Maintaining and repairing outdoor tools is essential for their longevity and efficiency. A comprehensive guide can significantly enhance your experience, helping you identify essential components and their functions. Whether you’re dealing with a routine maintenance task or addressing a specific issue, knowledge is key.

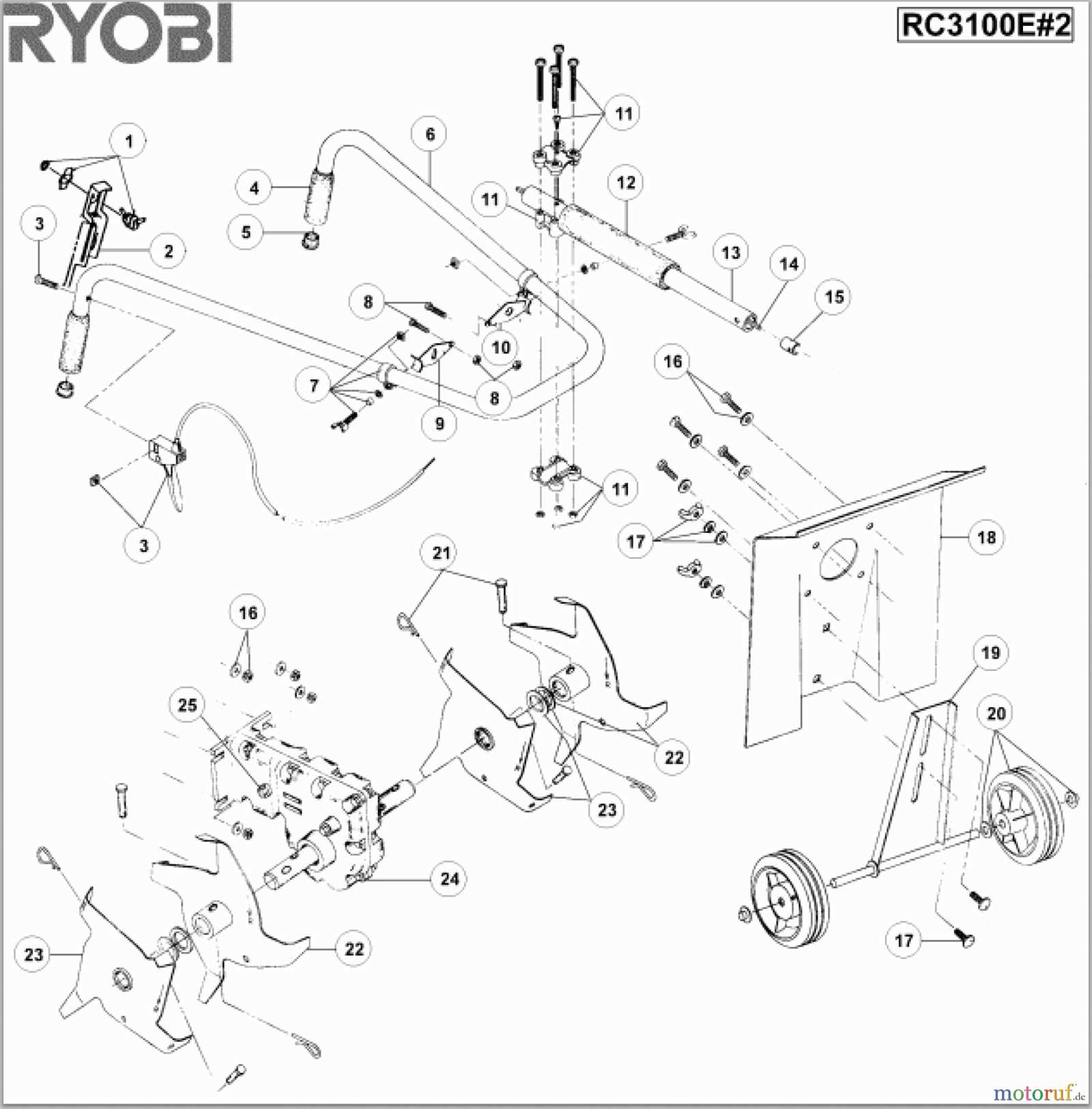

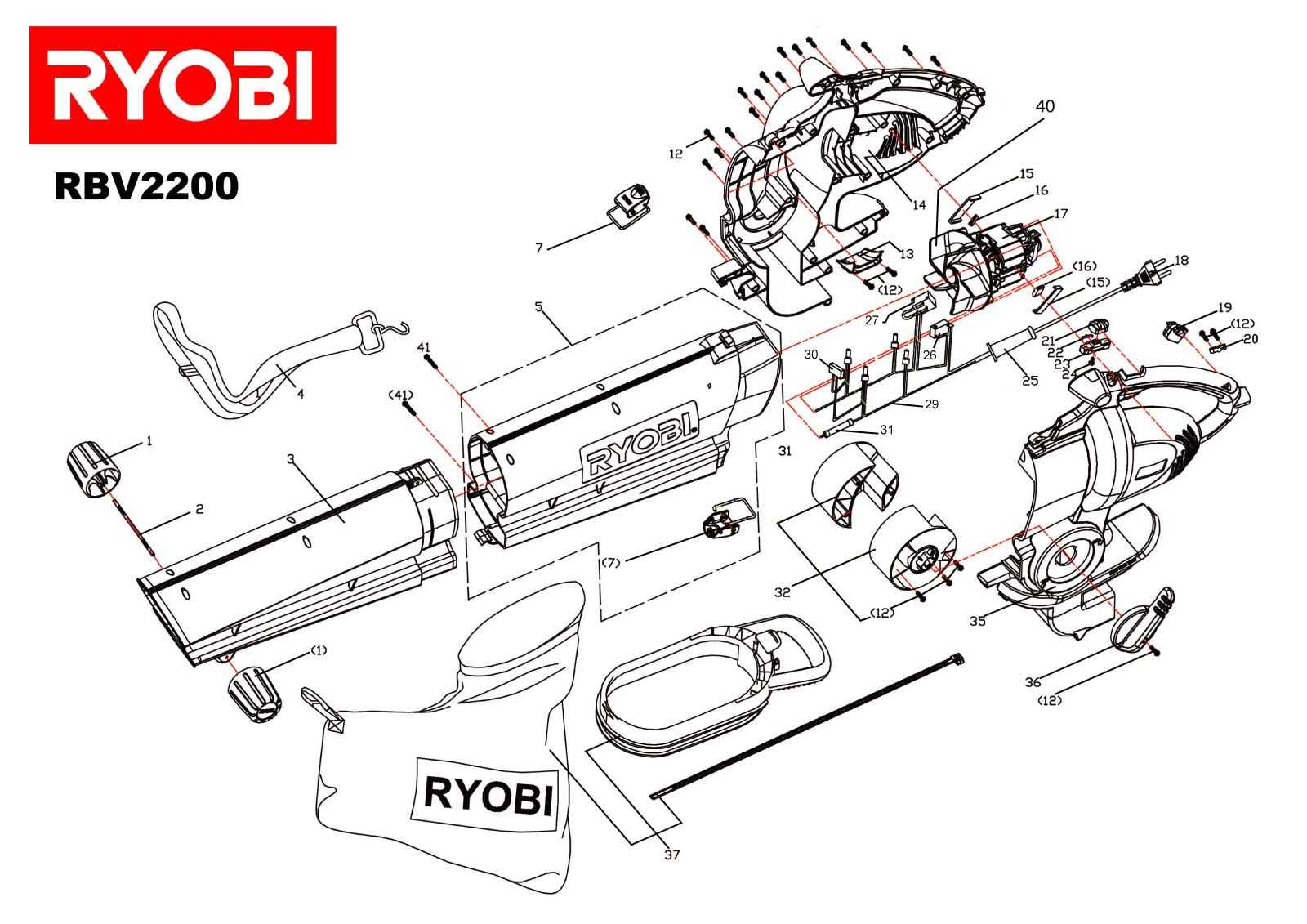

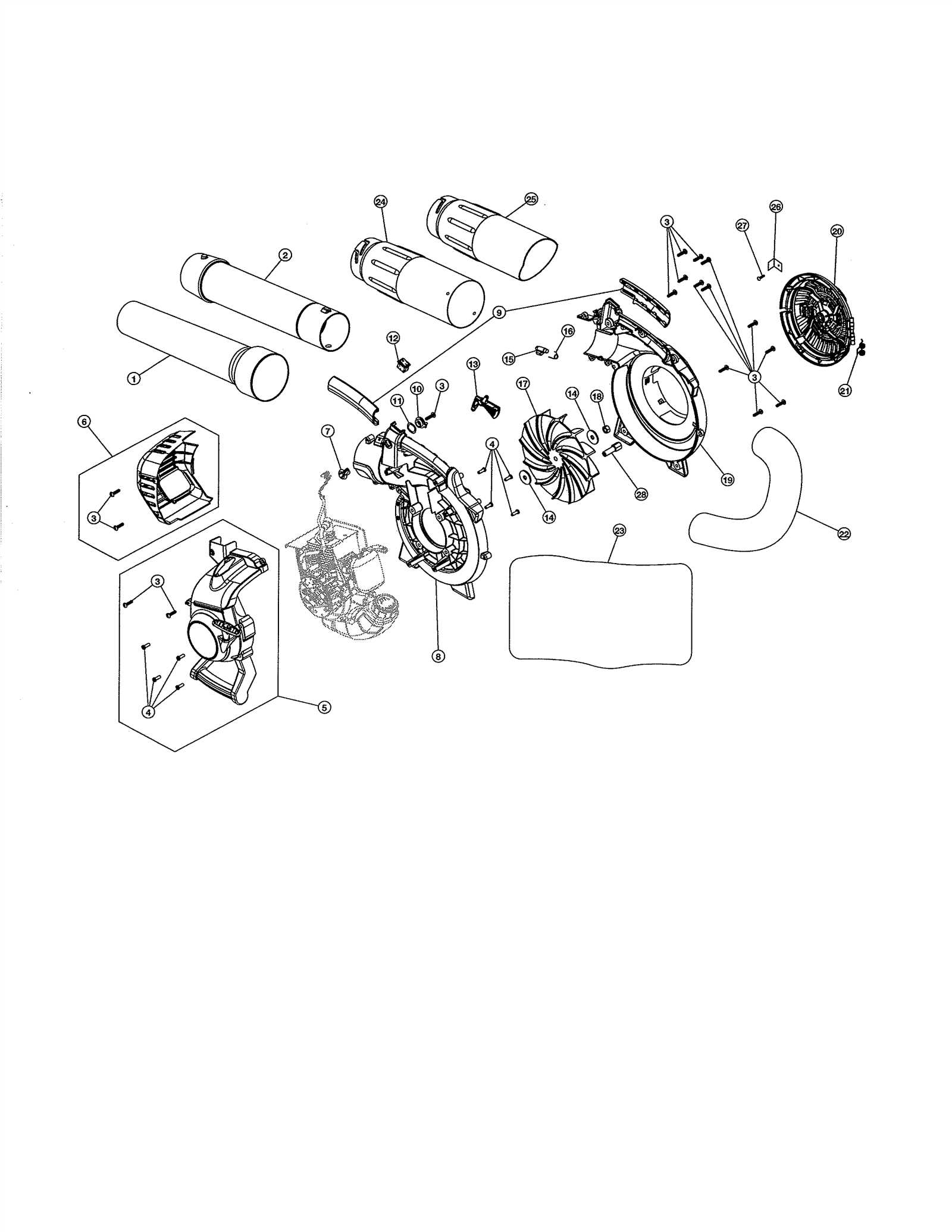

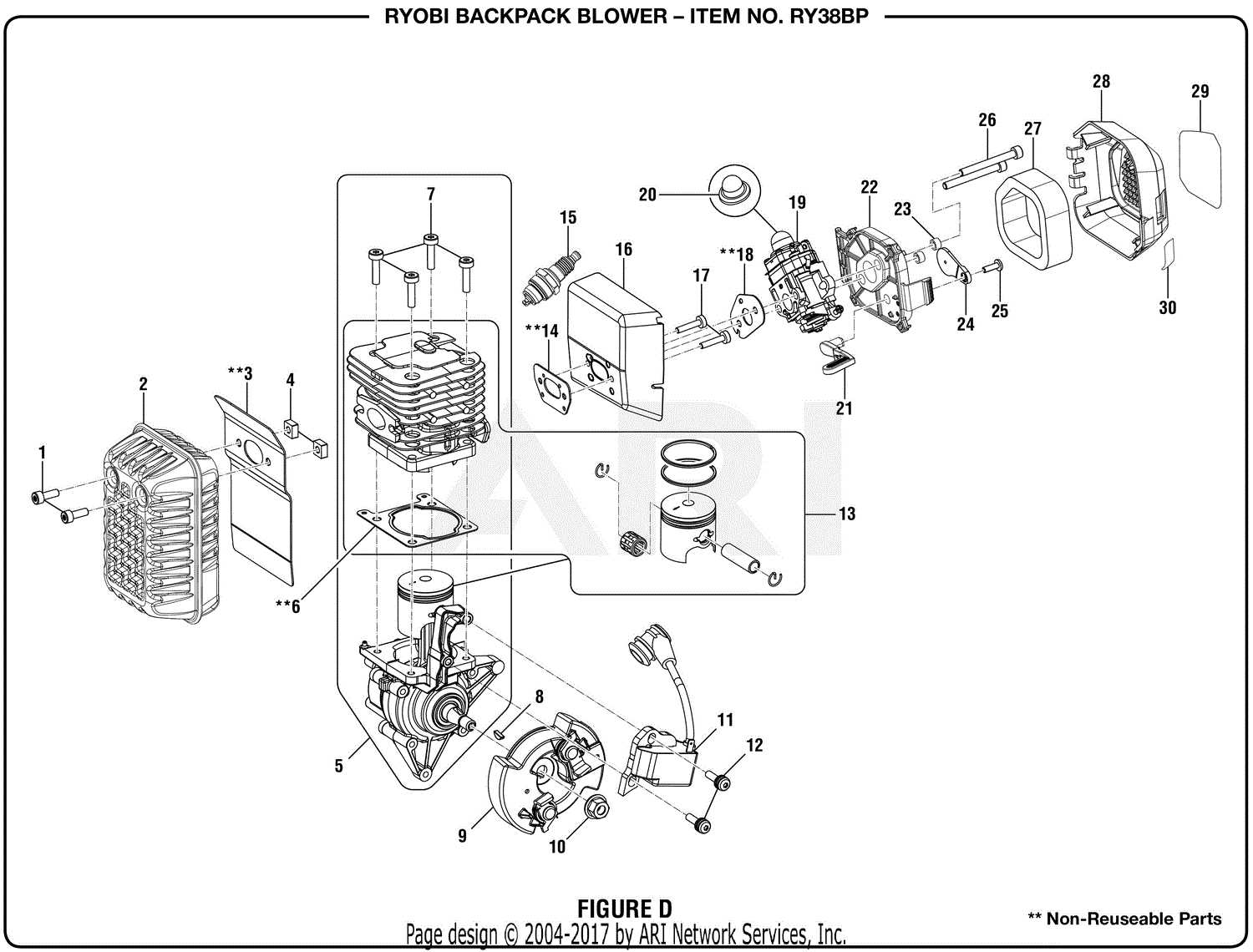

Visual aids can prove invaluable in navigating the complexities of your machinery. By referencing a well-structured illustration, you can easily locate individual elements and understand their roles within the system. This not only streamlines repairs but also fosters a deeper appreciation for the craftsmanship involved.

Ultimately, gaining insight into the assembly of your equipment empowers you to tackle challenges confidently. Delve into the intricacies of these tools to enhance your maintenance skills and ensure peak performance for all your outdoor projects.

Understanding Ryobi Blower Components

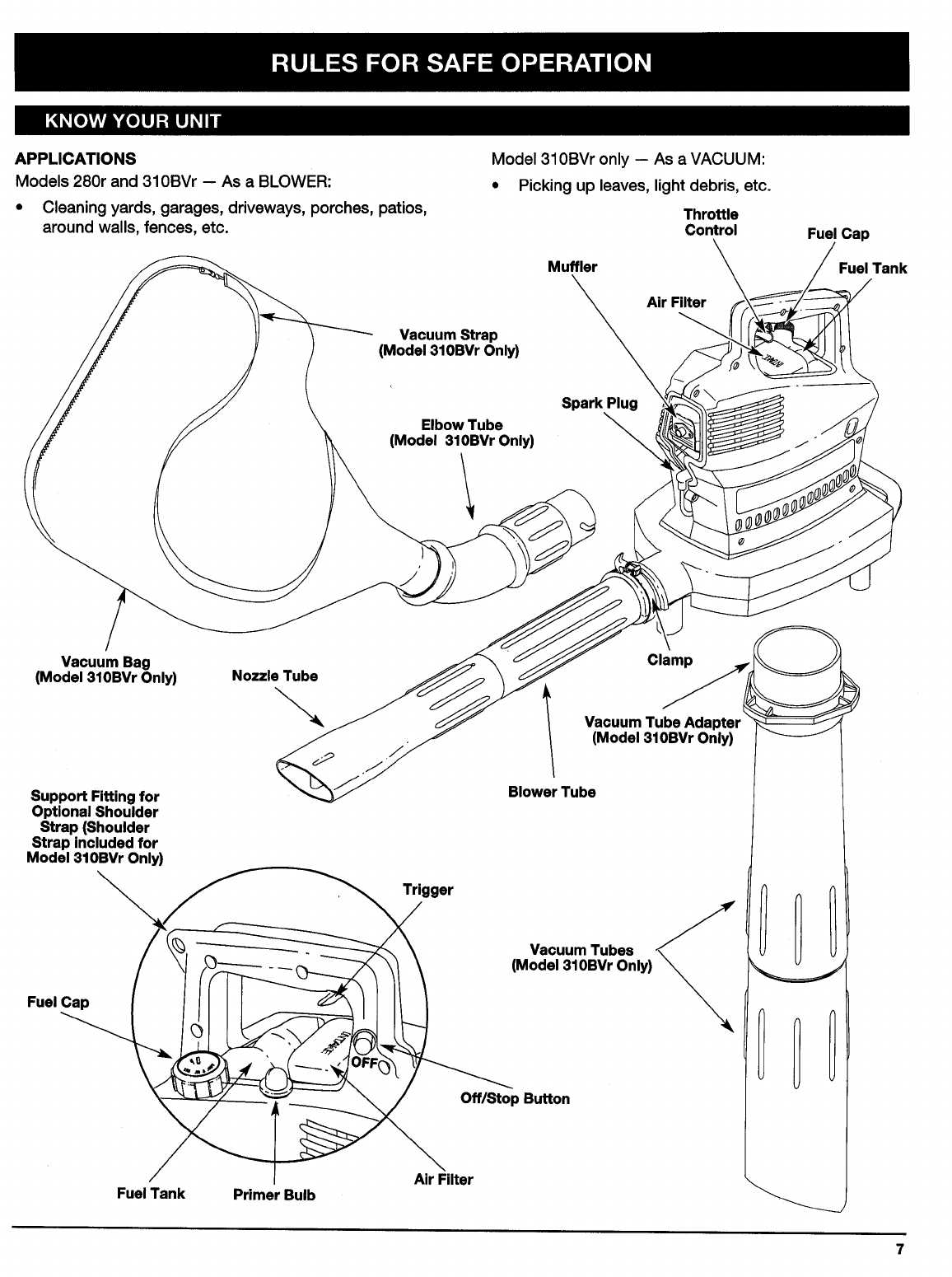

Exploring the intricate elements of a high-performance outdoor tool reveals the essential components that contribute to its efficiency and functionality. Each piece plays a crucial role in ensuring optimal operation, from the engine to the air intake system.

Core Functional Elements

The primary functional elements include the motor, which powers the device, and the fan assembly that generates airflow. Understanding these components is vital for maintenance and troubleshooting, allowing users to identify potential issues effectively.

Supportive Structures

Supportive structures, such as housing and handles, are equally important as they provide stability and ease of use. Familiarity with these parts enhances the user experience, making the tool more manageable and efficient during operation.

Essential Parts of Ryobi Blowers

Understanding the key components of outdoor air-moving tools is crucial for effective maintenance and operation. Each element plays a vital role in the overall functionality and efficiency of the equipment.

- Motor: The powerhouse that drives the airflow.

- Fan: Responsible for generating the necessary air movement.

- Housing: The outer shell that protects internal mechanisms.

- Filter: Prevents debris from entering the motor and fan.

- Handle: Provides grip and control during use.

- Nozzle: Directs airflow to enhance performance.

By familiarizing oneself with these fundamental components, users can ensure optimal functionality and longevity of their tools.

Common Issues with Blower Parts

When operating outdoor equipment, several challenges can arise that affect performance and efficiency. Understanding these issues can help in troubleshooting and maintaining the functionality of your device.

- Reduced Airflow:

This is a frequent problem, often caused by clogs in the intake or exhaust. Debris accumulation can hinder airflow, leading to diminished effectiveness.

- Inconsistent Power:

Variations in performance may indicate issues with the motor or fuel system. It’s crucial to inspect fuel lines and filters for blockages or leaks.

- Noisy Operation:

Excessive noise can signal wear on internal components. Checking for loose parts or damage to the casing can help identify the source of the sound.

- Vibrations:

Unusual vibrations during use may suggest misalignment or imbalance. Regular maintenance can help address this before it leads to more severe issues.

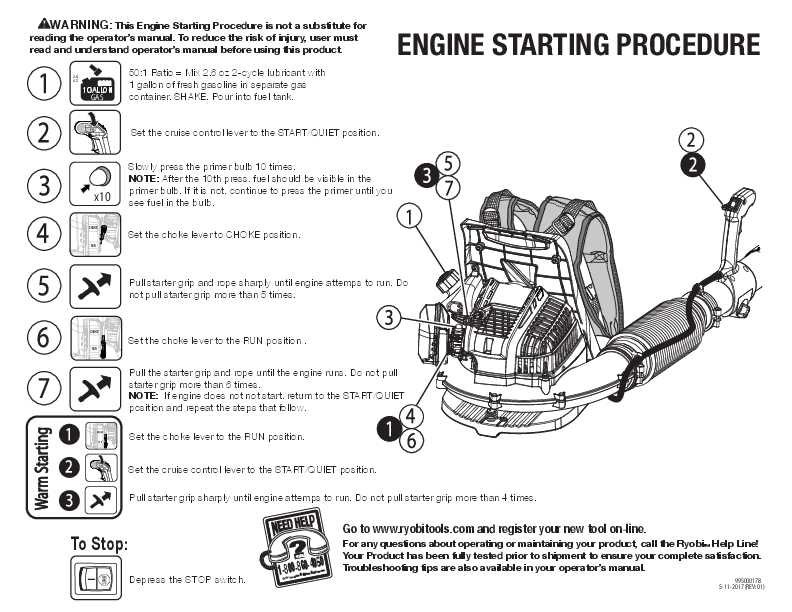

- Difficulty Starting:

Problems with starting may stem from issues in the ignition system or fuel delivery. Ensuring proper maintenance of these components can alleviate this issue.

Regular inspections and timely repairs can significantly enhance the longevity and efficiency of your equipment, ensuring it performs optimally when needed most.

How to Identify Part Numbers

Identifying the correct item codes is essential for ensuring compatibility and functionality when replacing components in any equipment. Proper identification not only helps in finding the right pieces but also simplifies the repair or maintenance process. This guide will provide you with useful tips on how to accurately determine these numbers.

Start by checking the user manual that typically accompanies the device. This document often contains a comprehensive list of the components along with their corresponding codes. If the manual is unavailable, locating the manufacturer’s website can be beneficial, as many brands offer downloadable manuals or parts lists.

Another effective method is to examine the device itself. Many manufacturers print the identification codes directly on the equipment or on a sticker attached to a specific area. Make sure to clean the surface to reveal any obscured information.

| Method | Description |

|---|---|

| User Manual | Look for a parts list or item codes within the document. |

| Manufacturer’s Website | Access downloadable manuals or parts catalogs online. |

| Device Inspection | Check for printed codes or stickers on the unit. |

If all else fails, consider contacting customer support for assistance. They can provide guidance on identifying the necessary codes and may even help you locate the right components for your needs.

Benefits of Using Genuine Parts

Utilizing authentic components for your equipment ensures optimal performance and longevity. These original pieces are designed specifically for the machinery, providing a perfect fit and compatibility that enhances functionality.

One significant advantage is the assurance of quality. Genuine components are manufactured to strict standards, reducing the risk of failure and extending the lifespan of your device. This reliability translates to fewer repairs and lower maintenance costs over time.

Additionally, using original pieces often maintains warranty coverage, safeguarding your investment. Non-genuine alternatives might seem cost-effective initially, but they can lead to issues that void warranties or require more extensive repairs.

Ultimately, opting for authentic components not only guarantees superior performance but also contributes to a safer and more efficient operational experience. Investing in quality ensures your equipment remains in top condition, maximizing its potential.

Step-by-Step Repair Process

This section outlines a comprehensive method for effectively restoring your equipment to optimal working condition. By following a structured approach, you can ensure that each component is addressed carefully, minimizing the risk of future issues.

Preparation and Assessment

Begin by gathering all necessary tools and components. Conduct a thorough examination of the device to identify any malfunctioning areas. Document your findings to streamline the repair process.

Disassembly and Replacement

Carefully disassemble the unit, taking care to keep track of all screws and pieces. Replace any damaged elements with new ones, ensuring they match specifications. Reassemble the unit, following the reverse order of disassembly, and conduct a final inspection to confirm everything is secure.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires consistent care and attention. By following simple maintenance practices, you can enhance performance and extend the lifespan of your tools.

- Regularly clean the exterior to prevent dirt buildup.

- Inspect components for wear and replace as needed.

- Store in a dry, sheltered area to avoid weather-related damage.

- Check and change filters to maintain optimal airflow.

- Lubricate moving parts periodically to reduce friction.

By incorporating these strategies, you can achieve the ultimate reliability from your equipment while minimizing repair costs.

Where to Buy Replacement Parts

Finding components for your equipment can be a straightforward process if you know where to look. There are numerous sources that offer a wide selection of high-quality replacements to keep your device running smoothly.

Online Retailers: E-commerce platforms often provide a vast array of options. Websites specializing in tools and accessories typically have extensive inventories and user reviews that can guide your purchase.

Local Hardware Stores: Visiting nearby shops can yield immediate results. Staff can offer expert advice and help you find what you need quickly.

Manufacturer’s Website: The official site often lists authorized dealers and provides a direct way to access genuine components, ensuring compatibility and reliability.

Community Forums: Engaging in online communities can be beneficial. Enthusiasts often share tips and recommendations on where to source hard-to-find items.

By exploring these avenues, you can efficiently locate the necessary components to maintain your equipment at its best.

Tools Needed for Repair

When tackling a repair project, having the right instruments at your disposal is essential for efficiency and success. A well-equipped workspace not only streamlines the process but also ensures safety and precision in your work. Below are some crucial items that can make a significant difference.

Essential Instruments

First and foremost, a quality screwdriver set is vital for loosening and tightening components. Additionally, a wrench set will be necessary for tackling any nuts or bolts that may require extra torque. Don’t forget about pliers, as they can assist in gripping and manipulating small parts.

Maintenance Supplies

In addition to basic tools, consider having lubricants and cleaning agents on hand. These will help maintain the functionality of your equipment and prolong its lifespan. A reliable workbench will also provide a sturdy surface for repairs, enhancing your overall workflow.

Exploring Ryobi’s Product Line

The extensive range of outdoor power tools from this brand is designed to meet various landscaping needs, providing users with effective solutions for maintaining their gardens and yards. From compact units ideal for small spaces to more powerful models suited for larger areas, the diversity in their offerings ensures that there’s something for everyone.

Categories of Tools

The lineup includes several categories, each tailored for specific tasks. Whether you’re looking for tools for cleaning, trimming, or maintenance, this brand has a comprehensive selection that enhances productivity and efficiency.

| Category | Features |

|---|---|

| Cleaning Equipment | Lightweight, easy to maneuver, and efficient for debris removal. |

| Garden Care | Durable designs suited for trimming and shaping plants. |

| Power Tools | Robust performance for various outdoor tasks, from cutting to clearing. |

Innovation and Technology

Each model incorporates the latest advancements, ensuring reliability and ease of use. With user-friendly features and innovative designs, these tools facilitate a more enjoyable gardening experience.

Comparison of Ryobi Models

This section explores various models in the line of outdoor equipment, highlighting key differences and similarities to aid in decision-making. Each model offers unique features tailored for different tasks, ensuring that users can find the perfect fit for their needs.

-

Model A:

Designed for lightweight tasks, this version excels in portability and ease of use, making it ideal for small gardens.

-

Model B:

This variant provides more power, suitable for larger areas where efficiency is paramount. It includes features like adjustable speed settings.

-

Model C:

A heavy-duty option designed for demanding jobs, equipped with advanced technology to handle tough debris.

By comparing these models, users can delve into specifics that align with their ultimate requirements, ensuring an informed choice that meets their landscaping needs.

Safety Precautions During Repairs

When undertaking maintenance on equipment, prioritizing safety is essential. Proper precautions not only protect the individual performing the repairs but also ensure the longevity and functionality of the device. Understanding the risks and implementing safety measures can significantly reduce the likelihood of accidents and injuries.

Always disconnect the power source before starting any repair work. This simple step prevents accidental activation, which could lead to severe injuries. Make it a habit to verify that the equipment is completely powered down.

Utilizing appropriate personal protective equipment is crucial. Items such as safety goggles, gloves, and ear protection shield against potential hazards like flying debris or loud noises. Depending on the nature of the repairs, consider using a dust mask to protect against inhaling harmful particles.

Ensure your workspace is organized and free from clutter. A tidy environment minimizes the risk of tripping and allows for efficient movement while working. Additionally, having all necessary tools within reach can prevent distractions that may lead to mishaps.

Finally, always follow the manufacturer’s guidelines and consult the manual for specific safety recommendations. Adhering to these protocols fosters a safer repair experience and enhances overall effectiveness.