When it comes to maintaining efficiency during the winter months, having a thorough understanding of the mechanical elements involved in a snow clearing device is essential. A well-organized visual representation can greatly assist users in identifying the various components, ensuring proper maintenance, and facilitating repairs when necessary.

Effective snow management relies heavily on the functionality of each individual component. Familiarizing oneself with the arrangement and role of these parts can not only enhance performance but also extend the lifespan of the equipment. Users can benefit significantly from a detailed overview that simplifies the identification process.

Whether you’re a seasoned operator or a new user, knowing how to navigate the intricate assembly of your snow removal machine can make a world of difference. This guide aims to illuminate the essential elements involved, making it easier to troubleshoot issues and carry out necessary replacements.

Understanding John Deere 1032D Snowblower

This section delves into the operational mechanics and essential components of a specific snow-clearing machine designed for efficiency and performance. By exploring its features and functionality, users can better appreciate how this equipment can tackle winter challenges and ensure safe, clear pathways during snowy conditions.

Key Features

Equipped with powerful engines and a robust design, this model stands out for its ability to manage heavy snowfall. The wide clearing path allows for quick and effective snow removal, while adjustable chute angles enhance control over the direction of the discharged snow. Additionally, features such as user-friendly controls and ergonomic handles contribute to a more comfortable operation.

Maintenance Considerations

Regular upkeep is vital for the longevity and efficiency of this snow-clearing equipment. Essential tasks include checking and replacing fluids, inspecting belts, and ensuring all moving parts are adequately lubricated. By adhering to a maintenance schedule, operators can prevent potential breakdowns and enhance the overall performance of the machine, ensuring reliable operation throughout the winter season.

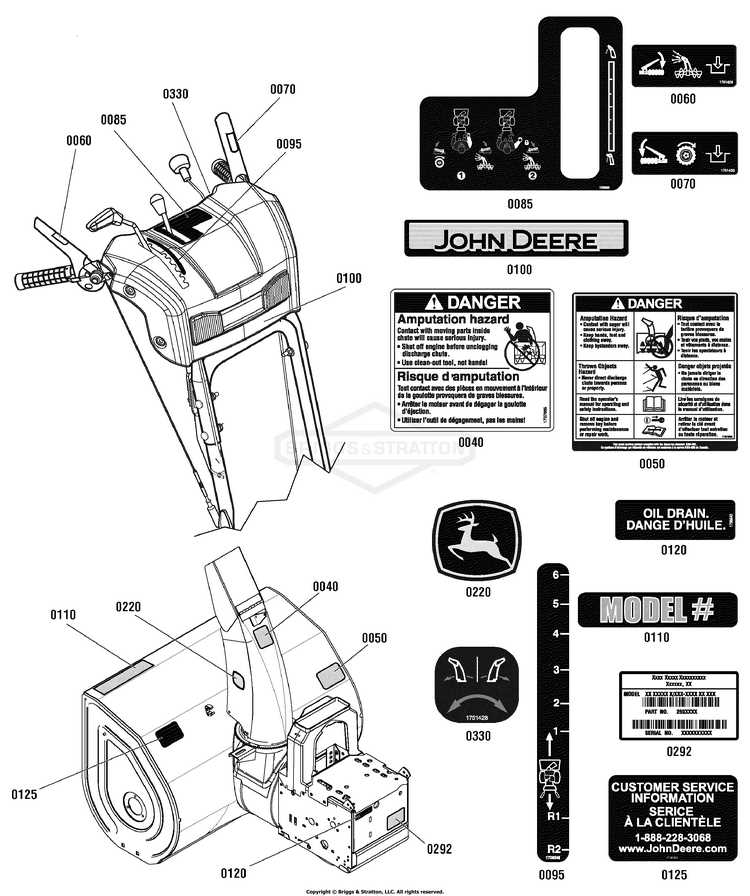

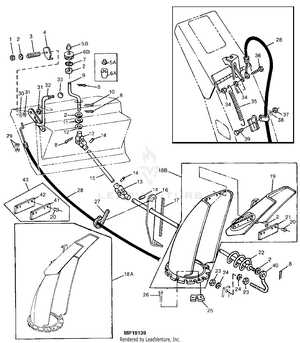

Essential Components of the Snowblower

Understanding the fundamental elements of a snow-clearing machine is crucial for effective operation and maintenance. These components work in harmony to ensure optimal performance, providing efficient removal of snow and ice from various surfaces. Familiarity with these parts can help users troubleshoot issues and enhance the longevity of the equipment.

Key Elements

- Auger: This rotating element collects and lifts the snow, directing it toward the chute for expulsion.

- Chassis: The frame supports all components and is designed for stability and durability during operation.

- Engine: The power source drives the entire machine, influencing speed and performance capabilities.

- Transmission: This component controls the movement and speed, allowing operators to navigate different terrains efficiently.

- Skid Shoes: These adjustable features control the height of the machine from the ground, ensuring proper clearance.

Additional Accessories

- Chute Deflector: This accessory helps direct the snow flow to desired areas, improving maneuverability.

- Headlight: Essential for visibility in low-light conditions, ensuring safe operation during early mornings or late evenings.

- Heated Handles: This comfort feature enhances user experience by providing warmth during cold weather operations.

By comprehensively understanding these essential elements and accessories, operators can maximize their efficiency and ensure a more effective snow removal process.

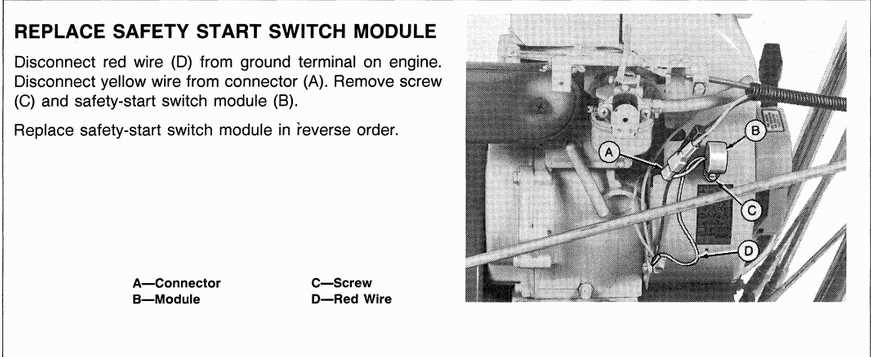

Importance of Accurate Parts Diagrams

Detailed illustrations showcasing components are crucial for effective maintenance and repair. These visual representations provide clarity, ensuring that users can identify each element with precision. Accurate schematics facilitate a better understanding of how various parts interact, leading to more efficient troubleshooting and assembly processes.

In any mechanical system, having reliable visuals contributes significantly to the overall functionality. When technicians and enthusiasts reference well-designed illustrations, they can avoid mistakes that might arise from misinterpretation. This not only saves time but also reduces the likelihood of damaging the machinery.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Clear visuals help users grasp the relationship between components. |

| Time Efficiency | Accurate visuals streamline the repair process by minimizing confusion. |

| Reduced Errors | Proper illustrations lower the risk of incorrect assembly and potential damage. |

In conclusion, the significance of precise visual representations cannot be overstated. They serve as essential tools for both novice and experienced users, promoting effective maintenance practices and ensuring longevity for machinery.

Common Repairs for John Deere 1032D

Maintenance of outdoor power equipment is crucial for optimal performance and longevity. Various issues can arise with these machines, but many can be addressed through simple repairs and adjustments. Understanding common problems and their solutions can help owners keep their equipment running smoothly and efficiently.

One frequent issue involves the drive system, which may experience wear and tear over time. Symptoms can include slipping or inadequate propulsion. Regular inspection and replacement of worn belts or chains can prevent more severe damage and ensure smooth operation.

Another area that often requires attention is the cutting mechanism. Dull blades can lead to ineffective performance, making it essential to sharpen or replace them regularly. Additionally, ensuring that the blade assembly is correctly aligned can improve cutting efficiency.

| Common Issue | Potential Cause | Suggested Repair |

|---|---|---|

| Slipping Drive System | Worn belts or chains | Inspect and replace as necessary |

| Dull Cutting Blades | Extended use without maintenance | Sharpen or replace blades |

| Electrical Failures | Faulty connections or blown fuses | Check connections and replace fuses |

| Fuel Issues | Old or contaminated fuel | Drain and replace fuel |

Routine upkeep not only resolves these issues but also prolongs the lifespan of the equipment. Familiarizing oneself with these common repairs allows operators to address problems proactively, ensuring reliable performance during use.

Finding Replacement Parts Online

Locating suitable components for outdoor machinery can be a straightforward task with the right approach. The internet offers a wealth of resources that enable users to identify, compare, and purchase essential items efficiently. By utilizing various online platforms, one can access detailed catalogs, user reviews, and specifications that aid in making informed decisions.

When searching for replacements, start by identifying the model number and specifications of your equipment. This information is crucial as it helps filter options and ensures compatibility. Many retailers and specialized websites provide advanced search features, allowing you to enter specific criteria to narrow down results effectively.

Online forums and communities can also be invaluable. Engaging with fellow enthusiasts or professionals can lead to recommendations for trustworthy suppliers and alternative solutions that may not be immediately apparent through conventional searches. Additionally, visual references and guides shared by users can assist in understanding the installation process.

Before making a purchase, it is wise to compare prices and shipping options across different websites. Some platforms might offer competitive rates or discounts for bulk orders, which can lead to significant savings. Always check the return policy as well to safeguard your investment in case of any discrepancies.

By leveraging online resources effectively, one can streamline the process of finding the right components for maintenance and repairs, ensuring optimal performance of outdoor machinery.

Maintenance Tips for Snowblower Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your winter equipment. Regular attention not only enhances performance but also extends the lifespan of the machine, saving you time and money in the long run. By adhering to a few straightforward practices, you can keep your apparatus in prime condition through the cold months.

1. Regular Cleaning: After each use, it is crucial to clean the exterior and interior components to remove snow, ice, and debris. This practice helps prevent rust and corrosion, which can lead to serious malfunctions over time. Ensure that all parts are dry before storing your equipment to avoid moisture buildup.

2. Lubrication: Frequent lubrication of moving parts is vital. Apply the appropriate lubricants to gears, bearings, and other friction points to reduce wear and tear. Refer to the manufacturer’s recommendations for specific products and intervals.

3. Fuel Management: Using fresh fuel is important for optimal performance. Store your machine with stabilized fuel to prevent issues caused by stale gas. Drain the fuel tank if you plan to store it for an extended period and replace it with new fuel before the season starts.

4. Inspect Belts and Cables: Regularly examine drive belts and cables for signs of wear. Look for fraying or cracking and replace any damaged components promptly. This proactive approach can prevent breakdowns during critical times.

5. Check the Oil: Regular oil changes are essential for maintaining the engine’s health. Check the oil level and quality frequently, and replace it according to the schedule outlined in the owner’s manual. Clean oil ensures smooth operation and reduces the risk of engine damage.

6. Store Properly: When the winter season concludes, store your equipment in a cool, dry place. Cover it to protect it from dust and moisture. Ensure that it is stored in an upright position to avoid fluid leaks and damage to the engine.

By following these maintenance tips, you can significantly enhance the reliability and longevity of your winter machine, ensuring it remains ready for action whenever you need it.

Troubleshooting Common Snowblower Issues

Maintaining optimal performance during winter conditions can be challenging when facing operational difficulties with your outdoor equipment. Identifying and resolving frequent problems is crucial for ensuring efficient snow removal. Below are common issues encountered, along with potential solutions and preventive measures to enhance the longevity of your machine.

| Issue | Symptoms | Solutions |

|---|---|---|

| Engine Won’t Start | Machine does not crank or make any noise. | Check fuel levels, inspect the spark plug, and ensure the battery is charged. |

| Loss of Power | Equipment operates sluggishly or stalls. | Clean or replace the air filter, and inspect the fuel system for clogs. |

| Clogged Chute | Snow does not discharge properly; material backs up. | Clear the chute of debris and ensure the auger is functioning correctly. |

| Uneven Snow Clearing | Some areas remain covered while others are cleared. | Adjust the height of the scraper blade and check the auger for wear. |

| Excessive Vibrations | Equipment shakes during operation. | Inspect for loose components and ensure all bolts are tightened. |

Regular maintenance and timely troubleshooting are essential to keep your equipment in peak condition. By addressing these issues proactively, users can enhance the reliability and efficiency of their machinery, making winter tasks less daunting.

Comparing Different Snowblower Models

When selecting a machine for clearing snow, it’s essential to understand the various options available on the market. Each model boasts unique features that cater to different needs and preferences, influencing performance and usability. This comparison will help prospective buyers make informed decisions by highlighting key aspects of different models.

Key factors to consider when comparing models include:

- Engine Power: The horsepower of the engine determines the machine’s ability to handle heavy snowfall and tough conditions.

- Clearing Width: A wider clearing width can reduce the time spent on snow removal, making it more efficient for larger driveways.

- Auger Design: The type of auger affects how effectively the snow is processed, with some designs being better suited for heavy, wet snow.

- Throwing Distance: The distance snow can be thrown impacts where it lands, which is especially important for properties with limited space.

- Weight and Maneuverability: Heavier models may provide stability, but lighter machines can be easier to maneuver in tight spaces.

In addition to these core features, buyers should also evaluate:

- Ease of Use: Controls and adjustments should be intuitive, allowing users to operate the equipment comfortably.

- Maintenance Requirements: Understanding what maintenance tasks are needed can help in assessing the long-term usability of the model.

- Warranty and Support: A good warranty can provide peace of mind and reflects the manufacturer’s confidence in their product.

- User Reviews: Feedback from other users can reveal potential strengths and weaknesses that may not be immediately apparent.

By carefully considering these factors, individuals can select a snow-clearing machine that best suits their specific requirements and preferences, ensuring efficient and effective snow removal during the winter months.

Seasonal Preparation for Snow Removal

As winter approaches, ensuring readiness for the inevitable snowfall is crucial for maintaining safety and accessibility. Proper planning and equipment maintenance can significantly enhance efficiency and effectiveness when dealing with icy conditions. This section outlines essential steps to prepare for the challenges that winter weather brings.

Begin by inspecting all equipment designated for snow management. This includes checking for any wear and tear, replacing worn-out components, and ensuring that all mechanical parts are functioning correctly. Regular maintenance helps to prevent unexpected breakdowns during critical times. Be sure to also familiarize yourself with the operation manual, which can provide valuable insights into optimizing performance.

Next, gather necessary supplies to streamline the snow removal process. Stock up on essential materials such as fuel, oil, and any other operational fluids. Additionally, consider the use of additives that can improve performance in cold temperatures. Having these items readily available will prevent delays when conditions worsen.

Lastly, formulate a strategic plan for snow removal activities. This includes determining priorities for clearing pathways, driveways, and critical areas around your property. Establishing a schedule can help manage expectations and ensure timely action during heavy snowfall events. With thorough preparation, you can navigate winter’s challenges more effectively and maintain a safe environment.

Expert Recommendations for Snow Equipment

When it comes to winter maintenance, having the right tools is essential for ensuring efficiency and effectiveness. Properly selecting and maintaining snow-clearing machinery can significantly enhance performance, safety, and longevity. Below are key insights from professionals that can guide you in making informed decisions about your winter equipment.

Choosing the Right Equipment

Selecting the appropriate machinery for your needs involves considering various factors:

- Type of Terrain: Assess the surfaces you will be working on. Equipment designed for uneven or icy ground may differ from that used on flat driveways.

- Snow Volume: Consider the typical snowfall in your area. Heavier snowfall may require more robust machinery.

- Storage Space: Evaluate how much room you have for storing the equipment when not in use. Compact options may be necessary for smaller spaces.

Maintenance Tips

- Routine Inspections: Check all moving parts and connections frequently to catch potential issues early.

- Oil Changes: Change the oil as per manufacturer recommendations to ensure optimal engine performance.

- Fuel Quality: Use high-quality fuel and consider fuel stabilizers to prevent engine problems during off-season storage.

Implementing these recommendations will help you maximize the efficiency and lifespan of your snow-clearing equipment, ensuring you’re well-prepared for the challenges of winter.

Customer Reviews and Experiences

This section aims to capture the voices of users who have engaged with the equipment in question. By sharing their insights and encounters, potential buyers can gain valuable perspectives on performance, reliability, and overall satisfaction. Customer feedback serves as an essential resource, offering real-world assessments that go beyond specifications and marketing claims.

Performance Feedback

Many individuals have noted the effectiveness of the machinery in various conditions. Users appreciate its ability to tackle heavy snowfall, often highlighting the ease with which it clears pathways and driveways. Reviews frequently emphasize the machine’s robust construction, which provides confidence during prolonged use. However, some users have pointed out that regular maintenance is crucial to maintain optimal functionality.

User Satisfaction

Overall, customer satisfaction levels appear high, with numerous reviewers expressing a strong recommendation. The ease of operation and the efficient clearing capabilities contribute to a positive user experience. However, there are occasional reports of minor issues that can arise, prompting users to seek assistance or replacement components. Engaging with community forums has proven beneficial for many, providing tips and solutions from fellow users.