When it comes to maintaining outdoor machinery, having a clear understanding of its various elements is crucial. This knowledge not only enhances the efficiency of your equipment but also ensures longevity and optimal performance. By exploring the intricate details of each section, users can effectively troubleshoot issues and facilitate repairs.

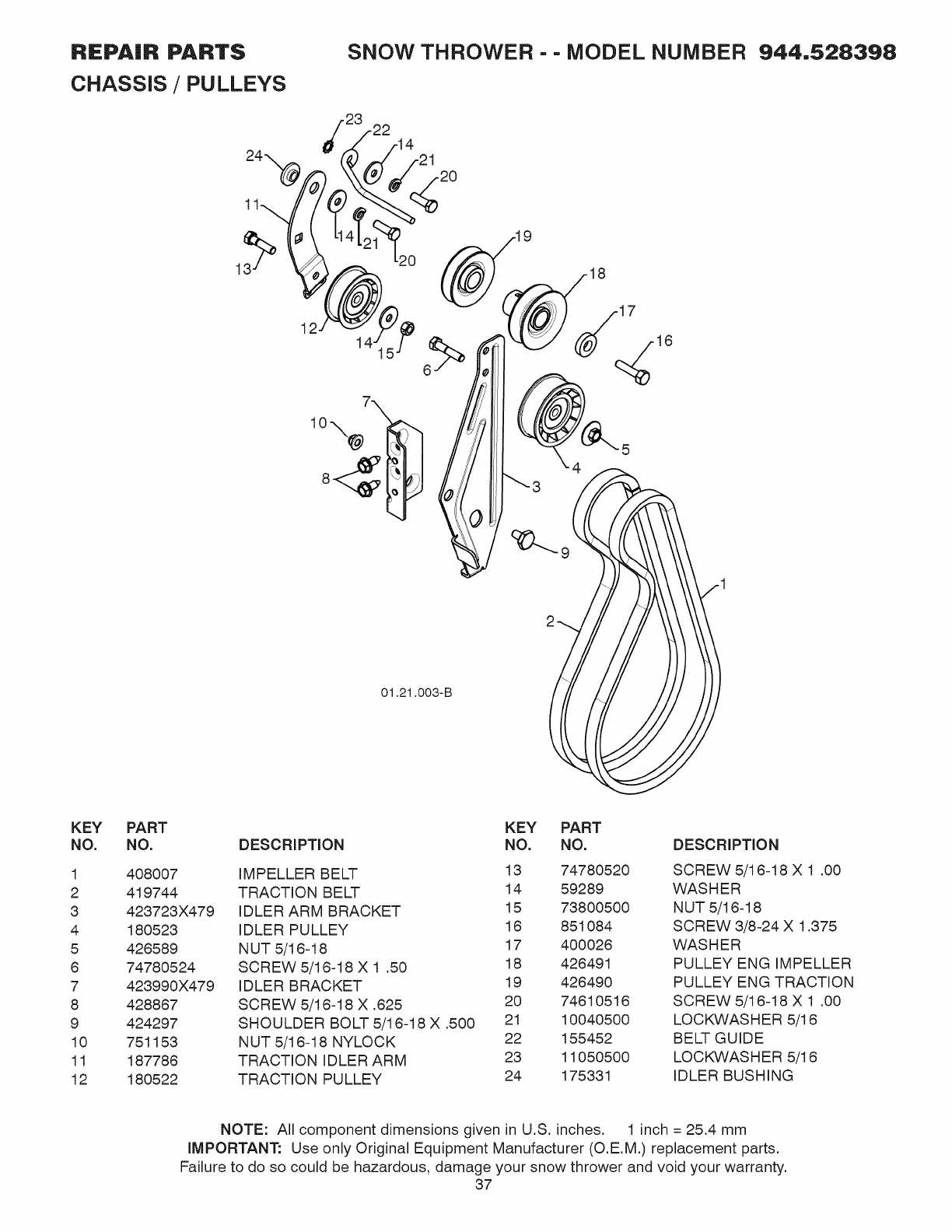

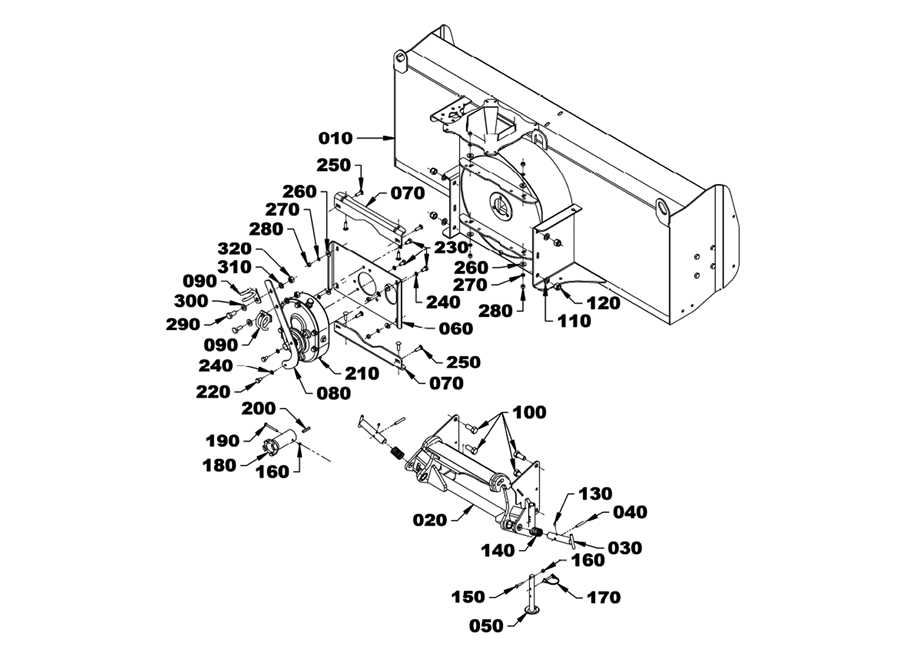

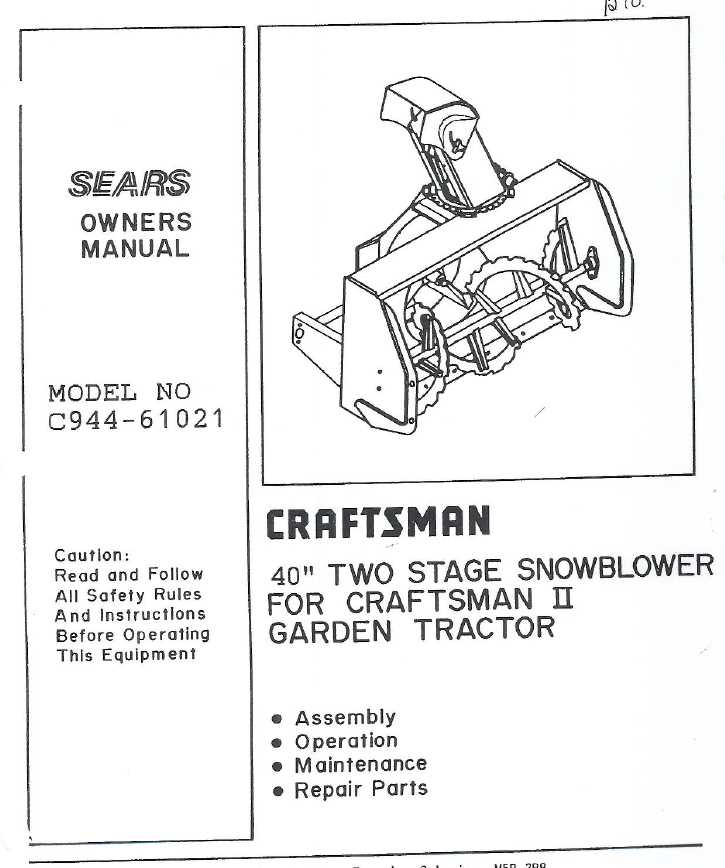

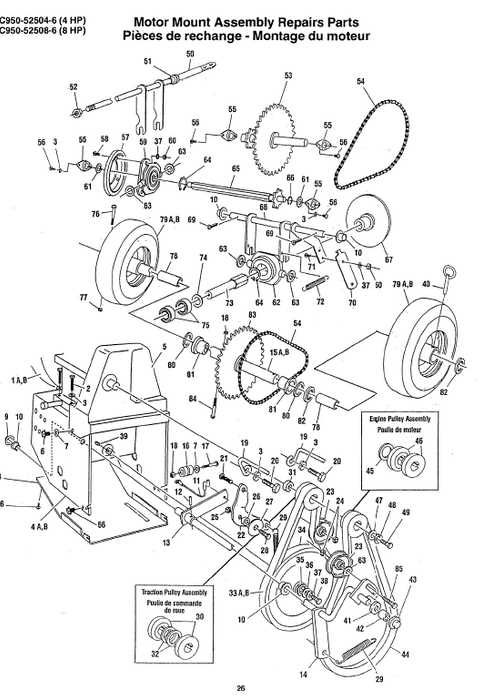

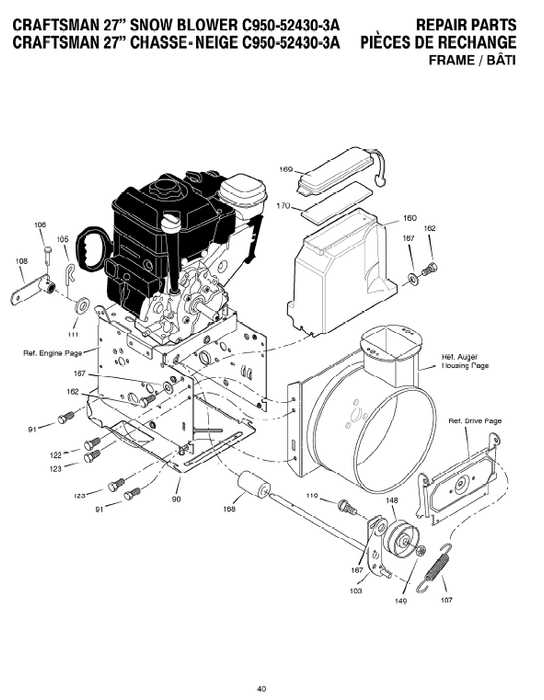

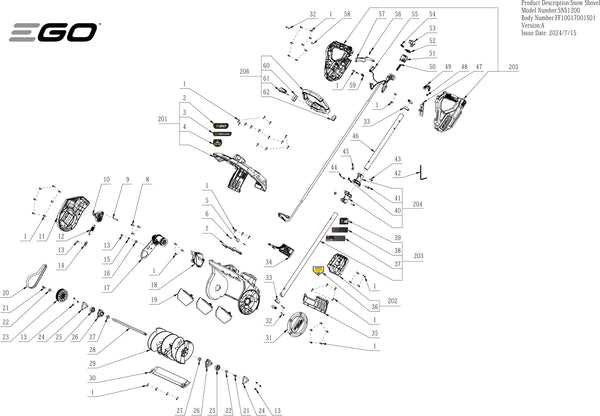

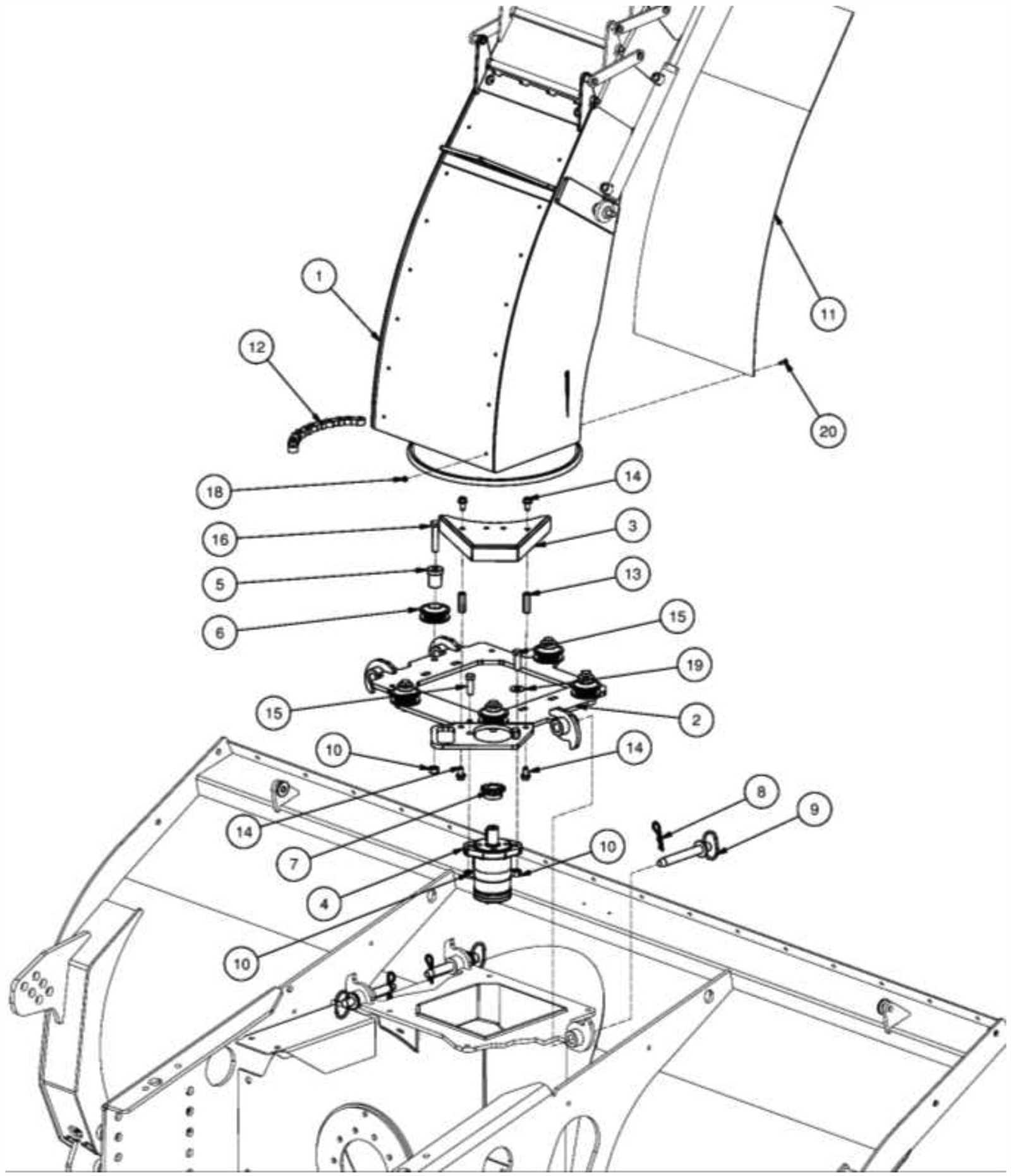

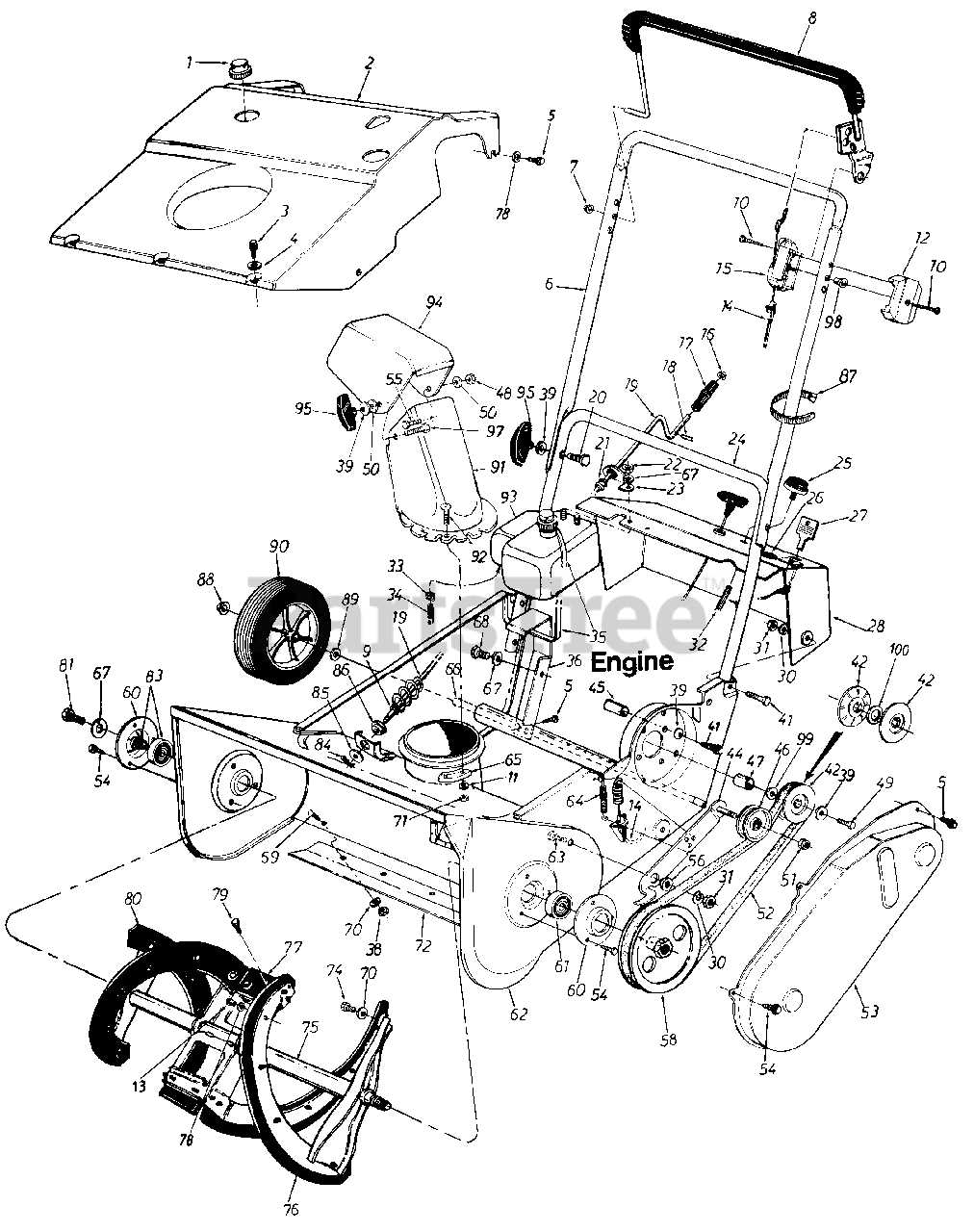

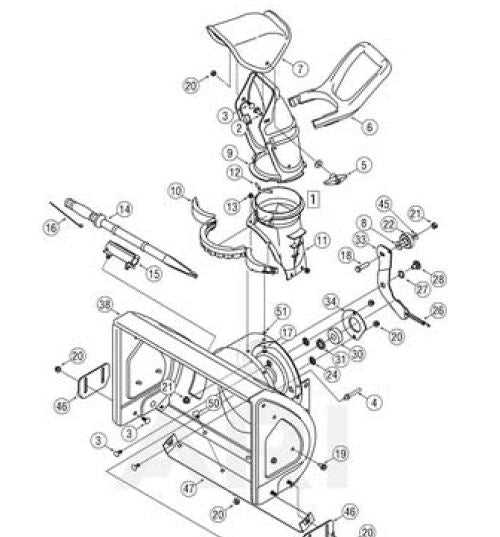

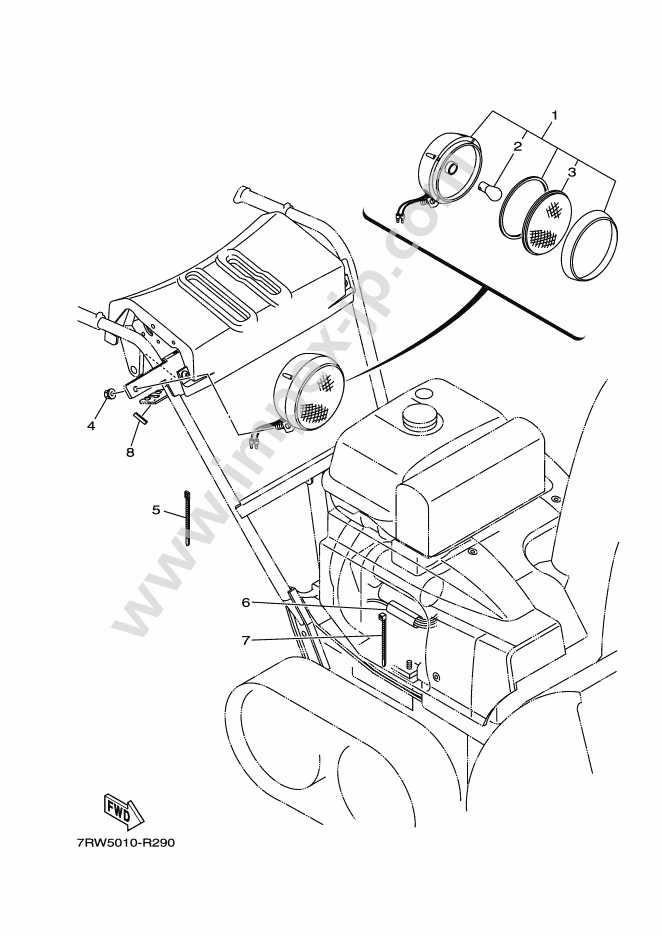

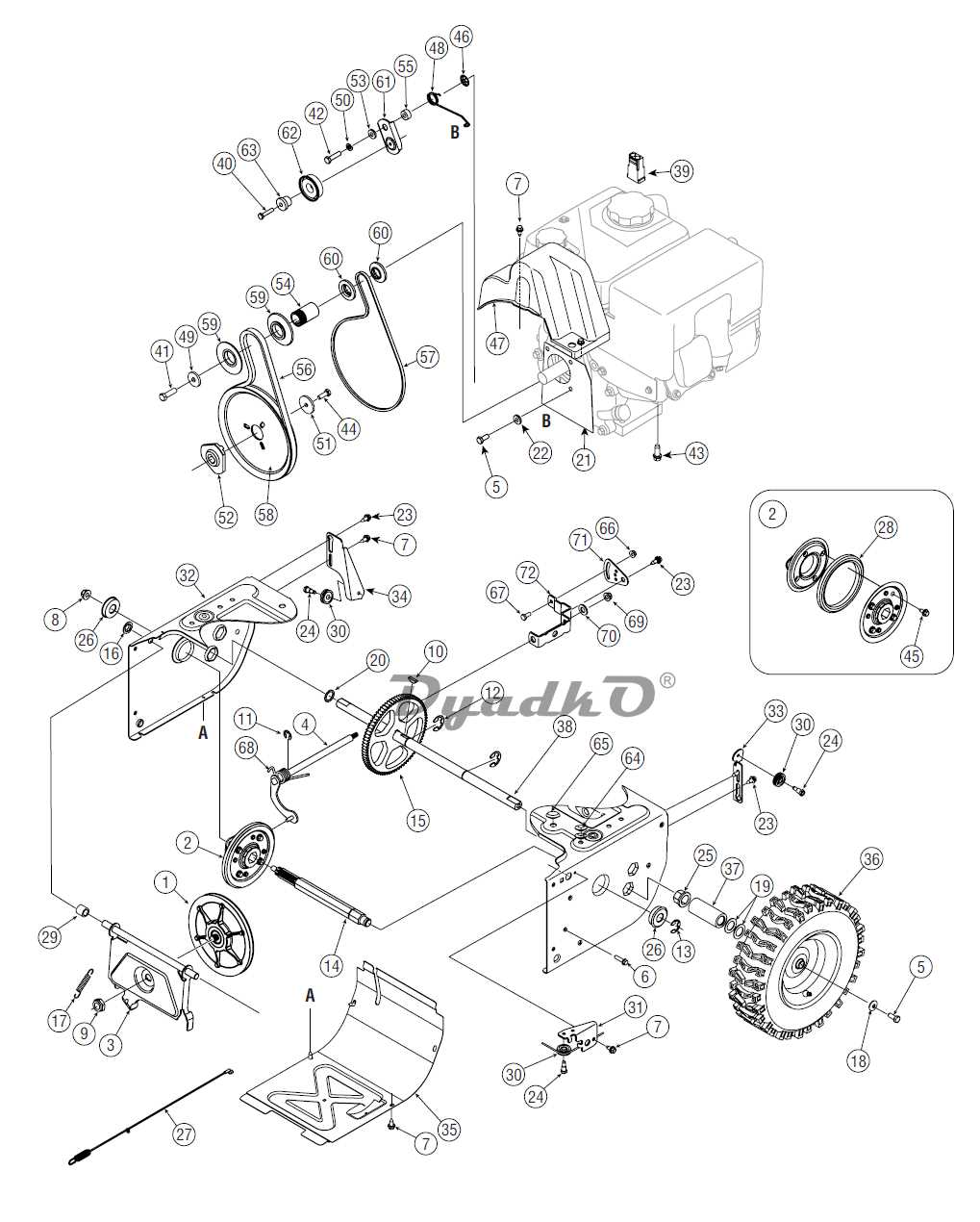

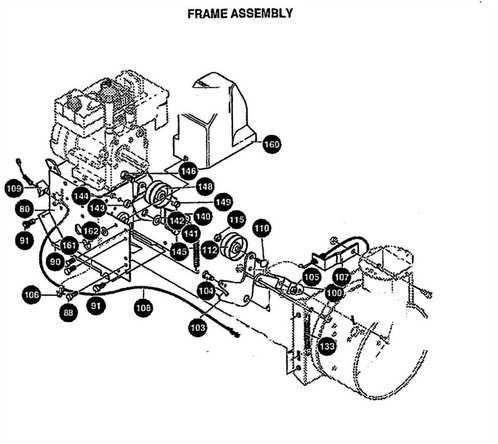

Visual representations of the machinery can serve as invaluable resources for both novice and experienced users. These illustrations break down complex assemblies into manageable parts, making it easier to identify specific components and their functions. Such clarity allows for more informed decision-making during maintenance and repair tasks.

Equipped with this understanding, you can confidently navigate the world of outdoor machinery, ensuring your equipment operates at its best. This journey into the inner workings empowers you to take control of your maintenance routine and address any challenges that may arise.

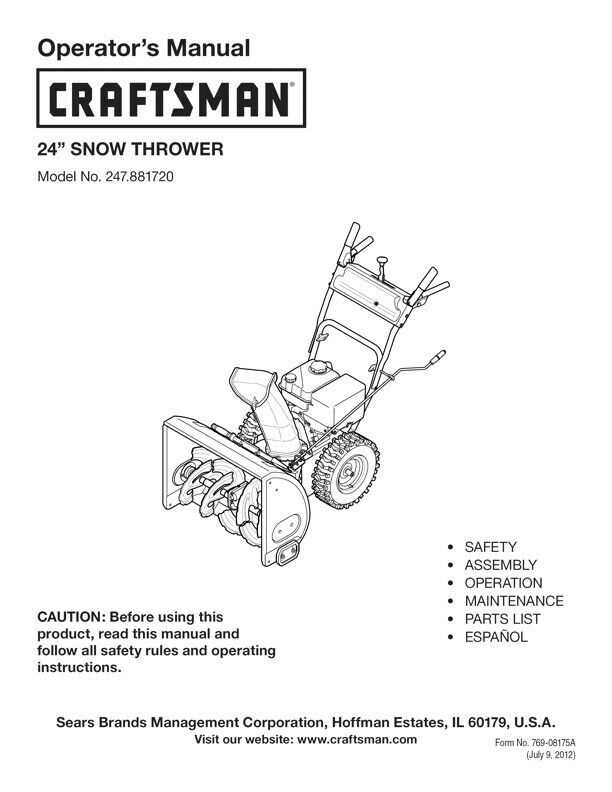

Understanding Craftsman Snowblower Components

When tackling winter challenges, it’s essential to familiarize yourself with the various elements that make up your equipment. Each component plays a crucial role in ensuring optimal performance and reliability. Knowing how these parts interact can enhance your ability to maintain and troubleshoot effectively.

Engine: The powerhouse of your machine, this element drives all operations and determines the overall efficiency. Understanding its specifications can help in choosing the right maintenance approach.

Auger: This mechanism is responsible for breaking up and gathering snow. Its design affects both the speed and effectiveness of snow removal, making it vital to inspect regularly for wear and damage.

Chassis: The frame provides the necessary support for all other components. A sturdy construction ensures durability, while its design can influence maneuverability in various conditions.

Controls: User interface elements are essential for smooth operation. Familiarizing yourself with their layout and functionality can lead to a more intuitive experience during use.

Drive System: This aspect powers the wheels or tracks, allowing the machine to navigate different terrains. Understanding how to maintain it can prevent potential operational issues.

By delving into these components, you equip yourself with the knowledge necessary for effective upkeep and optimal functionality during the harsh winter months.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. These illustrations provide clarity, ensuring that users can easily identify and locate each element, leading to effective maintenance and repair.

Benefits of Visual Representations

- Enhances comprehension of complex systems.

- Facilitates accurate troubleshooting.

- Streamlines the reassembly process.

Key Features to Consider

- Detailed labeling of each component.

- Clear depiction of connections and configurations.

- Accessibility for reference during repairs.

Common Snowblower Issues and Solutions

When dealing with winter equipment, encountering difficulties is not uncommon. Understanding potential problems and their remedies can enhance performance and ensure smoother operation. Here, we outline frequent challenges users may face, along with effective solutions to tackle them.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Won’t Start | Empty fuel tank, stale fuel, faulty spark plug | Refill with fresh fuel, check and replace spark plug if needed |

| Reduced Power | Clogged intake, worn blades, improper fuel mixture | Clear any obstructions, inspect and replace blades, adjust fuel mixture |

| Uneven Throwing Distance | Worn impeller, improper speed settings | Inspect impeller for wear, adjust speed settings accordingly |

| Vibrations | Loose components, unbalanced wheels | Tighten all loose parts, check and balance wheels |

| Difficulty Steering | Worn skids, improper tire pressure | Replace worn skids, ensure tires are properly inflated |

Key Components of Craftsman Models

Understanding the essential elements of outdoor power equipment is crucial for optimal performance and maintenance. Each model is designed with specific features that enhance functionality and ensure efficient operation, making it easier for users to tackle various tasks.

Engine: The heart of the machine, providing the necessary power for operation. A well-functioning engine is vital for reliable performance and longevity.

Auger: This component is responsible for gathering and moving material into the housing. Its design and strength are critical for effective processing.

Impeller: Positioned behind the auger, it plays a key role in discharging the processed material. A robust impeller ensures that debris is thrown far from the working area.

Chassis: The frame that holds all components together. A sturdy chassis provides stability and durability, allowing the unit to withstand rigorous use.

Controls: User-friendly controls enable easy operation and adjustments during tasks. Ergonomically designed levers and buttons contribute to a seamless experience.

Skids: These help regulate the height of the machine during operation, allowing for consistent contact with the ground and preventing damage to surfaces.

Each of these key elements contributes to the overall efficiency and effectiveness of the equipment, making them indispensable for any operator. Proper understanding and maintenance of these components are essential for achieving optimal results.

How to Identify Replacement Parts

Finding the right components for your equipment can seem daunting, but a systematic approach simplifies the process. Begin by familiarizing yourself with the machine’s specifications and any relevant manuals that provide guidance.

First, inspect the unit for any labels or serial numbers that may help pinpoint the model. Next, take note of the components that appear worn or damaged, as these are likely candidates for replacement.

Additionally, consider consulting online resources or forums dedicated to machinery repair, where enthusiasts often share valuable insights and detailed visuals. Cross-referencing these resources with your findings will enhance your ability to make informed decisions.

Ultimately, by taking the time to research and organize your information, you can effectively navigate the search for the necessary replacements.

Maintenance Tips for Snowblowers

Proper upkeep of your winter equipment is essential for optimal performance and longevity. Regular maintenance can prevent costly repairs and ensure that your machinery operates smoothly when you need it most. Below are some key tips to help you keep your device in top condition throughout the cold season.

1. Regular Cleaning: After each use, make sure to remove any accumulated snow and ice. This prevents corrosion and keeps the components functioning properly. A thorough clean can extend the life of your equipment.

2. Check the Oil: Regularly inspect and change the oil as recommended in the user manual. Fresh oil lubricates internal parts, reduces friction, and enhances overall efficiency.

3. Inspect Belts and Cables: Examine belts and cables for signs of wear or damage. Replacing worn components before they fail can prevent breakdowns during heavy snowfall.

4. Fuel Care: Use fresh fuel and consider adding a stabilizer if your device will be idle for an extended period. Old fuel can lead to starting issues and engine problems.

5. Blade Sharpening: Keep the blades sharp for effective snow removal. Dull blades can struggle and cause additional wear on the motor.

6. Battery Maintenance: For electric models, ensure the battery is charged and in good condition. Regularly check connections and clean terminals to avoid any power issues.

By following these simple maintenance steps, you can ensure that your winter equipment remains reliable and effective throughout the season, ready to tackle whatever winter throws your way.

Tools Needed for Repairs

To effectively conduct maintenance and repairs on your outdoor equipment, having the right tools is essential. These instruments not only facilitate the repair process but also ensure safety and efficiency.

Essential Tools: Begin with a quality set of screwdrivers–both flathead and Phillips–to tackle various fasteners. A wrench set is crucial for loosening and tightening bolts, while a socket set offers added versatility for different sizes.

Don’t forget a reliable multimeter for electrical troubleshooting, as well as pliers for gripping and bending tasks. Additionally, a work light can illuminate dark areas, ensuring you see every detail during the repair.

Safety Gear: Always prioritize safety by wearing gloves to protect your hands and safety goggles to shield your eyes from debris. This approach not only safeguards you but also promotes a more efficient workflow.

Safety Precautions When Repairing

When undertaking maintenance or repairs on outdoor machinery, ensuring safety is paramount. It is essential to recognize potential hazards and take appropriate measures to protect yourself during the process.

Always wear protective gear, including gloves and safety goggles, to shield against flying debris and sharp components. Additionally, ensure the equipment is powered off and disconnected from any electrical sources before starting your work.

Keep your workspace tidy and well-lit to avoid accidents. Be mindful of your surroundings and make sure that children and pets are kept at a safe distance from the area where repairs are taking place.

Familiarize yourself with the specific machinery you are handling, including its components and any potential risks associated with them. Consult the manufacturer’s guidelines for proper procedures and precautions.

Finally, if you are uncertain about any repair, it is always wise to seek professional assistance. Prioritizing safety not only protects you but also ensures that the equipment operates effectively and reliably.

Where to Find Replacement Parts

Locating suitable components for your outdoor equipment can be a straightforward process if you know where to look. Whether you are in need of new elements due to wear and tear or seeking upgrades, numerous avenues exist to procure what you need effectively.

One of the best resources is the official website of the manufacturer, where you can often find a comprehensive inventory of components along with schematics that help identify the correct items. Additionally, authorized dealers may provide assistance and guidance, ensuring that you obtain high-quality products that are compatible with your machine.

Online marketplaces also present a convenient option, offering a vast selection from various sellers. Make sure to check customer reviews and ratings to ensure reliability. Furthermore, local hardware stores and specialty shops can be invaluable for immediate needs, allowing you to inspect items in person.

Lastly, don’t overlook community forums and social media groups dedicated to equipment enthusiasts. Members often share insights about where to find specific items, and you may even discover second-hand options at a lower cost.

Comparing Different Snowblower Models

When it comes to choosing an efficient outdoor clearing machine, understanding the variety of available options is crucial. Each model offers distinct features and capabilities, catering to various needs and preferences. By analyzing key attributes, users can make informed decisions to find the ultimate fit for their requirements.

Key Features to Consider

- Engine Power: Evaluate the horsepower and type of engine for optimal performance.

- Clearing Width: Consider the width of the clearing path to suit your yard size.

- Weight: Heavier models may provide stability, while lighter ones are easier to maneuver.

- Fuel Type: Assess whether a gas or electric option aligns better with your needs.

Popular Models Overview

-

Model A: Known for its compact design and efficient clearing capacity, ideal for smaller driveways.

-

Model B: Offers a robust engine and larger clearing width, suitable for extensive areas.

-

Model C: Features advanced technology for ease of use, with electric operation for quieter performance.

Upgrading Your Snowblower Performance

Enhancing the efficiency of your winter equipment can significantly improve its functionality and longevity. By implementing specific modifications and upgrades, you can maximize its capability to tackle challenging weather conditions. Whether it’s about boosting power or increasing durability, there are various strategies to consider for an overall better performance.

One effective approach is to replace the existing motor with a more powerful variant. This upgrade can provide a noticeable increase in torque and speed, allowing for quicker and more efficient clearing. Additionally, consider using high-quality blades designed for optimal cutting performance, which can reduce strain on the machinery and ensure a cleaner operation.

Regular maintenance is crucial as well. Routine checks and timely replacements of worn components can prevent breakdowns and enhance performance. Upgrading the fuel system or adding enhancements for better fuel efficiency can also yield impressive results, ensuring that your equipment operates smoothly throughout the season.

Finally, investing in better traction mechanisms can significantly improve handling on icy surfaces. By exploring these modifications, you can create a reliable tool that meets your specific needs and tackles winter challenges with ease.

Frequently Asked Questions About Repairs

This section addresses common inquiries related to maintenance and troubleshooting of outdoor equipment. Understanding these frequently asked questions can help users navigate issues more effectively and ensure their machines operate smoothly throughout the season.

What should I do if my equipment won’t start?

If your machinery fails to start, first check the fuel level and ensure there are no blockages in the fuel line. Inspect the battery and connections for any signs of wear. Replacing the spark plug may also resolve the issue, as a faulty spark plug can prevent ignition.

How often should I perform maintenance?

Regular upkeep is crucial for optimal performance. It is generally recommended to conduct a thorough inspection at the beginning and end of the season. Monthly checks for wear and tear, along with oil changes as per the manufacturer’s guidelines, will prolong the life of your machine.