In this section, we will explore the various elements that make up a snow clearing device, emphasizing their functions and interactions. Each component plays a vital role in ensuring optimal performance, enabling efficient removal of snow from driveways and pathways. A comprehensive understanding of these parts can enhance maintenance practices and facilitate troubleshooting.

We will delve into how these individual elements work together to achieve the overall functionality of the machine. By examining the connections and mechanisms, users can gain valuable insights into how to care for and operate their equipment effectively. This knowledge not only aids in extending the lifespan of the device but also improves user experience during winter conditions.

Through detailed examination, users can identify the specific roles of various components, leading to better informed decisions regarding repairs and upgrades. Gaining familiarity with these aspects empowers individuals to maintain their equipment with confidence, ensuring reliable operation when it is needed most.

When it comes to managing winter weather, a reliable machine is essential. Familiarizing yourself with the various elements that comprise your equipment can enhance performance and facilitate maintenance. This section aims to provide insights into the different components and their functions, allowing users to better understand their machinery and address any issues that may arise.

Key Elements of Your Machine

- Engine: The heart of the equipment, responsible for powering all functions.

- Auger: Designed to collect snow and direct it towards the discharge chute.

- Chassis: The main frame that supports all components and provides stability.

- Discharge Chute: Directs the expelled snow away from the machine’s path.

- Controls: Includes levers and buttons that allow the operator to manage various functions.

Understanding Component Functions

- Identifying how each element contributes to overall operation is crucial for effective use.

- Regular inspections can prevent breakdowns and prolong the life of the machine.

- Knowing where to find replacement components can expedite repairs and maintenance.

Key Features of Honda HS624

This section outlines the notable characteristics of a high-performance snow-clearing machine designed for efficiency and reliability in harsh winter conditions. With advanced engineering and innovative design, this model offers exceptional functionality to tackle snow accumulation with ease.

Powerful Engine Performance

The snow-clearing unit is equipped with a robust engine that ensures consistent power output. This capability allows for efficient operation, enabling the user to clear significant amounts of snow in a shorter time frame. The engine’s reliability enhances the overall effectiveness of the machine during challenging weather conditions.

Exceptional Maneuverability

One of the standout features of this machine is its superior maneuverability. The compact design combined with effective steering mechanisms allows for easy navigation in tight spaces, making it suitable for various environments, including residential driveways and commercial areas. The user-friendly controls further enhance the handling experience, ensuring optimal comfort and efficiency.

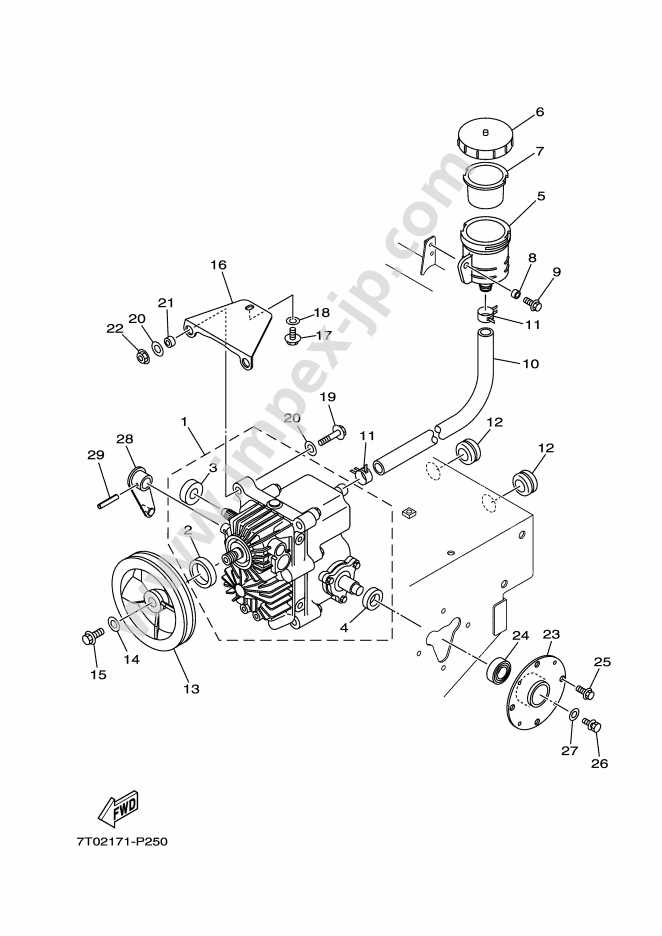

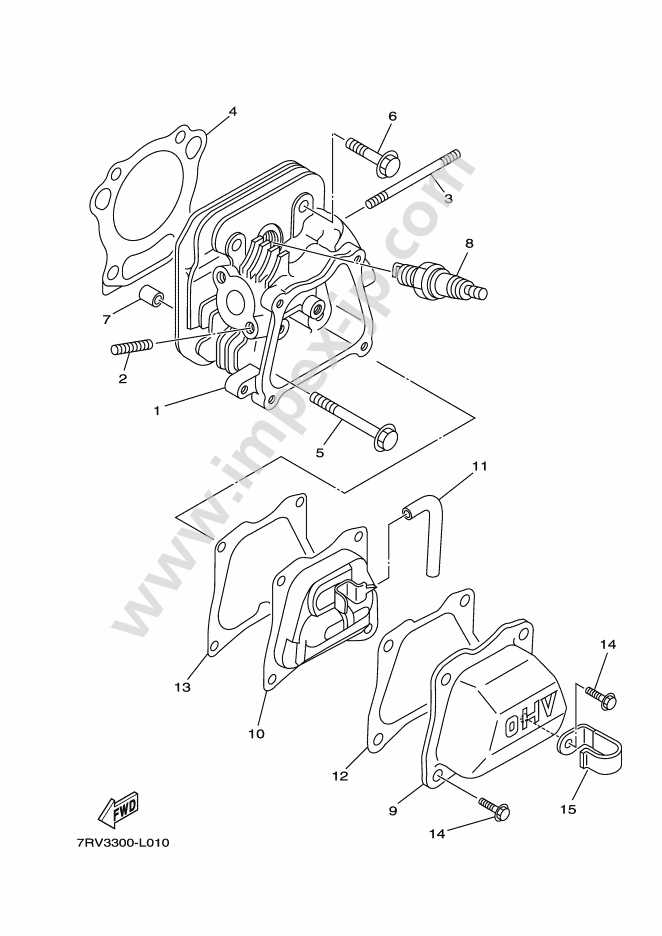

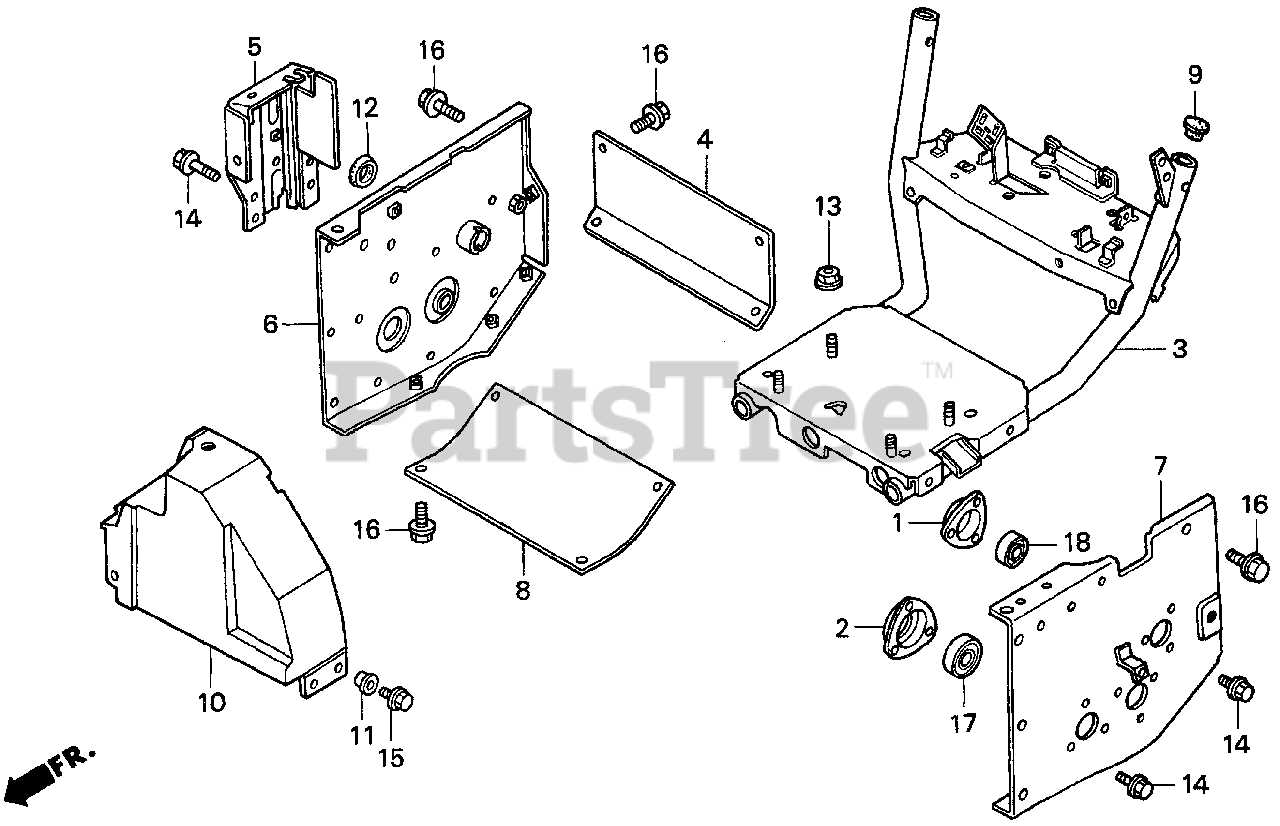

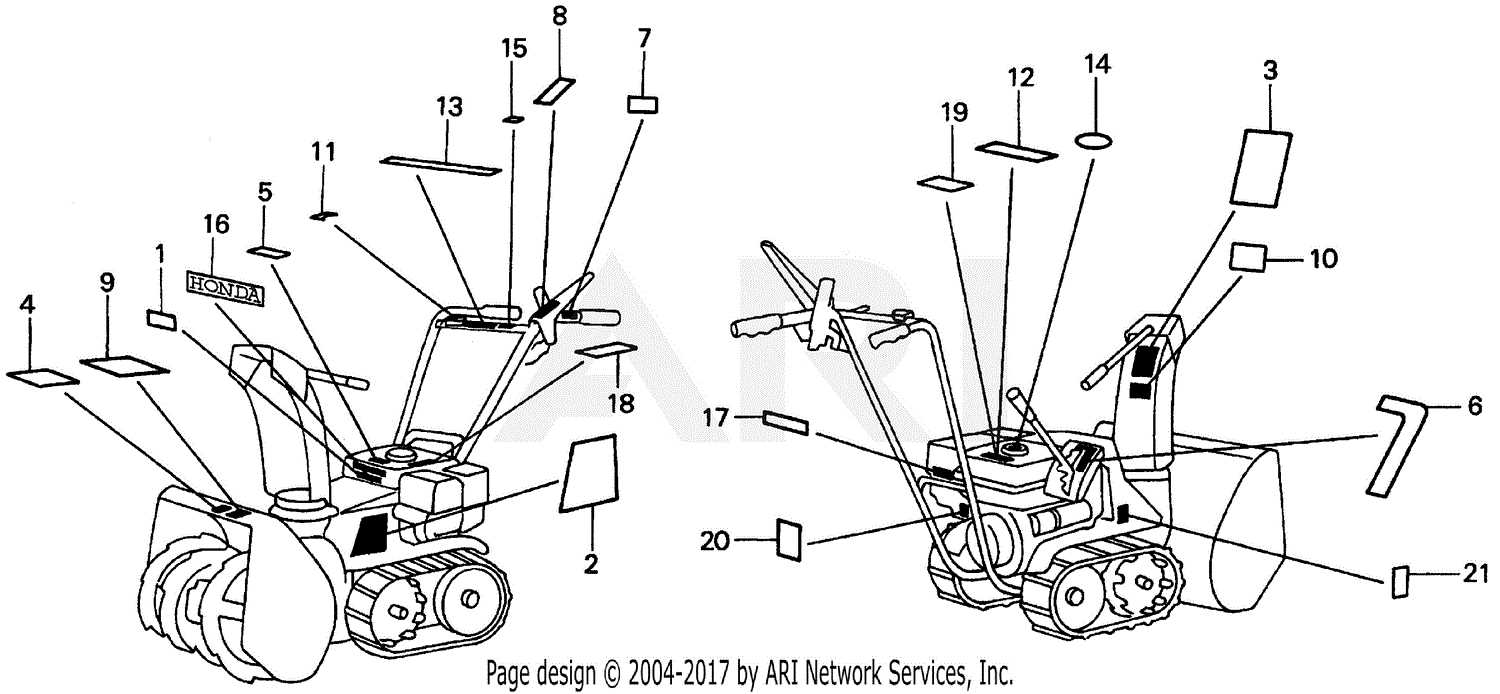

Identifying Essential Parts in Diagrams

Understanding the key components in schematics is vital for efficient maintenance and troubleshooting. By recognizing the different elements depicted in these illustrations, users can better comprehend how various mechanisms interact within the machinery. This knowledge empowers individuals to make informed decisions during repairs or upgrades.

Key Components to Recognize

When examining technical illustrations, focus on identifying the primary elements that contribute to the overall function of the equipment. Look for major assemblies, such as the engine and drive system, as well as secondary components like belts and switches. Each part plays a crucial role in ensuring optimal performance.

Interpreting Symbols and Labels

Diagrams often include symbols and labels that provide additional information about the components. Familiarizing yourself with these can enhance your understanding of how to effectively address issues. Pay attention to notes that indicate maintenance requirements or specific assembly instructions, as they are key to ensuring longevity and efficiency.

Maintenance Tips for Snowblower Parts

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment during the winter months. Proper care not only enhances performance but also helps to prevent costly repairs and replacements. This section will provide valuable guidance on how to maintain various components effectively.

1. Inspect and Clean Regularly: Frequent examination of the machinery is crucial. Remove any accumulated debris or ice that may hinder operation. Cleaning the exterior and interior areas helps to maintain optimal functionality.

2. Lubricate Moving Components: Ensure that all moving elements are adequately lubricated to prevent wear and tear. Using the appropriate type of lubricant can significantly enhance the smoothness of operations and reduce friction between parts.

3. Check for Wear: Pay attention to the condition of all critical elements. Look for signs of wear, such as cracks or deformities, which may affect performance. Timely replacement of worn-out components can save you from further complications down the line.

4. Store Properly: After the season ends, store your equipment in a dry, sheltered location. Proper storage protects against rust and other environmental factors that may damage the machinery.

5. Follow Manufacturer’s Guidelines: Always adhere to the recommendations provided by the manufacturer regarding maintenance schedules and practices. This ensures that your equipment remains in peak condition and operates safely.

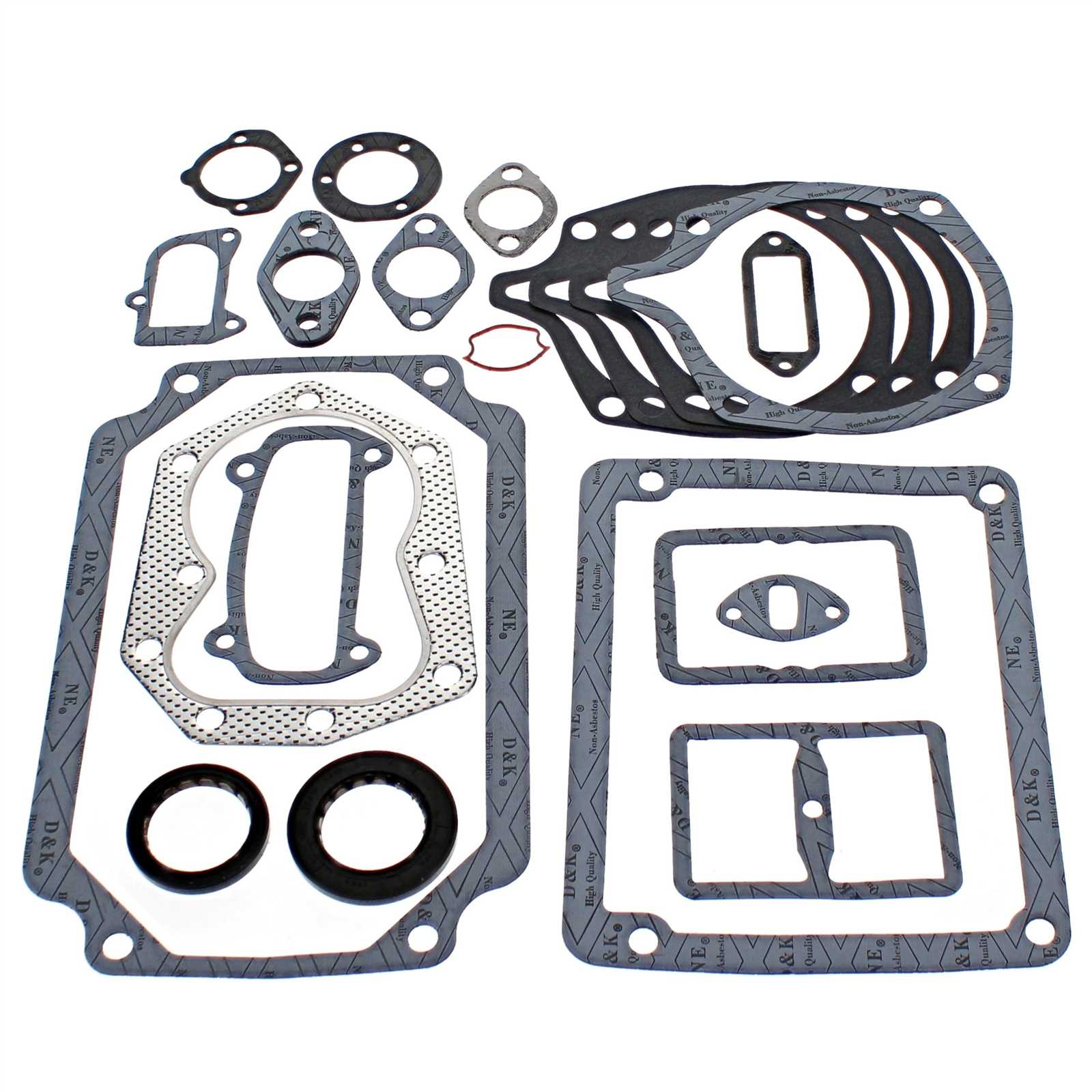

How to Replace Snowblower Components

Replacing various elements of your winter clearing machine can significantly enhance its efficiency and longevity. Understanding the essential steps and proper techniques for component replacement ensures that the machine operates smoothly, especially during heavy snowfall. This section provides a comprehensive guide to help you carry out these replacements with ease.

Gather Necessary Tools

Before starting the replacement process, it is crucial to collect all required tools and materials. Commonly needed items include wrenches, screwdrivers, pliers, and replacement components. Having everything on hand minimizes interruptions and allows for a more efficient workflow.

Step-by-Step Replacement Process

Begin by disconnecting the power source to ensure safety during the replacement. Next, follow the manufacturer’s guidelines to remove the old component, which may involve unscrewing bolts or unclipping fasteners. Carefully install the new part by reversing the removal steps, making sure to secure it firmly in place. Finally, reconnect the power and perform a functionality test to confirm that everything is operating correctly.

Common Issues with Honda HS624

Owners of this powerful snow clearing machine may encounter a variety of challenges during operation. Understanding these frequent problems can help users troubleshoot effectively and maintain optimal performance. This section highlights typical concerns associated with the equipment and offers insights for resolution.

Starting Difficulties

A common issue users face is difficulty in starting the engine. This can result from various factors, including stale fuel, a weak battery, or faulty spark plugs. Regular maintenance, such as checking fuel quality and ensuring proper battery charge, can alleviate these starting problems.

Auger Performance Issues

Another frequent concern involves the auger not functioning correctly. This may manifest as a lack of power in clearing snow or strange noises during operation. Causes can range from damaged belts to blockages in the auger assembly. Regular inspections and timely replacements of worn components can help maintain smooth performance.

Ordering Replacement Parts Online

Finding and acquiring necessary components for your equipment can be a straightforward process with the right approach. Utilizing online platforms allows you to easily browse through a wide selection, ensuring you locate the specific items needed to maintain or repair your machinery effectively.

Benefits of Online Ordering

- Convenience: Access a variety of options from the comfort of your home.

- Time-saving: Quickly find and order what you need without visiting multiple stores.

- Price comparison: Easily compare costs across different websites to find the best deal.

Steps for Successful Online Ordering

- Identify the specific component you need.

- Search reputable online retailers or manufacturer websites.

- Review product descriptions and specifications carefully.

- Add the selected items to your cart and proceed to checkout.

- Confirm your order details and complete the payment process.

Seasonal Preparation for Snowblowers

As winter approaches, ensuring optimal functionality of your outdoor equipment becomes essential. Proper maintenance and readiness can enhance performance and extend the lifespan of your machinery. This section discusses the crucial steps to prepare for the cold season, ensuring reliability when you need it most.

Check Fuel and Oil Levels

Before the first snowfall, it’s vital to examine and replenish fuel and lubrication fluids. Using fresh fuel prevents engine issues, while adequate oil levels ensure smooth operation.

Inspect Belts and Cables

Worn or frayed belts and cables can lead to performance failures. Regularly inspecting these components helps identify potential problems early, allowing for timely replacements and avoiding costly repairs.

Clean and Store Properly

After each use, removing snow and debris from the machine is important to prevent rust and corrosion. When storing for the season, place the equipment in a dry location, ensuring it is covered to protect it from the elements.

Test Functionality

Before heavy snowfall begins, it’s wise to test all functions of the equipment. Checking controls, lights, and operational parts helps ensure everything works correctly, reducing the chance of malfunction during critical moments.

Safety Measures During Operation

Ensuring safety during operation is crucial for preventing accidents and injuries while using equipment designed for snow removal. Adhering to specific precautions can enhance user protection and ensure a smooth workflow.

Before starting the equipment, it is essential to perform a thorough inspection to identify any potential hazards or issues that may affect its performance. Always familiarize yourself with the operational guidelines and maintain a clear understanding of the equipment’s functions.

| Safety Measure | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment, including gloves, goggles, and sturdy footwear, to shield against potential injuries. |

| Clear Area of Debris | Ensure the working environment is free of obstacles and hazards to prevent accidents during operation. |

| Maintain Proper Distance | Keep a safe distance from bystanders and pets to avoid injuries from flying debris or equipment malfunctions. |

| Check Fuel Levels | Regularly monitor fuel levels and avoid refueling while the equipment is running to prevent fire hazards. |

| Follow Manufacturer Instructions | Always adhere to the manufacturer’s guidelines for operation and maintenance to ensure safe usage. |

Expert Recommendations for Upkeep

Maintaining outdoor power equipment is essential for ensuring optimal performance and longevity. Regular attention to various components can prevent costly repairs and enhance efficiency. Following a few expert tips can keep machinery running smoothly through seasons.

First and foremost, regular inspections are crucial. Checking for wear and tear on essential elements can help identify potential issues before they escalate. Additionally, ensuring that all moving parts are adequately lubricated will minimize friction and reduce the risk of mechanical failure.

Furthermore, cleaning the equipment after each use is highly recommended. Removing debris and buildup not only improves functionality but also helps prevent rust and corrosion. Make it a habit to store the machinery in a dry, sheltered location to protect it from the elements.

Lastly, consulting the manufacturer’s guidelines for specific maintenance schedules can provide invaluable insights. Adhering to these recommendations will enhance the overall reliability and effectiveness of the equipment, ensuring it is always ready for action.

Exploring Aftermarket Part Options

When maintaining outdoor machinery, considering alternatives to original components can be beneficial. Aftermarket items often provide a cost-effective solution while delivering comparable performance. This section delves into the advantages and considerations of utilizing these substitutes for enhancing functionality and reliability.

Benefits of Aftermarket Solutions

Cost-Effectiveness: One of the primary advantages of opting for aftermarket options is their affordability. Many manufacturers offer high-quality substitutes at a fraction of the price of original equipment, allowing users to maintain their machinery without overspending.

Compatibility and Quality

Varied Choices: Aftermarket alternatives come in a wide array of options, making it easier to find compatible components that fit specific needs. It is essential to research and select reputable brands to ensure the quality and durability of the items. Additionally, customer reviews and ratings can provide valuable insights into the performance of these substitutes.