When maintaining garden equipment, having a clear overview of its various components is essential for optimal performance and longevity. This section will provide insight into the intricate parts of your gardening tool, helping you identify and manage each element effectively.

From the engine to the handling mechanisms, each component plays a crucial role in ensuring smooth operation. By familiarizing yourself with these elements, you can not only troubleshoot issues more effectively but also enhance the overall efficiency of your equipment.

In addition, understanding the configuration of these elements allows for better care and timely replacements, ensuring that your gardening tasks are performed without unnecessary interruptions. This guide aims to delve into the essential features and arrangements that define your gardening equipment.

Understanding Ryobi Tiller Components

Grasping the elements of gardening machinery is essential for efficient operation and maintenance. Each component plays a crucial role in the overall functionality, ensuring that tasks like soil preparation are carried out effectively. A comprehensive understanding of these elements not only enhances performance but also extends the lifespan of the equipment.

Key Elements: The primary components include the engine, which provides power; the tines, responsible for breaking up the soil; and the wheels, which aid in maneuverability. Additionally, there are various control mechanisms that enable the user to adjust settings for different gardening tasks.

Maintenance Tips: Regular inspection and servicing of these elements can prevent breakdowns. It’s advisable to consult the user manual for specific guidelines on maintaining each component, as proper care can significantly improve performance and durability.

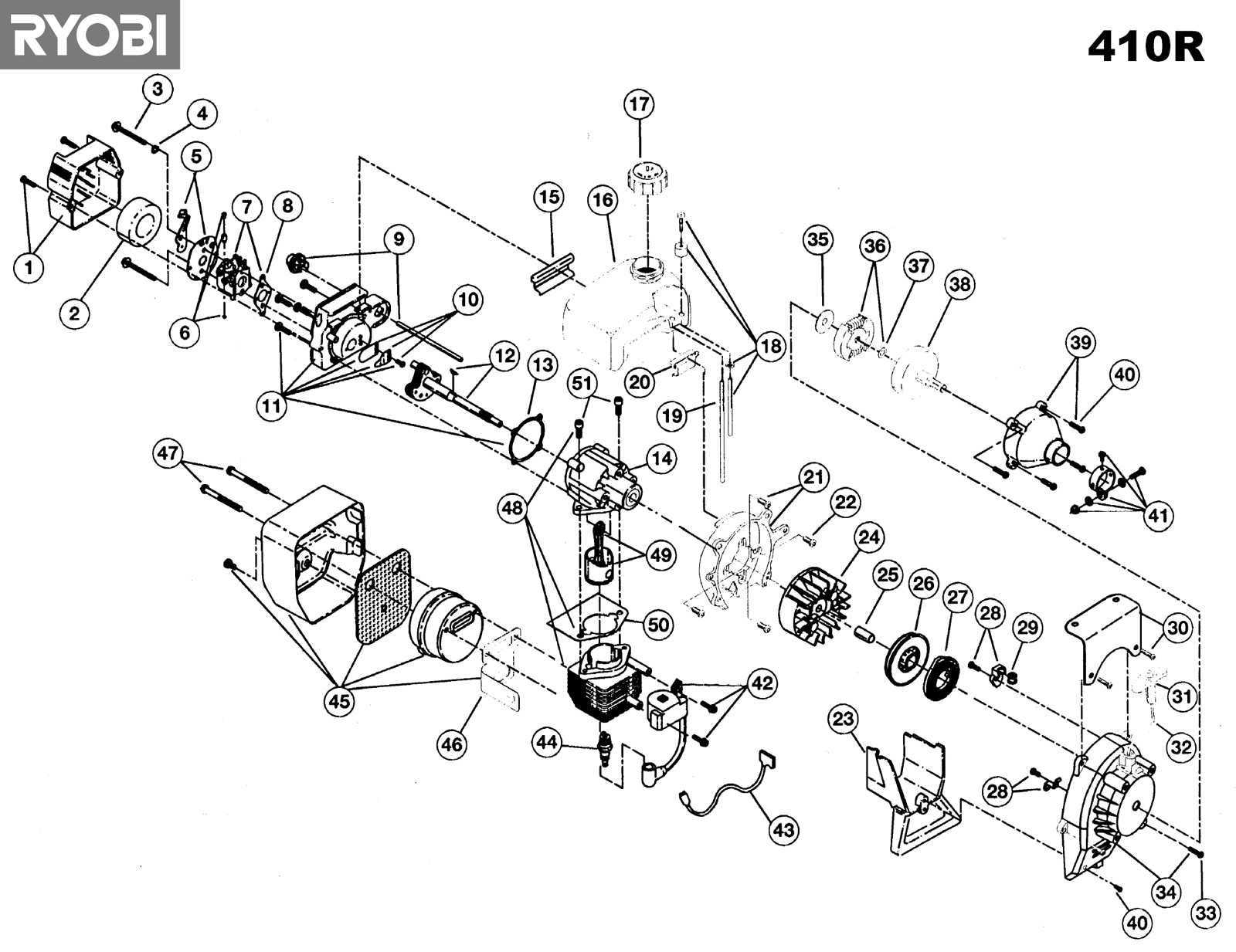

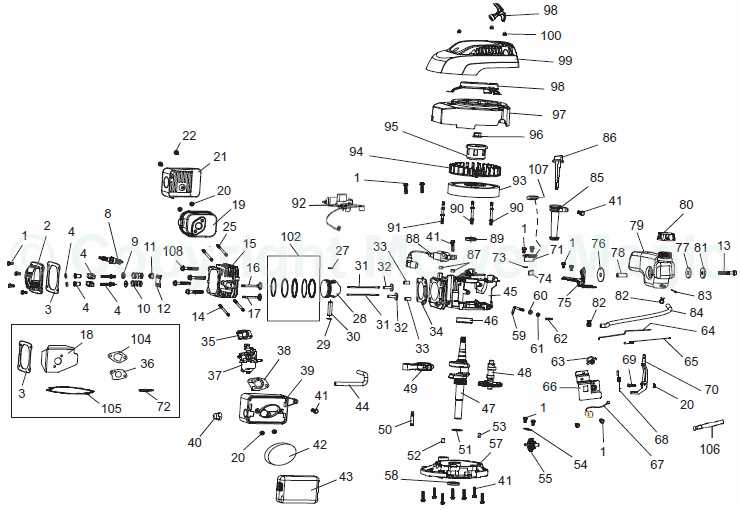

Importance of Parts Diagrams

Understanding the layout and components of equipment is crucial for effective maintenance and repair. Clear representations of each element not only enhance the ability to identify specific pieces but also facilitate the troubleshooting process. These visual aids serve as valuable references for both novice users and seasoned professionals, ensuring that every aspect is comprehended and addressed appropriately.

Benefits of Visual Guides

Visual schematics offer numerous advantages, including:

| Advantage | Description |

|---|---|

| Enhanced Understanding | Visuals provide a clearer grasp of how each component interacts within the whole. |

| Efficient Repairs | Knowing where parts are located speeds up the repair process. |

| Reduction of Errors | Visual aids help minimize mistakes during assembly or disassembly. |

Conclusion

Having access to accurate representations of machinery is essential for maintaining optimal performance. Such resources not only empower users but also extend the lifespan of the equipment, ultimately leading to cost savings and increased efficiency.

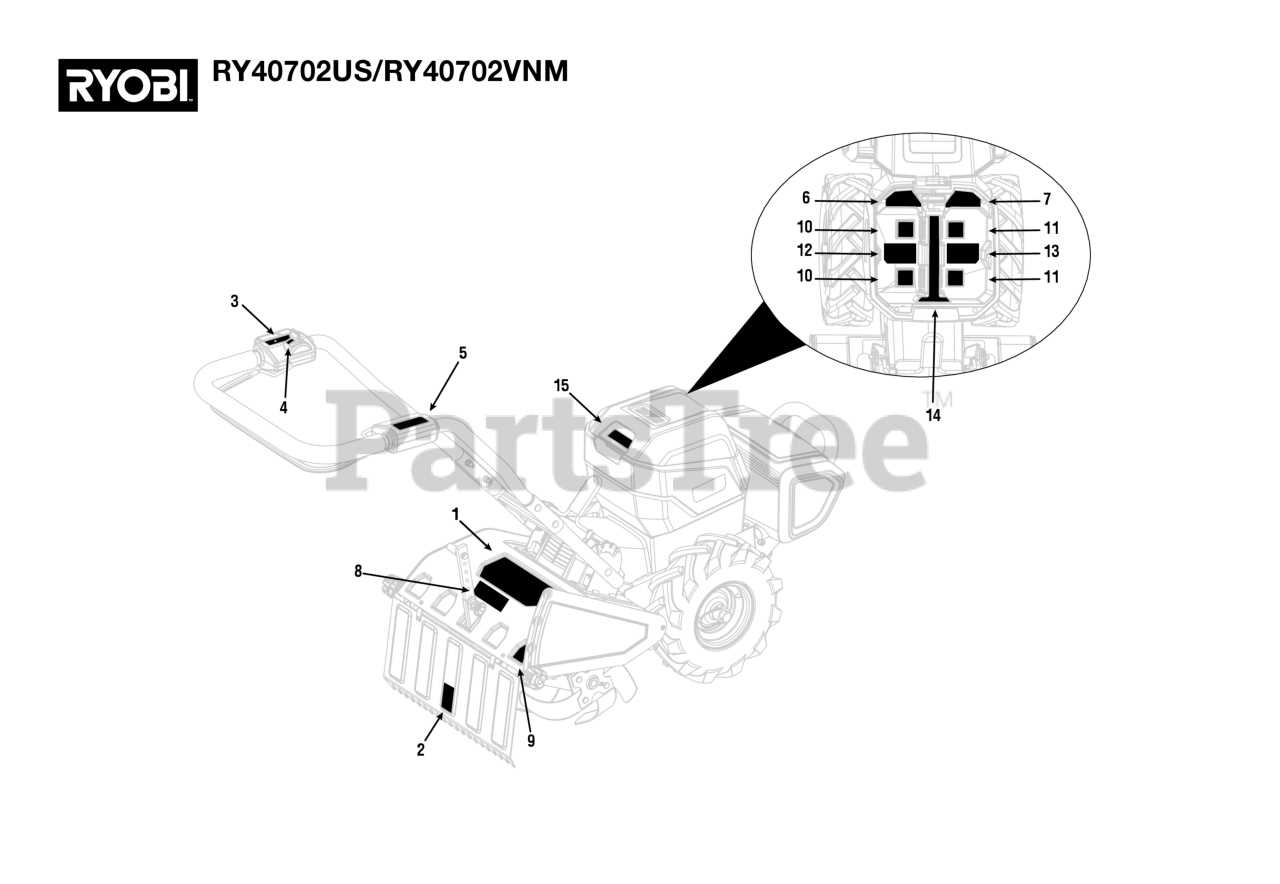

Common Ryobi Tiller Models

This section highlights several popular models of garden cultivators, showcasing their features and specifications. These machines are designed to help users effectively manage their gardening tasks, offering various options to suit different needs.

Here are some frequently encountered models:

- Model A: Known for its lightweight design and user-friendly controls, making it ideal for small gardens.

- Model B: Offers a powerful motor and enhanced tilling depth, perfect for larger areas and tougher soil conditions.

- Model C: Features adjustable handles and a compact structure, catering to urban gardeners with limited space.

- Model D: Equipped with advanced technology for efficient performance, suitable for both novice and experienced users.

Each of these cultivators is designed to meet specific gardening demands, ensuring that there is a suitable option for everyone.

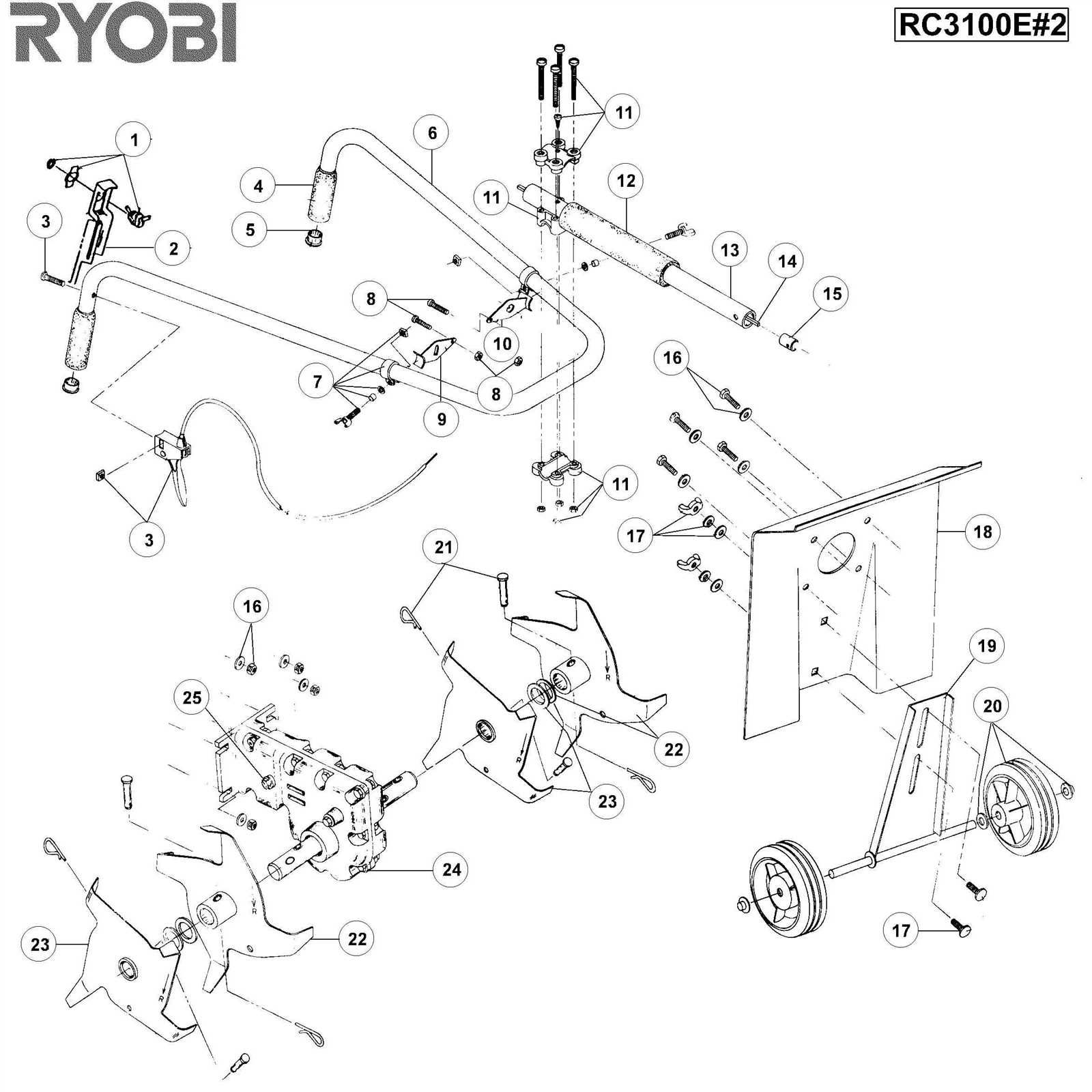

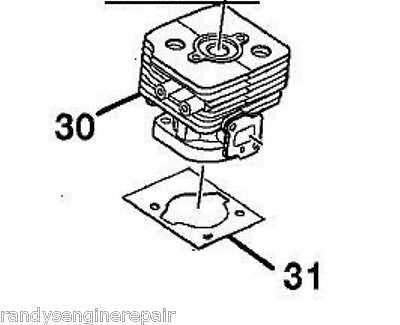

Key Parts of a Tiller Explained

Understanding the essential components of garden cultivation equipment is crucial for efficient operation and maintenance. Each element plays a vital role in enhancing performance, ensuring that tasks like soil preparation are carried out effectively. This section will delve into the main components, offering insights into their functions and importance.

Engine and Power System

The engine serves as the powerhouse, providing the necessary energy to drive the machinery. Typically, these systems are designed for durability and efficiency, ensuring optimal performance over time. The power delivery mechanism, often involving a series of gears and belts, facilitates smooth operation and adaptability to various soil conditions.

Working Tools

The working tools, commonly known as tines or blades, are crucial for breaking up and aerating the soil. These components are engineered to penetrate the earth, allowing for better nutrient absorption and root growth. Different designs and configurations can influence their effectiveness, making it essential to choose the right type for specific gardening needs.

In summary, a thorough understanding of these critical components not only aids in effective use but also enhances longevity and reliability in the field.

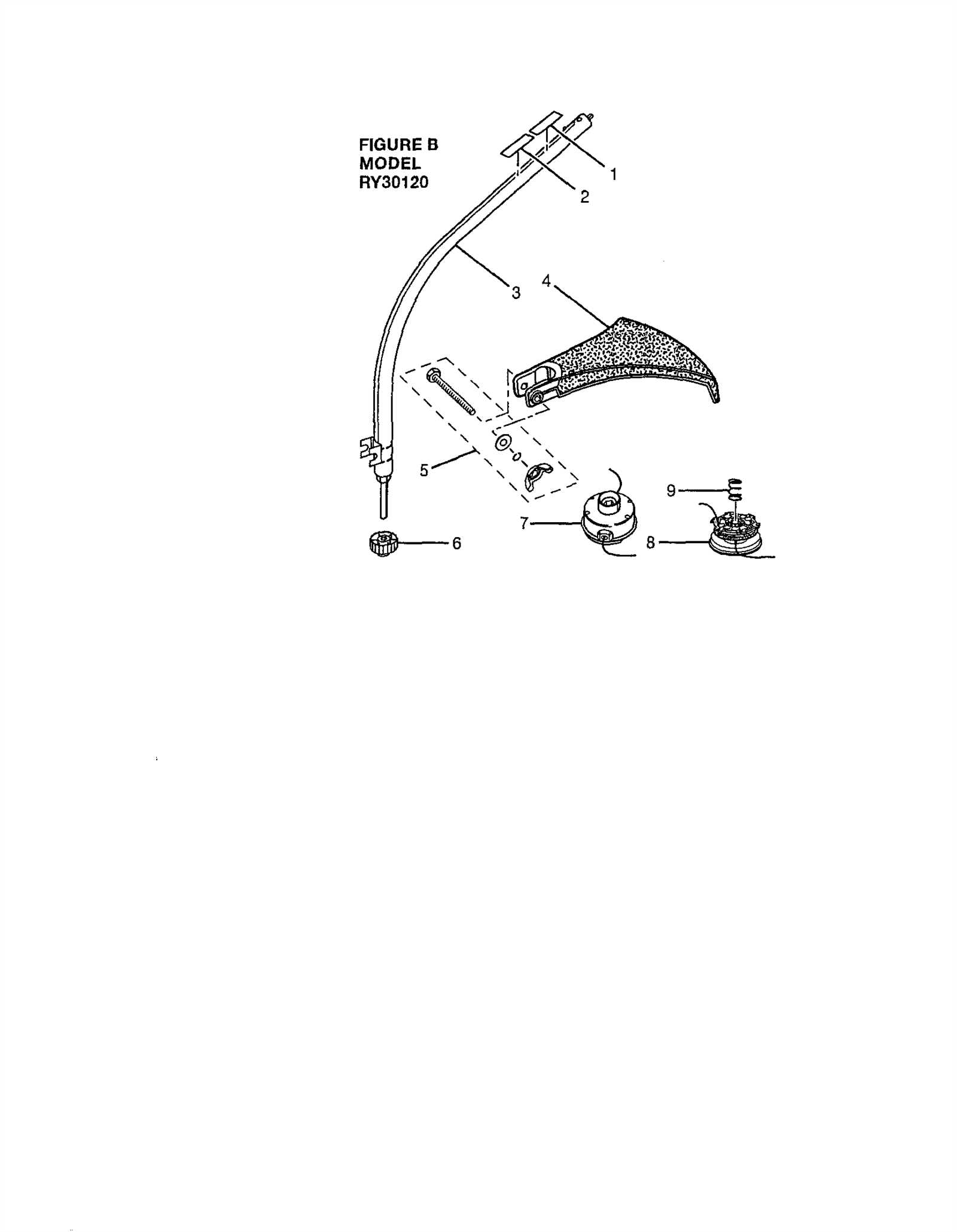

Identifying Replacement Parts Easily

Understanding how to locate and select components for your gardening equipment can greatly enhance its efficiency and lifespan. Recognizing the right elements ensures that repairs are straightforward and effective, allowing you to maintain optimal performance with minimal hassle.

Utilizing Reference Guides

One of the most effective methods to identify the necessary components is through comprehensive reference guides. These resources typically include illustrations and specifications, making it easier to match the required item with its corresponding model. Taking the time to consult these guides can save you both time and frustration.

Leveraging Online Resources

The internet is a valuable tool for finding information about specific components. Numerous websites provide searchable databases that can help you pinpoint the exact item you need. Engaging with online forums and communities can also provide insights from fellow users who have encountered similar issues, offering advice on compatibility and quality.

In summary, effective identification of components relies on utilizing reference materials and online platforms. By being proactive in your search, you can ensure that your gardening tools remain in excellent working condition.

How to Read Diagrams Effectively

Understanding visual representations of complex systems is crucial for effective maintenance and repairs. These illustrations serve as guides, simplifying intricate components and their relationships. By mastering the art of interpreting these visuals, users can enhance their problem-solving skills and make informed decisions.

Key Steps to Interpretation

- Familiarize Yourself with Symbols: Different illustrations utilize unique symbols. Take time to learn what each represents to avoid confusion.

- Identify Major Components: Start by locating the main elements. This helps in grasping the overall structure and flow.

- Follow the Connections: Pay attention to how parts are linked. Arrows and lines indicate movement and interaction, essential for understanding functionality.

- Refer to the Legend: Most visuals include a legend or key. This provides additional clarity on the symbols used and their meanings.

Tips for Enhanced Understanding

- Take Notes: Jot down important details as you analyze the visual. This aids retention and understanding.

- Cross-Reference with Manuals: Use accompanying documents to gain deeper insights into specific components and their functions.

- Practice Regularly: The more you engage with these visuals, the more intuitive interpretation becomes.

- Seek Help if Needed: Don’t hesitate to consult experts or online resources if you encounter difficulties.

Maintenance Tips for Ryobi Tillers

Proper upkeep is essential for ensuring the longevity and efficiency of your gardening equipment. Regular maintenance not only enhances performance but also prevents costly repairs in the future.

- Check and clean air filters regularly to ensure optimal airflow.

- Inspect and replace spark plugs as needed to maintain engine performance.

- Keep the blades sharp for effective soil cultivation.

- Regularly examine and tighten bolts and screws to prevent wear and tear.

Additionally, always refer to the manufacturer’s guidelines for specific maintenance intervals and procedures.

Where to Find Parts Diagrams

Understanding the components of your equipment is essential for effective maintenance and repair. Accessing detailed schematics can greatly simplify the process of identifying and sourcing the necessary items. Various resources are available to help users find these informative illustrations.

Online Resources

The internet offers a plethora of websites dedicated to machinery and tool repairs. Manufacturer websites often provide downloadable guides, while forums and specialized repair sites can also be valuable sources. Utilizing search engines with specific queries will yield numerous results, helping enthusiasts to delve deeper into the subject.

Local Retailers and Repair Shops

Many local stores that specialize in outdoor equipment often maintain physical copies of component illustrations. Additionally, professional repair shops can be a great resource, as they usually possess extensive knowledge and may even share copies of relevant materials. Don’t hesitate to ask for assistance; the ultimate goal is to ensure your equipment functions smoothly.

Using OEM vs. Aftermarket Parts

The choice between original components and alternatives can significantly impact the performance and longevity of your equipment. Understanding the differences between these options is crucial for making informed decisions that affect efficiency and reliability.

Original components are designed and manufactured by the same company that produced the machinery. They often ensure a perfect fit and compatibility, which can lead to better overall performance. Users frequently report higher satisfaction with these components due to their adherence to specific standards set by the manufacturer.

On the other hand, alternative components are produced by third-party manufacturers and may offer cost advantages. These options can be appealing for budget-conscious individuals. However, the quality can vary significantly, and some alternatives might not meet the same durability or performance benchmarks as their original counterparts. It’s essential to conduct thorough research and consider reviews when opting for these components.

In conclusion, the decision to use original or alternative components should be based on individual needs, budget constraints, and long-term performance expectations. Balancing cost with quality is key to maintaining optimal functionality in your equipment.

Common Issues with Tiller Parts

When operating soil cultivation equipment, users often encounter various challenges that can hinder performance. Understanding these frequent problems is essential for maintaining efficiency and prolonging the lifespan of the machine.

Frequent Mechanical Failures

Mechanical failures can manifest in several forms, impacting functionality and reliability. Common issues include wear and tear of components, leading to decreased power transfer and operational inefficiency.

Maintenance Oversights

Neglecting regular upkeep can result in significant complications. Proper care, including lubrication and cleaning, is crucial to avoid issues that could escalate and require costly repairs.

| Issue | Description | Solution |

|---|---|---|

| Worn Blades | Reduced cutting efficiency. | Regular sharpening or replacement. |

| Loose Bolts | Components may come apart during use. | Frequent inspections and tightening. |

| Clogged Filters | Engine overheating and performance drops. | Regular cleaning or replacement of filters. |

Step-by-Step Repair Guide

Repairing garden equipment can seem daunting, but with the right approach, it becomes a manageable task. This guide will walk you through a systematic process to address common issues, ensuring your machine functions optimally once more.

1. Identify the Problem: Start by observing the equipment’s performance. Is it struggling to operate, making unusual noises, or exhibiting signs of wear? Documenting these symptoms will help narrow down potential issues.

2. Gather Necessary Tools: Before diving into repairs, collect all essential tools. Commonly needed items include wrenches, screwdrivers, pliers, and replacement components. Having everything on hand will streamline the process.

3. Consult the Manual: Refer to the user manual for specific instructions related to your model. It often contains troubleshooting tips and a breakdown of components, which can be invaluable during repairs.

4. Disassemble the Equipment: Carefully disassemble the machine by removing screws and components. Keep track of all parts to ensure they are reassembled correctly. Take photos during this step for reference.

5. Inspect and Replace: Examine each part for damage or wear. If you find any broken or malfunctioning components, replace them with new ones. Ensure that replacements are compatible with your model.

6. Reassemble: Once repairs are made, carefully reassemble the equipment. Follow your documentation and any photos taken to ensure all pieces fit back together as they should.

7. Test the Equipment: After reassembly, conduct a thorough test to ensure everything is functioning properly. Monitor for any persistent issues, and if necessary, revisit the earlier steps.

By following these steps, you can effectively address and resolve common problems with your garden machinery, extending its life and performance.

Tools Needed for Tiller Repairs

When it comes to maintaining and fixing garden machinery, having the right equipment is essential. Proper tools not only facilitate the repair process but also ensure that tasks are completed efficiently and safely. Here, we’ll explore the necessary implements that every user should have on hand for effective maintenance.

Essential Hand Tools

Start with a set of basic hand tools. A screwdriver set, including both flathead and Phillips options, is vital for loosening and tightening screws. Additionally, wrenches in various sizes will be crucial for adjusting nuts and bolts. Pliers are also necessary for gripping and manipulating small components during repairs.

Specialized Equipment

Beyond the basics, some specialized tools can make a significant difference. A socket set allows for easier access to tight spaces, while a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications. For more complex repairs, having a multimeter can help diagnose electrical issues, making troubleshooting much more manageable.

Safety Precautions During Maintenance

Ensuring safety while performing upkeep tasks is paramount. Proper precautions can prevent accidents and ensure the longevity of the equipment. Adhering to these guidelines will help maintain a secure working environment.

Preparation and Personal Protective Equipment

Before starting any maintenance, gather the necessary tools and ensure the workspace is clear. Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear. This equipment is essential for minimizing risks during operation.

Power and Fuel Management

Disconnect the power source and allow the engine to cool before beginning any repairs. If applicable, drain any fuel to prevent spills and potential hazards. Working with energy sources can be dangerous; thus, handling them with care is critical.