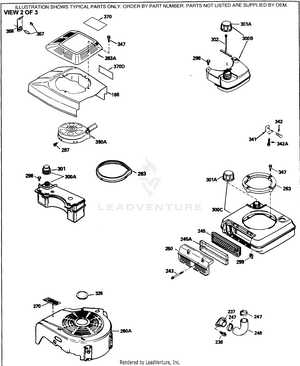

Understanding the key elements of small engines is essential for anyone involved in repair and maintenance. These systems consist of various interconnected parts, each playing a critical role in ensuring smooth operation and performance. A clear visual representation of these components can significantly aid in troubleshooting and assembly.

In this section, we will explore the various engine elements, highlighting their functions and importance. This guide will help you gain a better understanding of how individual components work together, providing clarity for both beginners and experienced mechanics.

Attention to detail is crucial when dealing with these systems, as even the smallest part can affect overall functionality. By familiarizing yourself with the internal structure of the engine, you will be able to identify potential issues and perform necessary repairs more efficiently.

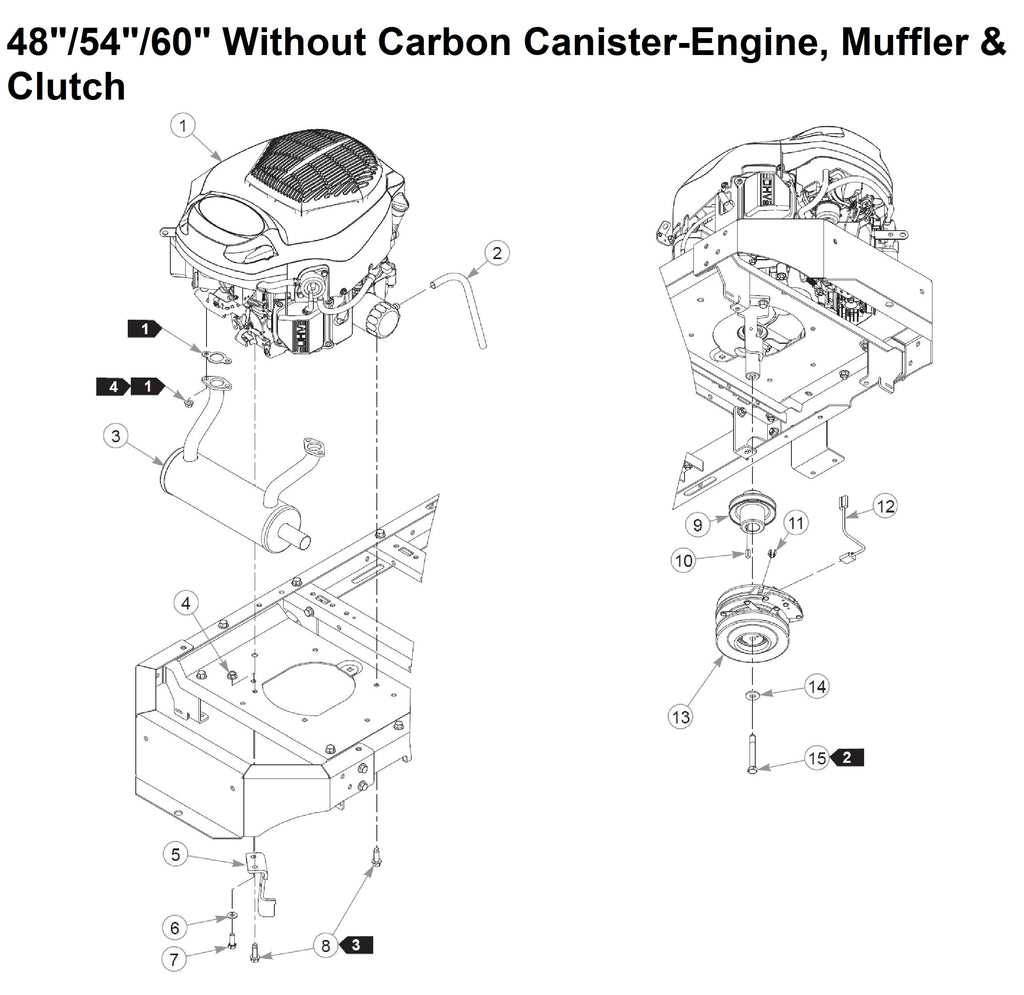

Understanding the Engine Mechanism

The engine is designed to provide reliable performance for a variety of small machines. Its efficient structure allows it to be used in numerous applications, delivering consistent power while maintaining durability. It’s essential to familiarize yourself with how the engine operates to ensure optimal functioning.

Below is a breakdown of key components:

- Fuel system: Responsible for delivering fuel to the combustion chamber, ensuring efficient energy conversion.

- Air filter: Prevents debris and dust from entering the engine, maintaining clean air intake.

- Cooling mechanism: Keeps the engine from overheating during operation, increasing longevity.

- Ignition system: Starts the engine and keeps it running smoothly through precise spark timing.

Regular maintenance of these elements can significantly extend the engine’s lifespan and performance.

Essential Engine Components Overview

Understanding the key components of an engine is crucial for maintaining its performance and ensuring longevity. Each part plays a vital role in the overall functionality of the machine, working together to provide efficient operation and power generation.

Below is a breakdown of the most important elements that contribute to a well-functioning engine:

- Cylinder Block – This is the core structure where the combustion process occurs, housing various other critical components.

- Piston – The piston moves within the cylinder, creating the necessary pressure for fuel combustion.

- Crankshaft – Converts the linear motion of the piston into rotational motion, powering the machine.

- Camshaft – Regulates the timing of the intake and exhaust valves, ensuring smooth engine operation.

- Valves – These control the flow of air and fuel into the engine and the release of exhaust gases.

Each of these components must be in good condition to keep the engine running efficiently. Regular maintenance and inspections can help prevent issues and prolong the life of the engine.

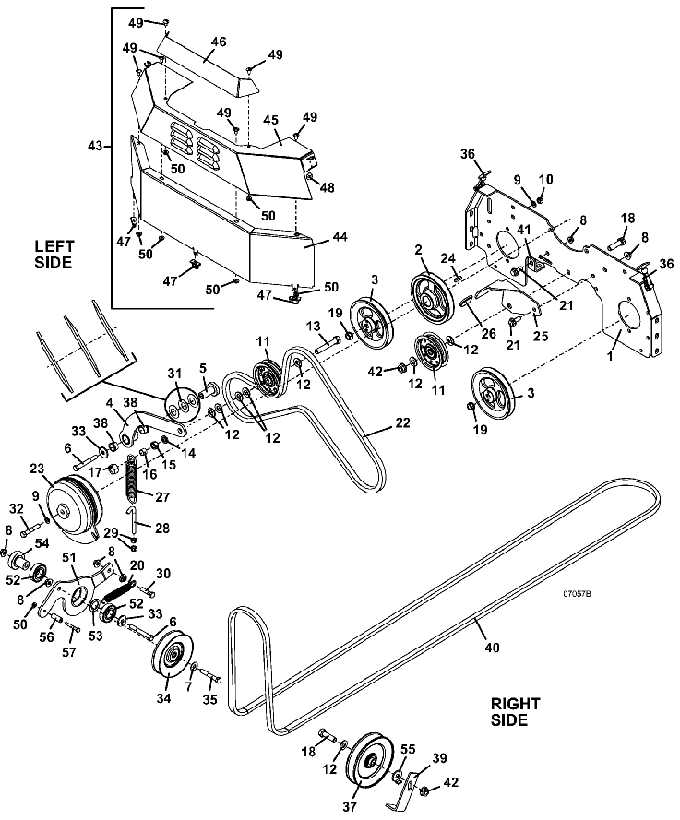

How to Identify Key Engine Parts

Understanding the main components of an engine is essential for proper maintenance and repair. Familiarizing yourself with the critical elements can help ensure the engine operates smoothly and efficiently. Whether it’s recognizing moving elements or stationary fixtures, knowing where to focus your attention is key.

Main Moving Components

The engine includes several important moving parts. The crankshaft is responsible for converting the up-and-down motion of the pistons into rotational energy. Pistons themselves move inside the cylinders, transferring energy from combustion to the crankshaft. Additionally, the camshaft regulates the timing of valve movements, ensuring proper fuel intake and exhaust.

Static Engine Components

Some parts remain stationary but play vital roles. The cylinder block forms the core structure, housing the moving components and supporting the engine’s overall frame. The cylinder head covers the top of the block, containing important parts like valves and spark plugs. Meanwhile, the oil pan sits below the engine, collecting and distributing lubrication to prevent wear.

Maintenance Tips for Longevity

Ensuring the long-term efficiency of your equipment requires regular care and attention. By adhering to a simple but consistent maintenance routine, you can enhance the performance and extend the lifespan of your machine. Below are practical steps to keep your equipment in optimal condition.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours of use | Use high-quality oil for better engine performance |

| Air Filter Cleaning | Monthly | Ensure the filter is free of dirt and debris |

| Spark Plug Inspection | Every 100 hours of use | Replace if worn or dirty for smooth ignition |

| Blade Sharpening | As needed | Sharp blades ensure cleaner cuts and reduce strain on the engine |

Common Issues with 500 Series Engines

Engines in this category can experience a range of typical mechanical and operational challenges. These issues often arise due to regular wear or improper maintenance. Understanding the root causes and addressing them promptly can help extend the lifespan of the motor.

Poor Starting Performance

A common problem that users encounter is difficulty starting the motor. This issue may stem from a clogged air filter, old fuel, or a faulty spark plug. Ensuring regular maintenance of these components can prevent starting troubles.

Overheating

Overheating is another frequent concern, typically caused by restricted airflow or low oil levels. Keeping cooling fins clean and regularly checking the oil can help avoid this issue. If not addressed, overheating can lead to significant engine damage.

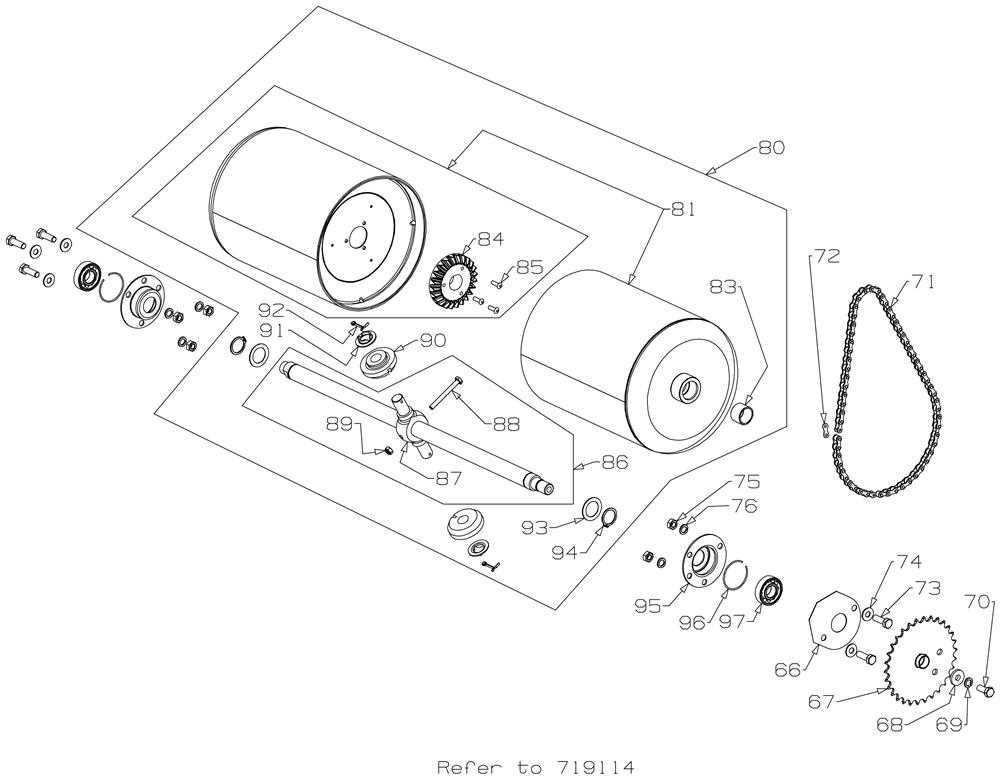

Replacing Worn Out Engine Parts

Maintaining optimal performance in your machine requires timely replacement of aged or damaged components. Over time, various elements of the engine can deteriorate due to wear and tear, affecting efficiency and functionality. Understanding how to identify and replace these crucial parts is essential for prolonging the life of your equipment.

Common Components That May Need Replacement

- Fuel Filters

- Air Filters

- Spark Plugs

- Carburetors

- Rings

- Gaskets

Steps for Effective Replacement

- Assessment: Regularly check the condition of engine elements for signs of wear, such as cracks, discoloration, or irregularities.

- Procurement: Acquire high-quality replacements from reliable suppliers to ensure compatibility and durability.

- Disassembly: Carefully remove the worn components, following the manufacturer’s guidelines to prevent damage to surrounding areas.

- Installation: Install the new parts, ensuring proper alignment and secure connections to avoid future issues.

- Testing: After replacement, run the engine to verify that it operates smoothly and efficiently.

By regularly monitoring and replacing worn components, you can enhance the reliability and longevity of your machinery, ensuring it performs at its best for years to come.

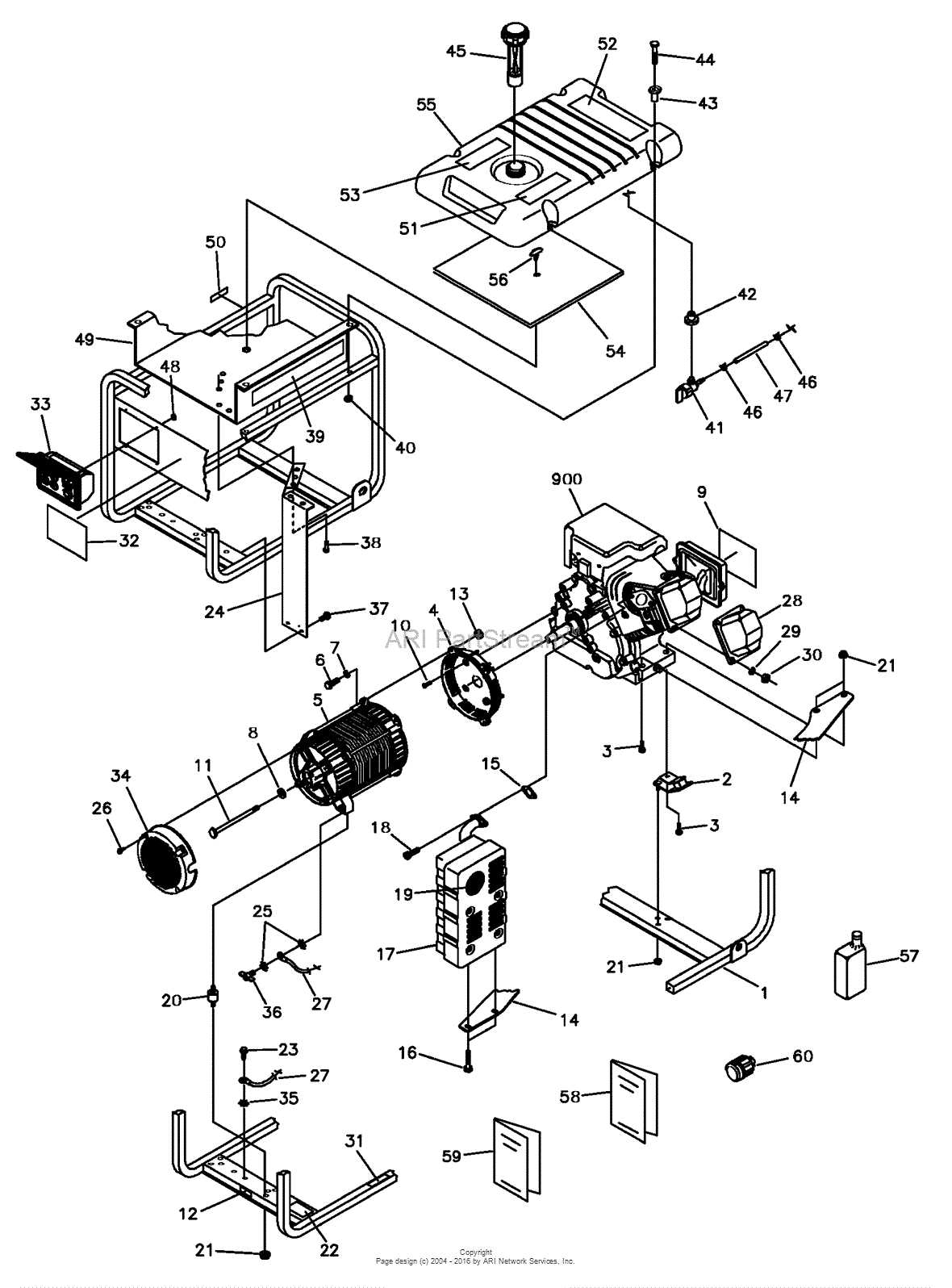

Understanding the Fuel System

The fuel system is a critical component of any engine, responsible for delivering the necessary energy source for operation. It plays a vital role in ensuring optimal performance and efficiency. Understanding its various elements and functions can help in troubleshooting and maintenance, leading to improved longevity and reliability.

Key Components

The fuel system consists of several essential parts that work together to supply fuel to the engine. Here are the main components:

- Fuel Tank: Stores the fuel until it is needed.

- Fuel Pump: Transfers fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel before it reaches the engine.

- Carburetor or Fuel Injector: Mixtures fuel with air for combustion.

- Fuel Lines: Connects various components of the system.

System Functionality

Each part of the fuel system has a specific role in maintaining efficient operation:

- The fuel tank holds the gasoline or alternative fuel until it is required.

- The fuel pump draws the fuel from the tank and pushes it through the filter.

- The filter cleans the fuel to prevent contaminants from damaging the engine.

- The carburetor or injector creates the ideal mixture of fuel and air for combustion.

- The fuel lines ensure that fuel flows seamlessly to the engine.

Understanding these components and their interactions is essential for proper maintenance and troubleshooting of the fuel system.

Air Filter Maintenance and Replacement

Proper upkeep of the air filtration system is essential for ensuring optimal performance of your outdoor power equipment. A clean air filter enhances airflow to the engine, promoting efficiency and longevity. Regular inspection and timely replacement of the filter can prevent engine wear and improve fuel economy.

To maintain the air filter, start by removing it from the housing. Inspect it for dirt and debris. If it appears clogged or excessively dirty, it should be cleaned or replaced. Cleaning can be done by gently tapping the filter to dislodge dust or using compressed air. For filters that are beyond cleaning, selecting a high-quality replacement is crucial. Make sure the new filter fits snugly and is compatible with your equipment.

Routine maintenance should be scheduled based on usage; however, a good practice is to check the filter every few months or before each season. Keeping the air filter in optimal condition not only enhances performance but also reduces the risk of potential engine issues down the line.

Ignition System Troubleshooting Guide

Diagnosing issues within the ignition mechanism is crucial for optimal engine performance. This guide provides essential steps and considerations for identifying and resolving common ignition-related problems. Proper troubleshooting ensures efficient operation and prolongs the life of your equipment.

Common Symptoms of Ignition Issues

- Engine fails to start

- Irregular or rough idling

- Difficulty in restarting after initial operation

- Unusual backfiring noises

- Loss of power during operation

Troubleshooting Steps

- Check the spark plug for wear or damage. Replace if necessary.

- Inspect the ignition coil for signs of corrosion or breaks.

- Verify that the wiring connections are secure and free of fraying.

- Examine the battery for sufficient charge and condition.

- Test the kill switch and other safety features for proper functionality.

Following these steps can help pinpoint the root cause of ignition problems, allowing for effective repairs and maintenance.

Carburetor Parts and Adjustment Tips

The proper functioning of the fuel delivery system is crucial for optimal engine performance. Understanding the components involved and knowing how to adjust them can significantly enhance efficiency and longevity. This section will explore essential elements of the carburetor and provide valuable guidance for making necessary adjustments.

Key Components

Central to the fuel delivery mechanism are the float, needle valve, and throttle plate. The float regulates the fuel level, ensuring consistent delivery. The needle valve controls fuel flow based on the float’s position. Lastly, the throttle plate adjusts the air-fuel mixture, impacting engine speed and power.

Adjustment Techniques

For optimal performance, regularly inspect these components for wear and tear. Adjusting the needle valve height can help maintain the correct fuel level. Additionally, tweaking the throttle plate can improve acceleration and response. Always consult the user manual for specific settings and guidelines tailored to your equipment.

Proper maintenance and adjustments to these components can lead to a smoother running engine, improved fuel efficiency, and reduced emissions. Regular checks will help identify potential issues before they escalate, ensuring reliable performance for your outdoor power equipment.

Overview of Exhaust System Components

The exhaust system is a critical part of small engines, playing a vital role in the efficient operation and performance of the machinery. It is responsible for channeling exhaust gases away from the engine, reducing noise, and minimizing emissions. Understanding the key elements of this system is essential for maintenance and troubleshooting.

Main Components of the Exhaust System

- Exhaust Manifold: This component collects exhaust gases from the engine cylinders and directs them into the exhaust pipe.

- Exhaust Pipe: A conduit that transports exhaust gases from the manifold to the muffler.

- Muffler: A device designed to reduce engine noise by dissipating sound waves and altering gas flow.

- Exhaust Gasket: A seal that prevents gas leaks between the manifold and the engine, ensuring proper function.

- Exhaust Tips: The visible end of the exhaust system, which can also enhance the aesthetic appeal of the equipment.

Functions of the Exhaust System

The exhaust system serves several important functions, including:

- Effective removal of exhaust gases from the engine.

- Noise reduction during engine operation.

- Emission control to meet environmental regulations.

- Improving engine performance by maintaining optimal back pressure.

Choosing the Right Replacement Parts

When maintaining outdoor equipment, selecting suitable components is crucial for optimal performance and longevity. The right replacements ensure that your machine operates smoothly and efficiently, reducing the likelihood of future issues.

Understanding Compatibility is essential when looking for new components. Always check the specifications of your equipment to ensure that the replacements fit correctly and function as intended. Incompatibility can lead to poor performance or even damage.

Quality Matters when it comes to selecting components. Opt for reputable brands that are known for their durability and reliability. While generic options may seem tempting due to lower prices, investing in high-quality components can save you money in the long run by reducing the need for frequent replacements.

Additionally, consulting a professional or referring to manuals can provide valuable insights. Experts can help identify the most appropriate options based on your specific needs, ensuring that you make informed decisions.

In conclusion, taking the time to carefully choose the correct replacements not only enhances the performance of your equipment but also contributes to its overall lifespan. Always prioritize compatibility, quality, and expert advice when making your selection.