procedures.