In the intricate world of automotive engineering, the assembly responsible for transmitting power to the wheels plays a crucial role in vehicle performance. This collection of components works in harmony to ensure smooth operation and stability, particularly when navigating various terrains. A thorough grasp of these elements is essential for anyone involved in maintenance or repair tasks, as well as for enthusiasts keen on enhancing their vehicles.

Visualizing how these components fit together can significantly aid in troubleshooting and repairs. By examining a comprehensive representation of the assembly, one can gain insights into the arrangement and functionality of each piece. Understanding the role of each part allows for informed decisions during upgrades or replacements, ultimately contributing to a more efficient and reliable driving experience.

Whether you are a seasoned mechanic or a passionate car owner, familiarizing yourself with the key components of the axle system is invaluable. This knowledge not only empowers you to tackle maintenance tasks with confidence but also enhances your overall appreciation of automotive technology and engineering.

The integral mechanism responsible for distributing power to the wheels is crucial for maintaining traction and stability in various driving conditions. Understanding this component’s operation provides insight into its role in enhancing vehicle performance, especially when navigating challenging terrains. This section aims to clarify the essential functions and responsibilities of this system, ensuring optimal operation and longevity.

This assembly serves to transfer rotational force from the engine to the wheels, allowing for effective handling and maneuverability. It facilitates smooth transitions during turns and assists in maintaining grip on slippery surfaces, thus ensuring safety and control.

| Functionality | Description |

|---|---|

| Torque Distribution | Evenly distributes power to the wheels to enhance traction. |

| Turning Assistance | Allows wheels to rotate at different speeds during turns for better handling. |

| Traction Maintenance | Helps maintain grip on various surfaces, improving vehicle stability. |

| Shock Absorption | Minimizes the impact of bumps and irregularities on the road. |

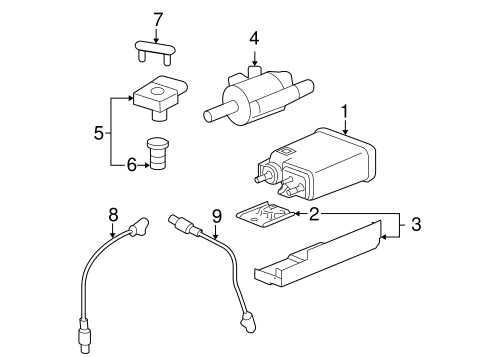

Key Components of the Assembly

The intricate structure of the drivetrain unit encompasses several essential elements that work in harmony to ensure optimal functionality and performance. Understanding these crucial components is vital for effective maintenance and repair of the assembly.

Each segment of the mechanism plays a specific role in facilitating power transfer and enhancing vehicle maneuverability. Below is a comprehensive overview of the primary elements found within the system.

| Component | Description |

|---|---|

| Housing | The outer casing that protects internal components and contains lubricating fluids. |

| Ring Gear | A large gear that transfers torque from the drive shaft to the axle shafts. |

| Pinion Gear | The smaller gear that meshes with the ring gear to facilitate rotational movement. |

| Side Gears | Components that connect to the axle shafts and allow for differential action during turns. |

| Spider Gears | Small gears positioned between the side gears, enabling smooth rotation and power distribution. |

| Seals | Elements that prevent fluid leakage and protect internal parts from contaminants. |

Common Issues with Front Differentials

Understanding the challenges associated with the drive mechanism can help owners maintain optimal performance and reliability. Various factors contribute to complications, from wear and tear to inadequate lubrication. Recognizing these issues is crucial for timely intervention and prevention of more severe damage.

Wear and Tear

Over time, components within the drive assembly can experience significant wear. Friction from constant use can lead to the degradation of gears and bearings, resulting in noise or rough operation. Regular inspections can identify early signs of wear, allowing for proactive maintenance.

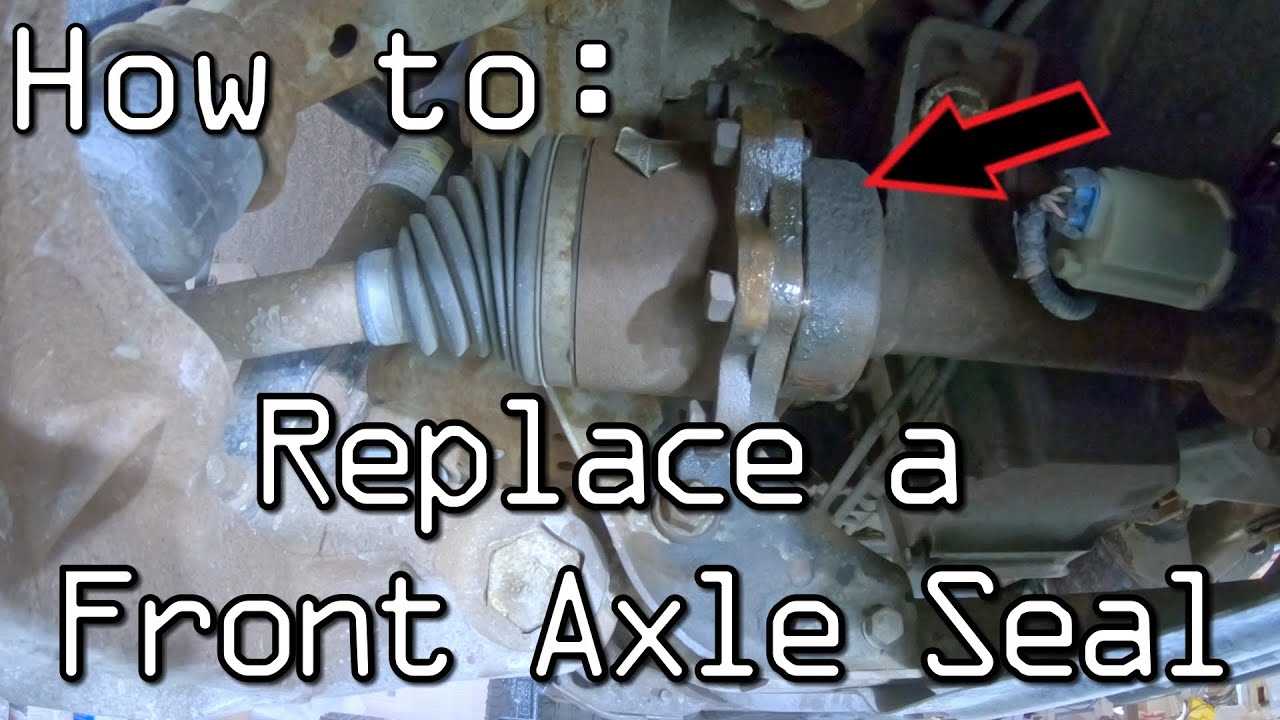

Fluid Leaks

Fluid leaks are a common concern that can lead to serious complications if not addressed promptly. Insufficient lubrication can cause overheating and eventual failure of the internal components. It is essential to regularly check for any leaks and ensure that the lubricant levels are maintained to keep the system functioning smoothly.

Importance of Regular Maintenance

Routine upkeep of your vehicle’s components is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to significant issues that affect not only the functionality but also the safety of your automobile. By dedicating time to regular checks and servicing, you can prevent costly repairs and enhance the overall reliability of your machine.

Periodic inspections enable early detection of wear and tear, allowing for timely replacements and adjustments. This proactive approach helps maintain the efficiency of various systems, ensuring that each element operates harmoniously. Furthermore, a well-maintained vehicle is less likely to experience unexpected breakdowns, providing peace of mind during your travels.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Fluid Checks | Every 3,000 miles | Ensures proper lubrication and cooling |

| Component Inspections | Every 6 months | Identifies wear before it leads to failure |

| Cleaning | Monthly | Prevents buildup and promotes efficiency |

| Tire Rotations | Every 5,000 miles | Extends tire life and improves handling |

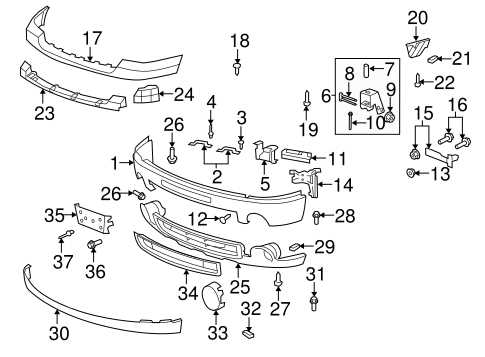

Step-by-Step Assembly Instructions

This section provides a comprehensive guide for assembling the components of the drivetrain system. Following these detailed steps will ensure proper integration and functionality of each element, contributing to optimal performance.

Gathering Required Tools and Components

- Wrenches of various sizes

- Socket set

- Torque wrench

- Lubricants and sealants

- Replacement gaskets

- Cleaning supplies

Assembly Steps

- Begin by ensuring all components are clean and free from debris.

- Lay out all parts in an organized manner to facilitate easy access during assembly.

- Apply the appropriate lubricant to the mating surfaces of the housing.

- Position the main assembly components and secure them using the bolts and nuts provided.

- Use the torque wrench to tighten each bolt to the manufacturer’s specified torque settings.

- Install any additional components, such as seals or covers, ensuring they fit snugly.

- Double-check all connections and fittings to prevent leaks or misalignments.

- Perform a final inspection to confirm everything is assembled correctly before proceeding to reinstallation.

Tools Needed for Differential Repairs

Repairing the gear assembly in your vehicle requires a specific set of tools to ensure the job is done correctly and efficiently. Having the right equipment can make the repair process smoother, allowing for precise adjustments and the replacement of worn components. This section outlines the essential tools you will need to tackle such maintenance tasks.

Essential Hand Tools

To begin with, a selection of hand tools is necessary for disassembly and reassembly. These tools will help you access various components and perform adjustments with accuracy.

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening and tightening bolts and nuts on the gear assembly. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications. |

| Breaker Bar | Provides additional leverage for removing stubborn fasteners. |

| Screwdrivers | Used for various applications including prying components apart. |

| Pry Bar | Assists in separating components without causing damage. |

Specialized Tools

In addition to standard tools, specialized equipment can enhance your repair experience, especially for specific tasks that require precision.

| Tool | Purpose |

|---|---|

| Gear Puller | Used for removing gears and bearings from shafts. |

| Dial Indicator | Measures backlash and ensures correct gear alignment. |

| Seal Installer | Makes installing seals easier and prevents damage. |

| Fluid Pump | Helps in filling gear cases with the proper lubricant. |

| Magnetic Tray | Keeps small parts organized and prevents loss during repairs. |

Understanding Gear Ratios

Gear ratios play a crucial role in determining how effectively power is transmitted from one component to another within a mechanical system. They define the relationship between the number of teeth on two interacting gears, influencing the speed and torque produced by the system. By manipulating these ratios, engineers can optimize performance for various applications, enhancing efficiency and control.

When considering gear ratios, it is essential to recognize their impact on acceleration and top speed. A lower gear ratio often allows for quicker acceleration, making it ideal for tasks requiring rapid movement or increased torque. Conversely, a higher gear ratio can facilitate greater speeds, suitable for highway driving or scenarios where high velocity is advantageous. Understanding these dynamics enables enthusiasts and professionals to make informed choices about gearing setups to match their specific needs.

Additionally, the choice of gear ratios can influence fuel efficiency and engine strain. A well-calibrated ratio can lead to smoother operation and reduced wear on engine components. Therefore, selecting the appropriate gearing is not just about performance; it also involves balancing power, efficiency, and durability to achieve optimal results in any mechanical design.

Identifying OEM vs. Aftermarket Parts

When it comes to vehicle maintenance and repairs, understanding the differences between original equipment manufacturer (OEM) components and aftermarket alternatives is crucial for ensuring performance and longevity. Each option presents unique advantages and potential drawbacks that can affect your vehicle’s functionality.

OEM components are crafted by the vehicle’s manufacturer or an authorized supplier, ensuring they meet specific quality standards and compatibility requirements. In contrast, aftermarket options are produced by third-party manufacturers, offering a wider range of choices and often more competitive pricing.

- Quality Assurance: OEM items generally provide higher quality assurance since they are designed to fit and perform like the original.

- Compatibility: OEM components are guaranteed to be compatible with your vehicle, reducing the risk of fitment issues.

- Cost: Aftermarket alternatives may be more affordable, but it’s important to research the manufacturer’s reputation for quality.

- Variety: Aftermarket suppliers often offer a broader selection, allowing for customization and performance enhancements.

Ultimately, the choice between OEM and aftermarket options depends on individual preferences, budget considerations, and the specific needs of your vehicle. Careful evaluation can lead to a well-informed decision, enhancing your vehicle’s performance and reliability.

Signs of Differential Wear

Understanding the indicators of wear in a drivetrain component is essential for maintaining vehicle performance. Over time, various elements within this assembly can degrade, leading to noticeable changes in operation. Recognizing these signs early can help prevent further damage and costly repairs.

Unusual Noises

One of the first symptoms of wear is the presence of strange sounds emanating from the area. Grinding, whining, or clunking noises often suggest that internal components are suffering from excessive friction or misalignment. Listening for these irregularities during acceleration or deceleration is crucial.

Vibration and Handling Issues

A vehicle exhibiting unexpected vibrations while driving may indicate a malfunctioning assembly. If the steering feels unsteady or the ride quality deteriorates, it’s advisable to inspect the related components. These symptoms can signify that the system is struggling to operate smoothly, which can affect overall control and safety.

How to Diagnose Differential Problems

Identifying issues within the drive mechanism can be challenging but essential for maintaining optimal vehicle performance. A thorough understanding of the components involved and their functions can aid in spotting potential failures. Here are some steps to assist in recognizing common concerns:

- Listen for Unusual Noises: Pay attention to any strange sounds such as grinding, whining, or clunking, which may indicate internal wear or damage.

- Check for Fluid Leaks: Inspect the area beneath the vehicle for any signs of leaking lubricant. Low fluid levels can lead to serious damage.

- Examine Vibration and Handling: Notice if the vehicle vibrates or handles poorly during operation, which may suggest misalignment or imbalance in the system.

- Monitor Temperature: Overheating can signal inadequate lubrication or excessive friction, necessitating immediate investigation.

- Evaluate Response During Turns: If the vehicle exhibits a delay or harshness when making turns, this may be a symptom of trouble within the assembly.

By systematically addressing these areas, one can more effectively pinpoint the source of any problems and determine the necessary corrective measures.

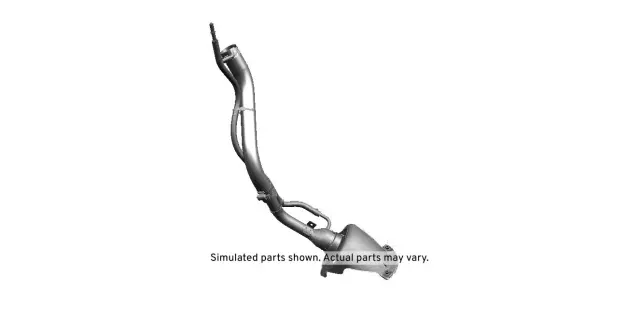

Replacement Options and Costs

When it comes to addressing the components that facilitate power distribution in your vehicle’s drive system, several alternatives are available to consider. Evaluating these choices involves understanding the various types of replacements that can restore functionality while keeping budget constraints in mind. This section explores the options for acquiring new or refurbished components, alongside their associated expenses.

Aftermarket Components

One popular route is opting for aftermarket components, which are often produced by third-party manufacturers. These options may provide a cost-effective solution compared to original equipment manufacturer (OEM) parts. Prices can vary significantly based on the brand and quality, typically ranging from $100 to $500, depending on the specific component required.

OEM Parts

For those who prefer reliability and quality assurance, choosing OEM parts is a viable alternative. These components are made by the original manufacturer and are generally more expensive, with costs ranging from $300 to $1,200. While the upfront expense is higher, investing in OEM parts often translates to enhanced longevity and performance, making them a worthwhile consideration for critical repairs.

Where to Find Quality Parts

Locating reliable components for your vehicle can be a challenging endeavor, but with the right approach, you can ensure that you invest in high-quality replacements. Various avenues exist for sourcing these essential items, ranging from local retailers to online marketplaces. Understanding where to search will enhance your chances of finding the ideal options for your needs.

Local Auto Supply Stores

Visiting nearby auto supply shops is a practical first step. These establishments often stock a range of items suitable for different models and can provide immediate assistance. Furthermore, many store personnel possess valuable expertise that can guide you toward selecting the appropriate replacements.

Online Retailers

The internet offers an extensive selection of components, allowing you to compare prices and specifications with ease. Reputable online platforms often feature customer reviews, which can assist in assessing the quality of the offerings. Additionally, some websites specialize in specific vehicle types, ensuring you find exactly what you need.

In summary, whether you opt for local shops or digital marketplaces, ensuring the authenticity and quality of the items should be your top priority. Investing time in research will ultimately lead to successful procurement.