In the world of textile artistry, knowing the intricate components of your crafting apparatus is essential for optimal performance. A thorough comprehension of each element can significantly enhance your creative process and ensure the longevity of your equipment. This guide will explore the various sections and functionalities, allowing you to familiarize yourself with the tools at your disposal.

Mastering the anatomy of your device not only empowers you to troubleshoot issues effectively but also fosters a deeper appreciation for the engineering behind it. Recognizing how each component interacts can lead to a more efficient workflow and inspire new projects. Whether you’re a seasoned artisan or a beginner, having a solid grasp of your apparatus’s layout is invaluable.

By delving into the specifics of the various components, you can unlock the full potential of your creative endeavors. Each part plays a crucial role in the overall functionality, making it vital to understand their individual purposes and how they contribute to the seamless operation of your tool.

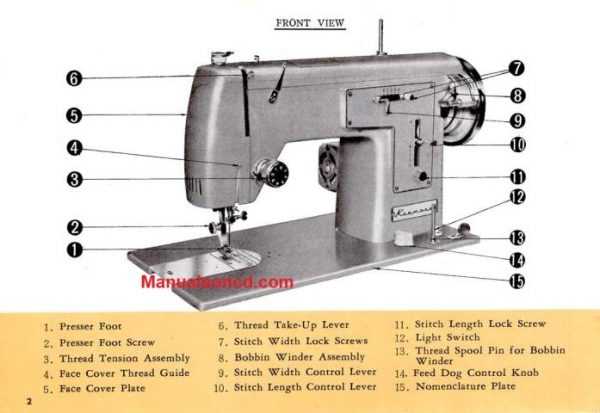

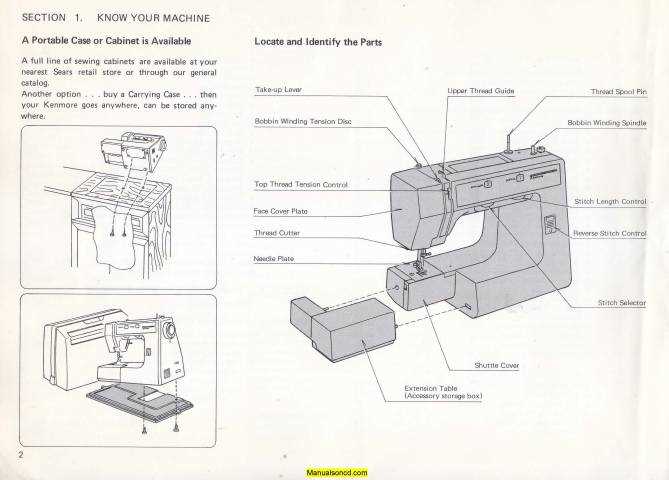

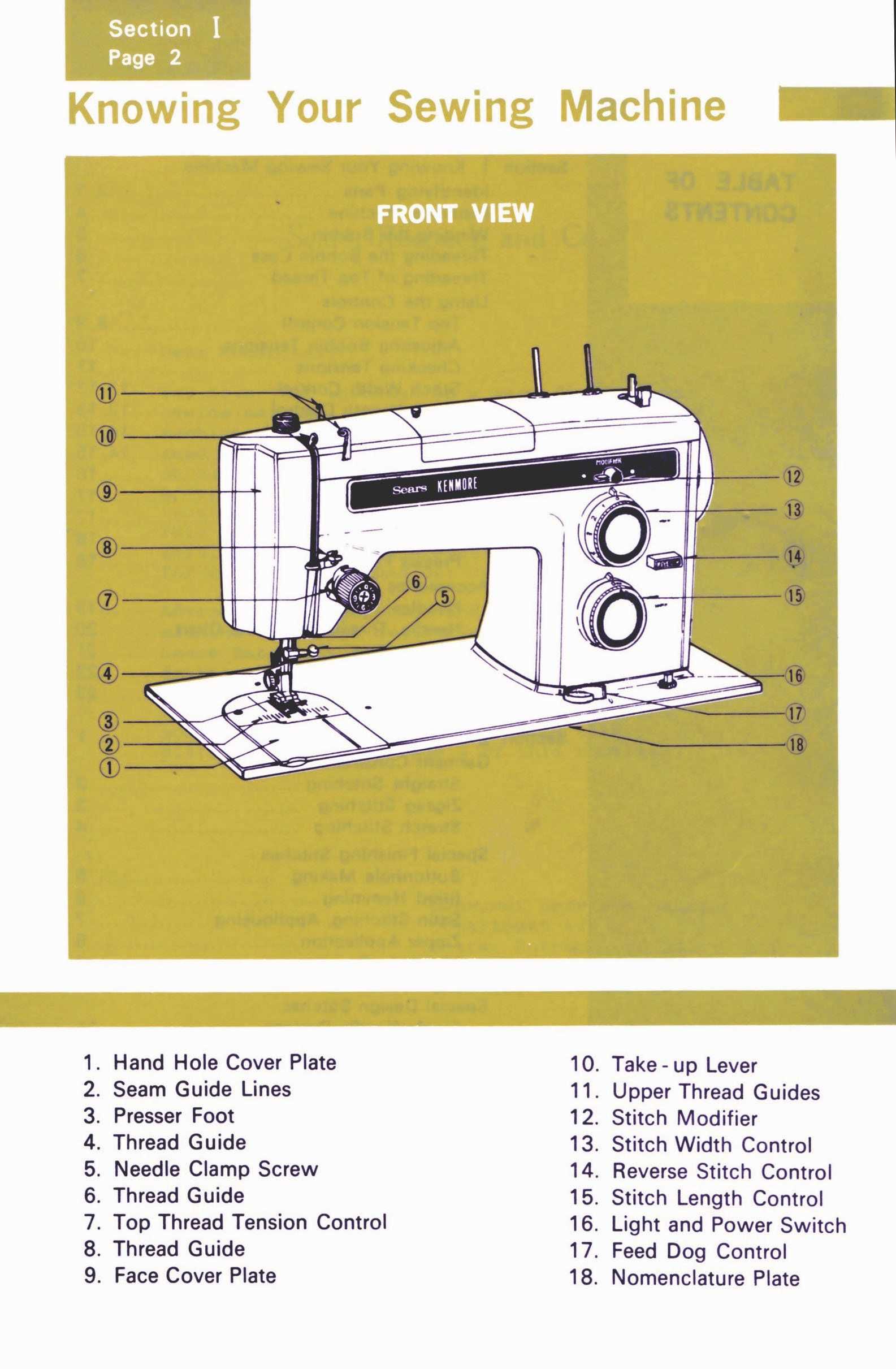

Understanding the essential components of a stitching apparatus is crucial for effective usage and maintenance. Each element plays a significant role in ensuring the device operates smoothly and efficiently. Familiarizing yourself with these features will enhance your overall experience and assist in troubleshooting any potential issues.

Key Components to Recognize

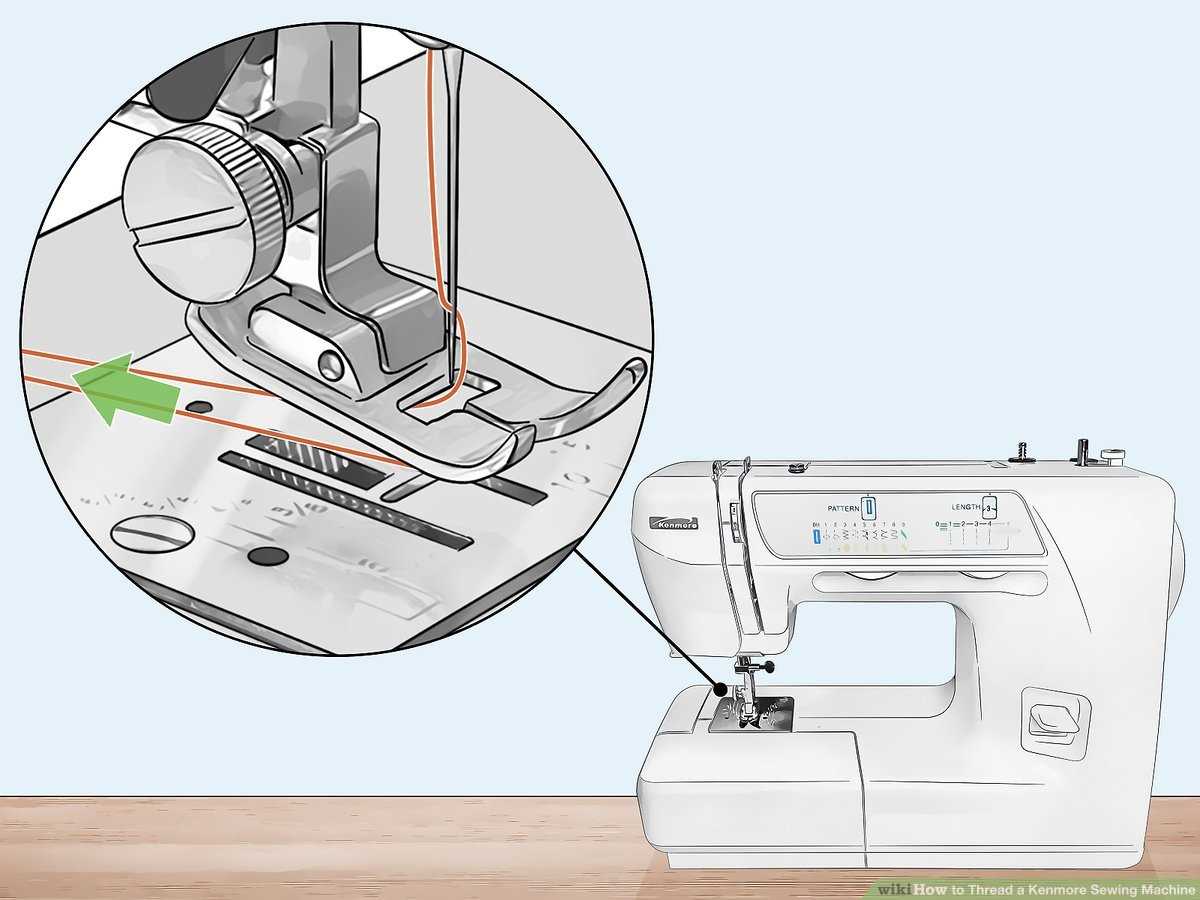

- Needle Holder: This is where the needle is secured, allowing for precise fabric manipulation.

- Foot Pedal: The control mechanism that regulates the speed and activation of the apparatus.

- Feed Dogs: These are the small teeth that grip the fabric and move it through the system.

- Bobbins: Small spools that hold the lower thread, essential for creating stitches.

- Thread Tension Control: This feature adjusts the tightness of the thread, affecting stitch quality.

Additional Elements to Explore

- Stitch Selector: A dial or lever that allows the user to choose different stitch types.

- Hand Wheel: This component is used to manually raise and lower the needle for precise placement.

- Power Switch: The on/off control for the entire unit.

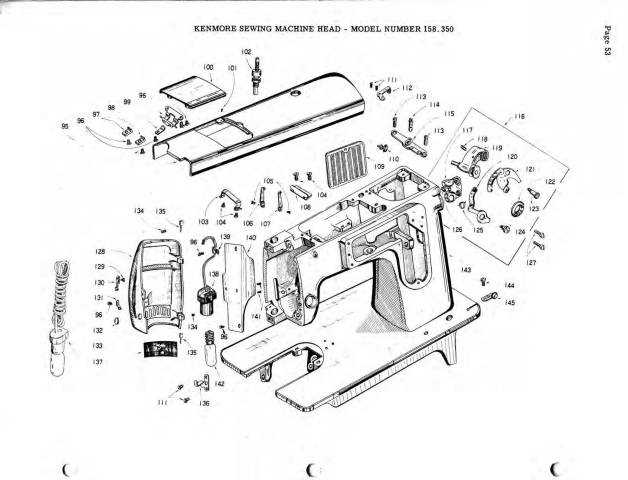

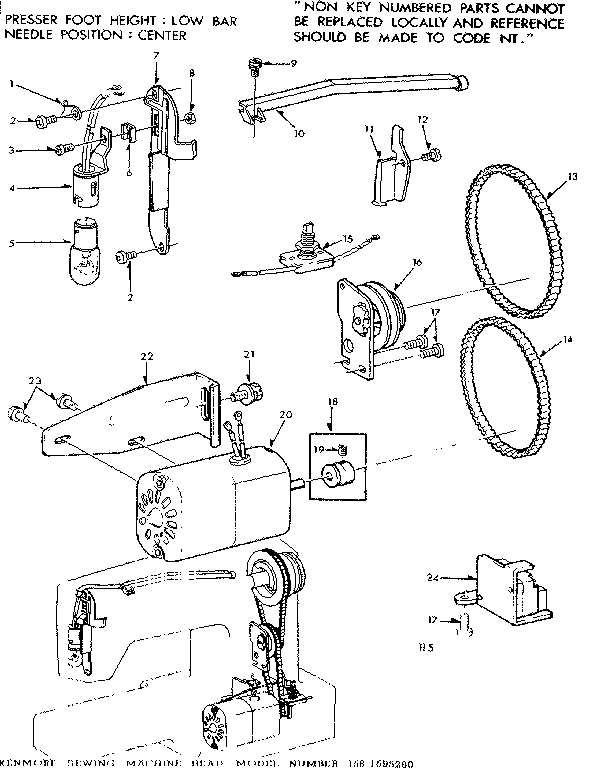

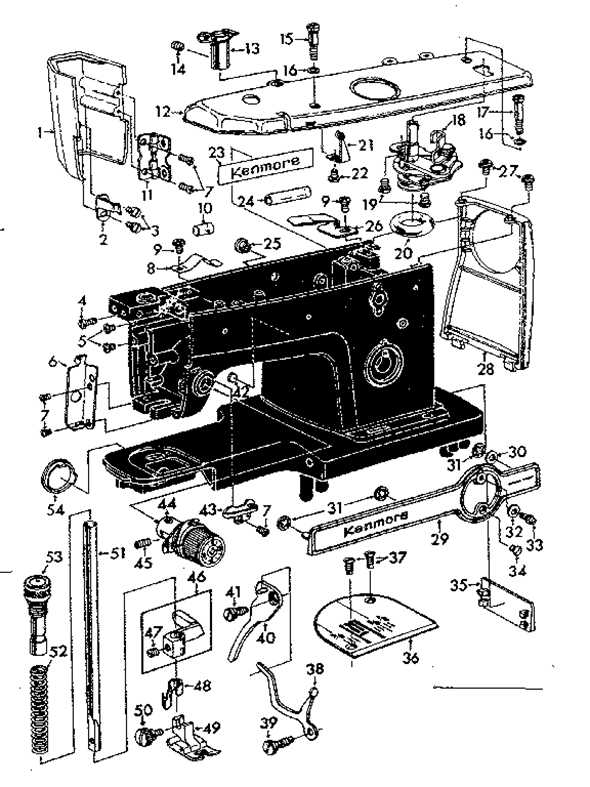

How to Read the Diagram

Understanding the layout of components is crucial for effective operation and maintenance. A well-structured visual representation provides essential information about the various elements, their functions, and their relationships. Familiarizing yourself with the symbols and labels used can greatly enhance your ability to troubleshoot and perform necessary adjustments.

Key Elements to Identify

- Symbols: Each icon or symbol typically corresponds to a specific component. Recognizing these will help in quick identification.

- Labels: Text descriptions next to symbols provide further clarity on the function of each part.

- Connections: Arrows or lines indicate how different elements interact with one another.

Steps to Interpret the Visual Representation

- Start by locating the legend or key, which explains the symbols and markings used.

- Identify the main sections and familiarize yourself with their layout.

- Follow the connections to understand how each part works in unison with others.

- Refer to the labels for specific functions or instructions related to adjustments and maintenance.

Common Issues with Machine Parts

When operating a textile apparatus, users may encounter various challenges related to its components. Understanding these common dilemmas can aid in effective troubleshooting and maintenance.

Wear and Tear: Over time, frequent use can lead to deterioration of crucial elements. This can manifest as reduced functionality or even complete failure of specific functions.

Misalignment: Components may become misaligned due to improper handling or accidental impacts. This misalignment can cause uneven stitching or hinder movement, resulting in frustration for the operator.

Blockages: Dust and fabric fibers can accumulate, leading to blockages in moving parts. Regular cleaning is essential to maintain smooth operation and prevent complications.

Loose Connections: Fasteners or screws might loosen, causing instability. Checking these connections periodically can ensure that everything remains secure and functional.

Electrical Issues: In electronic models, wiring problems or faulty circuits can disrupt operation. Identifying and rectifying electrical concerns promptly is crucial for safe and efficient use.

Maintenance Tips for Longevity

To ensure the prolonged functionality of your device, regular upkeep is essential. By implementing simple yet effective care strategies, you can significantly enhance its lifespan and maintain optimal performance.

Regular Cleaning: It is vital to keep the equipment clean from dust and debris. Regularly wipe down surfaces and remove any lint or particles that may accumulate. This will prevent blockages and ensure smooth operation.

Lubrication: Applying the appropriate lubricant to moving parts can help reduce friction. This not only enhances efficiency but also prevents wear and tear, allowing for a more seamless experience during use.

Check Tensions: Maintaining proper tension in various components is crucial for achieving the best results. Regularly assess and adjust the tensions as needed to avoid unnecessary strain on the system.

Storage Practices: When not in use, store the device in a cool, dry place. Use a protective cover to shield it from dust and moisture, which can lead to damage over time.

Professional Servicing: Schedule periodic professional inspections to ensure all components are functioning correctly. This proactive approach can help identify potential issues before they escalate, ensuring longevity.

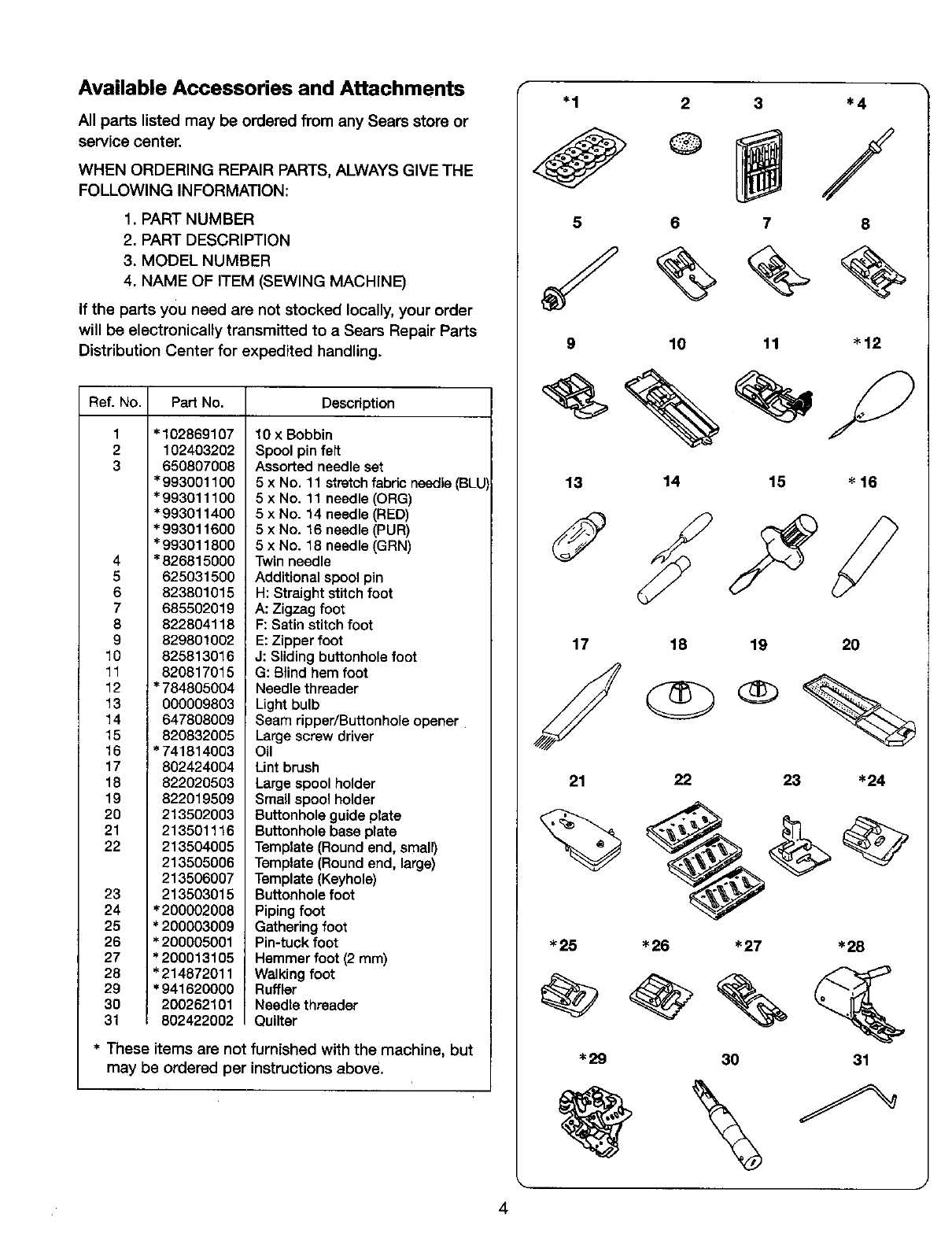

Replacing Worn-Out Components

Over time, certain elements of your textile equipment may begin to show signs of wear, affecting performance and efficiency. It is essential to identify these components and replace them to ensure seamless operation and maintain the quality of your projects. Regular maintenance and timely replacements can prevent further damage and enhance the longevity of your device.

Identifying Worn Parts: Start by inspecting your equipment for any signs of damage or excessive wear. Look for frayed belts, worn gears, or any other components that may not function as they should. Pay attention to unusual noises or performance issues, as these can indicate that a part needs attention.

Replacement Process: Once you have identified the worn components, refer to your user manual for specific instructions on how to remove and replace them. Ensure that you have the necessary tools and replacement parts ready. Follow the steps carefully to avoid causing additional issues during the replacement process.

Final Checks: After replacing the worn components, conduct a thorough check to ensure everything is functioning correctly. Test your equipment with a small project to confirm that the performance has improved. Regular inspections and replacements will help keep your device in top condition and extend its lifespan.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward process if you know where to look. Various resources are available to help you find the right pieces needed for maintenance or repairs. By exploring both online and offline options, you can ensure that your device remains in optimal working condition.

Online retailers are a popular choice for sourcing specific items. Websites that specialize in electronic tools and accessories often carry a wide range of options, making it easy to compare prices and availability. Additionally, you can find specialized forums and communities where enthusiasts share tips and resources, including links to trusted vendors.

Local repair shops can also be invaluable resources. Many technicians have access to suppliers that may not be available to the general public. Visiting these establishments not only allows you to obtain necessary components but also provides an opportunity for professional advice on installation or troubleshooting.

Another option is to check with the original distributor or authorized dealers. They may offer genuine replacements, ensuring compatibility and quality. While this route may be pricier, it often comes with the assurance of a warranty or customer support.

Lastly, consider browsing second-hand marketplaces. While you should exercise caution, platforms that facilitate peer-to-peer sales can sometimes yield rare or discontinued items at a fraction of the retail price. Just ensure that the quality meets your requirements before purchasing.

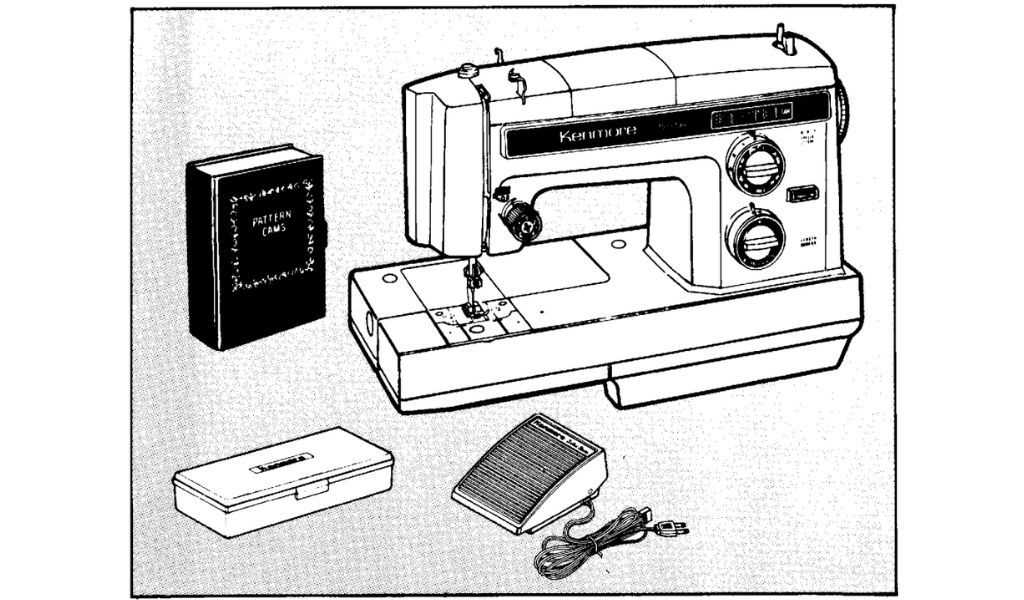

Helpful Tools for Repairs

When it comes to fixing your equipment, having the right tools can make all the difference. Various instruments can aid in the repair process, ensuring efficiency and precision. Whether you are tackling a minor issue or a more complex task, being well-prepared with essential tools is crucial for successful repairs.

Essential Toolkit: A basic toolkit should include screwdrivers of different sizes, pliers, and wrenches. These fundamental tools are necessary for loosening or tightening screws and nuts, making them indispensable for any repair job.

Specialized Instruments: Depending on the type of work you are doing, you might need specialized tools such as stitch removers, seam rippers, or thread cutters. These instruments help in addressing specific issues effectively, allowing for a more straightforward approach to repairs.

Measuring Tools: Accurate measurements are key to any successful fix. Utilizing a measuring tape or ruler ensures that you get the dimensions right, reducing the chances of errors during repairs.

Maintenance Supplies: Don’t forget about maintenance products such as lubricants and cleaning solutions. Keeping your equipment well-maintained prolongs its lifespan and enhances performance, making regular upkeep a vital part of the repair process.

Having the right tools at your disposal not only simplifies the repair process but also empowers you to tackle issues with confidence. With a well-equipped toolkit, you’re better prepared to address any challenge that may arise.

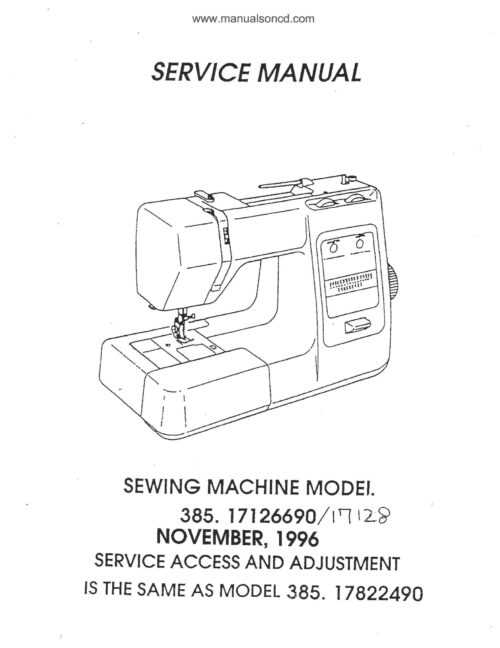

Diagram Variations Across Models

When exploring different versions of crafting devices, it becomes evident that each design showcases unique characteristics. Understanding these distinctions is essential for users who aim to optimize their experience and maintenance. Variations can stem from several factors, including the intended function, model age, and technological advancements.

- Functional Differences: Each design may cater to specific tasks, which can influence the layout and components illustrated in the visual guide.

- Model Evolution: As technology progresses, newer versions may incorporate features that older models lack, leading to significant changes in the configuration.

- Brand Specifics: Variations can also arise from branding decisions, as different manufacturers may emphasize certain functionalities, resulting in distinct setups.

By examining these variations, users can gain valuable insights into the best practices for their specific model, ensuring a more effective and enjoyable crafting experience.

Resources for Further Assistance

When navigating the intricacies of mechanical tools, having access to reliable resources is essential. These materials can provide valuable insights, troubleshooting tips, and expert guidance, ensuring a smooth experience for users at all levels. Whether you seek instructional content, community support, or professional advice, various options are available to enhance your understanding and proficiency.

Online Communities and Forums

Participating in online forums dedicated to crafting and technical maintenance can be incredibly beneficial. Engaging with fellow enthusiasts allows for the sharing of experiences, tips, and solutions to common challenges. Many forums also host discussions on various topics, making them a great place to ask questions and gain new perspectives.

Manufacturer Resources and Support

Exploring the official resources provided by manufacturers can yield comprehensive guides and manuals. These documents often contain detailed explanations, illustrations, and specifications that can assist in both routine maintenance and troubleshooting. Additionally, reaching out to customer service can provide personalized support tailored to specific issues or inquiries.