When dealing with mechanical systems that rely on internal combustion engines, it becomes essential to know how various components interact. Each element plays a vital role in ensuring efficient operation, and a clear representation of their configuration can make maintenance or repairs much easier.

In this guide, we will explore the specific layout and connection of key elements within a two-stroke engine. By breaking down the essential elements, you’ll gain insights into how they fit together and the overall functionality of the system.

Through a detailed look at the various mechanical components, we aim to simplify the complexity of these systems and help you better understand their structure and working principles. Whether you’re troubleshooting or performing routine upkeep, this information will be an invaluable resource.

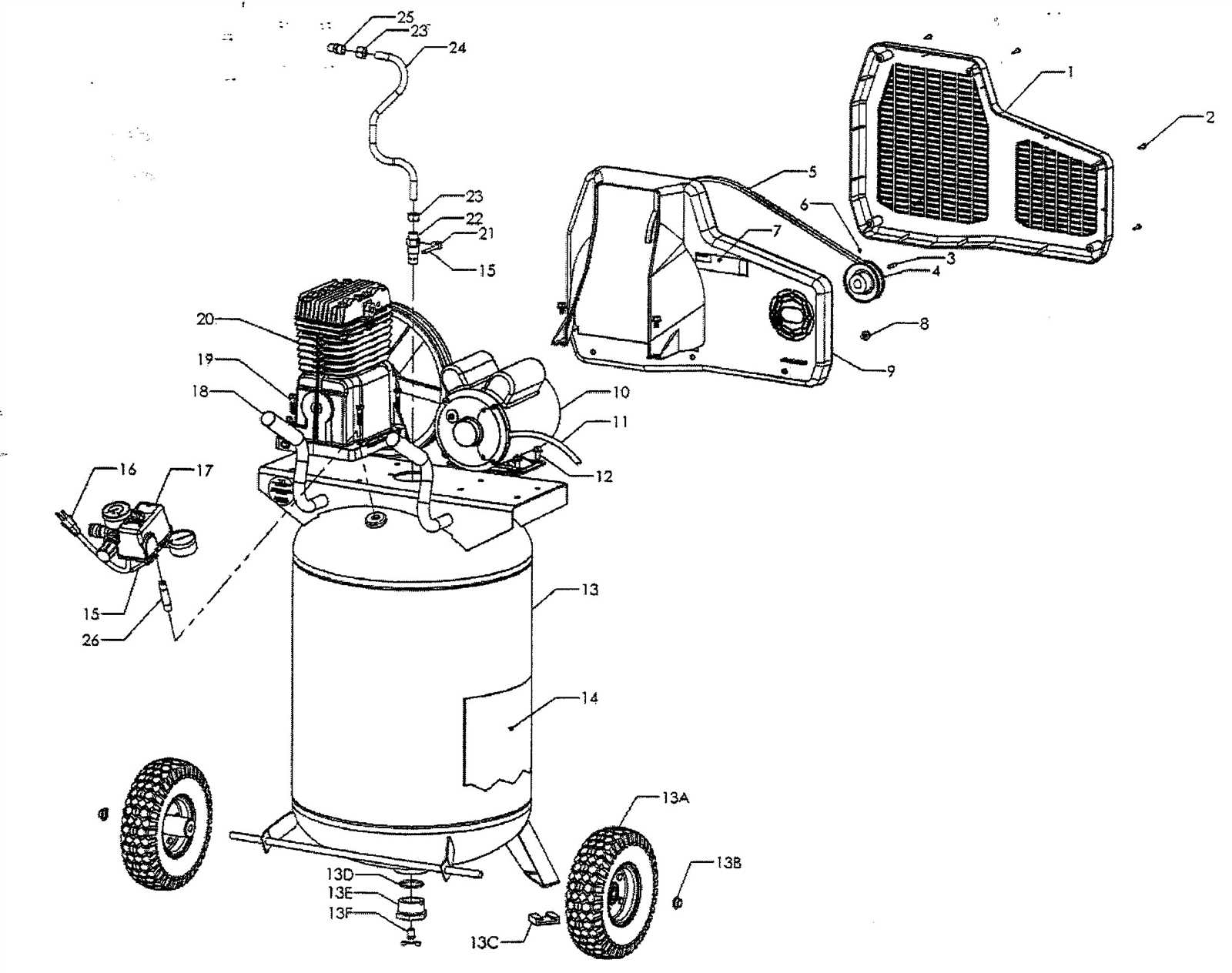

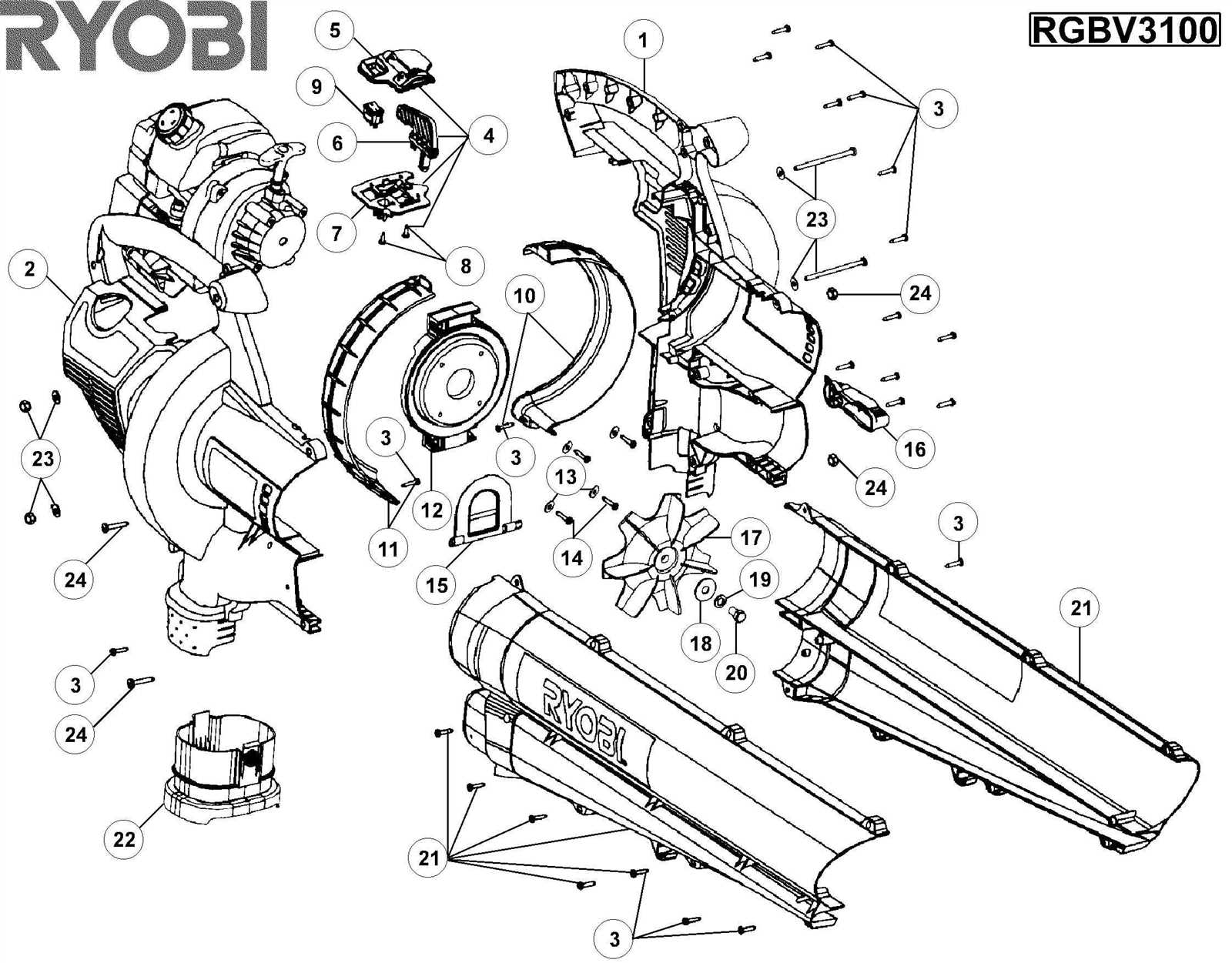

Overview of Ryobi Full Crank System

The engine system of this machinery is built to deliver efficient and reliable performance for extended use. It is designed to ensure smoother operation, reducing wear and providing durability over time. By optimizing the internal components, this mechanism offers enhanced energy transfer, contributing to better power output and lower maintenance requirements.

This configuration enables consistent functioning, even under demanding conditions. It minimizes vibrations, leading to a more comfortable experience for users while also improving overall machine longevity. The system is ideal for those seeking long-term efficiency and reduced operational strain.

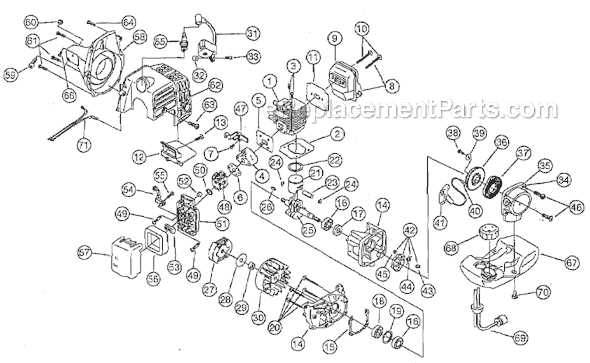

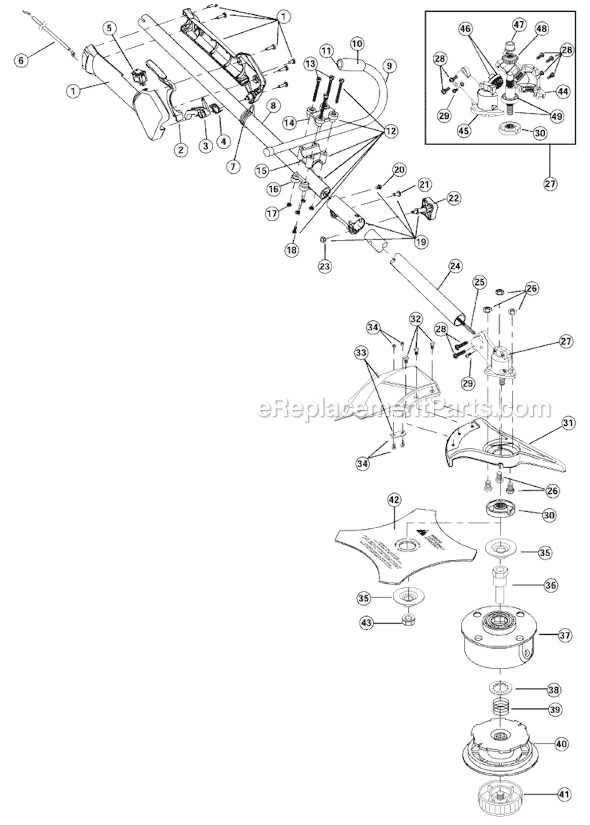

Key Components of Ryobi 2-Cycle Engine

This engine model includes several critical elements that work together to deliver consistent performance. Each component has a specific role in ensuring efficient operation, balancing power, and maintaining engine durability over time. The coordination of these elements is essential for smooth functioning, making the engine reliable and powerful.

Core Engine Elements

The engine features a combustion chamber, where fuel mixes with air and ignites to generate power. Supporting this process are the piston and cylinder, which move in harmony to create the necessary pressure for engine operation. These components must be carefully maintained to prevent wear and ensure longevity.

Supporting Mechanisms

Additional parts, such as the carburetor and exhaust system, manage the intake of fuel and expel gases. The carburetor regulates the air-fuel mixture, optimizing performance, while the exhaust removes combustion by-products to keep the engine running efficiently. Proper function of these systems is crucial for consistent power output.

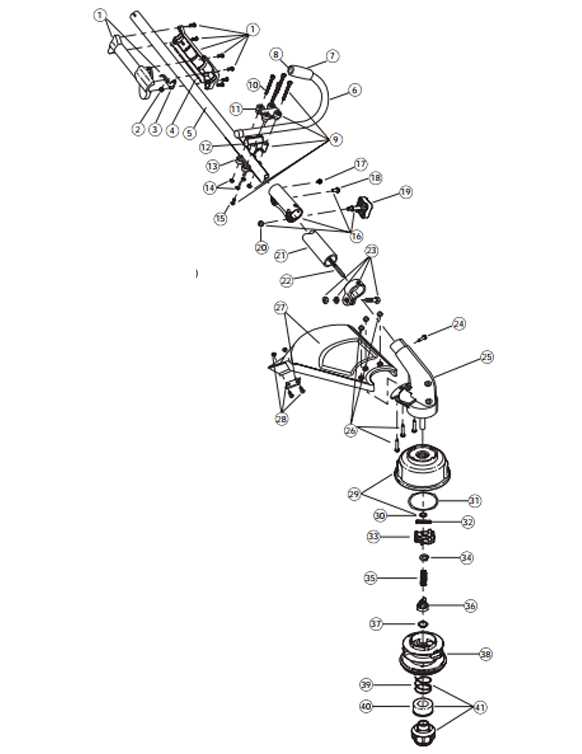

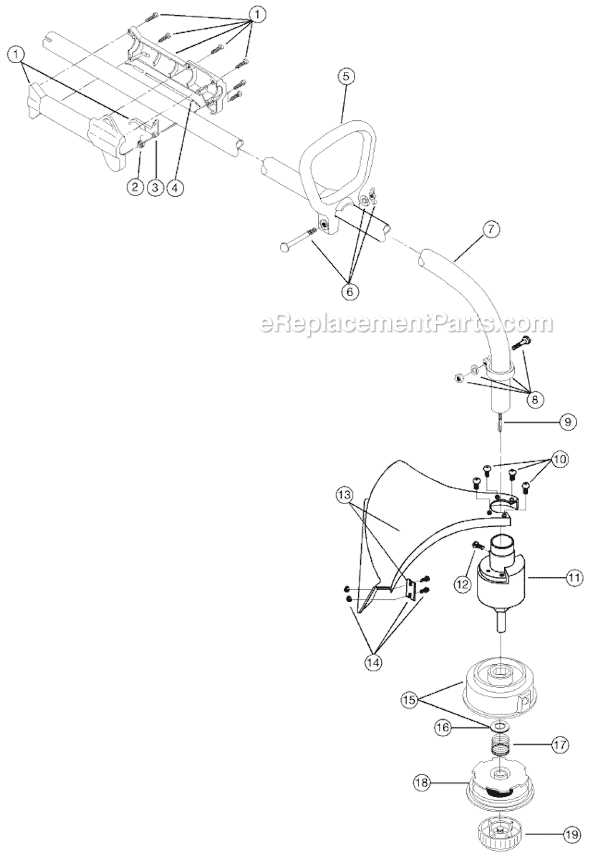

| Component | How the Crankshaft Operates in Ryobi Engines

The internal mechanism responsible for converting linear motion into rotational energy plays a critical role in the overall functionality of small engines. This key component ensures that the energy generated within the combustion chamber is effectively transmitted to power the tool’s moving parts. Understanding its operation is vital for maintaining peak engine performance and extending the life of the equipment. At the core of its function is the ability to transform the up-and-down movement of the piston into circular motion. As the piston moves within the cylinder, this element, connected via a rod, spins continuously. This process not only keeps the engine running smoothly but also drives the connected systems, ensuring steady and efficient operation. Precision and balance are essential for smooth functioning, as improper alignment or wear can lead to vibrations or loss of power. Regular inspection and timely maintenance help prevent potential damage, ensuring long-term reliability and efficiency of the equipment. Understanding the Ignition System in Ryobi ToolsThe ignition system plays a critical role in powering handheld tools by providing the necessary spark to ignite the engine. This system ensures the proper timing and energy delivery required for smooth and efficient engine operation. Without a functional ignition, the engine cannot start or maintain its operation, making it an essential component of any small engine-powered tool. Spark plug connections, wiring, and other elements are meticulously designed to ensure optimal performance. These components work together to create a controlled explosion that powers the engine, allowing the tool to function efficiently. Proper maintenance and regular inspection of these elements are vital for the tool’s reliability and longevity. Faulty connections or worn components can disrupt the ignition process, leading to engine misfires or failure to start. Ensuring that all components are in good condition and functioning as expected is key to maintaining the overall health of the engine. Regular cleaning and replacement of parts, when necessary, can help prevent larger issues down the line. Fuel System Parts and Their Functions

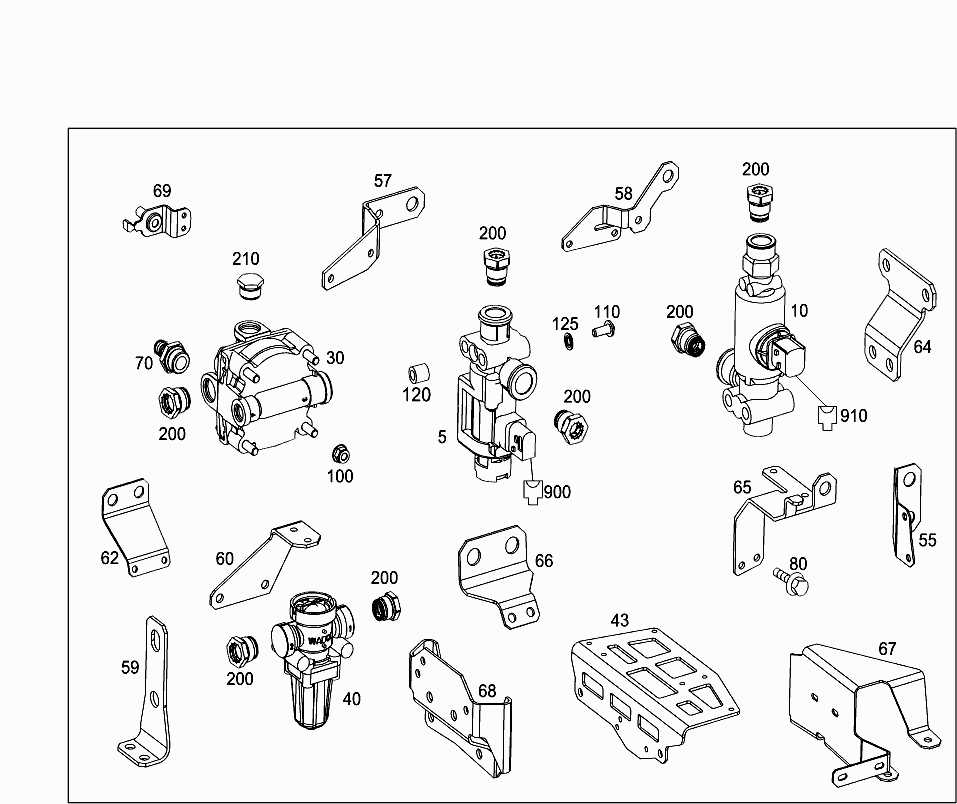

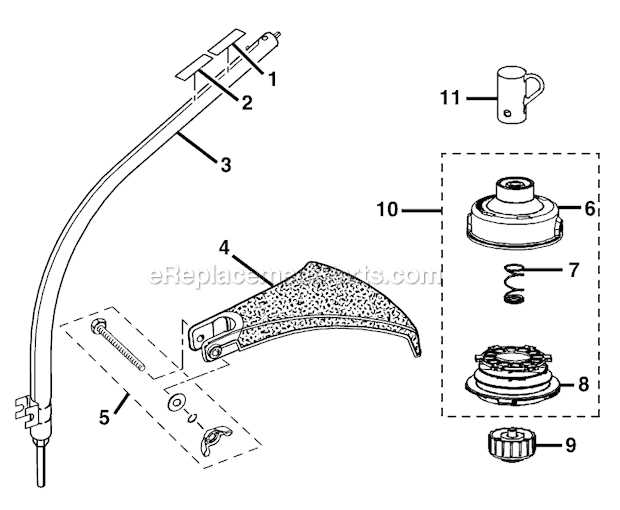

The fuel system is a crucial component that ensures the smooth operation of combustion machinery. It is responsible for delivering the necessary fuel to the engine, enabling efficient energy conversion. Understanding the individual components of this system and their roles can help maintain and optimize engine performance.

|

|---|