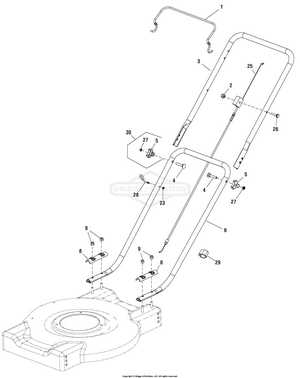

Exploring the intricacies of small engine components is essential for anyone looking to maintain or repair outdoor equipment. A thorough grasp of how each element interrelates can significantly enhance the efficiency and longevity of your machinery. This section delves into the visual representation of essential components, providing clarity and insight into their arrangement and functionality.

With a well-structured visual guide, users can easily identify individual parts, facilitating better understanding and informed decision-making during repairs or replacements. Recognizing the specific roles of each component not only streamlines the maintenance process but also minimizes the risk of errors that could lead to more significant issues down the line.

By engaging with these detailed layouts, enthusiasts and professionals alike can optimize their equipment’s performance. Whether you are troubleshooting a malfunction or performing routine upkeep, a comprehensive overview of engine elements serves as a valuable resource for effective management and care.

Understanding Briggs and Stratton 450e Series

This section explores the intricate workings of a specific engine model renowned for its reliability and performance. By examining the various components and their interactions, users can gain insights into the functionality and maintenance of this machinery.

Key Features

This engine is designed with efficiency in mind, offering robust power output and easy operation. Its user-friendly design simplifies maintenance tasks, making it accessible for both novices and seasoned users.

Maintenance Tips

Essential Components of 450e Engines

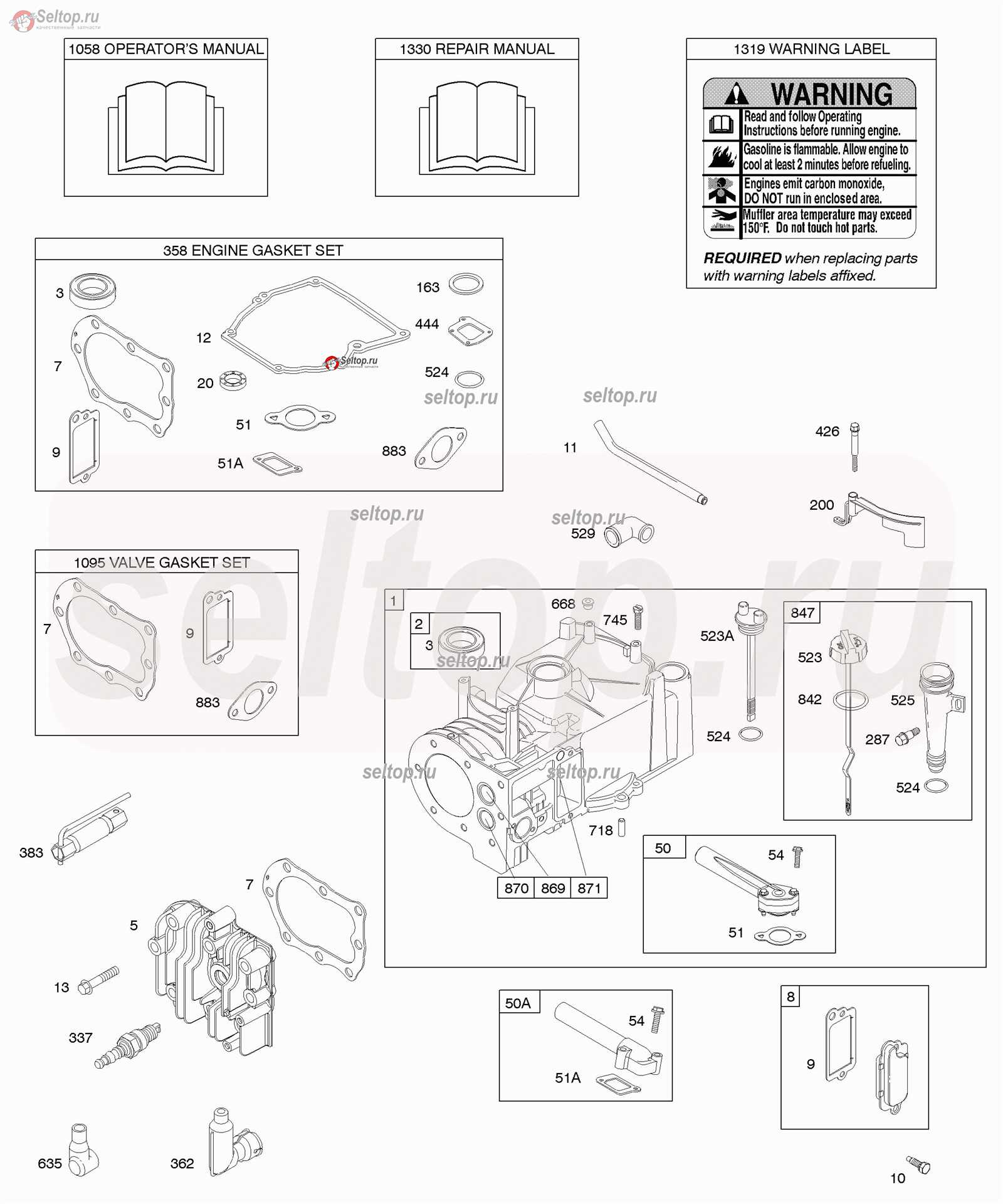

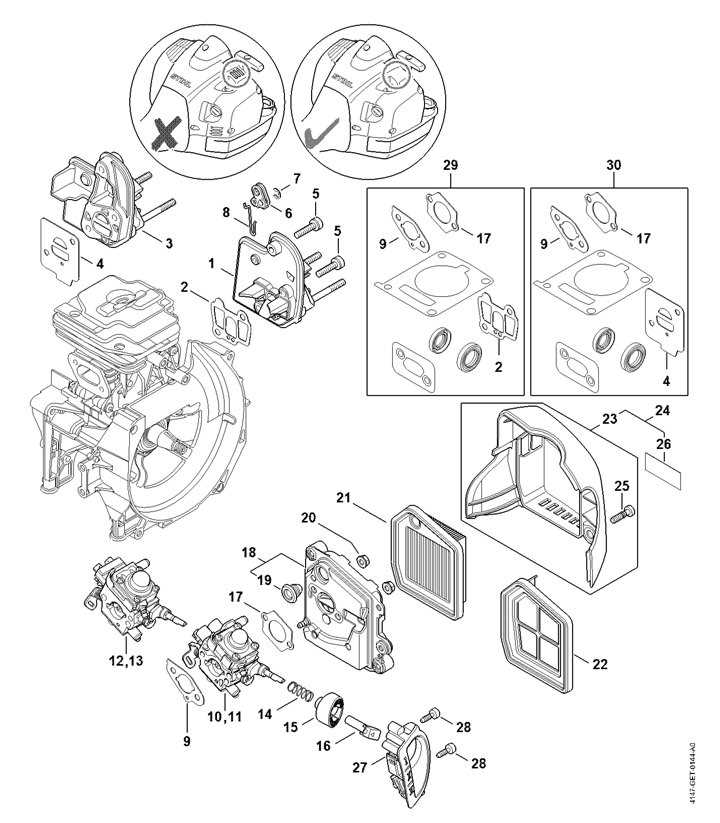

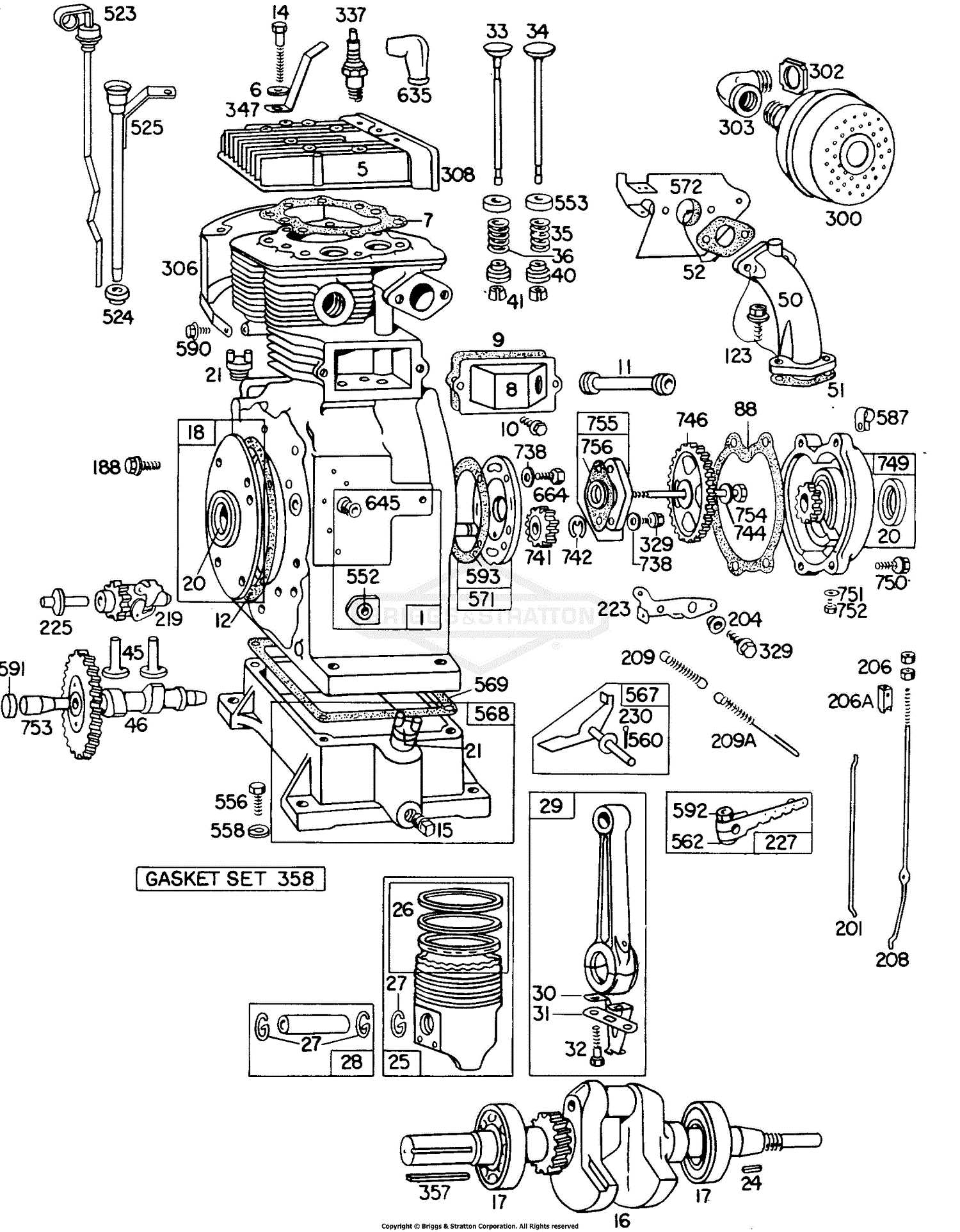

Understanding the fundamental elements of small power units is crucial for maintenance and performance enhancement. Each component plays a vital role in the overall functionality, contributing to the efficiency and reliability of the engine. Familiarity with these key parts allows users to troubleshoot issues effectively and optimize usage.

Core Elements

Among the most significant components are the cylinder, which houses the combustion process, and the crankshaft, responsible for converting linear motion into rotational energy. The valve system regulates airflow and fuel intake, ensuring optimal combustion conditions. Additionally, the ignition system ignites the fuel-air mixture, a critical step for engine start-up and operation.

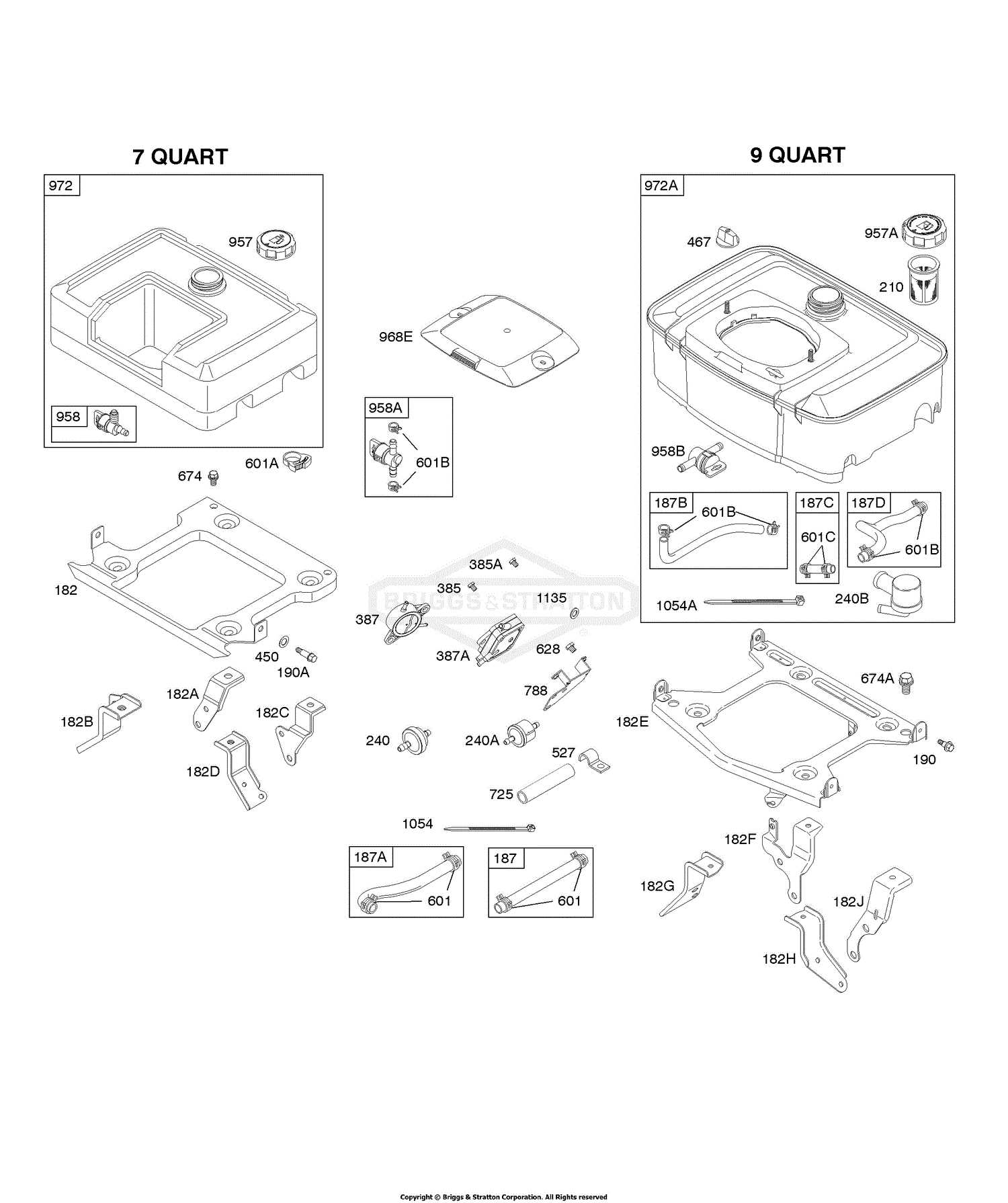

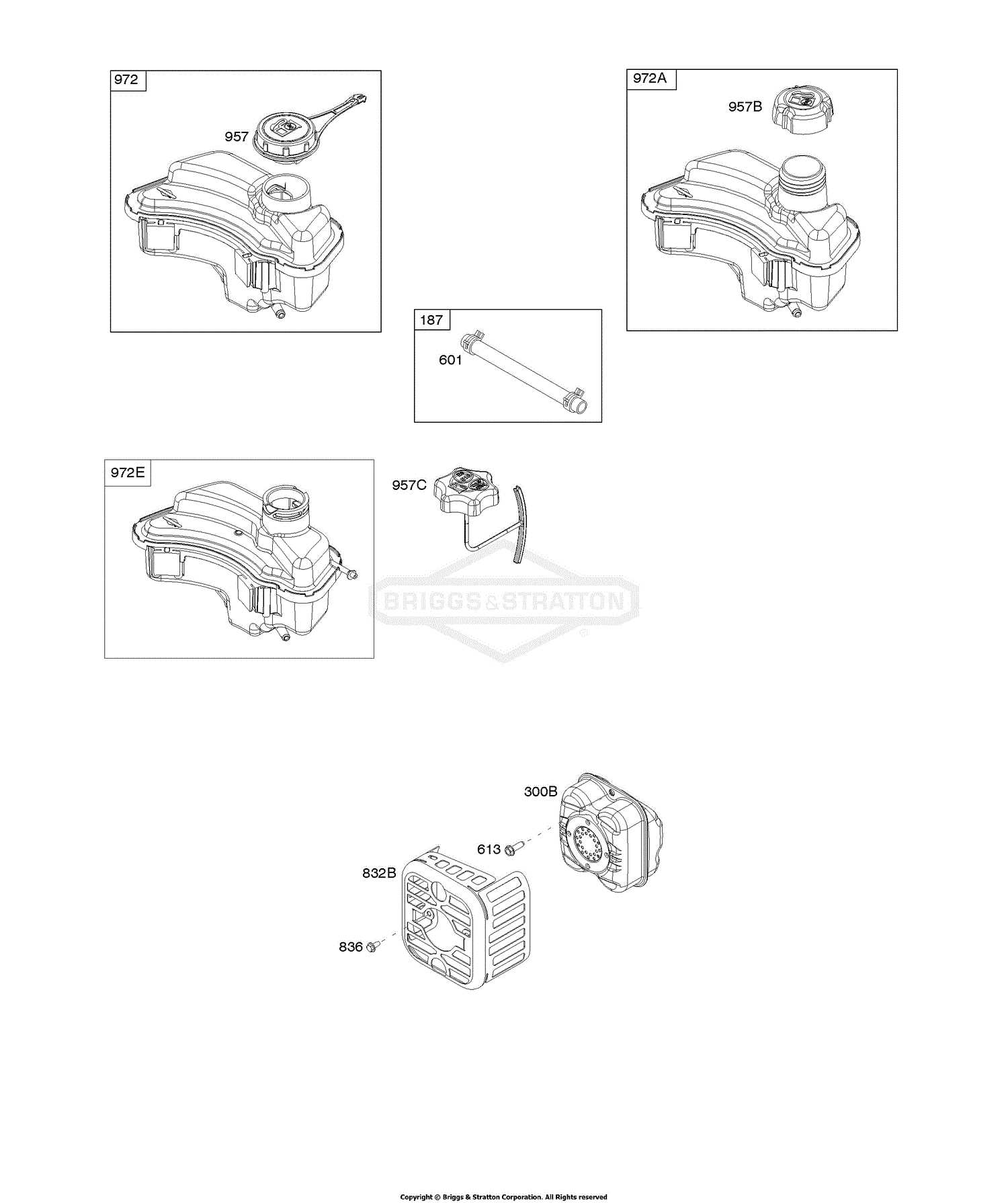

Supporting Mechanisms

Equally important are the fuel tank and carburetor, which work together to deliver the right mixture of fuel and air. The lubrication system ensures all moving parts operate smoothly, reducing friction and wear. Finally, the cooling system prevents overheating, maintaining the engine’s performance over extended use.

Common Issues with 450e Series Parts

Understanding frequent challenges encountered with these engine components can significantly enhance maintenance and operational efficiency. Proper identification of typical malfunctions not only aids in timely repairs but also prolongs the lifespan of the equipment.

| Issue | Description | Potential Solutions |

|---|---|---|

| Starting Difficulties | Engines may struggle to start due to fuel or spark plug issues. | Check fuel quality and replace spark plugs as needed. |

| Overheating | Excessive heat can lead to engine failure if cooling systems are compromised. | Ensure proper airflow and check coolant levels. |

| Uneven Performance | Engines may run inconsistently, causing erratic operation. | Inspect the air filter and fuel lines for blockages. |

| Oil Leaks | Leaks can lead to reduced lubrication and potential engine damage. | Examine seals and gaskets, replacing any that are worn. |

| Vibration Issues | Excessive vibration can indicate misalignment or loose components. | Tighten loose parts and ensure proper alignment of the engine. |

Importance of Regular Maintenance

Regular upkeep of equipment plays a crucial role in ensuring optimal performance and longevity. Consistent attention to maintenance not only enhances efficiency but also prevents potential breakdowns, ultimately saving time and money.

Enhancing Performance

When machinery is regularly serviced, it operates more smoothly, allowing for better fuel efficiency and reduced emissions. This contributes to an overall enhancement of functionality, making tasks easier and faster.

Preventing Costly Repairs

Proactive maintenance can identify issues before they escalate into significant problems. By addressing minor repairs early, users can avoid the high costs associated with major repairs and extend the lifespan of their equipment.

How to Identify Replacement Parts

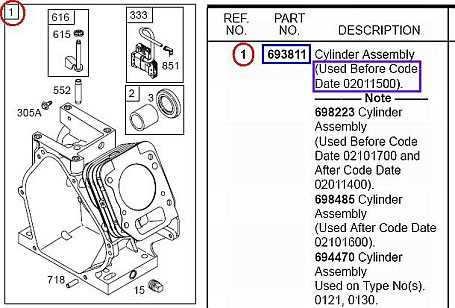

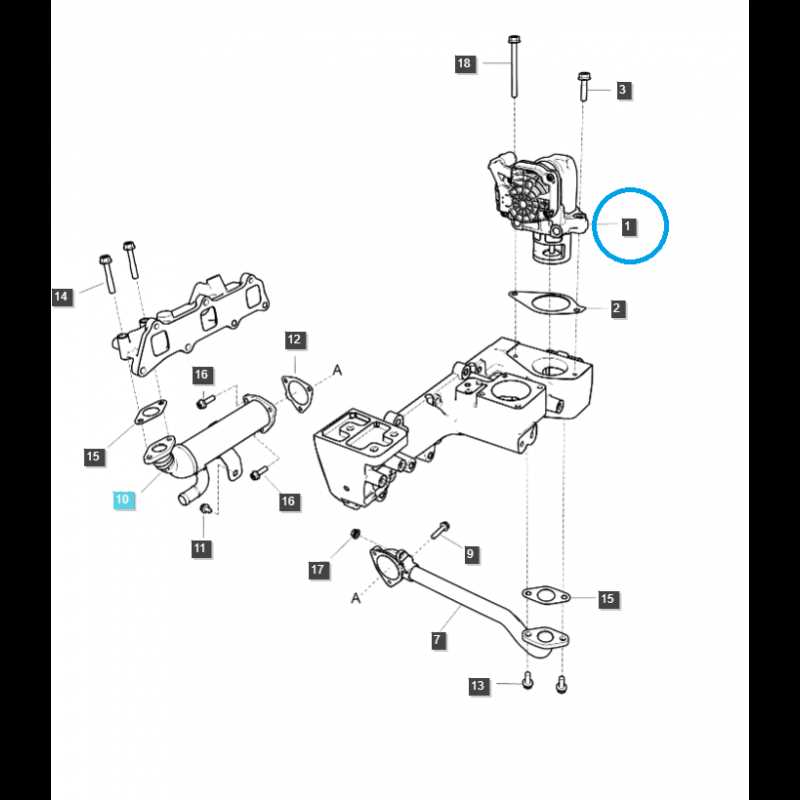

Understanding how to locate suitable components for your outdoor equipment is essential for maintaining its performance. When a part wears out or fails, knowing how to find the right replacement ensures that your machine continues to operate efficiently. This guide will help you navigate the process of identifying the necessary elements without confusion.

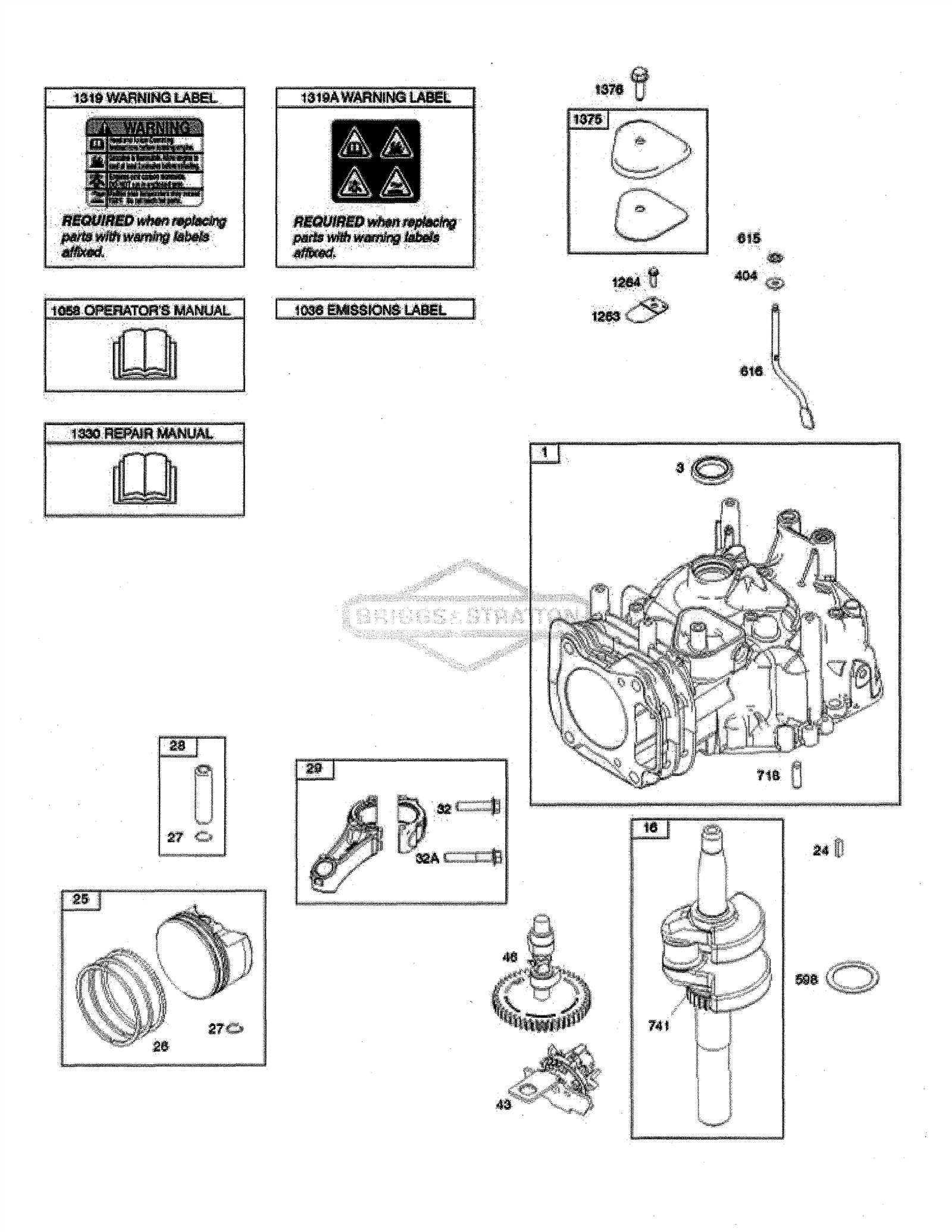

Start by checking the owner’s manual, which typically contains detailed information about the components used in your equipment. The manual often includes specifications, part numbers, and illustrations that can simplify the search for replacements. If you don’t have the manual on hand, many manufacturers provide digital copies online.

Next, inspect the damaged or worn component closely. Look for any identifying numbers or markings on the part itself, which can be crucial in finding an exact match. Make sure to take note of the dimensions, shape, and any unique features that can assist in the identification process.

Utilizing online resources is another effective method. Numerous websites offer comprehensive catalogs where you can search for components based on the model of your equipment. These platforms often feature user-friendly interfaces that allow you to filter results by various criteria.

Finally, consult with local dealers or repair shops. Their expertise can be invaluable when it comes to sourcing components. They can often recommend compatible alternatives or even assist in ordering the correct parts directly.

Tools Needed for Repairs

Having the right tools is essential for effective maintenance and repair tasks. Proper equipment not only simplifies the process but also enhances safety and precision. Whether you are a novice or a seasoned professional, understanding which instruments are necessary can significantly improve your efficiency.

For basic repairs, a set of wrenches and screwdrivers is indispensable. These tools allow you to tighten or loosen components easily. Additionally, pliers can be crucial for gripping and manipulating small parts. If you need to delve deeper into the assembly, consider investing in a torque wrench for accurate adjustments.

Moreover, having a reliable multimeter can help you troubleshoot electrical issues effectively. This tool provides valuable information about voltage, current, and resistance, allowing for more informed decisions during repairs. Lastly, always ensure you have safety gear, such as gloves and goggles, to protect yourself during the process.

Finding Genuine Parts Online

In today’s digital landscape, sourcing authentic components for outdoor equipment has become more accessible than ever. Consumers can leverage various online platforms to ensure they acquire quality items that enhance performance and longevity. However, navigating through countless options requires some discernment to avoid counterfeit alternatives.

Tips for Identifying Authentic Components

When searching for genuine items, consider the following strategies:

| Tip | Description |

|---|---|

| Research Retailers | Choose well-established sellers with positive reviews and a good reputation. |

| Check for Certifications | Look for certifications or seals indicating authenticity from manufacturers. |

| Compare Prices | Be wary of prices that seem too good to be true; they often signal fakes. |

| Read Product Descriptions | Thoroughly review descriptions to ensure compatibility and specifications match. |

Where to Shop

Numerous online marketplaces specialize in providing quality components. Consider official manufacturer websites or authorized distributors that guarantee genuine items. Additionally, popular e-commerce platforms often have sections dedicated to original products, ensuring a safer shopping experience.

Comparing Aftermarket and Original Parts

When maintaining or repairing small engines, the choice between manufacturer-certified components and third-party alternatives is crucial. Each option carries its own benefits and drawbacks, impacting performance, longevity, and cost. Understanding these differences can guide users in making informed decisions that align with their needs.

Quality and Performance

Original components often guarantee compatibility and reliability, as they are designed specifically for the engine model. In contrast, aftermarket items may vary in quality, with some outperforming originals while others fall short. It’s essential to evaluate the reputation of the brand and read reviews before purchasing.

Cost Considerations

Third-party components frequently offer a more budget-friendly alternative, making them attractive for those looking to save. However, it’s vital to balance cost with potential risks, as lower prices can sometimes indicate compromised quality. Ultimately, investing in dependable parts can lead to better long-term savings through enhanced performance.

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring a small engine, focusing on methodical troubleshooting and repair techniques. Following these steps will help ensure effective maintenance and longevity of your equipment.

- Begin by gathering all necessary tools and replacement components.

- Disconnect the power source to ensure safety during repairs.

- Carefully remove any coverings to access internal parts.

- Inspect each component for wear, damage, or corrosion.

- Consult the manual for specific guidance on disassembly.

- Replace any faulty parts with high-quality alternatives.

- Reassemble the unit in reverse order of disassembly.

- Reconnect the power source and perform a thorough test.

Regular maintenance following these steps can greatly enhance performance and reliability.

Upgrading Your 450e Engine

Enhancing the performance of your small engine can lead to improved efficiency and longevity. Whether you’re aiming for better power output or smoother operation, strategic upgrades can make a significant difference. Here, we will explore various options to elevate your engine’s capabilities.

Common Upgrade Options

- High-Performance Air Filters

- Modified Exhaust Systems

- Advanced Carburetors

- Improved Ignition Systems

Benefits of Upgrading

- Increased horsepower and torque.

- Enhanced fuel efficiency.

- Better overall reliability.

- Extended lifespan of components.

Resources for Further Learning

Expanding your knowledge about small engine maintenance and repair can greatly enhance your skills and understanding. A variety of resources are available to help enthusiasts and professionals alike. Whether you’re looking for technical guides, online courses, or community forums, the following information will guide you in the right direction.

Online Resources

| Resource Type | Website |

|---|---|

| Tutorials | Example Tutorials |

| Forums | Example Forums |

| Video Guides | Example Video Guides |

Books and Manuals

Consulting literature specific to engine repair can provide in-depth insights. Look for manuals that cover your engine model comprehensively, as well as books focusing on general repair techniques.