When it comes to maintaining a pristine outdoor space, having a thorough grasp of the various components of your machinery is essential. Familiarizing yourself with the intricate elements that work in harmony not only enhances performance but also extends the lifespan of your equipment. Whether you are a novice or an experienced user, knowledge of these components empowers you to make informed decisions during maintenance and repairs.

In this section, we will delve into the essential elements that comprise your outdoor machinery. From the fundamental structures to the intricate systems that drive functionality, each component plays a pivotal role in ensuring optimal operation. Understanding these elements not only aids in troubleshooting but also in recognizing the significance of regular upkeep.

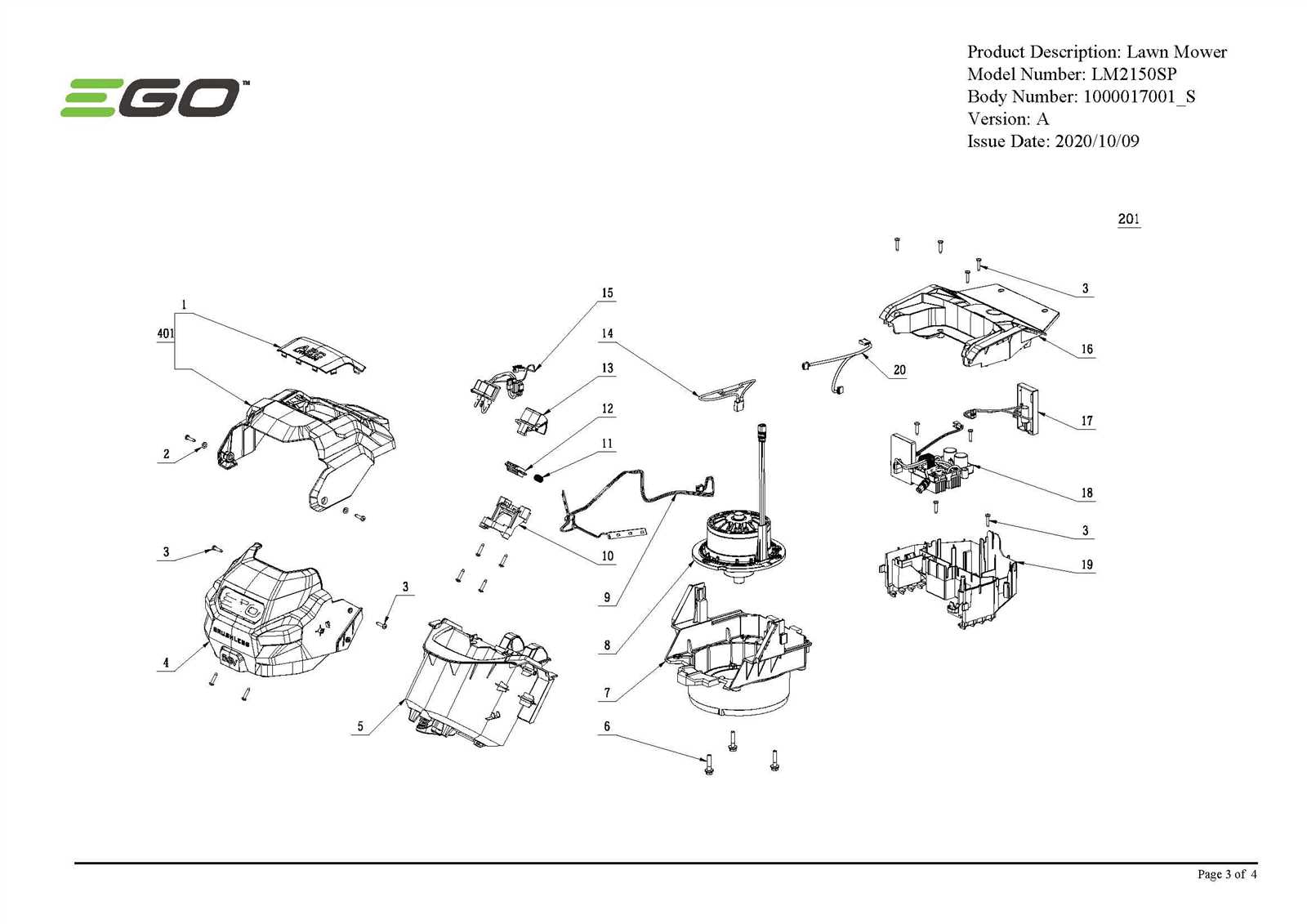

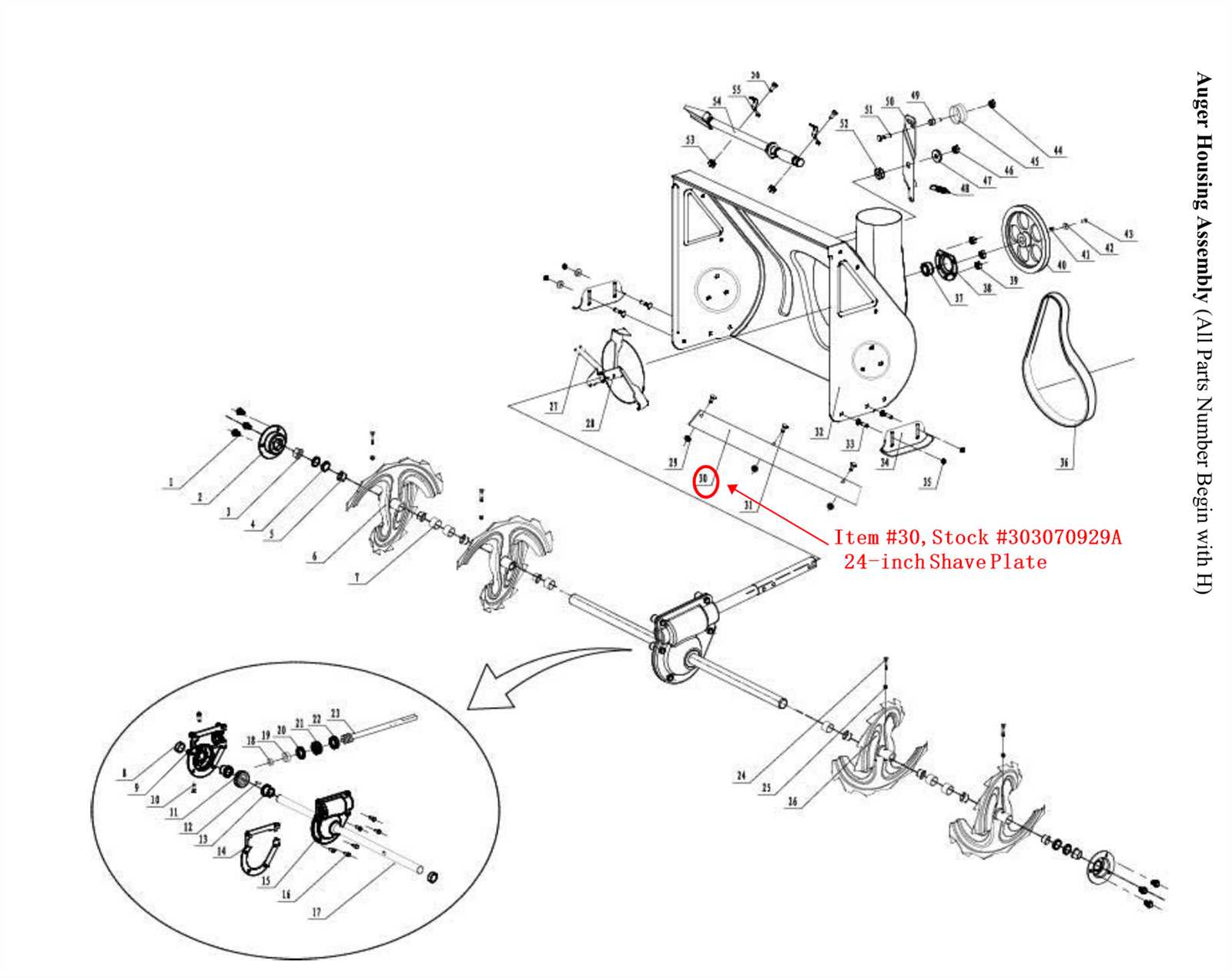

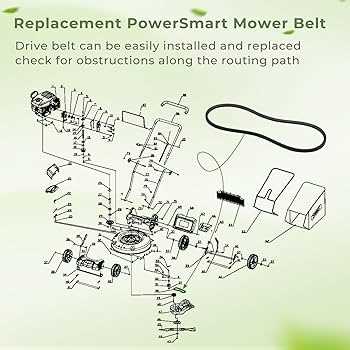

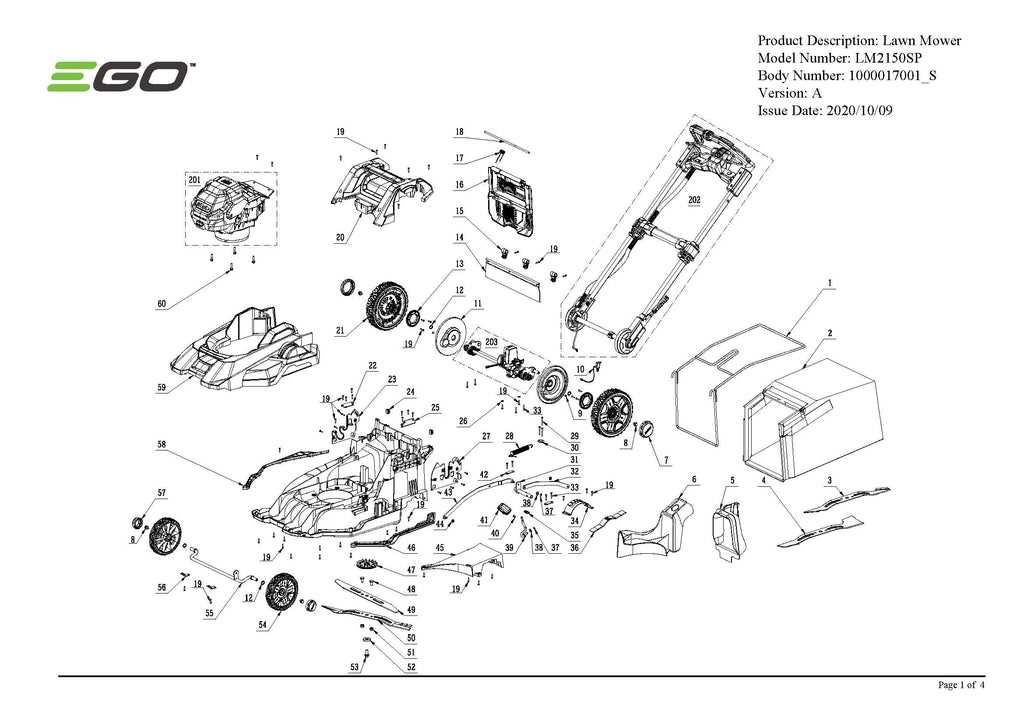

Furthermore, visual aids can significantly enhance your comprehension of how everything fits together. By exploring a detailed representation of these components, you will gain insights into their interactions and overall contribution to the efficiency of your machinery. This knowledge is vital for anyone looking to achieve a well-maintained outdoor environment.

Powersmart Lawn Mower Overview

This section provides a comprehensive insight into a popular gardening device known for its efficiency and user-friendly features. Designed for ease of use, this equipment is ideal for maintaining a neat and tidy outdoor space. Understanding its components and functionalities can greatly enhance the user experience and ensure optimal performance.

Key Features

Among the standout characteristics of this device are its powerful motor, adjustable cutting heights, and lightweight design. Users can benefit from a smooth operation, which allows for quick and effective trimming of grass and foliage. The ergonomic handles and easy maneuverability contribute to a comfortable and less strenuous gardening experience.

Maintenance Tips

To ensure longevity and reliable performance, regular upkeep is essential. Checking the blades for sharpness and cleanliness is vital, as well as inspecting the motor for any debris accumulation. Additionally, storing the device in a dry, sheltered area can protect it from environmental factors, further enhancing its lifespan.

Understanding Lawn Mower Components

Grasping the various elements that comprise outdoor maintenance equipment is essential for optimal performance and upkeep. Each component plays a critical role in ensuring efficiency and durability, contributing to the overall functionality of the device. Familiarity with these key elements not only aids in troubleshooting but also enhances the experience of using the equipment.

The engine serves as the powerhouse, converting fuel into mechanical energy. This energy drives the blades, which are crucial for achieving a clean and even cut. Another important feature is the deck, which houses the blades and determines the cutting width, influencing the time taken for landscaping tasks.

Wheels and tires provide mobility and stability, allowing for easy maneuverability across various terrains. The handle, often adjustable, offers user comfort and control, enhancing the operational experience. Additionally, safety mechanisms are integrated into the design to prevent accidents and ensure user protection during operation.

Understanding these components allows for better maintenance practices, helping to prolong the life of the equipment and improve performance. Regular checks and knowledge of how each part functions can lead to more effective landscaping results.

Importance of Maintenance and Repairs

Regular upkeep and timely repairs are crucial for the longevity and efficiency of any mechanical equipment. Neglecting these aspects can lead to diminished performance, increased operational costs, and ultimately, the need for costly replacements. Ensuring that all components are in optimal condition not only enhances functionality but also promotes safety during usage.

Benefits of Regular Upkeep

Preventative maintenance serves as the first line of defense against unexpected breakdowns. By routinely inspecting and servicing machinery, users can identify potential issues before they escalate. This proactive approach not only saves time but also minimizes disruption in regular operations.

Cost-Effectiveness of Timely Repairs

Addressing minor issues promptly can significantly reduce long-term expenses. Ignoring small problems often leads to more extensive damage, resulting in expensive repairs or replacements. By investing in regular checks and swift repairs, owners can maintain their equipment in peak condition while ensuring maximum efficiency and performance.

Identifying Key Replacement Parts

Understanding the essential components of your equipment is crucial for effective maintenance and repair. Recognizing the key elements that may require replacement can ensure your machine operates smoothly and efficiently. This knowledge not only aids in troubleshooting issues but also extends the lifespan of your equipment.

Commonly, the most critical components include the cutting mechanism, the motor, and the control systems. Familiarizing yourself with these elements will allow for quicker identification of any malfunctioning parts. Additionally, it is beneficial to know the various accessories and attachments that enhance functionality, as they may also need occasional replacements.

To accurately pinpoint these components, consulting a schematic can be invaluable. These visual guides provide a comprehensive overview, making it easier to locate and assess the condition of each part. By maintaining awareness of these key elements, you can ensure that your equipment remains in optimal condition for years to come.

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repair. These illustrations serve as valuable guides, enabling users to identify various elements and their relationships within a device. Grasping how to interpret these visuals can save time and enhance the repair process.

1. Familiarize Yourself with Symbols: Each illustration employs specific symbols and notations to represent different components. Take time to review the legend or key, as it provides essential information about what each symbol signifies.

2. Identify Major Sections: Most visual representations are organized into distinct areas, each corresponding to a particular function or part of the system. Recognizing these sections helps you navigate the illustration more efficiently.

3. Trace Connections: Pay attention to lines or arrows that indicate how components are linked. Understanding these connections is vital for comprehending how the system operates as a whole.

4. Note Component Numbers: Components are often labeled with numbers that correspond to a list. This can assist you in ordering replacements and ensure you acquire the correct items.

5. Review Instructions: Accompanying text or notes often provide context or additional guidance on assembly or disassembly. Reading these details can clarify any uncertainties that arise while interpreting the visual.

By mastering these steps, you can confidently navigate and utilize any visual representation, facilitating more efficient repairs and maintenance.

Common Issues and Solutions

Every outdoor maintenance tool may encounter certain challenges that affect its performance. Understanding these typical problems and their remedies can enhance efficiency and prolong the lifespan of the equipment. Here are some prevalent issues along with their corresponding solutions.

Engine Fails to Start

If the engine doesn’t respond when you try to start it, check the fuel level and ensure it is fresh. Stale fuel can cause ignition problems. Additionally, inspect the spark plug for any signs of wear or damage; replacing it may resolve the issue. Lastly, ensure that all connections are secure and free of corrosion.

Uneven Cutting Performance

Uneven cutting can result from a dull blade or improper height settings. Sharpening or replacing the blade is essential for achieving a clean cut. Also, ensure that the cutting height is adjusted according to the type of terrain being serviced. Regular maintenance will help prevent this issue from recurring.

Tools Needed for Repairs

Having the right equipment is essential for effective maintenance and repairs. Proper tools not only facilitate the process but also ensure that tasks are completed safely and efficiently. Below is a list of essential items that will assist you in carrying out various repair tasks effectively.

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for removing and tightening screws on various components. |

| Wrench Set | Helpful for loosening and tightening nuts and bolts. |

| Socket Set | Allows for easy access to fasteners in tight spaces. |

| Pliers | Useful for gripping, bending, and cutting wires. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Multimeter | Used to measure voltage, current, and resistance for electrical diagnostics. |

| Safety Gear | Includes gloves and goggles to protect yourself during repairs. |

Where to Purchase Replacement Parts

Finding high-quality components for your equipment can greatly enhance its performance and longevity. It is essential to know the best sources for obtaining these items, ensuring you can restore functionality quickly and effectively.

Online Retailers

- Specialty websites often offer a vast selection of items tailored to specific models.

- Large e-commerce platforms provide user reviews and competitive pricing.

- Manufacturer websites may stock original components, ensuring compatibility.

Local Stores

- Home improvement centers typically carry a range of essential supplies.

- Automotive shops may have universal options suitable for various equipment.

- Local repair shops can offer personalized assistance and recommendations.

Exploring both online and local options will ensure you find the right components to keep your machinery in top shape.

Tips for Safe Operation

Ensuring a secure and effective experience while using outdoor equipment is crucial for both personal safety and optimal performance. Following proper procedures and being mindful of your surroundings can significantly reduce the risk of accidents and injuries.

1. Read the Manual: Familiarize yourself with the user guide before operating the device. Understanding the controls, safety features, and maintenance requirements is essential for safe use.

2. Wear Protective Gear: Always don appropriate clothing, including sturdy shoes, gloves, and eye protection. This helps shield against debris and minimizes the risk of injury.

3. Clear the Area: Inspect the worksite for any obstacles, such as rocks or branches, that could pose a hazard. A clear area allows for smoother operation and reduces the chance of damage or accidents.

4. Maintain Focus: Stay alert while operating the machinery. Avoid distractions, and do not engage in conversations or use your phone during operation.

5. Check Equipment Regularly: Perform routine inspections to ensure all components are functioning properly. Address any issues before starting to prevent malfunctions that could lead to dangerous situations.

6. Follow Safety Protocols: Adhere to recommended safety practices, such as keeping hands and feet away from moving parts and never attempting to clear clogs while the machine is running.

7. Turn Off When Not in Use: Always switch off the equipment when it is not in operation, especially when refueling or performing maintenance tasks. This simple action can prevent accidental starts and enhance safety.

Benefits of Regular Inspections

Routine evaluations of outdoor equipment play a crucial role in maintaining performance and extending lifespan. By conducting these checks, users can identify potential issues before they escalate, ensuring efficient operation and safety.

Here are some key advantages of performing regular assessments:

| Advantage | Description |

|---|---|

| Early Problem Detection | Identifying wear and tear or faults before they lead to significant failures. |

| Enhanced Performance | Ensuring equipment operates at optimal efficiency, reducing energy consumption. |

| Cost Savings | Avoiding costly repairs and replacements by addressing minor issues promptly. |

| Safety Assurance | Minimizing the risk of accidents or injuries by maintaining equipment in good condition. |

| Longevity | Extending the lifespan of machinery through consistent upkeep and care. |

Seasonal Maintenance Checklist

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. Following a seasonal maintenance checklist helps to identify areas needing attention and prevents potential issues. This proactive approach not only enhances efficiency but also saves time and resources in the long run.

Here’s a comprehensive checklist to follow throughout the seasons:

- Spring:

- Inspect and clean the exterior to remove dirt and debris.

- Check and sharpen blades for effective cutting.

- Change the oil and replace the oil filter.

- Examine belts and cables for wear and tear.

- Replace air filters to ensure optimal airflow.

- Summer:

- Monitor fuel levels and add stabilizer as necessary.

- Inspect tires for proper inflation and wear.

- Clean the underside to prevent grass buildup.

- Check for any loose screws or components.

- Autumn:

- Prepare for storage by cleaning the unit thoroughly.

- Change the oil and replace the oil filter.

- Empty the fuel tank or use a fuel stabilizer.

- Inspect for rust or corrosion and address accordingly.

- Winter:

- Store in a dry, covered area to protect from harsh weather.

- Remove batteries and store them in a temperature-controlled environment.

- Conduct a general inspection to plan for repairs needed in spring.

- Ensure all components are lubricated as per guidelines.

By following this checklist each season, you can maintain your equipment in peak condition, ensuring reliable performance when you need it most.

Upgrading Parts for Better Performance

Enhancing your equipment’s capabilities can lead to improved efficiency and a smoother user experience. By selecting high-quality components, you can optimize performance, extend the lifespan, and ensure reliability during operation. This section focuses on key upgrades that can significantly impact functionality and effectiveness.

Key Components to Consider

When looking to upgrade your machinery, several critical components should be prioritized. These improvements can lead to better overall performance:

| Component | Benefits |

|---|---|

| Blades | Enhanced cutting efficiency and precision |

| Engine | Increased power output and fuel efficiency |

| Wheels | Improved traction and maneuverability |

| Filters | Better air and fuel filtration for optimal performance |

Installation Tips

Proper installation is crucial for maximizing the benefits of any upgrades. Ensure you follow manufacturer guidelines and consider seeking professional assistance if needed. Regular maintenance post-upgrade will also help maintain peak performance levels over time.