In the realm of winter maintenance, having a reliable tool is essential for effective snow management. Various elements work together to enhance the functionality and efficiency of these implements. Recognizing how each component interacts can significantly improve performance and usability.

This section aims to provide a comprehensive overview of the individual pieces that contribute to the seamless operation of a snow-clearing attachment. From connections to functional features, each part plays a vital role in achieving optimal results during snowy conditions.

Diving deeper into this topic allows operators to not only familiarize themselves with their equipment but also to troubleshoot and replace specific components when necessary. A clear understanding of these elements can lead to a more enjoyable and effective winter season.

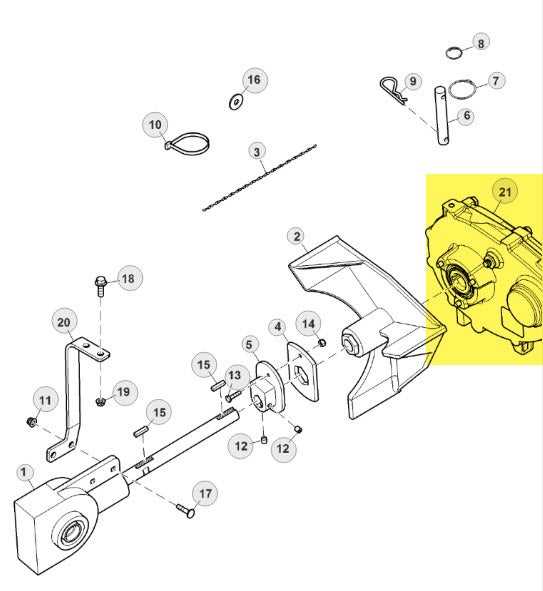

Understanding the John Deere 47 Quick Hitch

This section delves into the intricacies of a specific attachment system designed to enhance the functionality of lawn maintenance equipment. By examining its components and operational mechanics, users can better appreciate how it improves performance during winter tasks.

Key Features of the Attachment System

The mechanism offers several advantages that streamline the process of attaching and detaching implements. Its design facilitates quick connections, reducing downtime and allowing for seamless transitions between various tasks.

Components Overview

| Component | Description |

|---|---|

| Frame | Provides the structural support for the attachment, ensuring stability during operation. |

| Connection Pins | Enable secure attachment to the machinery, ensuring safety and reliability. |

| Lever Mechanism | Allows for easy engagement and disengagement of the implement, promoting user convenience. |

Understanding the components and functionality of this system is essential for efficient use during colder months, ensuring that users can maximize their equipment’s capabilities.

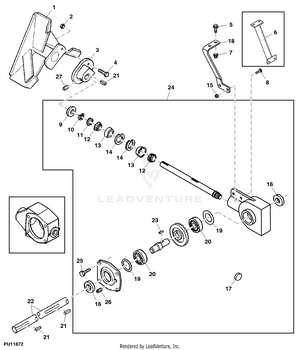

Key Components of Snowblower Assembly

Understanding the essential elements of a snow-clearing machine is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficient operation, allowing for effective removal of snow from various surfaces. By familiarizing oneself with these integral parts, operators can enhance functionality and extend the lifespan of their equipment.

The primary structure includes the frame, which supports all other components and provides stability during use. The impeller is vital for propelling snow, while the auger effectively gathers and channels it toward the discharge chute. The engine serves as the powerhouse, driving the entire mechanism and ensuring sufficient power for challenging conditions.

Additional features like the control panel allow users to manage settings conveniently, while the wheels or tracks provide necessary mobility across different terrains. Understanding these fundamental elements enables operators to troubleshoot issues and perform maintenance tasks more efficiently, ultimately leading to a more effective snow-clearing experience.

Importance of Parts Diagram Clarity

Clear illustrations of components are essential for effective maintenance and repair. They provide a visual reference that simplifies the understanding of complex assemblies, making it easier for users to identify each element and its function. This clarity enhances the ability to troubleshoot issues and perform necessary replacements with confidence.

Precision in these visuals reduces the risk of errors during reassembly. When individuals can easily see how each piece fits together, the likelihood of misalignment or incorrect installation diminishes significantly. This attention to detail ensures that machinery operates efficiently and safely.

Moreover, well-organized representations aid in the training of new users. Familiarity with component layouts fosters quicker learning and better retention of information. As a result, individuals become more adept at handling equipment, ultimately leading to improved productivity and reduced downtime.

Maintenance Tips for Snowblower Efficiency

Ensuring optimal performance during the winter season requires regular care and attention. Proper upkeep not only extends the lifespan of your equipment but also enhances its functionality when you need it most. Implementing a few straightforward practices can lead to significant improvements in efficiency.

Routine Inspections

Conducting periodic checks can help identify potential issues before they escalate. Focus on the following components:

- Check belts for wear and tear.

- Inspect the auger and impeller for damage or blockages.

- Examine the skid shoes and scraper blades for even wear.

Lubrication and Cleaning

Keeping moving parts well-lubricated is essential for smooth operation. Additionally, regular cleaning helps prevent buildup that can hinder performance.

- Use appropriate lubricants on bearings and pivot points.

- Clean the machine after each use to remove snow, ice, and debris.

- Check and change the oil as recommended in the owner’s manual.

Following these maintenance tips can greatly enhance the performance and longevity of your winter equipment, ensuring you are ready to tackle even the toughest weather conditions with ease.

Common Issues with Snowblower Parts

Operating a winter clearing machine can lead to several challenges that may hinder its performance. Understanding these frequent problems can help ensure smooth operation and maintenance. Below are some typical issues encountered with these machines.

| Issue | Description |

|---|---|

| Clogging | Accumulation of snow and ice in the chute can restrict flow, causing inefficiency. |

| Wear and Tear | Components may degrade over time, affecting overall functionality and requiring replacement. |

| Starting Problems | Difficulty in initiating operation often arises from fuel or electrical issues. |

| Uneven Clearing | Inconsistent performance can be caused by incorrect settings or imbalanced components. |

Where to Find Replacement Parts

Finding suitable components for your equipment can be a straightforward task if you know where to look. Various sources offer a wide selection of alternatives, ensuring you can maintain your machinery in optimal condition.

Here are some reliable options to consider:

- Official Retailers: Authorized dealers often have the most comprehensive inventory and can provide expert advice on compatibility.

- Online Marketplaces: Websites like eBay or Amazon feature numerous sellers, allowing you to compare prices and find specific items.

- Local Repair Shops: Independent service centers frequently stock common components and may assist with installation.

- Manufacturer’s Website: Checking the official site can reveal available options and any recommended retailers.

When searching, ensure to verify the specifications to avoid compatibility issues. Additionally, reading reviews can help you gauge the reliability of the components and the sellers.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to assist you in effectively addressing common issues with your equipment. Following these detailed steps will ensure that you can perform repairs efficiently, minimizing downtime and maintaining optimal performance.

Preparation and Safety

Before starting any maintenance work, ensure that the machine is turned off and disconnected from its power source. Gather all necessary tools, including wrenches, screwdrivers, and replacement components. Wearing protective gear, such as gloves and safety goggles, is crucial to avoid injuries during the repair process.

Repair Procedure

Begin by examining the equipment for visible signs of wear or damage. Carefully remove any fasteners or coverings that obstruct access to the malfunctioning area. Replace any defective parts with new ones, ensuring that they are compatible with your model. Once replacements are made, reassemble the unit in reverse order, making sure all connections are secure. Finally, test the equipment to confirm that repairs were successful.

Comparing Models: John Deere Options

When evaluating different equipment models, it’s essential to consider various features and specifications that cater to specific needs. Each model offers unique benefits, making it vital to assess which aligns best with your requirements.

Versatility is a key factor, as some machines are designed for a range of tasks, while others excel in specific applications. Performance capabilities also vary, influencing factors such as efficiency and effectiveness in different conditions.

Another important aspect is accessibility of components and support services. Easy access to maintenance and replacement parts can significantly enhance the longevity of the equipment. Additionally, ergonomics and user comfort can influence overall productivity during operation.

Ultimately, taking the time to delve into the characteristics of each option will help users make informed decisions, ensuring that their chosen equipment meets their expectations and operational needs.

Upgrades for Enhanced Snow Removal

Enhancing your snow clearing equipment can significantly improve efficiency and performance during winter months. Investing in the right upgrades can lead to faster results and reduced physical strain. Below are several recommendations to optimize your setup.

- High-Performance Blades: Upgrading to more durable and efficient blades can enhance cutting power, making it easier to tackle heavy accumulations.

- Power Assist Features: Incorporating power-assisted mechanisms can reduce the effort required for maneuvering, allowing for smoother operation.

- Improved Throwing Distance: Look for enhancements that increase the throwing range of the cleared snow, ensuring wider coverage and preventing snow from accumulating back onto pathways.

In addition to these features, consider the following modifications:

- Heated Components: Installing heated parts can prevent snow from sticking and freezing, leading to a more efficient clearing process.

- LED Lighting: Adding bright, energy-efficient lighting allows for safer operation during low-visibility conditions.

- Advanced Controls: Upgrading to more user-friendly control systems can enhance handling and make adjustments easier during operation.

By implementing these upgrades, you can transform your equipment into a highly efficient tool for managing winter weather challenges.

Seasonal Preparations for Snow Equipment

As winter approaches, ensuring your machinery is ready for the challenges ahead is crucial. Proper maintenance and preparation not only enhance performance but also prolong the lifespan of your equipment. A systematic approach to seasonal readiness can make all the difference when the snow begins to fall.

Essential Maintenance Steps

- Inspect belts and chains for wear and tear.

- Check fluid levels, including oil and fuel.

- Sharpen cutting edges to improve efficiency.

- Clean any debris from previous use.

Additional Preparations

- Test the equipment to ensure proper functionality.

- Stock up on necessary supplies, such as fuel and lubricants.

- Review safety features and ensure they are operational.

- Store the machinery in a dry, accessible location.

User Reviews: Performance Insights

This section delves into the experiences and evaluations shared by users regarding the efficiency and reliability of the equipment in question. Analyzing feedback offers valuable insights into its operational capabilities and overall satisfaction levels among users.

Strengths Highlighted by Users

Many reviewers emphasize the robust performance of the machinery, particularly in challenging weather conditions. Users frequently report high satisfaction due to its ability to clear heavy accumulations of snow with ease, often citing speed and effectiveness as key advantages.

Areas for Improvement

While the equipment receives generally positive feedback, some users have pointed out specific areas that could be enhanced. Commonly mentioned issues include the need for better maintenance instructions and concerns regarding the durability of certain components over extended use.

| Review Aspect | Positive Feedback | Negative Feedback |

|---|---|---|

| Performance | Efficient in heavy snow | Struggles with icy conditions |

| Ease of Use | User-friendly controls | Confusing maintenance guidelines |

| Durability | Sturdy build quality | Some parts wear out quickly |