The intricate workings of a crafting implement rely on a variety of essential elements, each contributing to its overall functionality. Gaining insight into these components can enhance one’s proficiency and appreciation for the artistry involved in textile creation. By familiarizing oneself with these vital aspects, users can achieve greater mastery over their crafting endeavors.

Each element plays a unique role, harmonizing with others to produce seamless results. Recognizing how these integral pieces interact allows for more effective troubleshooting and maintenance. As users delve deeper into the mechanics of their crafting instrument, they unlock new potential for creativity and efficiency in their projects.

Moreover, understanding these features can inspire confidence in both novice and seasoned creators. With a solid grasp of how each component operates, one can explore various techniques and styles, expanding their repertoire. This knowledge serves as a foundation for all who wish to elevate their crafting skills and explore the limitless possibilities of fabric manipulation.

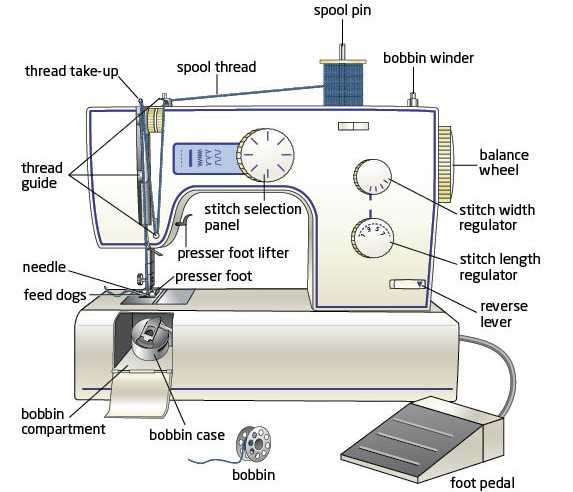

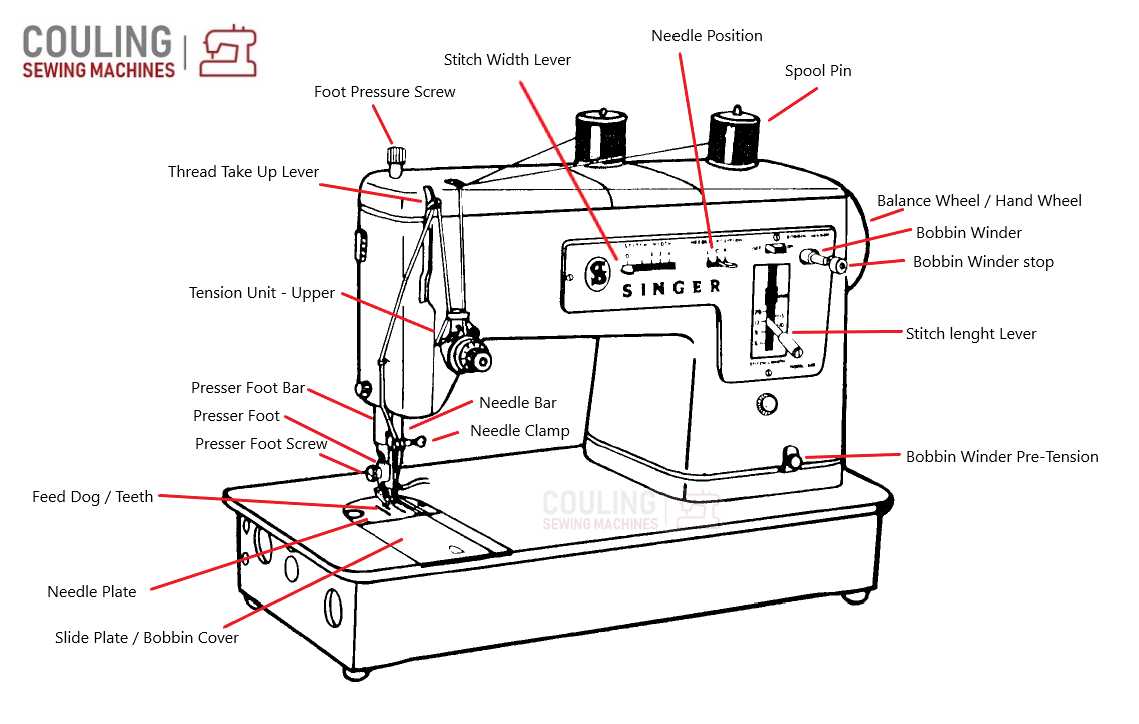

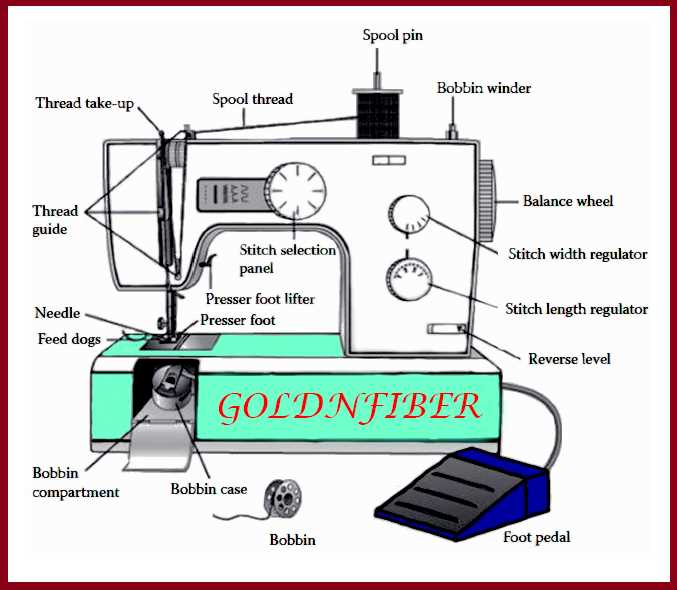

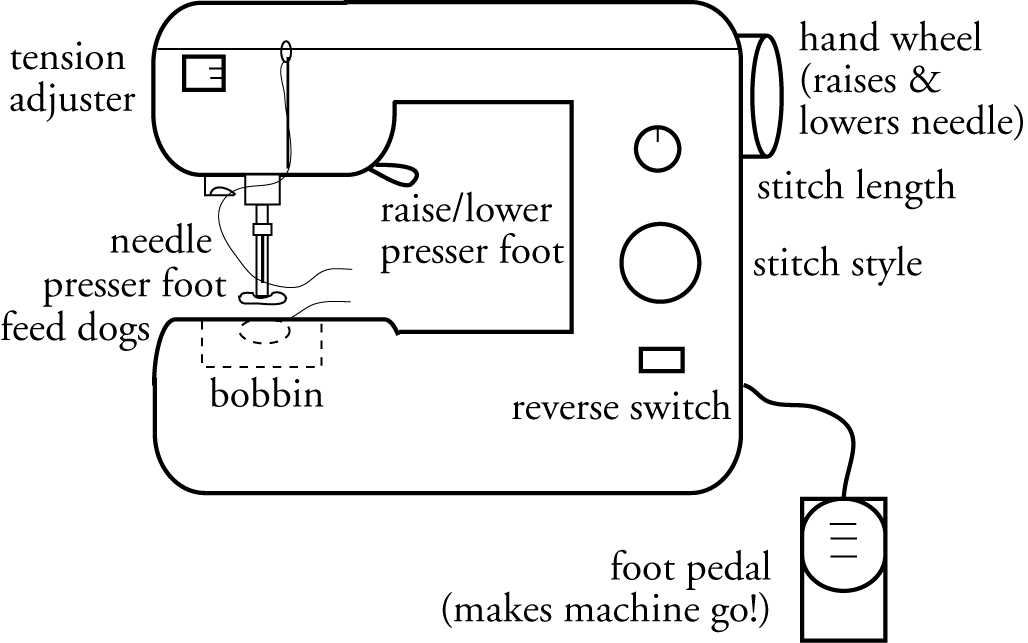

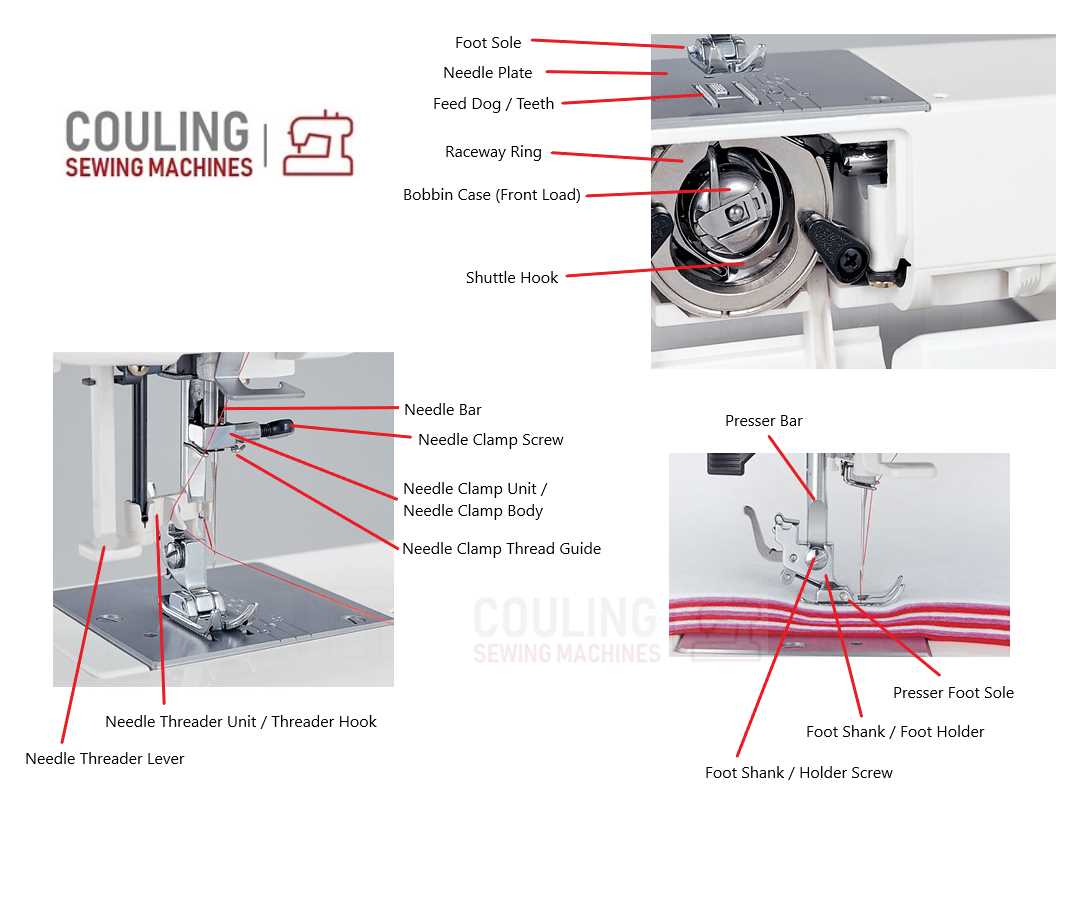

Understanding the function of feed dogs is essential for anyone involved in textile crafts. These components play a crucial role in guiding fabric through the needle area, ensuring smooth and precise stitching. Their operation directly influences the quality of the finished product.

Feed dogs are equipped with specific features that contribute to their effectiveness:

- Movement: These elements move up and down in a coordinated pattern to grip and advance the material.

- Height Adjustment: They can be adjusted to accommodate various fabric thicknesses, ensuring versatility.

- Synchronization: Their movement is synchronized with the needle’s action, facilitating seamless stitching.

The interaction between the fabric and these components significantly impacts the overall sewing experience. Proper maintenance and adjustments can enhance their performance, leading to better results in various textile projects.

Importance of the Presser Foot

The presser foot plays a crucial role in the functionality of fabric handling during the stitching process. It ensures that materials are held firmly in place, allowing for accurate and consistent seams. Its design and functionality can significantly impact the quality of the final product.

Here are some key aspects highlighting the significance of the presser foot:

- Stability: It keeps the fabric steady while you work, preventing slipping or shifting.

- Feed Mechanism: It works in conjunction with the feed dogs to move the material through the working area smoothly.

- Precision: Different types of presser feet enable various stitching techniques, ensuring precision in your work.

- Versatility: Various designs accommodate different fabric types and sewing styles, enhancing creative possibilities.

- Ease of Use: Properly fitted, it simplifies the sewing process, making it accessible for beginners and experts alike.

Overall, the presser foot is essential for achieving high-quality results in any fabric-related task. Its importance cannot be overstated, as it enhances both the ease of use and the final appearance of the stitched items.

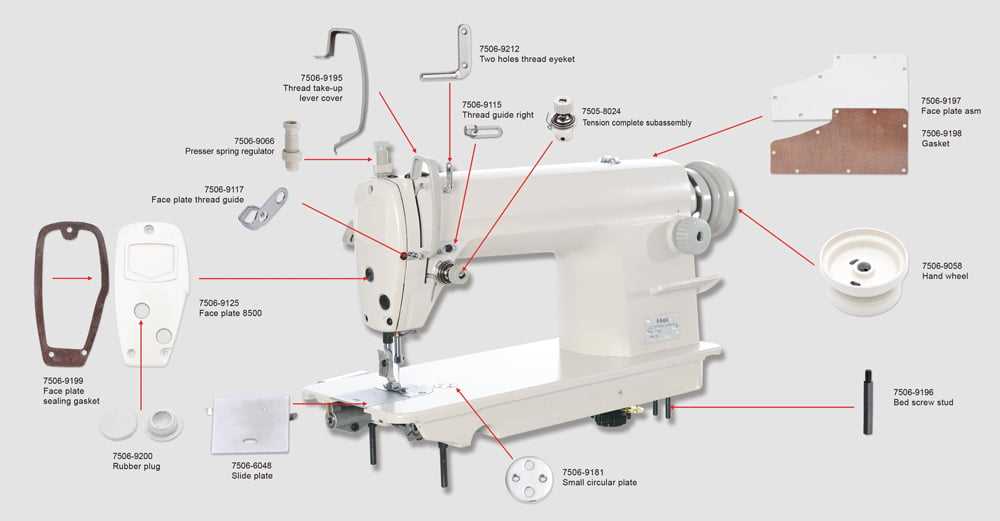

Exploring the Tension Mechanism

The tension system plays a crucial role in achieving balanced and precise stitching in any fabric manipulation process. By regulating the amount of thread tension, this component ensures that the threads interlock correctly, resulting in uniform seams. A well-adjusted mechanism prevents issues such as puckering or uneven stitches, which can compromise the overall quality of the crafted item.

Understanding Thread Tension

Thread tension is essential for creating consistent stitches. It involves adjusting the pull of both the upper and lower threads, allowing them to work harmoniously together. If the upper thread is too tight, it can cause puckering on the fabric surface. Conversely, if it is too loose, the stitches may become weak and break easily. Finding the right balance is key to successful outcomes.

Common Adjustments

Proper maintenance of the tension system is vital for optimal performance. Regularly checking and adjusting the tension can help prevent common issues. Here are some typical adjustments that can be made:

| Adjustment Type | Description |

|---|---|

| Upper Tension | Adjusts the pull of the upper thread, influencing how it interacts with the lower thread. |

| Lower Tension | Regulates the tension of the lower thread, affecting the stitch formation from beneath the fabric. |

| Tension Discs | Controls the amount of thread that passes through, allowing fine-tuning of the overall tension. |

Understanding the Stitch Selector

The stitch selector is a crucial element that enables users to customize their fabric creation experience. By providing various options, it allows for adjustments in the appearance and functionality of the stitches, enhancing both aesthetics and durability. Understanding this feature can significantly influence the outcome of your projects, making it an essential aspect to master.

Types of Stitches Available

Different designs can be chosen based on the type of work you wish to accomplish. Here are some common types:

- Straight Stitch

- Zigzag Stitch

- Decorative Stitch

- Overlock Stitch

How to Use the Selector

Using the stitch selector is straightforward. Follow these simple steps:

- Identify the desired stitch type from the options available.

- Adjust the selector to the corresponding number or icon.

- Test the stitch on a scrap piece of fabric to ensure the desired effect.

Identifying the Power Switch and Controls

Understanding the function of various switches and adjustments is essential for effective operation. These components are vital for controlling the energy supply and managing the different settings during the crafting process.

Power Switch Overview

The power switch serves as the primary control for activating or deactivating the device. Its location may vary depending on the design, but it is typically easily accessible for quick operation.

Control Features

- Speed Adjustment: This feature allows users to modify the pace at which the needle moves, providing flexibility for different types of projects.

- Stitch Selector: A control that enables the selection of various stitch styles, enhancing creativity in design.

- Reverse Function: This button allows for backward stitching, which is crucial for securing seams and reinforcing the ends of threads.

Familiarity with these controls not only enhances usability but also contributes to more precise and enjoyable crafting experiences.

Overview of the Throat Plate Features

The throat plate is a crucial element in any stitching apparatus, serving as a foundation that supports the fabric during the sewing process. This component plays a significant role in ensuring accurate needle placement and consistent fabric feeding. Understanding its characteristics can greatly enhance the sewing experience and improve the quality of the final product.

Key Characteristics

Several important features define the throat plate’s functionality and efficiency. These characteristics include the following:

| Feature | Description |

|---|---|

| Needle Positioning | The throat plate often has marked guides that indicate the correct needle placement for various stitches. |

| Feed Dog Access | It provides openings for feed dogs, allowing them to grip the fabric and assist in feeding it through the apparatus. |

| Durability | Typically made from sturdy materials, the throat plate is designed to withstand regular use and maintain its shape. |

| Interchangeability | Many devices allow for the swapping of throat plates, enabling users to select the best option for specific projects. |

Importance of Maintenance

Regular upkeep of the throat plate is essential for optimal performance. Keeping this component clean and free of lint can prevent issues such as skipped stitches or uneven feeding. Proper maintenance contributes to a seamless sewing experience and prolongs the life of the apparatus.

Maintenance Tips for Key Parts

Regular upkeep of essential components is crucial for ensuring optimal performance and longevity. By following a few simple practices, you can keep these critical elements functioning smoothly, preventing unnecessary wear and tear. This section offers practical advice for maintaining various vital sections of your device.

First, it is important to regularly clean the areas where dust and debris can accumulate. Use a soft brush or cloth to remove any particles that may hinder operation. Additionally, periodic lubrication of moving elements helps reduce friction, allowing for more efficient operation.

Another essential aspect is to check for any signs of damage or wear. Inspecting these areas frequently allows for timely repairs or replacements, minimizing the risk of malfunction. Always refer to the manufacturer’s guidelines for specific maintenance schedules and recommended products to ensure proper care.

Finally, storing the equipment in a dry and protected environment can help safeguard it from environmental factors that may lead to deterioration. Proper storage not only protects against physical damage but also maintains the integrity of all internal functions.