When the chilly season approaches, having reliable equipment to tackle snow removal becomes essential. Familiarizing oneself with the individual components of these powerful machines can significantly enhance their functionality and maintenance. Whether for residential or commercial use, a thorough grasp of how each piece operates is invaluable.

By exploring the layout and interaction of various elements, users can effectively troubleshoot issues and ensure optimal performance. A well-maintained unit not only saves time but also increases safety during operation. This guide will help you navigate through the intricacies of your winter equipment’s inner workings.

Delving into the specifics can reveal the ultimate understanding necessary for efficient use. With clear visual representations and detailed descriptions, mastering your equipment becomes a more approachable task, empowering you to handle the challenges of winter with confidence.

Understanding Honda HS928 Snowblower

This section explores the essential components and functionality of a specific model designed for clearing snow effectively. A thorough comprehension of its elements can enhance performance and maintenance.

Key features include:

- Powerful engine for efficient operation

- Robust construction for durability

- Advanced auger system for effective snow removal

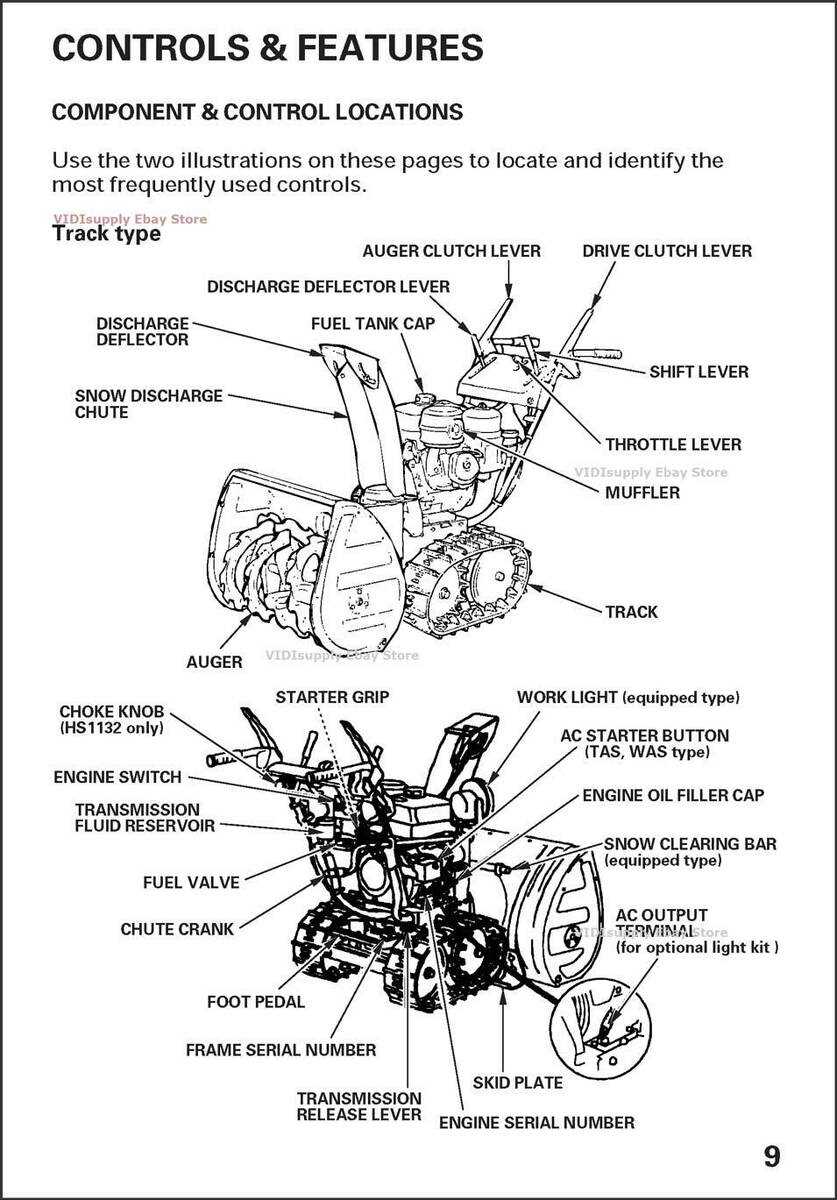

Familiarizing oneself with various components is crucial for optimal use. Here are some critical elements to consider:

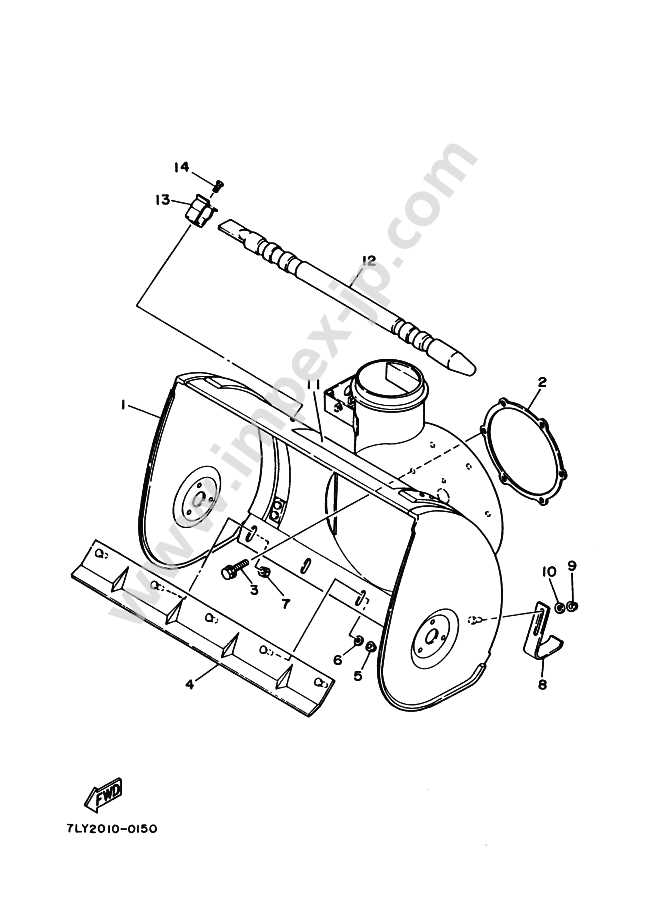

- Chassis: Provides structural integrity and stability during operation.

- Intake: Essential for gathering snow before it is discharged.

- Auger: Responsible for breaking up and moving snow towards the discharge chute.

- Discharge chute: Directs the expelled snow away from the working area.

Understanding these components not only facilitates effective operation but also aids in troubleshooting and repairs, ensuring a reliable experience throughout the winter season.

Key Components of HS928 Model

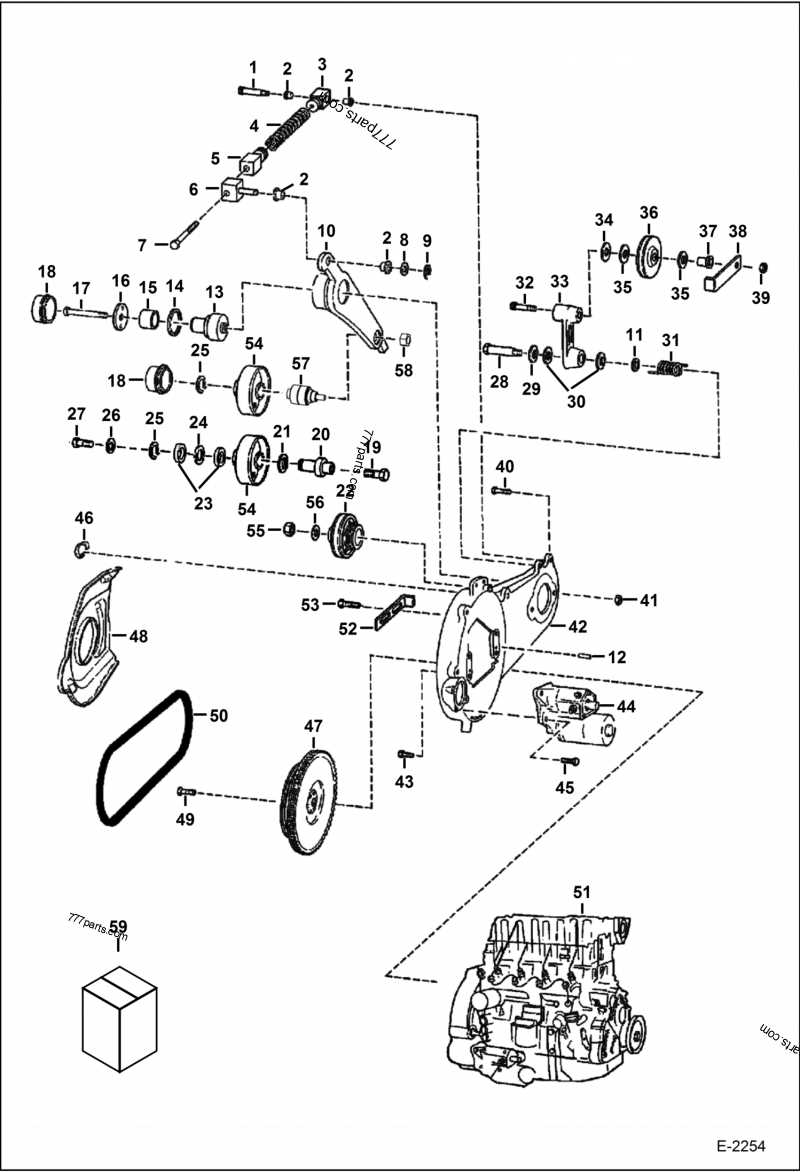

This section explores the essential elements of a powerful snow-clearing machine, focusing on their roles and interconnections. Understanding these vital components can enhance maintenance and ensure optimal performance during winter challenges.

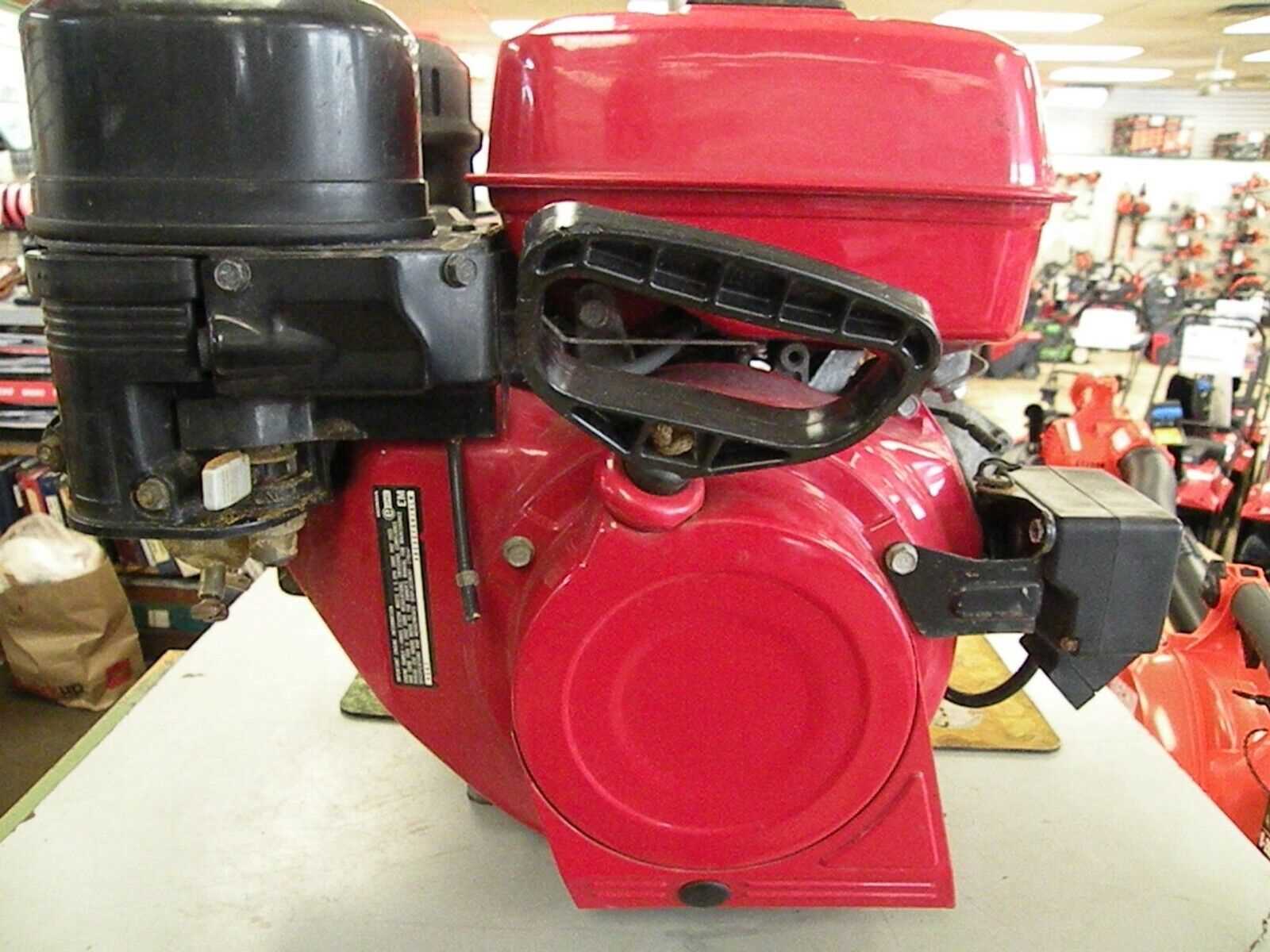

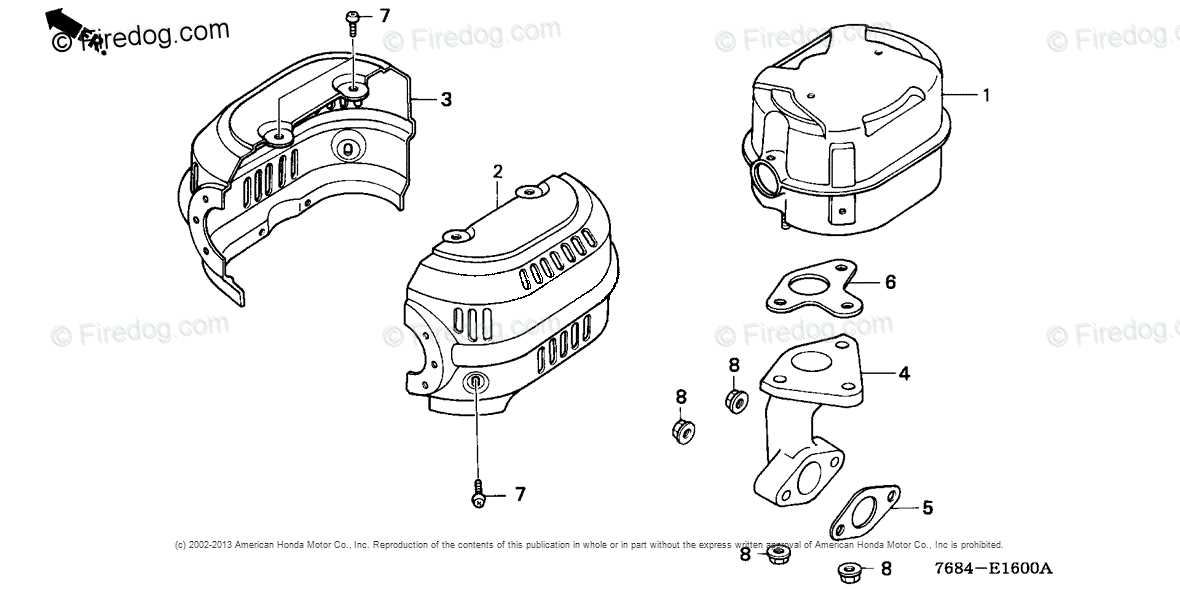

Engine: The heart of the machine, the engine, provides the necessary power for efficient operation. A robust motor allows for tackling heavy snowfall and icy conditions, ensuring reliability and effectiveness.

Auger: This component is responsible for breaking up and gathering the snow, making it easier to discharge. A well-designed auger can significantly improve the clearing process, allowing for swift and thorough snow removal.

Chute: The chute directs the snow after it has been collected, allowing users to control where the snow is thrown. Adjustable features enhance flexibility, making it easier to maneuver around obstacles and achieve precise clearing.

Transmission: This system transmits power from the engine to the wheels and auger, ensuring smooth operation. A reliable transmission contributes to overall efficiency and helps maintain consistent performance, even in challenging conditions.

Controls: The user interface, including levers and buttons, allows for intuitive operation. Ergonomically designed controls make it easier to adjust settings, enhancing comfort and efficiency during use.

By familiarizing oneself with these key components, operators can maximize the effectiveness of their equipment, ensuring a smooth experience throughout the winter months.

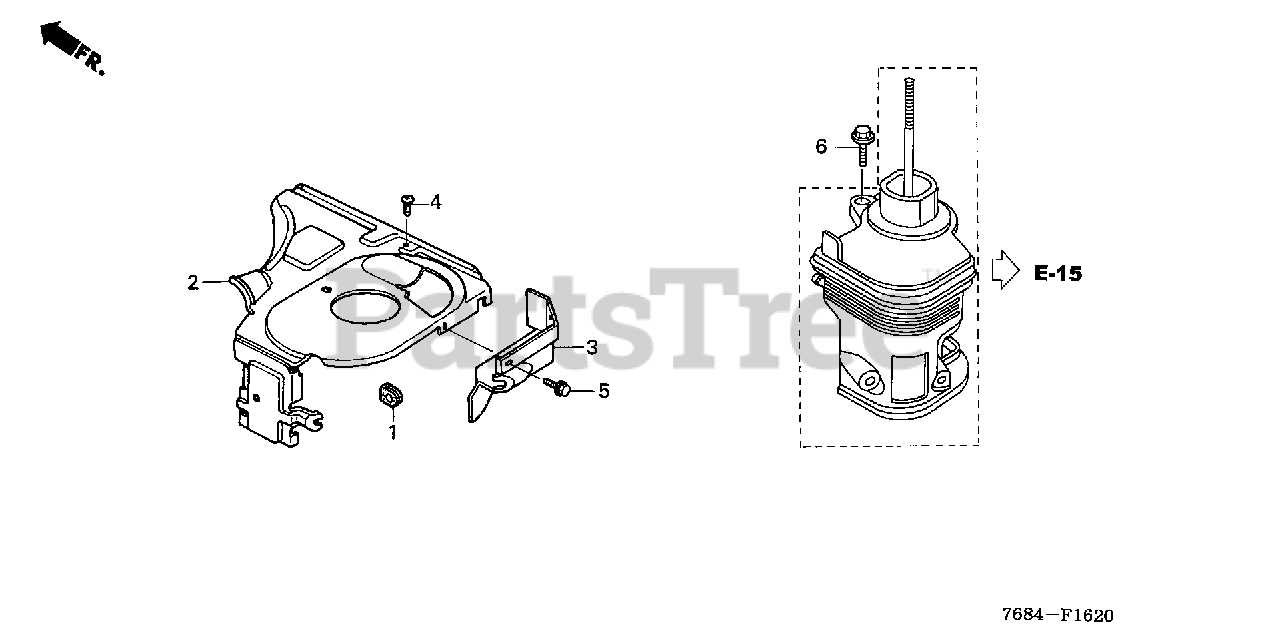

Importance of Parts Diagrams

Understanding the intricate layout of machinery components is essential for efficient maintenance and repair. Visual representations serve as invaluable tools, providing clarity and aiding in the identification of each element’s function. By referring to these illustrations, users can enhance their troubleshooting skills and streamline the repair process.

Benefits of Visual Guides

- Clarity: Visual aids eliminate confusion, allowing users to quickly locate specific elements.

- Efficiency: Quick reference saves time during repairs and maintenance tasks.

- Learning Tool: Great for new users to understand how different parts interact within the machinery.

Facilitating Successful Repairs

- Improved Diagnostics: Visual aids help pinpoint issues more accurately.

- Better Planning: Users can gather necessary tools and replacement items beforehand.

- Enhanced Safety: Understanding the layout minimizes the risk of accidental damage during repairs.

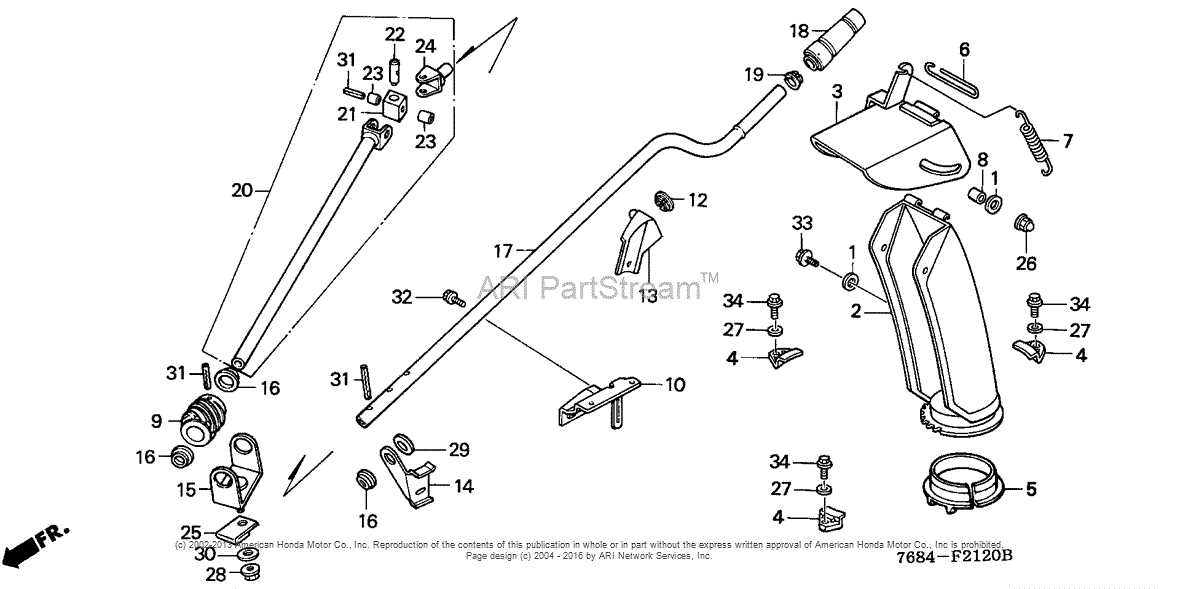

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This guide will help you navigate through these illustrations, making it easier to identify and locate specific elements you may need.

Here are some key steps to follow:

- Familiarize Yourself with Symbols:

Each illustration uses standardized symbols and labels to represent various items. Take time to learn what each symbol signifies.

- Identify Sections:

Visuals are often divided into sections based on functionality. Recognizing these areas can help you quickly find what you need.

- Refer to the Legend:

A legend or key usually accompanies the illustration, explaining the symbols and colors used. Always check this reference for clarity.

- Follow the Numbers:

Many representations use numerical designations next to each component. This numbering corresponds to a list or inventory, providing detailed descriptions and specifications.

- Cross-Reference with Manuals:

Use user manuals or repair guides in conjunction with the visual to gain a deeper understanding of how each part functions within the whole.

By following these steps, you’ll enhance your ability to interpret visual component layouts effectively, ensuring more efficient repairs and maintenance.

Common Issues with HS928 Parts

When operating outdoor equipment designed for winter conditions, users often encounter various challenges that can hinder performance. Understanding these common problems can help in identifying solutions and maintaining functionality.

Wear and Tear: Regular use can lead to degradation of components. Inspecting and replacing worn-out elements is crucial to ensure efficiency.

Mechanical Failures: Malfunctions in the drive system or auger can disrupt operation. Regular maintenance and timely repairs can prevent severe breakdowns.

Clogging Issues: Accumulation of snow or ice can block pathways. Clearing any obstructions promptly helps in maintaining smooth performance.

Fuel System Problems: Issues with fuel delivery can affect the overall operation. Regular checks on filters and lines can enhance reliability.

Where to Find Replacement Parts

Locating the necessary components for your outdoor equipment can be a straightforward process if you know where to look. There are various reliable sources to help you acquire the essential items to ensure your machine operates efficiently.

- Authorized Dealers: Start by checking with official dealers who specialize in the brand of your equipment. They typically carry genuine replacements and can offer expert advice.

- Online Retailers: Numerous e-commerce platforms provide a wide selection of components. Websites like Amazon, eBay, and specialized sites often have competitive prices and customer reviews.

- Local Hardware Stores: Don’t overlook nearby hardware or home improvement stores. Many of these establishments stock common items and may order specific components for you.

- Forums and Community Groups: Engaging with online communities dedicated to outdoor machinery can lead to valuable recommendations for sourcing parts. Users often share their experiences and trusted vendors.

- Manufacturer Websites: Visit the official website of the equipment maker. They usually have a dedicated section for replacements, complete with part numbers and descriptions.

By exploring these options, you can find the right components to keep your equipment in top shape and ready for action.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular upkeep and attention. Proper maintenance not only enhances performance but also extends the lifespan of your machine, making it a worthwhile investment for any user. Following a few simple practices can lead to optimal functionality and reliability.

Regular Cleaning

After each use, clean the exterior and remove any debris. This prevents rust and buildup that can hinder performance. Pay special attention to the intake and exhaust areas, as these can affect efficiency.

Routine Inspections

Conduct periodic checks on essential components. Look for wear and tear on belts, blades, and cables. Addressing small issues promptly can prevent larger, more costly repairs down the line.

Upgrading Your Snowblower Components

Enhancing the efficiency and performance of your winter equipment can significantly improve its functionality and lifespan. By focusing on key components, you can ensure optimal operation even in the harshest conditions. This section will explore effective upgrades that can make a substantial difference.

Choosing Quality Materials

Investing in high-quality materials for various components can lead to improved durability and performance. Consider stainless steel or heavy-duty plastics for parts that endure high stress and wear. This choice not only extends the life of your machine but also enhances its reliability.

Enhancing Efficiency

Upgrading to more efficient mechanisms can streamline operations. For instance, consider an advanced impeller design that increases snow discharge power. Such modifications can greatly enhance productivity, allowing you to tackle larger areas in less time.

Cost Analysis of HS928 Parts

When maintaining outdoor equipment, understanding the financial implications of its components is crucial. This section delves into the expenses associated with essential elements, focusing on their impact on overall efficiency and performance. By evaluating costs, users can make informed decisions about repairs and replacements, ensuring optimal operation.

Replacement expenses can vary significantly based on the specific item in question. Some components may require only occasional replacement, while others are prone to wear and need frequent attention. It’s important to consider not just the initial purchase price, but also the long-term investment in terms of durability and reliability.

Labor costs also play a significant role in the total expenditure. Professional assistance can add to the financial burden, especially if multiple parts need attention simultaneously. Users who are skilled in DIY repairs may save considerably by handling simple tasks themselves, reducing the overall cost dramatically.

Additionally, market trends can influence pricing. Seasonal demand, availability, and manufacturer promotions can lead to fluctuations that savvy buyers can exploit. Staying informed about these factors can help in timing purchases to minimize expenses.

In conclusion, a thorough analysis of expenses related to essential components not only aids in budgeting but also enhances the longevity and performance of the machinery. Being proactive in this regard can lead to significant savings and improved functionality over time.

DIY Repairs vs. Professional Help

When it comes to maintaining equipment, individuals often face the decision of tackling repairs themselves or seeking assistance from a qualified technician. Each option presents its own set of advantages and challenges, influencing both time and cost considerations.

Advantages of DIY Repairs

Opting for self-repair can be highly rewarding. It offers a sense of accomplishment and the opportunity to save money. Additionally, with the plethora of online resources and communities, enthusiasts can easily find guidance and support for their projects.

When to Call a Professional

However, some situations demand expertise beyond what an individual may possess. Complex issues or time-sensitive repairs might warrant the involvement of a professional, ensuring safety and reliability. In such cases, investing in expert help can ultimately prevent further damage and additional costs.

Safety Precautions When Repairing

When undertaking maintenance tasks on machinery, it is essential to prioritize safety to prevent accidents and injuries. Adopting a methodical approach can significantly reduce risks associated with repairs.

Firstly, always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and steel-toed boots. These items shield against potential hazards while working on equipment.

Secondly, ensure the equipment is powered down and disconnected from any power sources before beginning repairs. This practice minimizes the likelihood of accidental starts that could lead to injuries.

Additionally, familiarize yourself with the specific components you will be working on. Having a clear understanding of how each part functions can prevent mishaps during disassembly and reassembly.

Lastly, keep your workspace organized and free of clutter. A tidy environment helps maintain focus and reduces the chance of tools or parts causing harm while you work.

Customer Reviews and Experiences

This section explores the insights and opinions shared by users who have interacted with their machines. Personal accounts highlight the efficiency, durability, and usability of these products in various winter conditions, providing potential buyers with valuable perspectives.

| Reviewer | Rating | Comment |

|---|---|---|

| John D. | 5/5 | Exceptional performance in heavy snowfall; highly recommend! |

| Sarah L. | 4/5 | Easy to use but slightly heavy for prolonged use. |

| Mike R. | 3/5 | Works well, but I had some issues with maintenance. |

| Lisa T. | 5/5 | Perfect for my large driveway; saves me hours! |