When the cold months arrive, having a reliable tool to clear away the accumulation of white can make all the difference. Familiarizing yourself with the components of this essential equipment ensures its optimal performance and longevity. Whether you are a seasoned user or new to this winter apparatus, knowing how everything fits together is crucial.

In this section, we will explore the intricate assembly of your equipment, breaking down each element to provide clarity on functionality and maintenance. By understanding the individual components, you can better troubleshoot issues and enhance your machine’s efficiency.

Additionally, we will delve into the ultimate guide for identifying and replacing any worn or damaged parts. This knowledge will empower you to keep your winter tool running smoothly, ready to tackle even the heaviest snowfall.

Ariens 1028 Snowblower Overview

This powerful machine is designed to tackle heavy snowfall, making winter maintenance efficient and manageable. Its robust construction and advanced features ensure reliability and performance, allowing users to clear driveways and pathways with ease.

Key Features

Equipped with a high-performance engine, this equipment boasts impressive throwing distance and speed. The user-friendly controls enhance maneuverability, while the adjustable chute allows for precise direction of the snow discharge. Additionally, its durable build withstands harsh weather conditions, ensuring longevity.

Maintenance Tips

Regular upkeep is essential for optimal functionality. Routine checks on the engine oil, spark plug, and belts can prevent common issues. Keeping the machine clean and free of snow buildup will also enhance performance and extend its lifespan. Always refer to the manufacturer’s guidelines for specific maintenance practices.

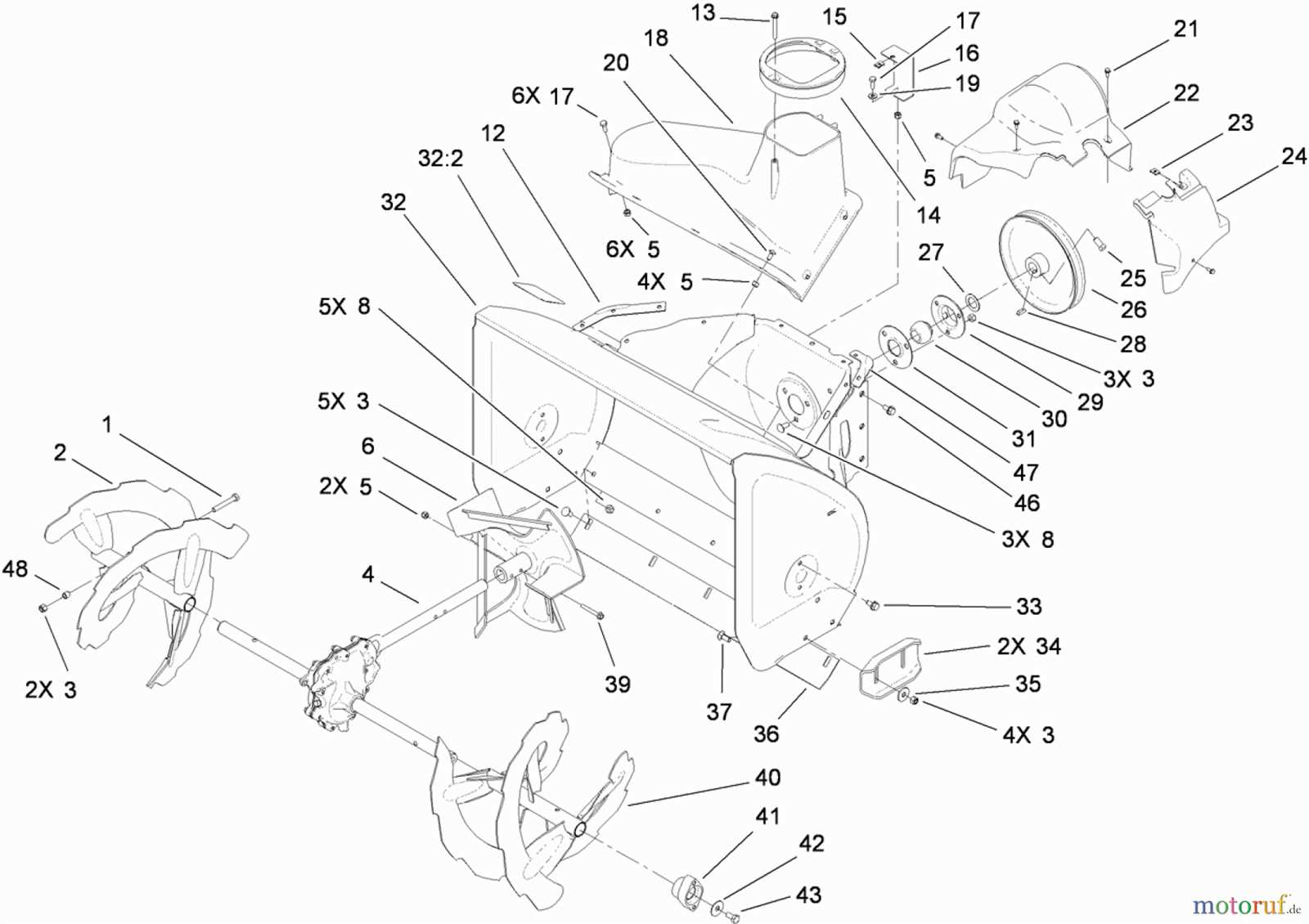

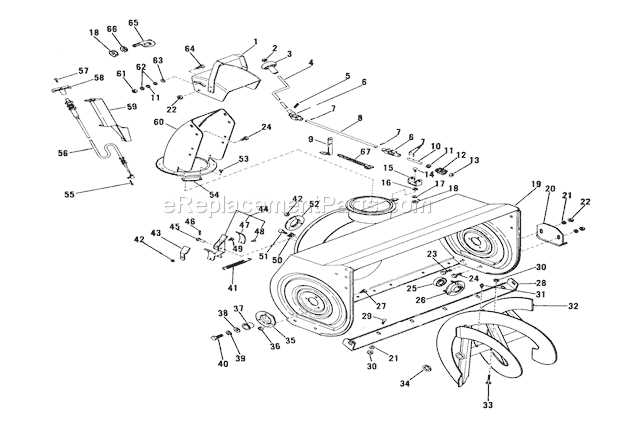

Essential Components Explained

Understanding the crucial elements of a winter clearing machine is vital for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance and longevity of the equipment.

- Engine: The heart of the machine, providing the necessary power to operate.

- Auger: Designed to gather and break up snow, facilitating easy discharge.

- Chute: Directs the cleared snow to the desired location, allowing for efficient disposal.

- Drive System: Ensures smooth movement and maneuverability across various terrains.

- Controls: User interface for managing settings and operation, enhancing usability.

Each of these parts contributes to the ultimate functionality and efficiency, making it essential to familiarize oneself with them for effective use.

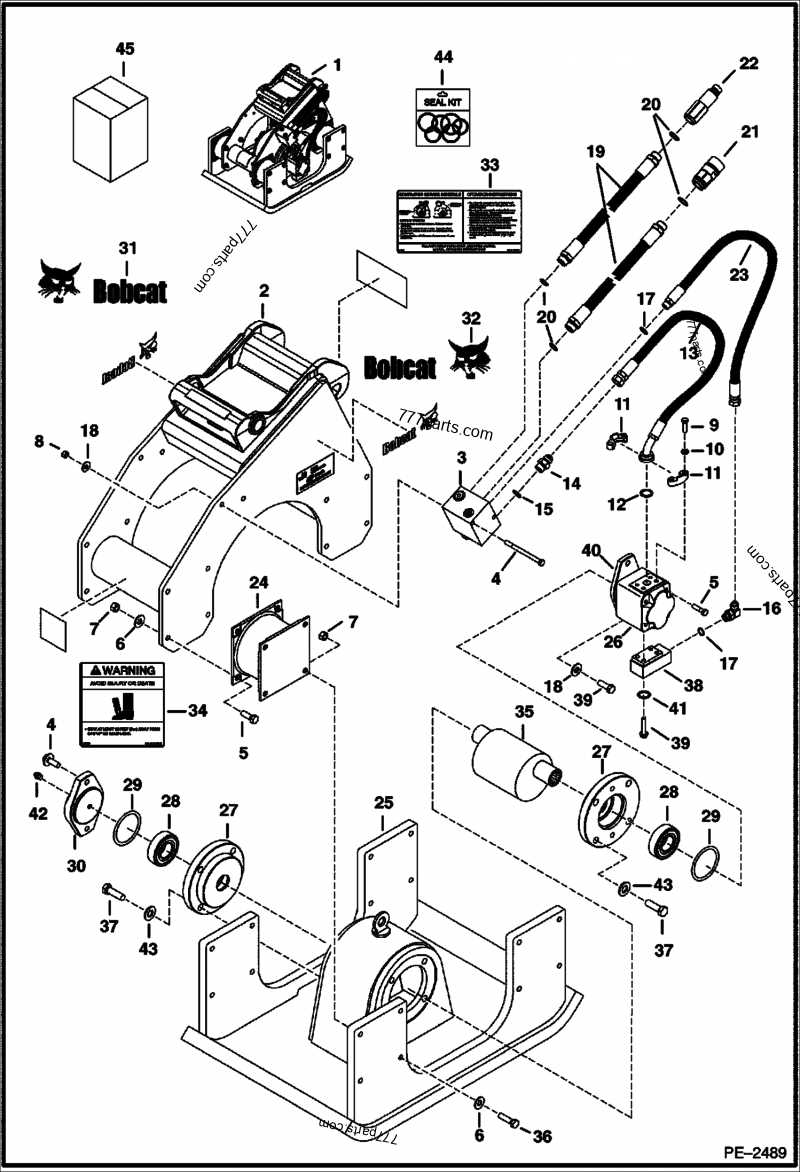

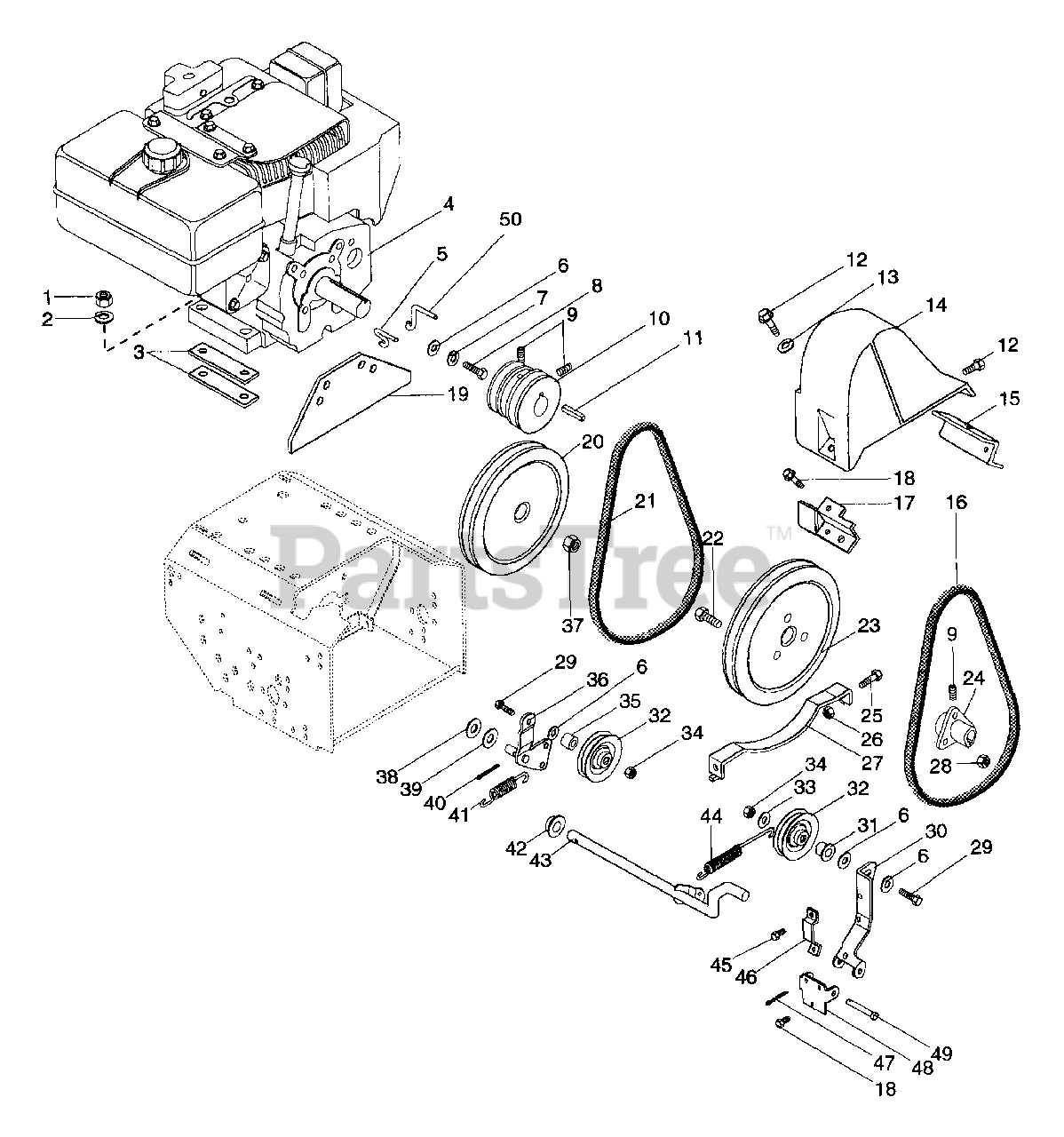

Understanding the Parts Diagram

Comprehending the layout of components is essential for effective maintenance and repair of machinery. A visual representation serves as a guide, illustrating how different elements fit together and function as a cohesive unit. By familiarizing yourself with this schematic, you can enhance your troubleshooting skills and streamline the process of identifying issues.

Key Elements of the Schematic

Each section in the visual representation highlights specific features and their interconnections. Notations often indicate the names, numbers, or functions of the various pieces, making it easier to locate the right parts for replacement or repair. Understanding these key elements empowers users to approach their tasks with confidence and efficiency.

Benefits of Familiarity

Being well-acquainted with the layout allows for quicker assessments and minimizes downtime during repairs. Additionally, it fosters a deeper understanding of how the equipment operates, which is invaluable when troubleshooting complex issues. A solid grasp of the components ultimately leads to more informed decisions regarding maintenance and enhancements.

Common Issues and Solutions

In the realm of winter equipment maintenance, users often encounter several recurring challenges that can hinder performance. Understanding these issues and their respective remedies can enhance functionality and prolong the lifespan of the machinery.

| Issue | Solution |

|---|---|

| Starting Problems | Check the fuel levels and spark plug condition; replace if necessary. |

| Ineffective Snow Clearing | Inspect the blades for wear and adjust or replace them accordingly. |

| Stalling | Examine the fuel line for clogs and ensure proper airflow. |

| Excessive Vibrations | Ensure all bolts are tightened and check for any misaligned components. |

| Difficulty in Maneuvering | Inspect the drive belt for wear and replace if it shows signs of damage. |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your outdoor equipment. Proper care not only extends the lifespan but also enhances performance during critical seasons.

- Check and change the oil regularly to ensure optimal engine performance.

- Inspect the spark plug and replace it if necessary to maintain ignition efficiency.

- Clean or replace air filters to promote better airflow and reduce strain on the engine.

- Sharpen the blades to ensure efficient operation and reduce wear on the machine.

Additionally, always store your equipment in a dry place to prevent rust and corrosion. Following these simple practices will help you get the ultimate value from your investment.

Replacement Parts Availability

Ensuring the efficiency of your equipment often hinges on the availability of suitable components. When maintenance is required, sourcing the right items becomes essential for optimal performance and longevity.

Access to a variety of replacement components can significantly enhance the upkeep process. Here are some key points to consider:

- Look for authorized dealers and retailers to guarantee quality.

- Explore online platforms for a wider selection and potential cost savings.

- Check local hardware stores for commonly needed items that can expedite repairs.

Additionally, it’s important to be aware of the following:

- Compatibility: Ensure that the replacements are designed for your specific model.

- Warranty: Verify if the new components come with a guarantee for added security.

- Reviews: Research user feedback to assess reliability and performance of the items.

Staying informed about the availability of these essential components can save time and enhance the overall efficiency of your equipment.

Choosing Quality Aftermarket Parts

Selecting high-quality replacement components is crucial for maintaining the efficiency and longevity of your equipment. Opting for reliable alternatives can enhance performance while often reducing costs. Understanding the key factors involved can lead to better decisions and improved functionality.

Here are some essential criteria to consider:

- Material Quality: Ensure that components are made from durable materials to withstand harsh conditions.

- Compatibility: Verify that the replacements fit seamlessly with your machinery to avoid malfunctions.

- Brand Reputation: Research manufacturers known for their reliability and positive customer feedback.

- Warranty and Support: Look for options that come with a warranty and accessible customer service for added security.

By focusing on these aspects, you can delve into a range of alternatives that promise ultimate performance without compromising on quality.

Tools Needed for Repairs

Effective maintenance and repair of outdoor machinery require a specific set of instruments to ensure efficiency and precision. Having the right tools not only simplifies the process but also enhances safety during the tasks at hand.

Essential tools typically include wrenches, screwdrivers, and pliers, which are fundamental for assembling and disassembling components. Additionally, a socket set can be invaluable for reaching tight spaces and securing fasteners effectively.

For thorough inspections, a torque wrench is necessary to achieve the proper tightness without damaging parts. Furthermore, a multimeter is useful for diagnosing electrical issues, ensuring optimal performance.

Finally, having a reliable workbench equipped with proper lighting will provide a comfortable environment for tackling repairs efficiently. Preparing your workspace with these tools will ultimately lead to successful outcomes in maintaining your equipment.

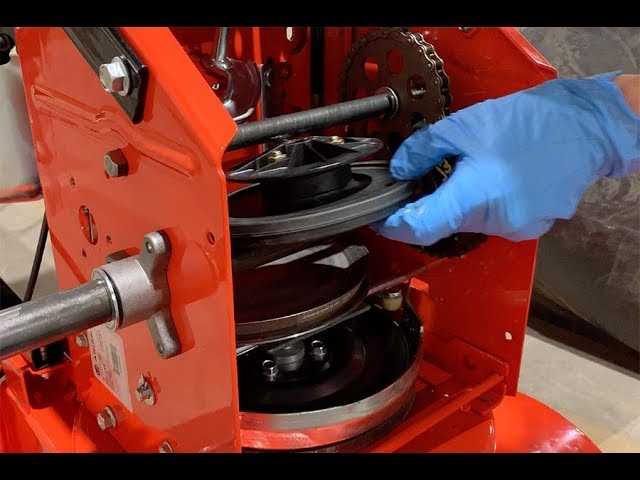

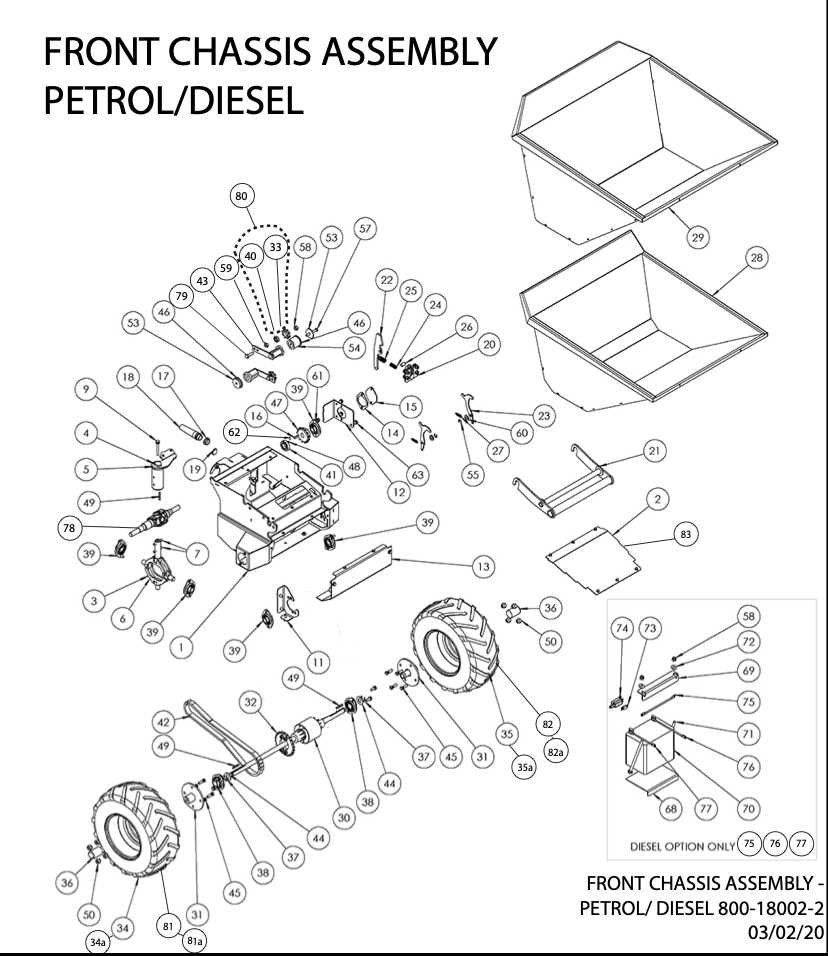

Assembly Process Breakdown

The assembly procedure is a crucial aspect of ensuring optimal functionality and performance of equipment designed for winter tasks. This section will delve into the essential steps involved in the assembly process, highlighting key components and their interrelations.

Initially, it’s vital to gather all necessary components and tools to streamline the assembly. Each piece plays a unique role, contributing to the overall efficiency of the unit. Understanding the purpose of each part can facilitate smoother assembly and enhance operational reliability.

Following the preparation, the assembly typically begins with the foundational components, ensuring they are securely attached. This foundational setup supports subsequent installations and adjustments. Careful attention to detail during this stage is paramount to prevent future complications.

As the process progresses, auxiliary components are incorporated. These elements may include various mechanisms that improve performance, such as drive systems or control features. Proper alignment and secure fastening are critical to ensure they function harmoniously with the primary structure.

Finally, after all components are assembled, thorough inspections are essential to confirm everything is in place and functioning as intended. This final review helps identify any potential issues before the equipment is put to use, ensuring it meets the highest standards of performance and reliability.

Winter Preparation Checklist

As the colder months approach, ensuring your equipment and home are ready is essential for a smooth transition. This checklist will help you navigate the necessary steps to prepare effectively for winter challenges, ensuring safety and efficiency throughout the season.

Essential Equipment

| Item | Status |

|---|---|

| Outdoor Equipment | Check |

| Heating Systems | Inspect |

| Emergency Supplies | Stock |

| Winter Clothing | Organize |

Home Safety Checks

| Task | Completion |

|---|---|

| Insulate Pipes | Done |

| Inspect Roof | Completed |

| Clear Gutters | Finished |

| Test Smoke Alarms | Verified |

Safety Precautions While Operating

When utilizing outdoor power equipment designed for snow removal, it is crucial to prioritize safety to prevent accidents and injuries. Understanding proper operating procedures and taking necessary precautions ensures a smooth and secure experience while working in challenging winter conditions.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes sturdy footwear with good traction, insulated gloves to protect hands from cold, and safety goggles to shield eyes from flying debris. Additionally, wearing a warm hat and layered clothing helps maintain body heat during prolonged exposure to frigid temperatures.

Pre-Operation Checks

Before starting the machine, conduct a thorough inspection to ensure all components are functioning correctly. Check for fuel leaks, ensure the safety switch is operational, and inspect the auger and discharge chute for any obstructions. Maintaining a clean work area free of debris minimizes the risk of accidents and enhances overall safety during operation.

Upgrading Your Snowblower Features

Enhancing your winter equipment can significantly improve performance and efficiency. By incorporating advanced components and technology, you can transform a basic machine into a powerful ally against harsh weather. Consider the benefits of modern upgrades that cater to both functionality and user convenience.

Improved Engine Power: Upgrading to a more robust engine can increase torque and speed, allowing for faster clearing of snow. A higher horsepower unit can tackle deeper accumulations with ease.

Enhanced Traction: Installing superior tires or tracks can boost stability and maneuverability on slippery surfaces. This upgrade ensures better grip and control during challenging conditions.

Advanced Control Features: Features such as electric start, adjustable speed settings, and remote chute control can simplify operation. These enhancements provide a more user-friendly experience and allow for greater customization while clearing.

Lighting Systems: Adding powerful LED lights can extend your working hours into the night. Improved visibility ensures safety and effectiveness, especially during heavy snowfall.

By thoughtfully considering these enhancements, you can create a machine that not only meets but exceeds your expectations, ultimately making winter maintenance easier and more efficient.

Customer Reviews and Feedback

This section aims to capture the insights and experiences of users regarding their machinery, highlighting the common themes in satisfaction and areas for improvement. Feedback plays a crucial role in understanding product reliability and performance, providing potential buyers with valuable information.

| Reviewer | Rating | Comment |

|---|---|---|

| John D. | 5/5 | Exceptional performance in heavy snow, very reliable. |

| Mary S. | 4/5 | Great for residential use, but a bit heavy to maneuver. |

| Tom R. | 3/5 | Had some issues with the start-up; needs improvement. |

| Linda K. | 4/5 | Good value for the price, does the job well. |