In the realm of heavy machinery, comprehending the arrangement of engine components is essential for efficient maintenance and repair. Familiarizing oneself with the various elements that make up these intricate systems can greatly enhance the understanding of how everything works together. This knowledge is particularly valuable for professionals and enthusiasts alike, allowing them to diagnose issues effectively and perform necessary upkeep.

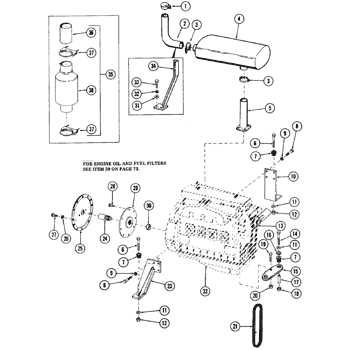

The illustration of engine configurations serves as a vital tool for anyone involved in the service and repair of machinery. It highlights the relationship between different elements, illustrating how they interact and contribute to the overall performance. By studying these configurations, individuals can gain insights into potential weak points and areas requiring attention, ultimately leading to improved reliability and longevity of the equipment.

As you delve into the details of these engine layouts, you’ll discover a wealth of information that can aid in troubleshooting and enhancing operational efficiency. Whether you are a seasoned mechanic or a newcomer to the field, understanding these essential layouts is key to unlocking the full potential of your machinery.

This section aims to provide a comprehensive overview of a specific line of heavy-duty engines, focusing on their design and functionality. By examining various components, readers will gain insights into the intricacies of these power units, which are widely used in the transportation industry. The exploration will highlight key elements, enhancing the understanding of their operational mechanisms.

Key Components of the Engine

Understanding the fundamental elements of the engine is essential for appreciating its performance. Each component plays a vital role in ensuring the overall efficiency and reliability of the engine.

| Component | Description |

|---|---|

| Cylinder Head | Houses the intake and exhaust valves, contributing to combustion efficiency. |

| Crankshaft | Transforms linear motion into rotational motion, vital for power delivery. |

| Fuel Injector | Sprays fuel into the combustion chamber for optimal burning. |

| Turbocharger | Increases air intake pressure, enhancing engine performance. |

Importance of Maintenance

Regular upkeep of the engine’s components is crucial for longevity and optimal operation. Preventive measures can help identify potential issues before they escalate, ensuring reliability in performance.

Key Components of the Engine

This section highlights the essential elements that contribute to the efficient operation of the power unit. Understanding these vital components is crucial for diagnosing issues and ensuring optimal performance.

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and forms the main structure of the engine. |

| Pistons | Move up and down within the cylinders, converting fuel energy into mechanical work. |

| Cylinder Head | Covers the top of the cylinders, containing valves and combustion chambers. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion. |

| Camshaft | Controls the opening and closing of the valves at the correct timing. |

| Fuel Injector | Delivers the appropriate amount of fuel into the combustion chamber. |

| Exhaust Manifold | Collects exhaust gases from the cylinders and directs them to the exhaust system. |

Importance of Proper Maintenance

Ensuring the longevity and efficiency of machinery relies heavily on regular upkeep and care. Without adequate attention, equipment can suffer from performance issues and reduced operational lifespan. Routine maintenance is essential to identify potential problems early, preventing costly repairs and downtime.

Benefits of Regular Upkeep

Consistent maintenance practices lead to enhanced performance and reliability. By regularly inspecting and servicing machinery, operators can ensure optimal functionality and safety. This proactive approach not only improves efficiency but also fosters a safer working environment.

Key Maintenance Tasks

| Task | Description | Frequency |

|---|---|---|

| Oil Changes | Replacing old oil to ensure proper lubrication and function. | Every 5,000 miles |

| Filter Replacements | Changing air and fuel filters to maintain clean airflow and optimal performance. | Every 10,000 miles |

| Fluid Checks | Regular inspection of coolant, transmission, and brake fluids to prevent leaks and overheating. | Monthly |

| Visual Inspections | Checking for signs of wear, leaks, or damage on key components. | Weekly |

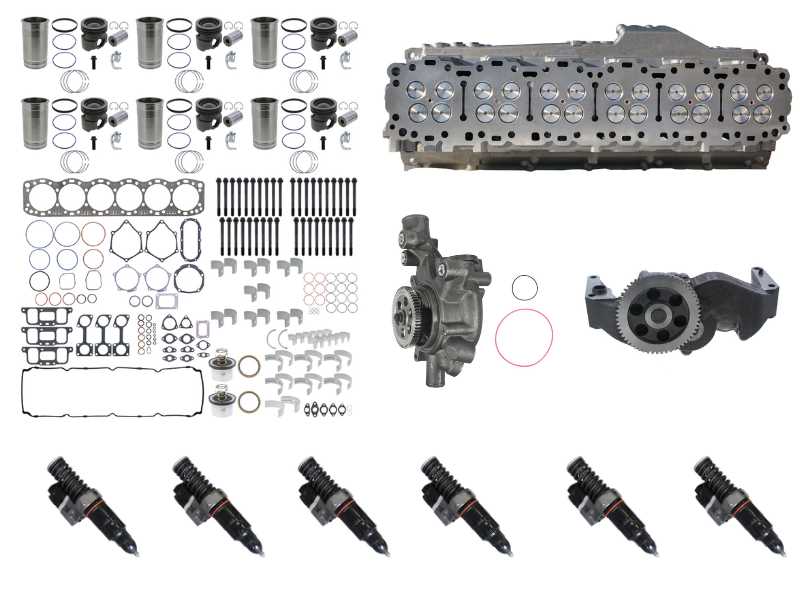

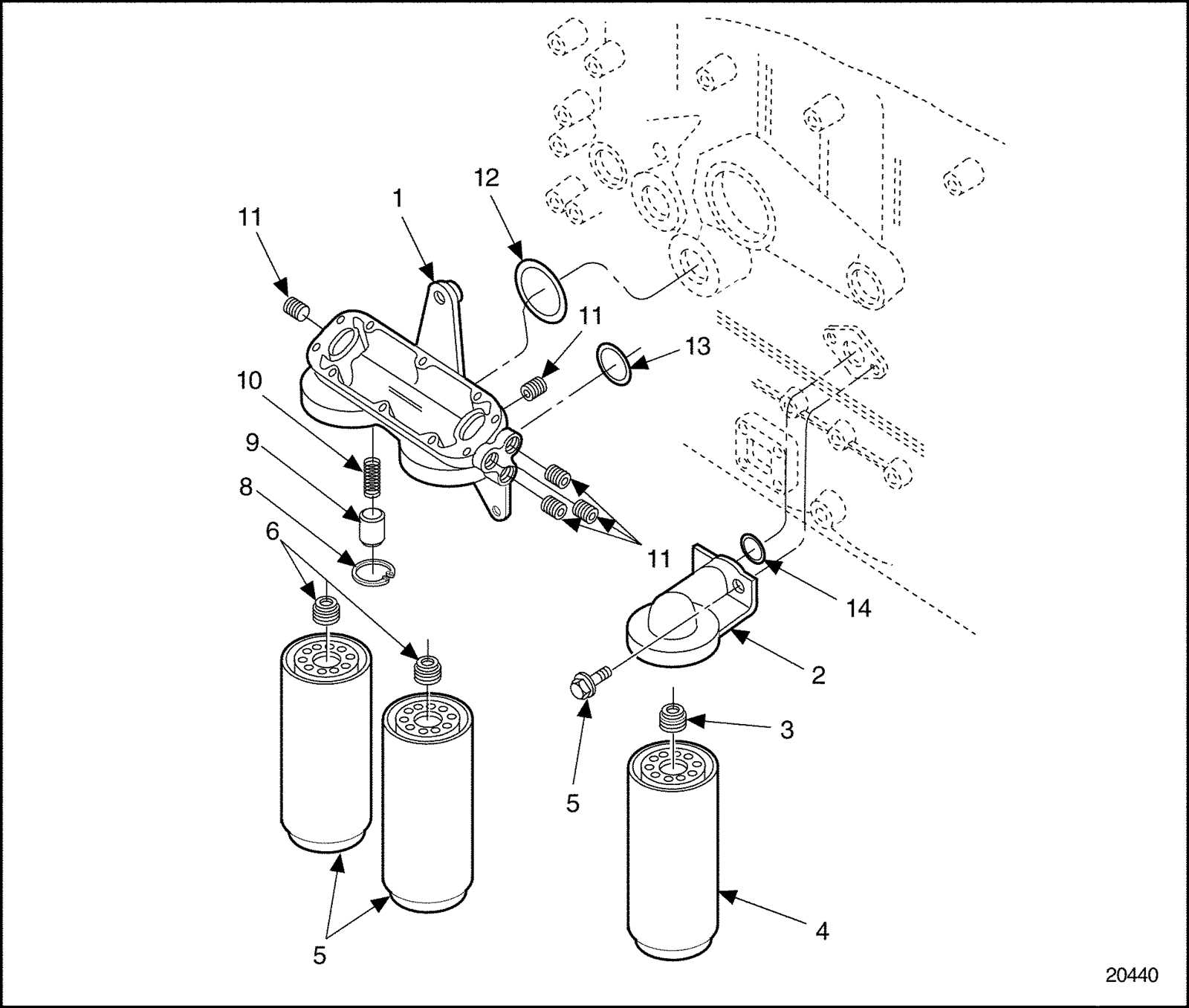

Common Replacement Parts Overview

Understanding the various components that may need to be replaced is essential for maintaining optimal performance. This section provides an insight into frequently required replacements that can enhance the longevity and efficiency of the machinery.

- Filters

- Gaskets

- Hoses

- Bearings

- Pulleys

- Belts

Regularly checking these items can prevent unexpected breakdowns and ensure that operations run smoothly. Below is a brief overview of the most common replacements:

- Filters: Essential for keeping fluids clean and preventing contaminants from damaging internal components.

- Gaskets: Critical for maintaining seals and preventing leaks in various systems.

- Hoses: Vital for fluid transfer, ensuring that liquids move efficiently between parts.

- Bearings: Necessary for reducing friction and facilitating smooth movement of moving parts.

- Pulleys: Important for the transmission of power within the system, ensuring that operations are efficient.

- Belts: Crucial for connecting various components and enabling them to work together effectively.

By staying aware of these common replacements, operators can maintain the equipment’s reliability and performance over time.

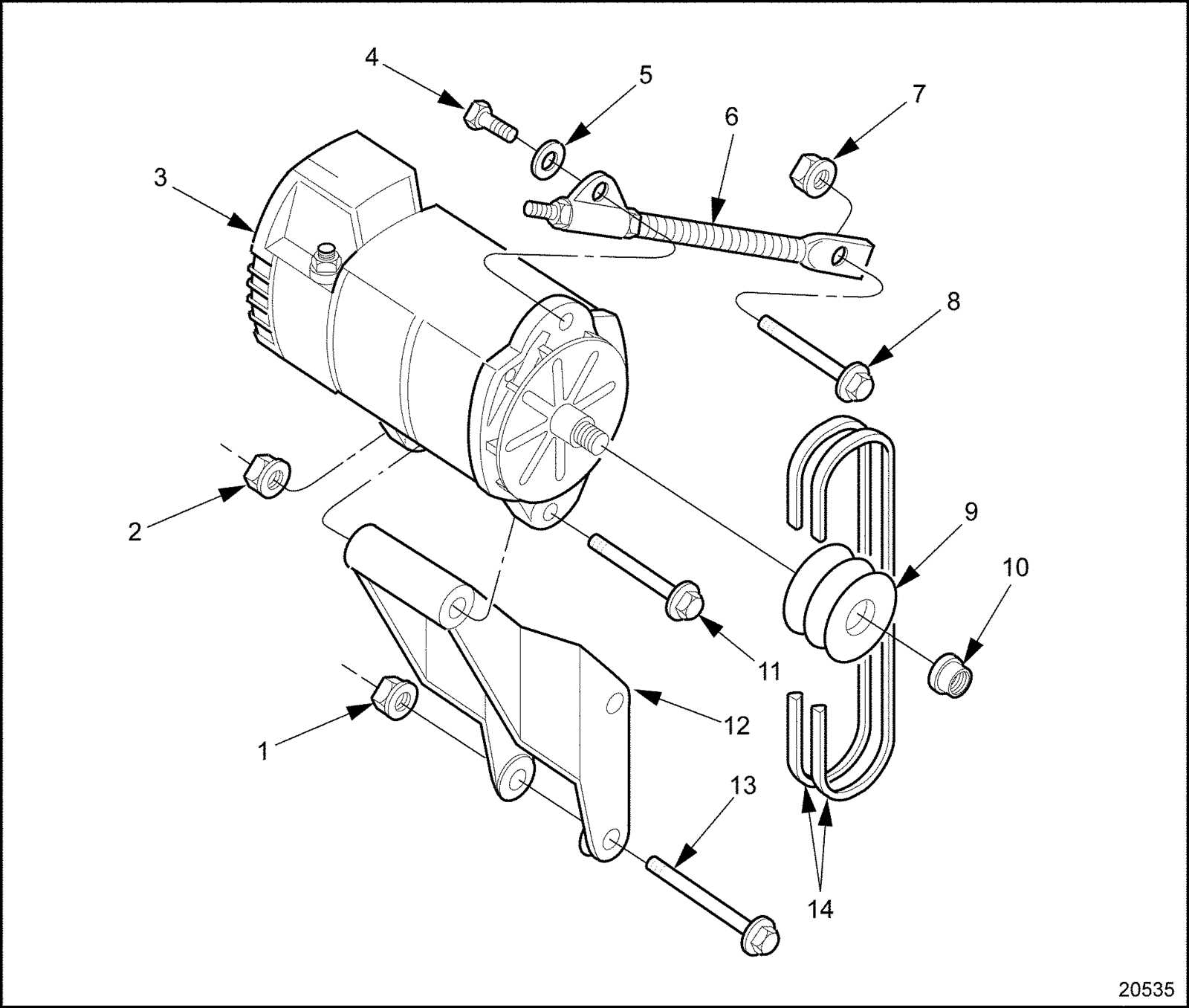

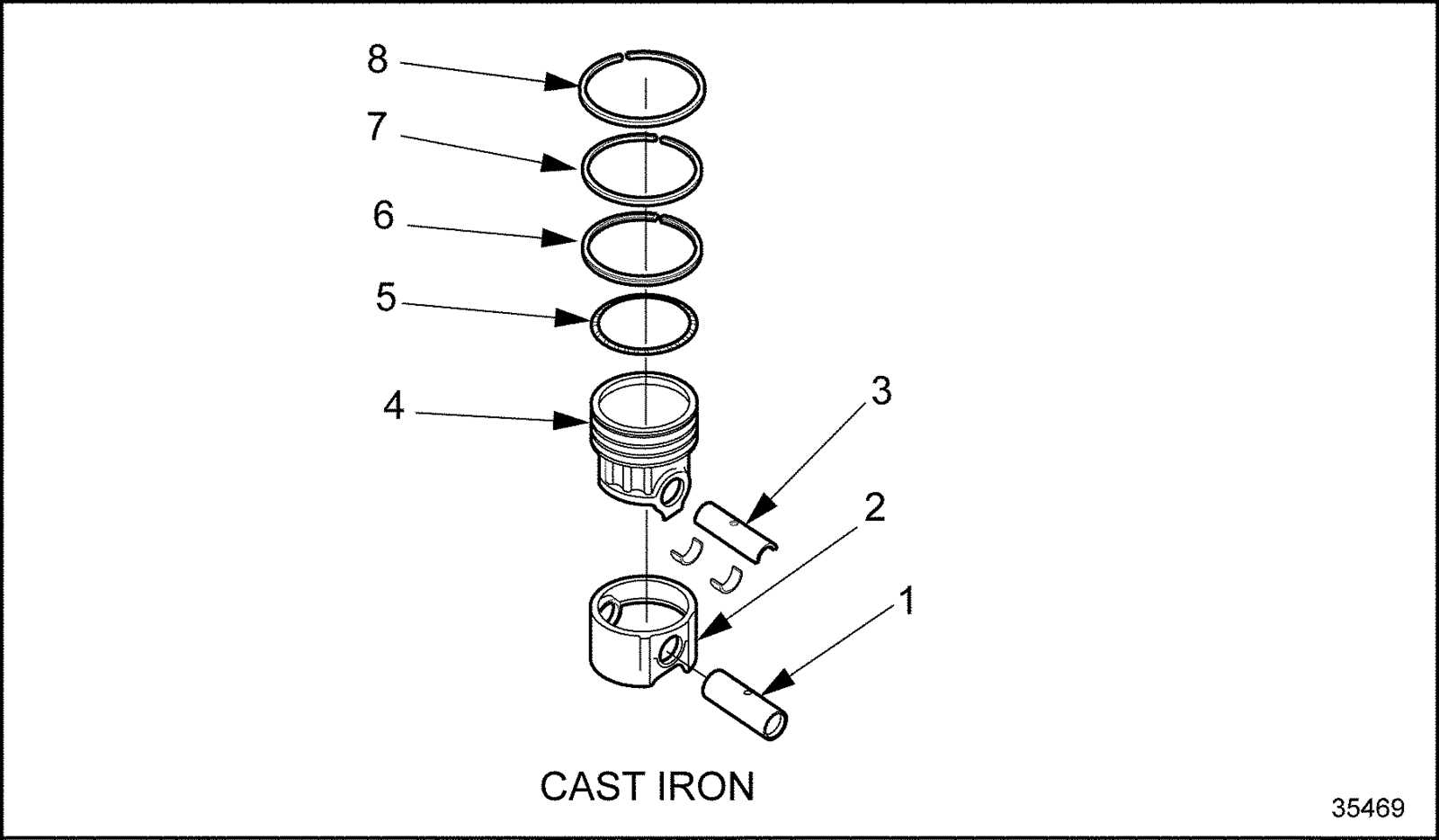

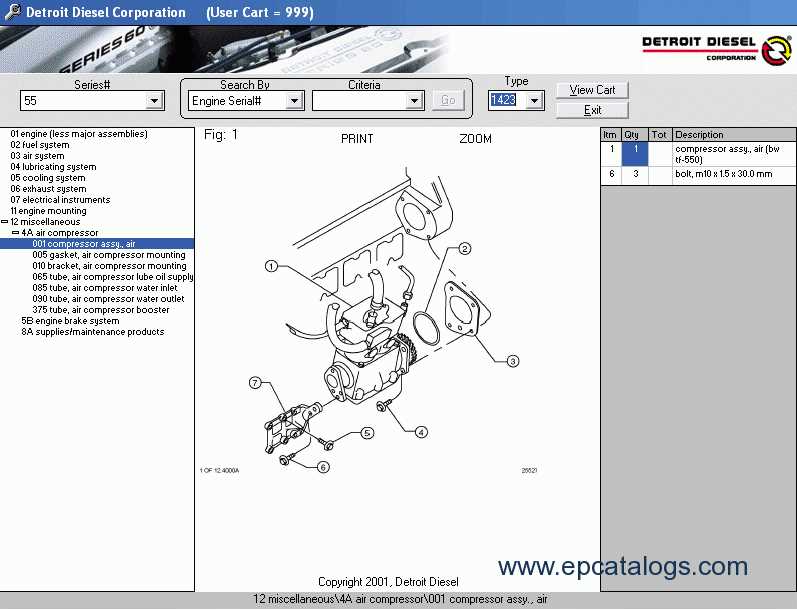

Visual Representation of Parts Diagram

The illustration of components plays a crucial role in understanding the intricate relationships between various elements within a machine. By providing a clear and organized view, this visual aid simplifies the process of identifying each part’s function and location. Such representations enhance the overall comprehension of mechanical structures and are invaluable for both maintenance and assembly tasks.

Importance of Visual Aids

Utilizing graphical representations enables users to quickly grasp the layout and interconnectivity of different elements. This approach not only saves time during repairs but also minimizes the risk of errors. When technicians can easily reference an organized visual guide, they are more likely to execute tasks efficiently and accurately.

Applications in Maintenance and Repair

In the realm of upkeep, having a detailed visual reference can significantly reduce downtime. Technicians can swiftly locate the components that require attention, ensuring that any issues are addressed promptly. Moreover, these illustrations are essential for training new personnel, equipping them with the necessary knowledge to navigate complex machinery.

Identifying Parts by Model Year

Understanding the specifics of different manufacturing years is crucial for effectively recognizing various components. Each production year often brings updates and modifications, which can influence the design and functionality of each element. By grasping these distinctions, one can ensure compatibility and optimal performance when replacing or repairing.

When examining components from various years, it’s essential to refer to the appropriate documentation. This ensures accurate identification and helps avoid common pitfalls associated with mismatched parts. Consulting reliable sources and diagrams can facilitate this process, providing a clearer picture of the unique features corresponding to each year.

Additionally, staying informed about recalls or upgrades can further aid in understanding the evolution of specific elements. Being aware of these changes not only enhances knowledge but also promotes better decision-making when it comes to maintenance and repairs.

Tools Needed for Repairs

When undertaking maintenance or restoration work, having the right tools is essential for achieving optimal results. The proper equipment not only enhances efficiency but also ensures that tasks are completed safely and accurately. Below is a list of essential tools commonly required for effective repairs.

Basic Hand Tools

- Wrenches: Various sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips for working with screws.

- Pliers: For gripping, twisting, and cutting wires or components.

- Hammers: To drive in nails or adjust parts without causing damage.

Power Tools

- Drills: For making holes or driving screws quickly.

- Impact Wrench: Useful for removing stubborn bolts.

- Angle Grinder: For cutting, grinding, and polishing materials.

- Socket Set: Provides versatility in working with different fasteners.

Having these tools readily available will facilitate smoother repair processes, allowing for effective troubleshooting and resolution of issues encountered during maintenance tasks.

How to Order Genuine Parts

When seeking to acquire authentic components for your vehicle, it’s essential to follow a systematic approach to ensure quality and compatibility. This process involves understanding your specific needs and sourcing them from reputable suppliers who guarantee the originality of their products.

Identify the Required Components

Start by determining which elements you need. Reviewing the vehicle’s manual can provide valuable insights into the specifications and part numbers you should look for. Taking note of the make and model will help streamline your search.

Find Authorized Dealers

Next, locate authorized distributors or dealerships that specialize in your vehicle’s brand. These establishments typically offer a range of genuine components, often with warranties and customer support. Contacting them directly can yield information on availability and pricing, ensuring you make an informed purchase.

By following these steps, you can confidently procure the necessary components to maintain your vehicle’s performance and reliability.

Common Issues and Solutions

This section highlights typical problems encountered with heavy machinery, along with practical solutions to address them. Understanding these common challenges can help operators maintain optimal performance and extend the lifespan of their equipment.

Frequent Mechanical Problems

Many users report issues related to wear and tear of essential components, which can lead to decreased efficiency. Common symptoms include unusual noises, reduced power output, and overheating. Regular inspections and timely replacements are crucial to prevent further damage.

| Issue | Symptoms | Suggested Solutions |

|---|---|---|

| Excessive Wear | Strange sounds, vibrations | Inspect and replace worn components |

| Overheating | High temperature readings | Check coolant levels, replace radiator |

| Power Loss | Slow response, sluggish operation | Examine fuel system, clean filters |

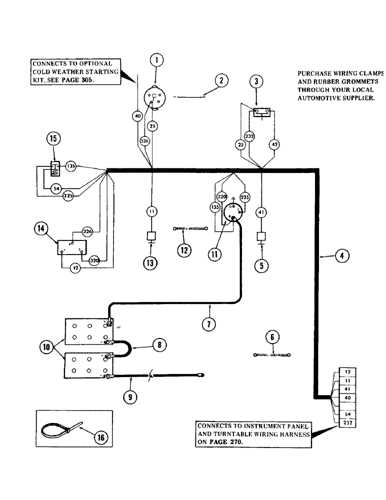

Electrical Malfunctions

Electrical issues can also hinder performance, leading to erratic behavior or complete shutdowns. Problems may arise from faulty wiring, poor connections, or failing sensors. Regular electrical system checks are essential for reliable operation.

| Issue | Symptoms | Suggested Solutions |

|---|---|---|

| Faulty Wiring | Intermittent failures | Inspect and repair damaged wires |

| Poor Connections | Inconsistent power supply | Re-secure loose connections |

| Sensor Failures | Incorrect readings | Test and replace faulty sensors |

Enhancing Performance with Upgrades

Upgrading components in your engine can significantly enhance its overall efficiency and power output. By focusing on key areas for improvement, you can achieve better performance metrics and ensure a smoother driving experience. Whether you are aiming for increased torque, improved fuel efficiency, or enhanced reliability, the right modifications can make a substantial difference.

Consider implementing the following upgrades to maximize the potential of your vehicle:

| Upgrade Type | Benefits |

|---|---|

| Intake System | Improves airflow, enhances combustion efficiency, and boosts horsepower. |

| Exhaust System | Reduces back pressure, enhances engine efficiency, and produces a more aggressive sound. |

| Tuning Software | Optimizes engine performance settings for better power delivery and fuel economy. |

| Cooling System | Maintains optimal operating temperatures, preventing overheating during heavy use. |

| Transmission Upgrade | Enhances shifting speed and improves power transfer to the wheels. |

By carefully selecting and implementing these upgrades, you can significantly elevate your vehicle’s performance and ensure it operates at its best for years to come.

Resources for Further Learning

This section provides a collection of valuable materials and platforms to deepen your understanding of the subject. Whether you are looking for detailed manuals, community forums, or instructional videos, these resources will enhance your knowledge and skills.

Recommended Books and Manuals

Books and manuals are excellent sources of in-depth information, offering both theoretical and practical insights. Below is a list of some highly regarded publications:

| Title | Author | Year |

|---|---|---|

| Comprehensive Engine Repair | John Smith | 2018 |

| Understanding Heavy Machinery | Jane Doe | 2020 |

| Advanced Mechanic’s Guide | Emily Johnson | 2019 |

Online Communities and Forums

Engaging with online communities can provide support and practical tips from fellow enthusiasts and professionals. Here are some popular platforms where you can connect with others:

| Platform | Description |

|---|---|

| Mechanics Forum | A community for discussing repair techniques and sharing experiences. |

| DIY Mechanics Group | A Facebook group focused on hands-on projects and troubleshooting. |

| YouTube Mechanics Channel | A channel featuring tutorials and repair demonstrations. |