The efficient operation of a powerful winter machine relies heavily on the intricate assembly of its various elements. Each segment plays a crucial role in ensuring performance and durability during challenging conditions. A comprehensive exploration of these components reveals their significance in maintaining optimal functionality.

For enthusiasts and operators alike, familiarizing oneself with the layout and relationships of these components can significantly enhance maintenance efforts. By examining an organized representation of the assembly, one can easily identify specific sections and troubleshoot potential issues. This knowledge empowers users to take charge of their equipment’s upkeep and extend its lifespan.

In this article, we will delve into the essential elements that contribute to the overall efficiency of your winter machine. From crucial mechanisms to smaller, yet vital, fixtures, understanding each part’s role will equip you with the ultimate insights for effective management and repairs.

Understanding John Deere 724D Components

Grasping the intricacies of this equipment’s elements is essential for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance, contributing to overall efficiency during use. Familiarity with these parts enables users to make informed decisions when it comes to repairs or enhancements.

Key Elements

There are several critical components that users should be aware of, each serving a distinct purpose. Knowing these parts helps in troubleshooting and enhancing the machine’s capabilities.

| Component | Description |

|---|---|

| Auger | Responsible for gathering and moving snow efficiently. |

| Chassis | The frame that supports all other elements and ensures stability. |

| Engine | Powers the unit, driving all mechanical functions. |

| Impeller | Helps to throw the snow away from the machine. |

Maintenance Considerations

Regular inspection and maintenance of these components are crucial for prolonging the lifespan of the machinery. Understanding how each part interacts can lead to more efficient troubleshooting and repairs.

Key Features of the 724D Snowblower

This section highlights the essential attributes that contribute to the efficiency and performance of a premium snow-clearing machine. Understanding these features can help users maximize their experience and ensure optimal operation during winter conditions.

Performance and Power

Equipped with a robust engine, this equipment delivers outstanding snow removal capabilities. The powerful motor enables users to tackle heavy snowfall and large areas with ease, ensuring reliable performance.

Design and Usability

The innovative design focuses on user comfort and maneuverability. Features such as adjustable handles and ergonomic controls make operation straightforward, allowing for extended use without fatigue.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine for efficient snow clearing. |

| Ergonomic Design | User-friendly controls and adjustable handles. |

| Durability | Built with high-quality materials for longevity. |

| Versatility | Effective in various snow conditions and terrains. |

Essential Maintenance Tips for Longevity

Proper care and regular upkeep are crucial for ensuring the extended lifespan of any equipment designed for winter conditions. By following a few key strategies, users can significantly enhance performance and reliability, minimizing the risk of breakdowns and maximizing efficiency.

1. Regular Inspection: Routinely examine the machinery for any signs of wear or damage. This includes checking belts, cables, and housing for cracks or fraying.

2. Lubrication: Ensure that all moving components are adequately lubricated. This reduces friction and helps prevent premature wear.

3. Cleanliness: After each use, remove any debris or snow build-up. This prevents rust and ensures optimal operation during the next use.

4. Fuel Care: Use high-quality fuel and consider adding stabilizers if the equipment will be stored for extended periods. This helps prevent fuel degradation.

5. Seasonal Prep: Before winter, conduct a thorough check, including battery maintenance and a full fluid check. This prepares the machine for heavy use.

6. Professional Servicing: Schedule regular professional maintenance. Experts can identify potential issues that may go unnoticed.

Implementing these tips will not only extend the life of your equipment but also enhance its overall performance, providing peace of mind during the harsh winter months.

Common Issues and Troubleshooting Guide

When operating outdoor equipment during winter months, several challenges may arise, affecting performance and efficiency. Understanding these common problems can help users effectively resolve issues and maintain optimal functionality.

| Issue | Possible Cause | Troubleshooting Steps |

|---|---|---|

| Equipment won’t start | Dead battery or fuel issues | Check battery connections and fuel levels. Recharge or replace the battery as needed. |

| Weak throwing distance | Clogged chute or dull blades | Inspect the chute for blockages and sharpen or replace blades if necessary. |

| Unusual noises | Loose components or worn parts | Tighten any loose bolts and inspect for wear on moving parts. Replace as needed. |

| Vibration during operation | Imbalanced components | Check for damaged or unevenly worn parts. Realign or replace as required. |

How to Order Replacement Parts

Finding the right components for your equipment can be essential for maintaining its performance and longevity. Whether you’re repairing a machine or upgrading its capabilities, knowing how to source these items efficiently is crucial.

Start by identifying the specific component you need. Consult your owner’s manual or online resources for detailed information about the item’s specifications. This will help ensure you order exactly what is necessary.

Next, visit authorized retailers or trusted online platforms specializing in machinery accessories. It’s important to verify the credibility of the seller to avoid counterfeit goods. Look for reviews and ratings to gauge reliability.

Once you’ve found a supplier, you can check their inventory for availability. If the item is out of stock, inquire about restock dates or alternative options. Many suppliers also offer assistance in locating hard-to-find components.

Finally, proceed with the order by following the supplier’s purchasing guidelines. Ensure that you input accurate details, including any model or serial numbers that may be required. This helps in receiving the correct item without delays.

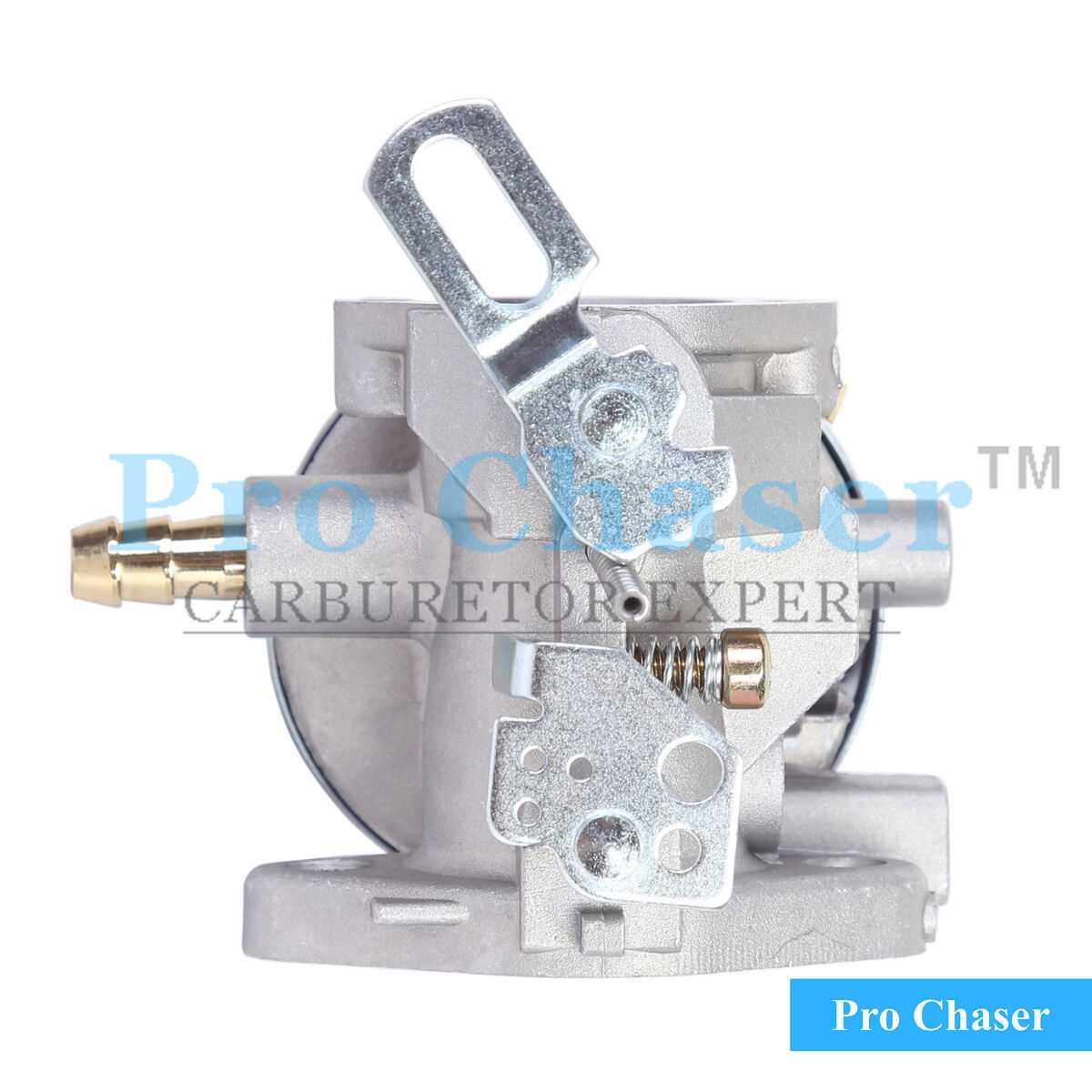

Benefits of Genuine John Deere Parts

Choosing authentic components for your machinery offers a range of advantages that enhance performance and longevity. These original pieces are designed to fit perfectly and work seamlessly, ensuring that your equipment operates at its best. By investing in these items, you can avoid common issues associated with inferior alternatives.

Quality Assurance

Original components undergo rigorous testing to meet high-quality standards. This ensures that:

- They provide reliable performance.

- They reduce the risk of malfunctions.

- They enhance safety during operation.

Optimal Performance

Using authentic components allows your machinery to achieve maximum efficiency. Benefits include:

- Improved fuel efficiency.

- Smoother operation with less wear and tear.

- Better compatibility with existing systems.

Investing in genuine components is a proactive step toward maintaining the integrity and functionality of your equipment.

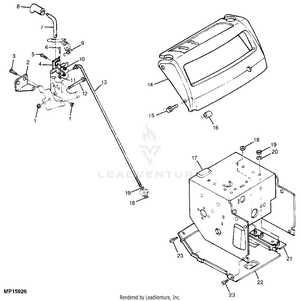

Step-by-Step Assembly Instructions

Assembling your equipment can seem daunting, but with a clear guide, the process becomes manageable. This section provides a straightforward approach to ensure each component is fitted correctly, enhancing overall functionality and performance.

Step 1: Begin by organizing all necessary components. Lay them out systematically to facilitate easy access during assembly.

Step 2: Refer to the included manual for a visual reference. This will help you understand how parts connect and align.

Step 3: Start with the base unit, ensuring that all fasteners are tightened appropriately. This step is crucial for stability.

Step 4: Proceed to attach the secondary elements, checking that each part fits snugly. Pay attention to any alignment markings.

Step 5: Once all components are assembled, conduct a thorough inspection. Ensure that everything is secure and functioning as intended.

Following these steps will lead to successful assembly, allowing you to delve into operation confidently.

Safety Precautions for Operation

Ensuring safety during the use of machinery is crucial for preventing accidents and injuries. Familiarity with operational guidelines can significantly enhance safety while working in challenging conditions.

- Always wear appropriate protective gear, including gloves, goggles, and sturdy footwear.

- Inspect the equipment before each use to ensure all components are functioning properly.

- Keep hands and feet clear of moving parts to avoid potential injuries.

- Operate the machine on stable, level ground to maintain control and prevent tipping.

By adhering to these guidelines, operators can create a safer environment for themselves and others while maximizing efficiency.

Comparative Analysis with Other Models

In this section, we explore the distinctions and similarities between various machinery options available for winter maintenance. By examining their design, efficiency, and user feedback, we aim to provide insight into how these models stack up against each other in real-world applications.

Performance: Different models often exhibit varying power levels and operational capabilities. Some may excel in heavy snowfall conditions, while others are better suited for lighter accumulations, affecting overall user satisfaction and efficiency.

Durability: Material quality and construction techniques play a critical role in longevity. A comparative analysis reveals that certain models are built to withstand harsher environments, ensuring reliable performance over extended periods.

Cost-effectiveness: Initial investment is just one aspect; maintenance and operational costs should also be evaluated. An effective comparison highlights which units offer better value over time, factoring in repair frequency and part availability.

User Experience: Feedback from operators provides valuable insights. Understanding preferences regarding ease of use, comfort, and handling can greatly influence the decision-making process when selecting the right equipment for snow management.

Seasonal Preparation and Storage Advice

As the colder months approach, ensuring that your equipment is ready for use is crucial for optimal performance. Proper preparation not only extends the lifespan of your machinery but also enhances its effectiveness during harsh weather conditions. A few key practices can make a significant difference in how well your tools function when you need them the most.

Inspection and Cleaning: Before storing your equipment, conduct a thorough inspection. Look for any wear and tear, and clean all components to remove dirt and debris. This prevents rust and corrosion, ensuring everything is in peak condition when winter arrives.

Fuel Management: Consider the type of fuel you use. For machines that operate on gasoline, using a fuel stabilizer can help maintain the integrity of the fuel over extended storage periods. This simple step can prevent starting issues later on.

Storage Environment: Choose a dry, temperature-controlled space for storage. Moisture can lead to various problems, including electrical issues and mold growth. Keeping your equipment indoors or in a sheltered area protects it from the elements.

Regular Maintenance: Schedule periodic check-ups even during the off-season. This practice allows you to identify any potential issues early and ensures your machinery is always ready to go when winter weather strikes.

By implementing these strategies, you can delve deeper into the art of seasonal preparation and maximize the functionality of your equipment throughout the winter months.

Community Resources and Support Forums

Engaging with fellow enthusiasts and professionals can significantly enhance your understanding and troubleshooting skills related to outdoor equipment. These platforms provide a wealth of knowledge, allowing users to share experiences, tips, and solutions. Whether you’re seeking guidance or offering advice, the collective wisdom found in these communities is invaluable.

Online forums are often the first stop for those looking to connect with others facing similar challenges. Here, you can find dedicated sections for discussions, where members post questions and share their insights. Many forums also feature technical guides and troubleshooting resources that can help demystify complex issues.

Additionally, social media groups and platforms offer another avenue for support. These spaces allow for real-time communication and foster a sense of camaraderie among users. Participating in these communities not only provides access to expert knowledge but also cultivates friendships with like-minded individuals.