When it comes to maintaining the functionality of a lawn care machine, having a clear representation of its components is essential. This section explores the intricate arrangement of various elements that contribute to the efficient operation of a specific model. By examining the structure, users can gain valuable insights into how each part interacts with one another.

Visual aids play a crucial role in simplifying the process of identification and replacement. Whether you’re a seasoned technician or a DIY enthusiast, familiarizing yourself with the layout can enhance your ability to troubleshoot issues effectively. Knowledge of how the different segments fit together not only aids in repairs but also fosters a deeper appreciation for the engineering behind the machinery.

In addition to supporting maintenance efforts, understanding the assembly assists in optimizing the performance of your equipment. By knowing where to focus your attention, you can ensure that all components function harmoniously, leading to a smoother and more efficient mowing experience. Engaging with the details of the machine’s construction empowers users to take control of their lawn care tasks with confidence.

This section provides a comprehensive introduction to a specific model of lawn maintenance machinery, focusing on its features, functionalities, and essential components. Understanding the key aspects of this equipment can aid users in maximizing its performance and efficiency.

| Feature | Description |

|---|---|

| Engine Type | Powerful engine designed for optimal cutting performance. |

| Cutting Width | Wide cutting area allowing for faster mowing. |

| Deck Material | Durable construction for long-lasting use. |

| Height Adjustment | Flexible height settings for different grass types. |

| Transmission | Smooth operation for enhanced maneuverability. |

Key Features of the 2760 Model

This model is designed to deliver exceptional performance and reliability in various outdoor tasks. Its engineering emphasizes efficiency and ease of use, making it a valuable asset for both residential and commercial applications.

Powerful Engine: Equipped with a robust power unit, this model ensures high productivity and the capability to tackle even the toughest challenges with ease.

Durable Construction: Built with high-quality materials, this equipment offers longevity and resilience against wear and tear, ensuring it withstands the demands of regular use.

Advanced Cutting Technology: The innovative cutting system enables precise and efficient trimming, allowing for clean results while minimizing operational downtime.

User-Friendly Controls: Designed with the operator in mind, the intuitive control layout ensures comfortable handling and effortless adjustments during operation.

Enhanced Maneuverability: Its compact design and agile nature facilitate smooth navigation through tight spaces, making it ideal for varied terrain.

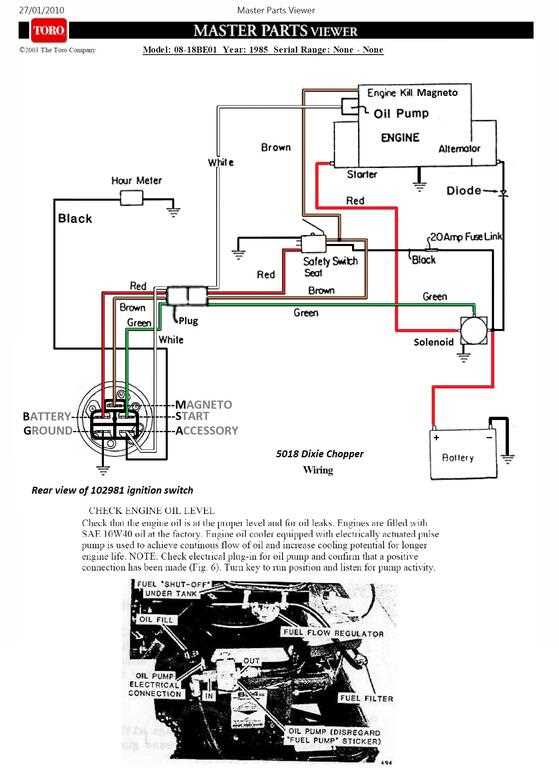

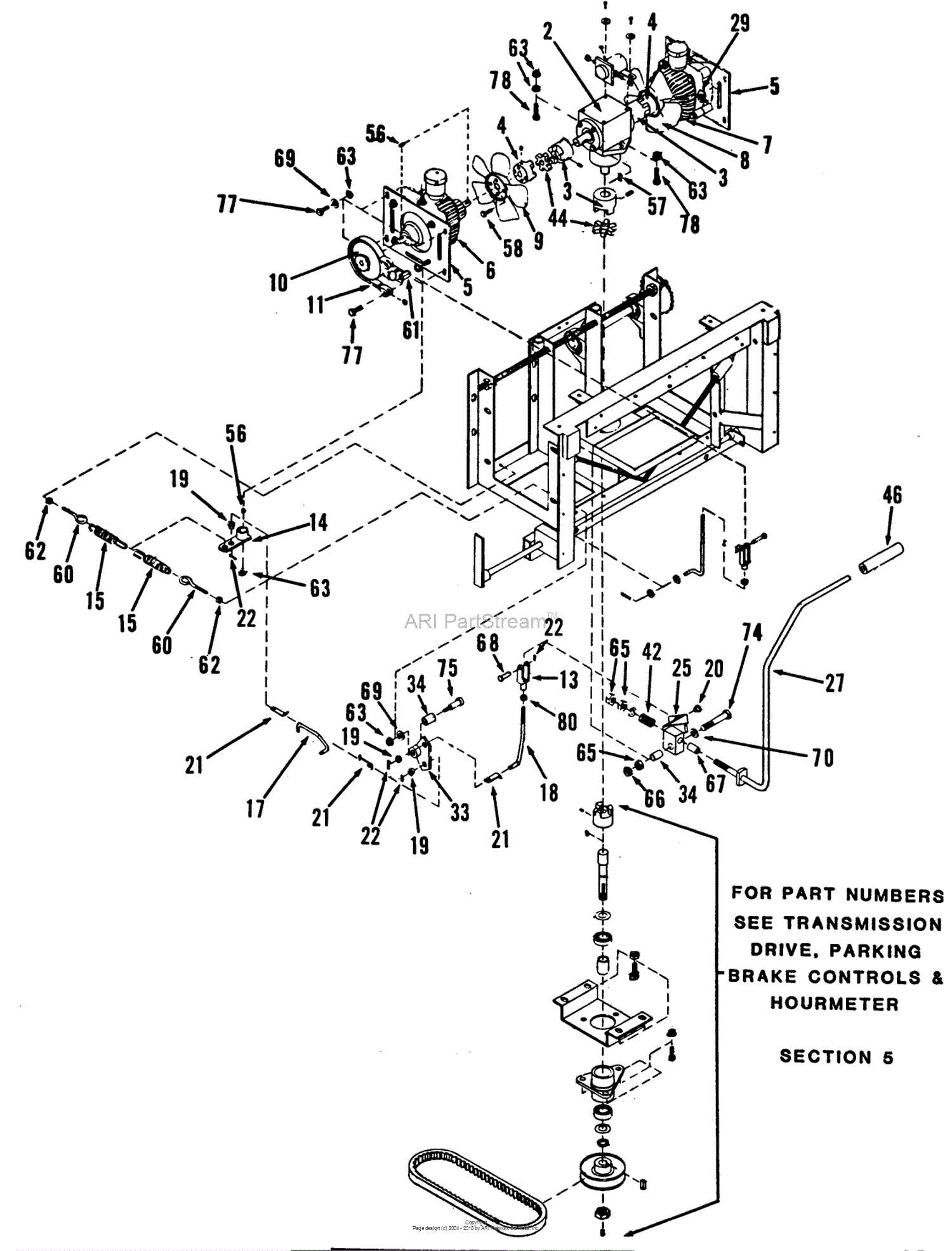

Understanding the Parts Diagram

Comprehending the visual representation of components is crucial for effective maintenance and repair. This illustration serves as a roadmap, detailing how various elements interact and function together within the system. Familiarity with this visual guide can significantly enhance troubleshooting efforts and streamline the replacement process.

Importance of Familiarity

Being well-acquainted with the visual layout allows users to quickly identify individual components and their respective functions. This knowledge not only facilitates swift repairs but also promotes efficient operation by ensuring that all parts are correctly aligned and maintained.

How to Read the Visual Guide

To effectively interpret the visual representation, one should focus on key indicators such as labels and connection points. These elements provide insights into the assembly process and highlight essential areas for inspection during maintenance checks.

| Component | Description | Function |

|---|---|---|

| Engine | Power unit for operation | Drives the entire mechanism |

| Transmission | System for power transfer | Controls speed and torque |

| Deck | Housing for cutting elements | Ensures effective cutting action |

Essential Components for Maintenance

Proper upkeep of machinery requires a thorough understanding of its vital elements. Recognizing and addressing the key components ensures optimal functionality and longevity. This section outlines the crucial elements that should be regularly checked and maintained to prevent issues and enhance performance.

Filters and Fluids

Regularly inspecting and replacing filters is essential for maintaining engine efficiency. Clean filters ensure that air and fuel flow smoothly, preventing contaminants from causing damage. Additionally, monitoring fluid levels, such as oil and hydraulic fluid, is critical. Keeping these fluids at optimal levels prevents overheating and reduces wear on internal parts.

Belts and Blades

Examining belts for signs of wear and ensuring they are properly tensioned is vital for the effective operation of the machine. Dull or damaged blades can affect cutting performance and should be sharpened or replaced as necessary. Routine checks on these components help maintain the overall efficiency and reliability of the equipment.

Common Issues and Solutions

When operating machinery, various challenges may arise, affecting performance and efficiency. Identifying these issues early on is essential for maintaining optimal functionality. Below are some frequent problems encountered and their respective solutions.

- Engine Not Starting:

This issue may stem from fuel supply problems, battery failures, or ignition system malfunctions. Ensure the fuel tank is filled, check the battery connections, and inspect the spark plug for wear or damage.

- Uneven Cutting:

Uneven cutting can result from dull blades or incorrect height adjustments. Regularly sharpen blades and verify that the cutting height is set according to the manufacturer’s specifications.

- Excessive Vibration:

Vibration may indicate loose components or unbalanced blades. Tighten all bolts and nuts, and check that the blades are correctly balanced and securely attached.

- Overheating:

Overheating can be caused by a clogged air filter or insufficient oil levels. Clean the air filter regularly and ensure the oil level is within the recommended range.

Addressing these common problems promptly can enhance the longevity and efficiency of the equipment.

Ordering Replacement Parts

When it comes to maintaining outdoor equipment, acquiring new components is essential for ensuring optimal functionality. Understanding how to efficiently procure these items can enhance the longevity and performance of your machinery.

Where to Find Components

There are several avenues to explore when searching for the necessary items:

- Official manufacturer websites

- Authorized dealers and distributors

- Online marketplaces and auction sites

- Local hardware and supply stores

Considerations for Ordering

Before placing an order, keep the following factors in mind:

- Verify compatibility with your specific model.

- Compare prices from different sources for the best deal.

- Check customer reviews to gauge product quality.

- Assess shipping options and estimated delivery times.

Installation Guidelines for Components

When assembling various mechanical elements, it is crucial to follow precise procedures to ensure optimal performance and longevity. Proper installation not only enhances the efficiency of the equipment but also minimizes the risk of future malfunctions.

Here are key steps to consider during the installation process:

- Preparation:

- Gather all necessary tools and components before beginning the installation.

- Refer to the manufacturer’s specifications for any specific requirements.

- Alignment:

- Ensure that all components are aligned correctly to avoid undue stress.

- Use alignment tools to verify proper positioning.

- Securing Components:

- Utilize appropriate fasteners and ensure they are tightened to the recommended torque settings.

- Double-check all connections to confirm they are secure.

- Testing:

- After installation, perform a thorough inspection to ensure all components function as intended.

- Run the system at low power to identify any irregularities before full operation.

Following these guidelines will help achieve a successful assembly and ensure reliable operation over time. Regular maintenance and periodic checks will further enhance the system’s performance.

Tools Needed for Repairs

Having the right equipment is essential for effectively conducting maintenance and repairs on machinery. Utilizing appropriate tools not only facilitates the repair process but also ensures safety and efficiency.

Before beginning any repair work, it is crucial to gather the necessary instruments. Below is a list of recommended tools that can assist in completing various tasks:

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for removing and securing screws of different types. |

| Socket Set | Helps in accessing hard-to-reach fasteners efficiently. |

| Pliers | Useful for gripping, twisting, and cutting wires or small components. |

| Multimeter | Allows for electrical testing and troubleshooting. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Safety Gear | Protects the technician during repair work, including gloves and goggles. |

Service Tips for Longevity

Maintaining equipment effectively can significantly extend its lifespan and improve performance. Regular care and attention to specific components play a crucial role in ensuring operational efficiency and reducing the risk of unexpected failures.

Regular Maintenance Checks

Conducting routine inspections is essential for identifying potential issues before they escalate. Check fluid levels, belts, and blades regularly to ensure everything is functioning optimally. Keeping the machinery clean from debris and dirt will also enhance its performance.

Utilizing Quality Replacement Parts

When repairs are necessary, always opt for high-quality replacement components. Using subpar materials can lead to premature wear and tear, ultimately shortening the equipment’s lifespan. Investing in reliable parts not only ensures better functionality but also reduces the frequency of repairs.

Comparative Analysis with Other Models

This section delves into a detailed examination of various models within the same category, highlighting their features, performance, and design differences. By comparing these alternatives, users can better understand the advantages and limitations of each option, ultimately aiding in informed decision-making.

When assessing the key characteristics of different machines, factors such as engine efficiency, cutting width, and overall durability play significant roles. The table below summarizes these aspects for easy reference.

| Model | Engine Power | Cutting Width | Weight | Fuel Capacity |

|---|---|---|---|---|

| Model A | 24 HP | 60 inches | 800 lbs | 5 gallons |

| Model B | 22 HP | 54 inches | 750 lbs | 4.5 gallons |

| Model C | 26 HP | 66 inches | 850 lbs | 6 gallons |

By analyzing these specifications, it becomes evident that different machines cater to varied needs and preferences. Users should consider their specific requirements, such as terrain type and mowing frequency, when selecting the most suitable model.

Resources for Further Assistance

For individuals seeking additional support and information regarding lawn maintenance equipment, various resources are available to enhance understanding and troubleshooting capabilities. Accessing the right tools and information can significantly improve the efficiency of operations and prolong the lifespan of the machinery.

Online Forums and Communities

Joining online forums dedicated to gardening machinery can provide valuable insights from experienced users. These platforms often feature discussions on common issues, maintenance tips, and modifications that can enhance performance. Engaging with the community allows users to share their experiences and seek advice.

Manufacturer’s Official Website

The manufacturer’s official website typically offers a wealth of resources, including user manuals, maintenance guides, and customer support options. These documents can assist in understanding the specific features and functionalities of the equipment. Additionally, users may find contact information for professional assistance if needed.