When it comes to maintaining winter machinery, having a clear understanding of its components is essential. Proper knowledge allows for efficient operation and timely repairs, ensuring that your equipment performs optimally during the snow season. Familiarity with the various elements that make up these machines can help you troubleshoot issues and carry out necessary maintenance tasks.

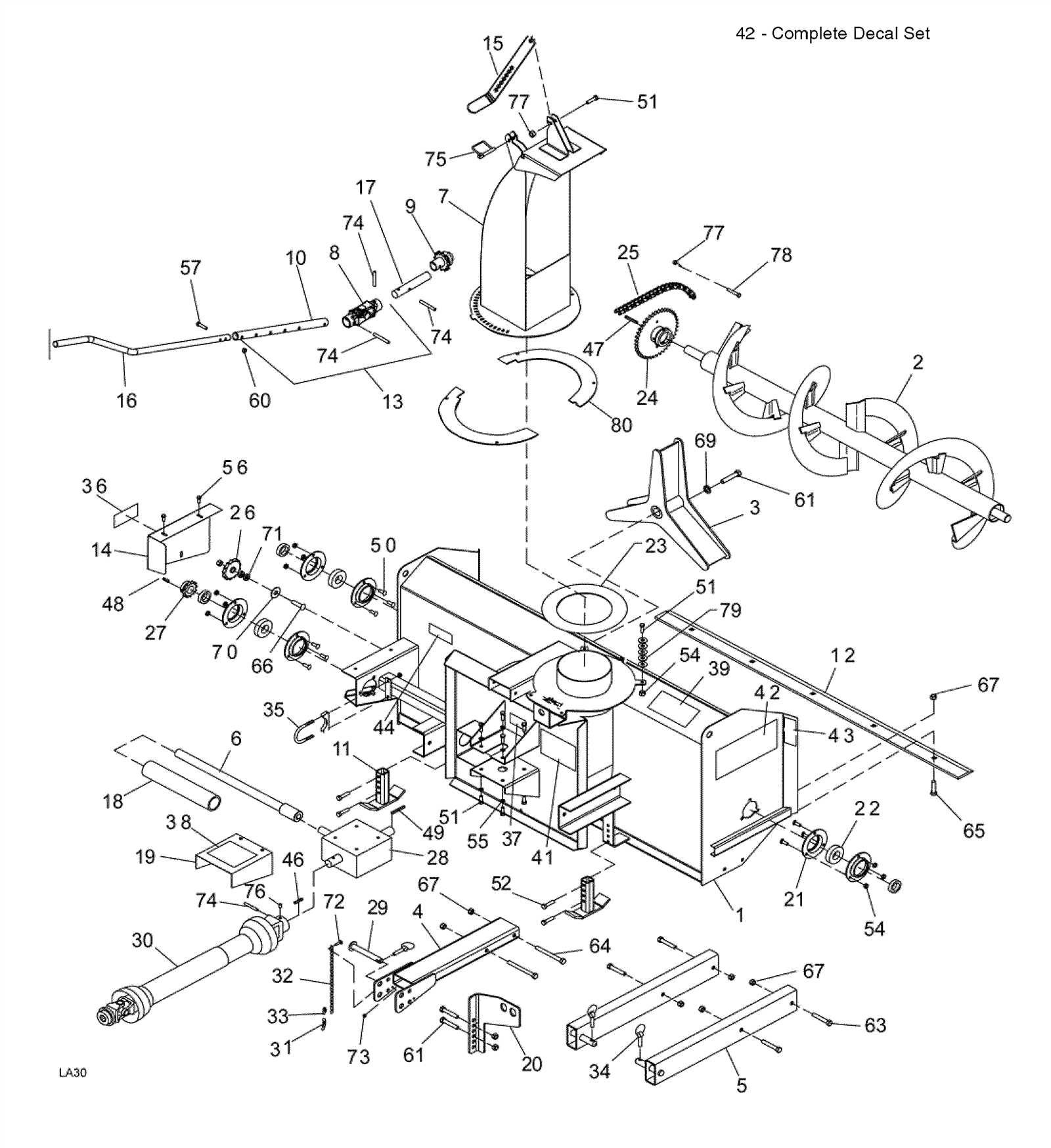

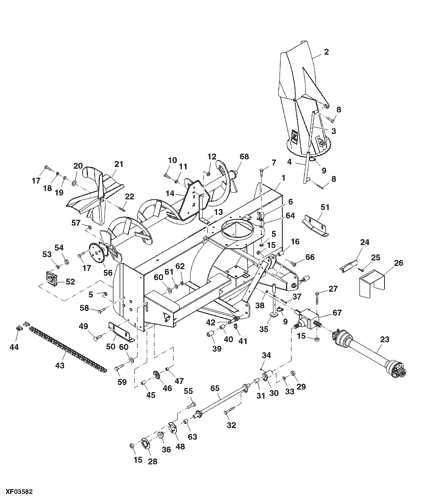

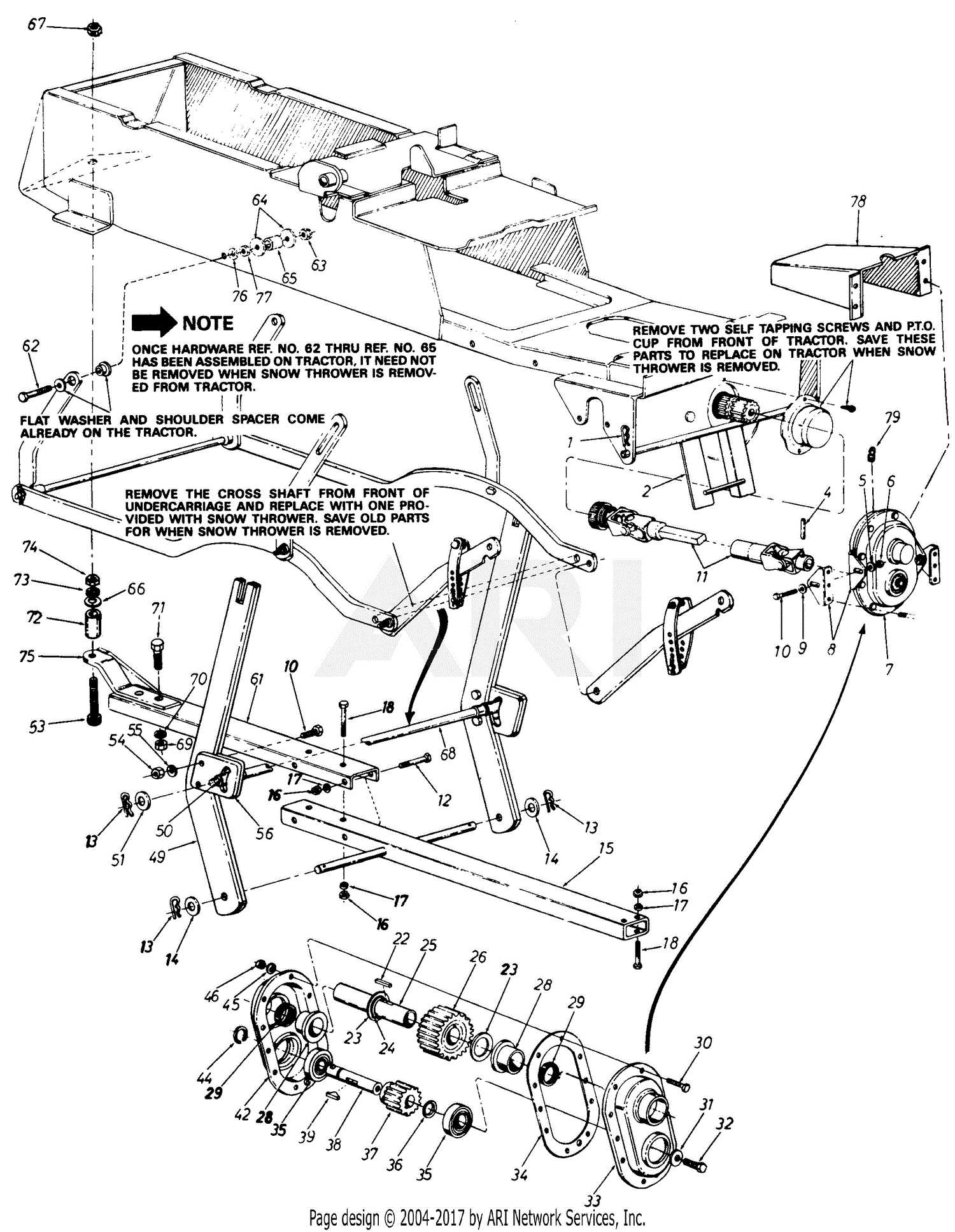

Visual aids can be incredibly beneficial in this regard. They offer a detailed representation of the assembly, highlighting how different parts interact and function together. By utilizing such resources, operators can gain valuable insights into their machinery, enabling them to identify potential problems before they escalate.

Whether you are a seasoned user or a novice, mastering the layout of your equipment will enhance your overall experience. Understanding the intricacies of your winter gear not only contributes to its longevity but also ensures that you are well-prepared for any snowfall that may come your way.

Overview of John Deere Model 49

This section explores a powerful piece of equipment designed for effective snow removal. Its robust construction and efficient operation make it a popular choice among homeowners and professionals alike, ensuring reliable performance even in harsh conditions.

Key Features

The equipment boasts a range of features that enhance its usability. With a high-capacity design, it easily tackles heavy snowfall, while user-friendly controls provide seamless operation. Durability is also a key aspect, allowing for prolonged use across multiple seasons.

Maintenance and Care

Regular upkeep is essential for optimal functioning. Routine checks and timely replacements of worn components will ensure longevity and reliability. Understanding the specific requirements for care can ultimately enhance performance and efficiency.

Key Features of the Snow Clearing Machine

This powerful tool is designed to tackle harsh winter conditions, providing efficiency and reliability for homeowners and professionals alike. Its robust construction and innovative design ensure optimal performance, making snow removal a seamless task.

Powerful Engine

Equipped with a high-performance engine, this device delivers exceptional power, enabling it to clear large areas quickly. The engine’s reliability ensures consistent operation even in the toughest weather conditions, making it an essential companion during winter storms.

User-Friendly Controls

Featuring intuitive controls, this equipment allows for easy maneuverability and adjustment. Operators can quickly switch between different settings, ensuring maximum efficiency and comfort while working. The ergonomic design enhances user experience, making snow removal less of a chore.

Common Parts Used in Maintenance

Maintaining outdoor equipment requires an understanding of various components essential for optimal performance. Regular upkeep ensures longevity and efficiency, minimizing the likelihood of unexpected breakdowns. Familiarity with key elements can greatly enhance the maintenance process.

Among the critical components are belts, which drive the machinery and require periodic inspection for wear and tear. Another vital item is the shear pin, designed to protect the system from damage during operation. Additionally, lubricants play a crucial role in reducing friction, contributing to smoother functioning. Filters, too, are essential for keeping the system clean and preventing debris accumulation.

Being aware of these elements not only facilitates better care but also empowers users to troubleshoot minor issues effectively. Investing time in understanding these components can ultimately lead to a more reliable and efficient machine.

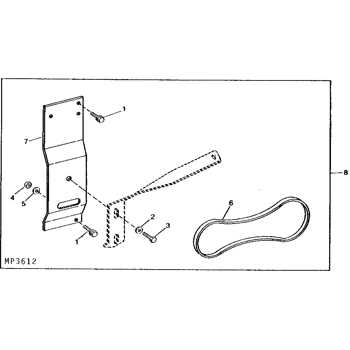

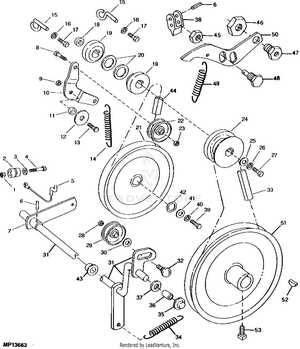

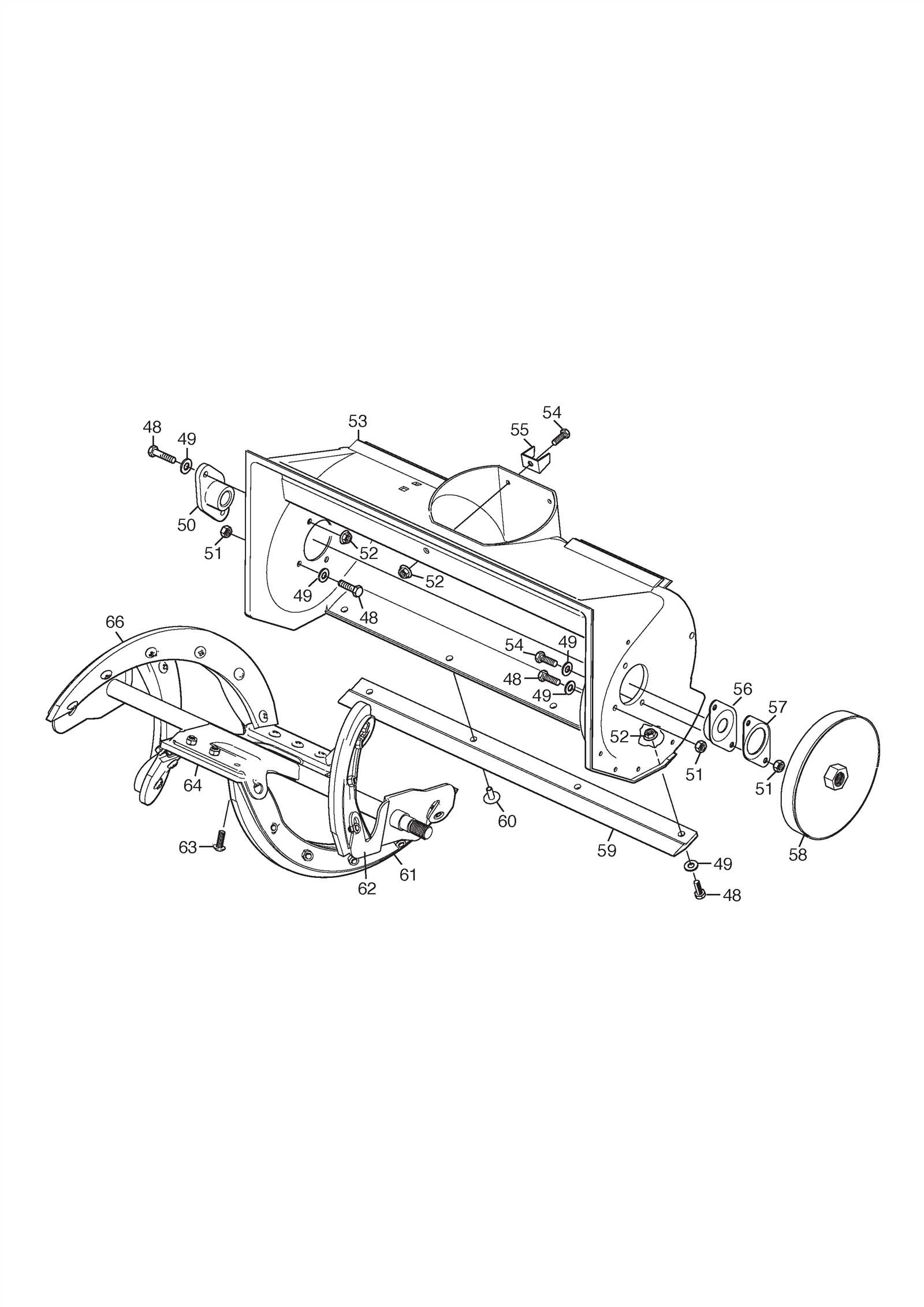

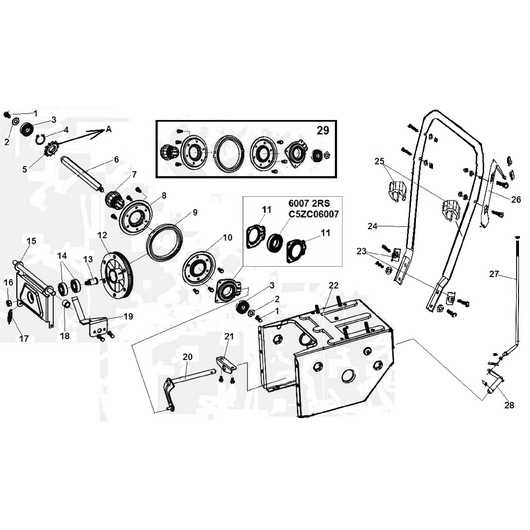

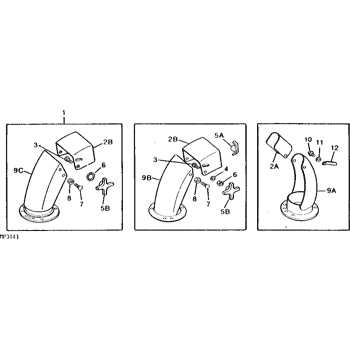

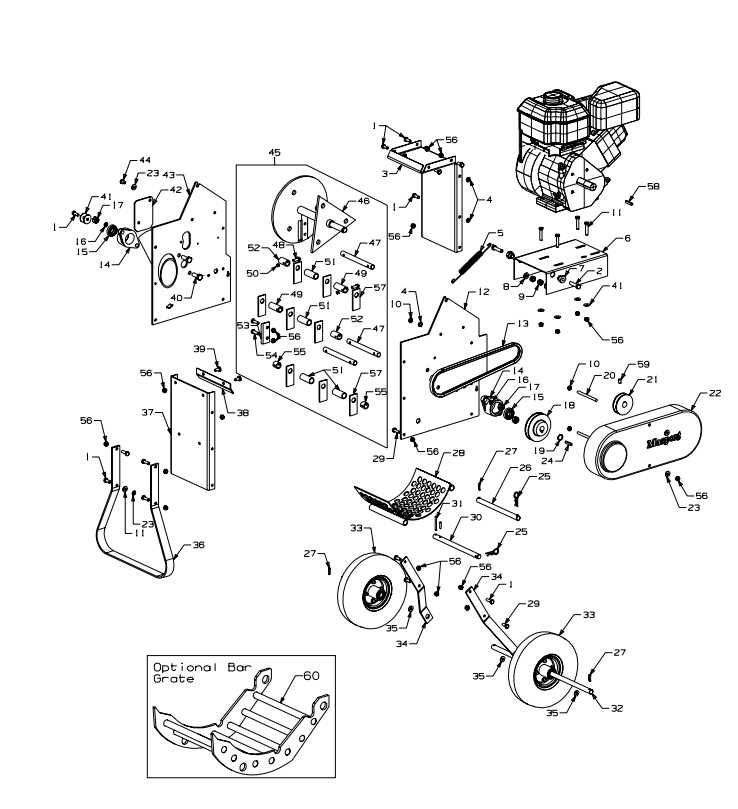

Understanding the Parts Diagram

Comprehending the layout of components is essential for efficient maintenance and troubleshooting. A well-structured visual representation facilitates the identification of individual elements and their functions within the system, promoting a better understanding of overall mechanics.

Importance of Familiarity

Having an in-depth knowledge of each segment is crucial for effective repairs. Recognizing the specific roles of various components can significantly enhance performance and longevity.

Tips for Utilization

When studying the illustration, take note of labels and connections between pieces. This will aid in recognizing potential issues and streamline the repair process, ensuring optimal operation.

Identifying Essential Components

Understanding the key elements of your equipment is crucial for effective maintenance and optimal performance. Each component plays a significant role in ensuring that the machine operates smoothly, especially in challenging conditions. Familiarizing yourself with these parts can enhance your ability to troubleshoot issues and perform necessary repairs.

Key Components Overview

Here is a brief overview of the main elements that you should be aware of:

| Component | Description |

|---|---|

| Auger | The rotating part that moves snow towards the discharge chute. |

| Discharge Chute | Directs the expelled snow away from the working area. |

| Drive Belt | Transfers power from the engine to the auger and wheels. |

Maintenance Tips

Regular inspection and upkeep of these crucial components will ensure longevity and reliability. Keep an eye out for wear and tear, and address any issues promptly to maintain peak functionality.

How to Use the Diagram Effectively

Understanding technical illustrations is crucial for efficient maintenance and repair tasks. These visuals can guide you through complex systems, ensuring that you identify components accurately and streamline your work process.

Familiarize Yourself with the Layout

Before diving into repairs, take time to understand the overall structure of the illustration. Pay attention to the following:

- Identify key sections and components.

- Look for any annotations or notes that provide additional context.

- Note the arrangement of parts to understand how they interact.

Follow a Step-by-Step Approach

When using the illustration for repairs or replacements, a systematic method is beneficial:

- Start by locating the part you need to address.

- Reference the visual to understand the removal or installation process.

- Keep tools handy as indicated, ensuring efficiency in your workflow.

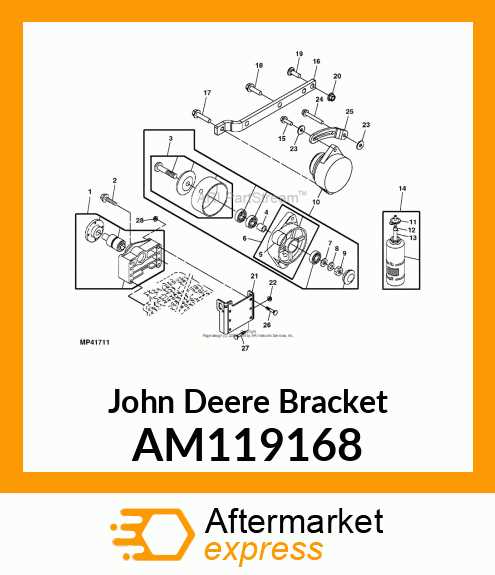

Tips for Ordering Replacement Parts

When it comes to acquiring components for your machinery, careful planning and attention to detail can greatly enhance the experience. Understanding the specifics of what you need will help you avoid unnecessary delays and ensure you get the right items for optimal performance.

Research Before You Buy

Before placing an order, take the time to gather information about the specific components required. Check the serial number and any relevant specifications of your equipment. This diligence can prevent costly mistakes and ensure compatibility with your existing machinery.

Choose Reliable Suppliers

Select vendors known for their quality and customer service. Look for reviews and testimonials from other customers. Establishing a relationship with trustworthy suppliers can provide additional support and guidance when needed, making your purchasing process smoother and more efficient.

Tip: Always keep a record of previous purchases to track what works best for your needs.

By following these guidelines, you can streamline your ordering process and maintain your equipment in top condition.

Maintenance Schedule for Optimal Performance

Regular upkeep is crucial for ensuring longevity and efficiency in any equipment. By adhering to a structured timetable, operators can prevent unexpected issues, enhance functionality, and maximize the lifespan of their machinery. A proactive approach not only improves performance but also saves time and resources in the long run.

Daily Checks

Before each use, it is vital to inspect the equipment for any visible wear or damage. Check fluid levels and ensure that all components are securely fastened. Cleaning the exterior after each operation will help maintain visibility and overall condition.

Seasonal Maintenance

At the beginning of each season, perform a comprehensive inspection. Replace filters and fluids as needed, and examine belts and chains for signs of wear. Sharpen blades to ensure efficient operation, and lubricate moving parts to reduce friction and wear.

Safety Precautions During Repairs

When undertaking maintenance tasks on any machinery, ensuring safety is paramount. Proper precautions help prevent accidents and injuries, allowing for a smoother repair process. Adhering to guidelines can make a significant difference in both personal safety and equipment longevity.

- Wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Ensure the machine is turned off and disconnected from power sources before beginning any work.

- Read the manufacturer’s manual thoroughly to understand the specific safety measures relevant to the equipment.

Additionally, consider the following steps:

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep tools organized and within reach to prevent unnecessary movement while working.

- Use tools that are in good condition, ensuring they are suitable for the task at hand.

Finally, always have a first-aid kit accessible and familiarize yourself with its contents. Being prepared for emergencies can mitigate the severity of accidents should they occur.

Compatibility with Other Models

Understanding the interchangeability of components across various machines is crucial for maintaining efficiency and performance. Many models share similarities that can facilitate the use of certain accessories and mechanisms, enhancing versatility.

Components designed for specific equipment often align with parts from other manufacturers, allowing for seamless integration. Compatibility may vary based on specific features, so it is essential to consult appropriate resources to ensure proper functionality. Identifying cross-compatible elements not only aids in repairs but can also improve overall operational effectiveness.

Common Issues and Solutions

When operating outdoor equipment designed for snow removal, various challenges can arise that affect performance and efficiency. Identifying these common problems and understanding how to address them can greatly enhance functionality and prolong the lifespan of the machine.

Typical Problems

- Clogging: Snow or debris may obstruct the chute, preventing effective clearing.

- Engine Issues: Difficulty starting or irregular running can indicate underlying mechanical issues.

- Insufficient Clearing: The equipment may fail to clear snow as expected, leaving piles behind.

- Drive Problems: Malfunctions in the drive system can hinder movement and maneuverability.

Effective Solutions

- For clogging, regularly clear the chute and ensure that it’s free from ice and snow buildup.

- If engine issues occur, check the fuel system, including filters and spark plugs, and consider a thorough tune-up.

- To improve clearing efficiency, adjust the height of the scraper blade and ensure it is in good condition.

- In case of drive problems, inspect the belts and chains for wear and replace them as necessary.

By proactively addressing these issues, operators can maintain optimal performance and enjoy a smoother experience during winter maintenance tasks.

Where to Find OEM Parts

Locating original equipment manufacturer components is crucial for maintaining the efficiency and longevity of your equipment. Authentic parts ensure optimal performance, compatibility, and reliability. Fortunately, there are several avenues to explore when seeking these essential elements for your machinery.

Authorized Dealers

One of the most reliable sources for genuine components is through authorized dealers. These vendors specialize in the brand’s products and often have a comprehensive inventory. Additionally, they can provide expert advice and support regarding installation and maintenance.

Online Retailers

The internet is a treasure trove for finding original components. Many online platforms offer a wide selection, allowing you to compare prices and availability. Be sure to check customer reviews and ratings to ensure you are purchasing from a reputable seller.

| Source Type | Advantages |

|---|---|

| Authorized Dealers | Expert advice, reliable inventory |

| Online Retailers | Convenience, price comparison |

| Manufacturer Websites | Direct access, latest products |

| Local Repair Shops | Hands-on support, local community |

User Reviews and Experiences

This section captures the thoughts and feedback from users who have engaged with the equipment. Their insights provide valuable information about functionality, durability, and overall satisfaction.

- Performance: Many users praise the efficiency in clearing heavy snowfall.

- Maintenance: Reviews highlight ease of upkeep, making it user-friendly for all skill levels.

- Durability: Customers frequently mention the robust build that withstands harsh conditions.

- Customer Support: Positive experiences with service teams have been noted, enhancing user confidence.

Overall, the shared experiences reflect a community of satisfied users who appreciate reliability and effectiveness in their equipment choices.