In this section, we explore a detailed breakdown of essential elements that contribute to the optimal functionality of a well-known machine. Whether you’re maintaining or repairing, understanding the core structure of these elements is crucial for ensuring reliable performance during winter months.

These components play a significant role in enhancing the operational efficiency of the machine, and knowing their arrangement helps avoid common issues. By diving into the technical layout, you can gain a deeper insight into how each part works together seamlessly.

Proper maintenance and periodic checks ensure that your equipment continues to function smoothly, even in the toughest conditions. Here, we provide a thorough explanation of how these mechanical elements fit into the larger system, helping you keep everything running efficiently.

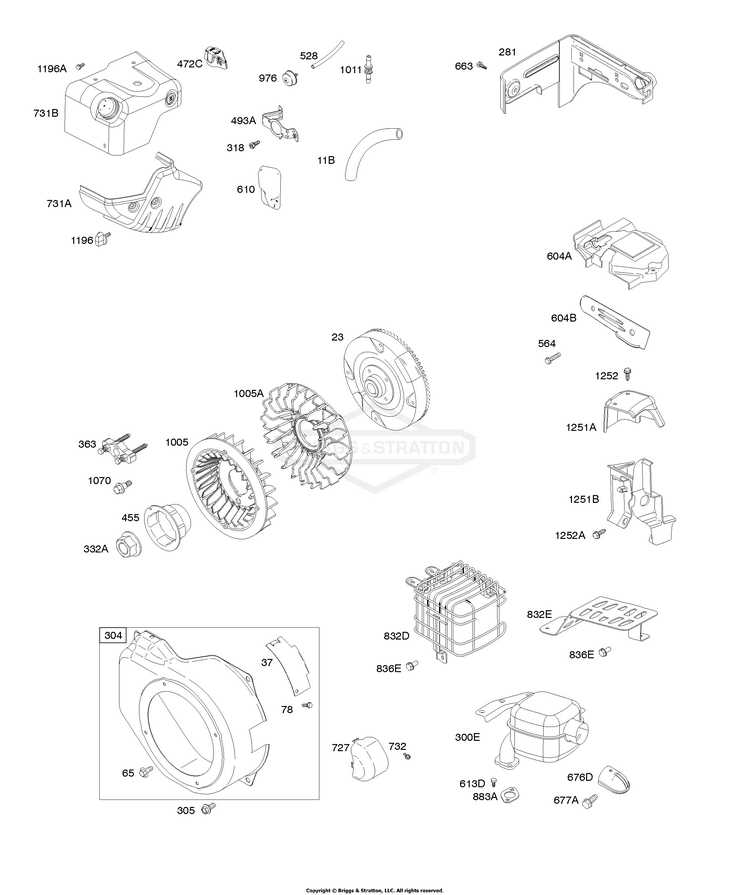

Briggs and Stratton Snowblower Component Overview

The efficient functionality of a modern outdoor clearing machine relies on a combination of key mechanical elements working together to ensure smooth operation. These essential parts contribute to both its durability and performance, providing users with a reliable solution for heavy-duty outdoor tasks. Below is a detailed examination of some of the major elements that play a vital role in the machine’s efficiency.

| Component | Description | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Unit | The power source responsible for generating the necessary energy to drive the entire system. Its reliability determines the machine’s overall effectiveness in tough conditions. | ||||||||||

| Auger System | This rotating mechanism is crucial for collecting and moving outdoor material into the discharge chute, making clearing operations

Understanding Key Engine ComponentsThe internal structure of a typical engine relies on several vital components that work together to ensure smooth operation and performance. Each element within the system plays a crucial role in transforming energy into motion, making it essential to grasp how these parts function collectively. Pistons and Crankshaft

Pistons are responsible for converting the pressure from combustion into mechanical energy. As they move within the cylinders, the crankshaft transforms this linear motion into rotational force, powering various mechanisms in the system. Ignition and Fuel SystemThe ignition system triggers the combustion process by igniting the air-fuel mixture. The fuel system, including injectors and fuel pump, ensures a precise delivery of fuel, maintaining efficiency and performance. Together, these systems provide the necessary energy for engine operation. Exploring the Carburetor StructureThe carburetor is a crucial component responsible for blending air and fuel to ensure optimal engine performance. Understanding its internal structure can help identify how it influences engine efficiency and functionality. Properly maintained, this mechanism can enhance the operation of the machine and extend its lifespan. Below is an overview of the primary sections of the carburetor and their roles in regulating fuel delivery and airflow:

Fuel System Layout and DesignThe fuel system plays a crucial role in ensuring the proper operation of any engine. Its configuration and flow pathways are designed to efficiently deliver the correct amount of fuel to the combustion chamber, enhancing performance and reliability. A well-maintained fuel system is essential for optimal engine functioning, as it influences both fuel efficiency and power output. Key Components of this system include the fuel tank, filters, and carburetor, each contributing to the smooth movement of fuel. The fuel travels through these components, ensuring that impurities are filtered and the proper air-fuel mixture reaches the engine. System design is focused on minimizing blockages and ensuring consistent fuel delivery, even under varying conditions. Regular inspection and cleaning of fuel filters and carburetors are important maintenance practices to avoid disruptions in fuel flow. Examining the Ignition System

The ignition setup is a critical component in ensuring the smooth operation of an engine. It initiates the combustion process by creating the necessary spark to ignite the air-fuel mixture, resulting in the engine’s power output. Understanding its structure and function can help in diagnosing and maintaining the system effectively. Main Components

The ignition system consists of several key elements, including the spark plug, magneto, and wiring. Each part plays a vital role in generating the spark required for the engine to start and run efficiently. Regular checks and maintenance of these components can help prevent common issues such as misfires or weak starts. Signs of Faulty OperationCommon indicators of problems in the ignition system include difficulty starting, sudden power loss, or uneven engine performance. By identifying these signs early, you can take steps to address potential issues and ensure the long-term reliability of the machine. Detailed Look at the MufflerThe muffler plays a crucial role in reducing noise produced by the engine during operation. It serves to direct exhaust gases away from the machine while minimizing sound levels, contributing to a more pleasant working environment. Construction and Design The design typically incorporates multiple chambers that work together to dissipate sound waves. This construction is essential for effective noise reduction and enhances the overall performance of the machine. Maintenance Considerations Regular inspection of the muffler is necessary to ensure optimal functioning. Accumulation of debris or damage can hinder performance, leading to increased noise levels and potential engine issues. Keeping the muffler clean and checking for any signs of wear can significantly extend its lifespan. How the Starter Mechanism WorksThe starter mechanism is a crucial component that initiates the operation of an engine. It functions by transforming electrical energy into mechanical motion, enabling the engine to start efficiently. This process involves several parts that work in harmony to achieve the desired result. Key Components

Operational Steps

This series of actions allows the engine to start and run smoothly, highlighting the importance of each component in the mechanism. Air Filter Functionality and Placement

The air filtration system is crucial for ensuring optimal engine performance. It serves to purify incoming air, preventing dust and debris from entering the combustion chamber. A clean airflow enhances fuel efficiency and reduces the risk of engine wear, thus extending the life of the machinery. Importance of Proper PlacementCorrect positioning of the air filter is essential for maintaining its effectiveness. It should be installed in a way that allows for unobstructed airflow while being shielded from contaminants. Regular checks on the filter’s location can help in identifying any potential blockages that could hinder its function. Maintenance TipsRoutine maintenance of the air filter involves cleaning or replacing it as needed. Inspecting the filter regularly can help ensure that it operates efficiently. A clogged or dirty filter can lead to decreased engine performance and increased fuel consumption, making it vital to adhere to maintenance schedules. Common Parts of the Throttle SystemThe throttle mechanism is essential for regulating the engine’s power output and ensuring optimal performance. It consists of various components that work in harmony to control airflow and fuel mixture, allowing for smooth operation across different conditions. Key elements of this mechanism include the throttle cable, which connects the control lever to the throttle plate, enabling the user to adjust engine speed effortlessly. The throttle plate itself is a pivotal part that opens and closes, controlling the flow of air into the engine. Another important component is the return spring, which ensures that the throttle plate returns to its closed position when not in use. Additionally, the governor arm plays a crucial role in maintaining a consistent engine speed by regulating the throttle plate’s position based on load and speed variations. Understanding these components helps in troubleshooting and maintaining the throttle system, ensuring reliable performance in various operating conditions. Dissecting the Flywheel AssemblyThe flywheel assembly plays a crucial role in the operation of small engines, particularly in terms of maintaining momentum and balancing the rotational forces. Understanding its components and functionality can enhance maintenance and repair efforts, ensuring optimal performance. Components of the Flywheel Assembly

Functionality and Maintenance TipsRegular inspection of the flywheel assembly is essential for maintaining engine efficiency. Key aspects to consider include:

Examining Snowblower Auger PartsUnderstanding the components of a snow-clearing machine is essential for optimal performance during winter conditions. The auger assembly plays a pivotal role in efficiently moving snow, making it crucial to familiarize oneself with its structure and function. The auger system is typically composed of several key elements, each contributing to the overall effectiveness of the device. Blades are designed to cut through and collect snow, while the housing encases the mechanism, providing support and durability. Additionally, the drive mechanism ensures that the auger rotates smoothly, allowing for consistent snow removal. Regular maintenance and inspection of these components can greatly enhance the longevity of the equipment. Identifying wear or damage early can prevent more significant issues and ensure that the machine operates at peak efficiency. Investing time in understanding these elements will lead to a more reliable and effective snow-clearing experience. Transmission Components and Their RoleThe transmission system is a vital element in the operation of snow-clearing machinery, facilitating power transfer from the engine to the wheels. This section explores the various components involved in the transmission process and their essential functions within the overall mechanism. Gears play a crucial role in adjusting speed and torque, allowing the machine to navigate different terrains effectively. By altering gear ratios, operators can achieve optimal performance under varying conditions. Belts are also key components, providing flexibility and ensuring smooth operation. They connect different parts of the transmission, absorbing shocks and vibrations to enhance durability and efficiency. Chain systems are utilized in many machines for their robustness and reliability. They maintain a constant connection between the engine and wheels, ensuring that power is transmitted efficiently, even under heavy loads. Understanding the functions of these components helps users maintain their machinery effectively, ensuring longevity and peak performance during use. Best Practices for Belt Maintenance

Proper upkeep of drive components is essential for optimal performance and longevity of machinery. Following certain guidelines can prevent premature wear and ensure efficient operation.

By implementing these best practices, operators can enhance the reliability and efficiency of their equipment, reducing downtime and maintenance costs. |