The effectiveness of winter machinery largely depends on the intricate network of its components. Understanding how these elements interact is crucial for optimal performance and longevity.

In this section, we will explore the key segments that contribute to the functionality of these machines. By examining their structure and arrangement, users can enhance their maintenance strategies and ensure reliable operation during the colder months.

Whether you are a seasoned operator or a newcomer, having a clear grasp of these essential elements will ultimately empower you to tackle any winter challenge. Join us as we delve into the specifics that make up this critical equipment.

Understanding John Deere Snowblower Components

This section aims to explore the various elements that make up a winter clearing machine, emphasizing their functions and interconnections. Each component plays a crucial role in ensuring efficient operation during challenging weather conditions, contributing to overall performance and reliability.

The key components include the engine, which provides the necessary power, and the impeller, responsible for directing the cleared material. Additionally, the housing protects internal mechanisms while enhancing durability. The chute and deflector allow for precise control over the discharge direction, enabling users to manage snow accumulation effectively.

Maintenance of these elements is vital for optimal performance. Regular inspections can prevent wear and tear, ensuring that the equipment remains in peak condition throughout the winter season. Understanding the layout and purpose of each piece facilitates better upkeep and enhances the longevity of the machine.

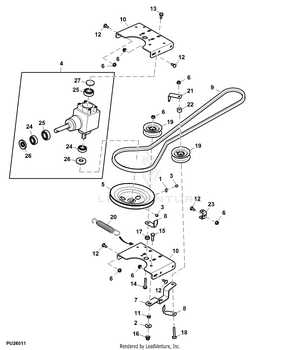

Essential Parts of Snowblower Models

Understanding the fundamental components of winter clearing machines is crucial for maintenance and effective operation. Each element plays a significant role in ensuring optimal performance and longevity, making it essential for users to familiarize themselves with them.

Key Components

Among the most vital elements are the motor, which provides power; the auger, responsible for collecting snow; and the chute, directing the cleared material. Each of these parts contributes to the overall functionality of the equipment.

Maintenance Overview

Regular upkeep of these components can prevent breakdowns and enhance efficiency. Ensuring that the motor is well-oiled and checking the auger for wear are just a few practices that can prolong the machine’s life.

| Component | Function |

|---|---|

| Motor | Drives the machine’s operation |

| Auger | Collects and moves snow |

| Chute | Disperses snow away from the path |

| Handle | Provides control and maneuverability |

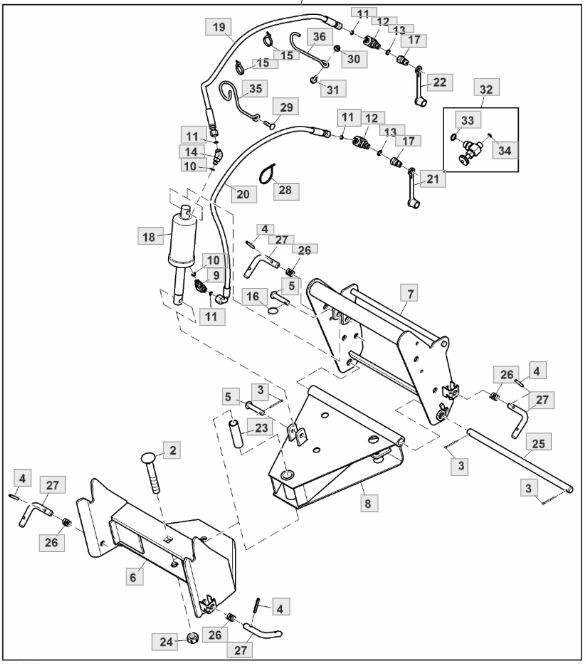

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations serve as a valuable tool, allowing users to identify individual elements and their interconnections. Familiarity with the symbols and layout enhances comprehension, enabling more efficient troubleshooting and assembly.

Typically, these visuals include several key features:

| Feature | Description |

|---|---|

| Labels | Each element is often marked with a code or number, referencing a specific description in accompanying documentation. |

| Legend | A guide explaining symbols and lines used in the illustration helps clarify the relationships between components. |

| View Angles | Different perspectives may be provided to offer a comprehensive understanding of the assembly and its layout. |

| Sections | Dividing the illustration into distinct areas can assist in isolating particular systems or assemblies for easier navigation. |

By mastering these elements, users can effectively interpret the visual guide, ensuring accurate repairs and optimal performance of the equipment.

Common Issues with Snowblower Parts

Maintaining equipment for winter conditions can be challenging. Various components may encounter problems that affect overall performance and efficiency. Understanding these common issues can help users troubleshoot and ensure reliable operation during harsh weather.

Wear and Tear

One of the most frequent challenges involves the degradation of moving components over time. Friction can lead to premature failure, especially in belts and blades. Regular inspection and timely replacement are essential to prevent further damage and maintain optimal functionality.

Blockages and Jams

Another prevalent issue is the buildup of snow and ice, which can cause obstructions in the machine. These blockages not only hinder performance but may also lead to overheating and mechanical stress. Clearing any debris promptly is crucial for smooth operation and longevity of the equipment.

Maintenance Tips for Snowblower Longevity

Ensuring the extended lifespan of your winter equipment requires a proactive approach to care and upkeep. Regular maintenance not only enhances performance but also prevents costly repairs and replacements.

1. Regular Cleaning: After each use, it’s crucial to remove any built-up snow and ice. This helps prevent rust and corrosion, which can damage internal components over time. A simple rinse and wipe-down can do wonders for longevity.

2. Check Fluids: Periodically inspect and change the oil according to the manufacturer’s guidelines. Clean, fresh oil lubricates moving parts and minimizes wear. Additionally, monitor the fuel system to ensure it remains clean and free of contaminants.

3. Inspect Belts and Cables: Regularly check for any signs of wear on belts and cables. Replacing worn components promptly prevents further damage and maintains optimal functionality.

4. Store Properly: When the winter season ends, store your equipment in a dry, sheltered location. Protecting it from the elements reduces the risk of rust and degradation, keeping it in top shape for the next season.

5. Follow the Manual: Always refer to the user manual for specific maintenance schedules and recommendations. Adhering to these guidelines ensures that all aspects of your machine are attended to appropriately.

By implementing these maintenance strategies, you can enhance the durability and efficiency of your winter machinery, ensuring it serves you well for many seasons to come.

Where to Find Replacement Parts

When it comes to maintaining outdoor equipment, sourcing components is essential for optimal performance. Fortunately, there are several avenues to explore when looking for the necessary elements to keep your machinery running smoothly.

- Manufacturer’s Website: The first place to check is the official site of the equipment maker. They often provide a comprehensive catalog of available components along with detailed specifications.

- Authorized Dealers: Local dealers who specialize in the brand can offer genuine replacements. These retailers usually have knowledgeable staff who can assist you in finding the right items.

- Online Retailers: E-commerce platforms are a convenient option. Websites like Amazon, eBay, or specialized equipment sites frequently list various components, often at competitive prices.

- Local Repair Shops: Many repair facilities keep stock of common components. Consulting with a local shop can save time and may provide additional insights into compatible alternatives.

- Salvage Yards: For those seeking budget-friendly options, salvage yards can be a treasure trove. These locations often have used items that can be refurbished or repurposed.

By exploring these resources, you can effectively locate the necessary components to ensure your equipment remains in top condition.

Upgrading Your Snowblower Effectively

Enhancing your winter equipment can significantly improve its performance and longevity. By focusing on key components and implementing strategic upgrades, you can ensure efficient operation during the cold months. This guide explores essential enhancements to consider.

Key Areas for Improvement

- Engine Power: Upgrading to a more powerful motor can enhance efficiency and speed.

- Auger Quality: Invest in high-quality augers to improve snow clearance capabilities.

- Chassis Strength: Reinforce the frame for better durability against harsh conditions.

Considerations for Upgrading

- Compatibility: Ensure new components are compatible with existing machinery.

- Performance Needs: Assess the specific requirements based on your typical snowfall.

- Budget: Balance performance enhancements with your financial plan.

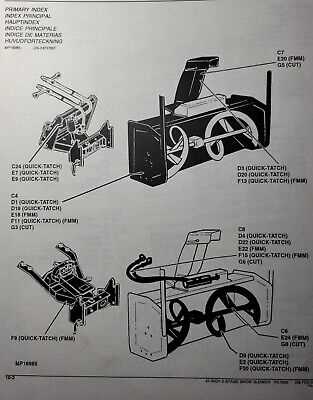

Comparing John Deere Snowblower Models

When considering the various models of outdoor clearing equipment, it’s essential to evaluate their unique features and capabilities. This comparison aims to highlight the differences that can influence performance, efficiency, and user satisfaction. Each model brings its own set of specifications tailored to meet diverse needs, whether for residential or commercial applications.

Key Features to Consider

- Engine Power: Assessing horsepower and torque can impact performance in heavy snow conditions.

- Clearing Width: Wider equipment can handle larger areas but may be less maneuverable.

- Throw Distance: Understanding how far snow is thrown can help in planning clearance strategies.

- Weight and Stability: Heavier models may offer better traction but can be challenging to maneuver.

- Controls and Ease of Use: Ergonomic design can significantly enhance user experience.

Popular Models Overview

-

Model A:

- Power: 24 HP

- Clearing Width: 30 inches

- Throw Distance: Up to 40 feet

-

Model B:

- Power: 20 HP

- Clearing Width: 26 inches

- Throw Distance: Up to 35 feet

-

Model C:

- Power: 28 HP

- Clearing Width: 32 inches

- Throw Distance: Up to 45 feet

Understanding these differences will guide users in selecting the most suitable equipment for their specific clearing needs, ensuring optimal performance and satisfaction during winter months.

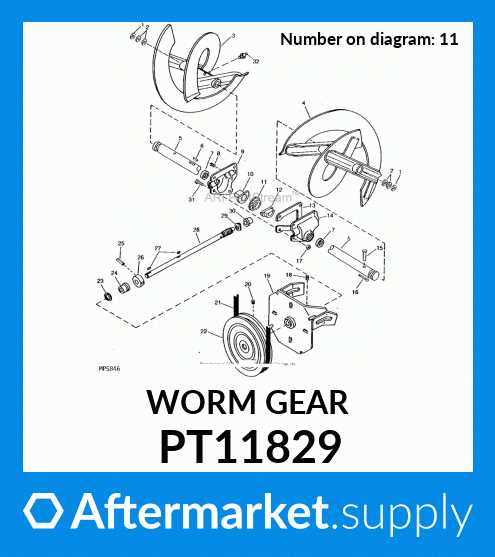

Identifying Snowblower Part Numbers

Understanding the various components of your equipment is crucial for effective maintenance and repair. Recognizing the specific identifiers associated with each piece can streamline the process of sourcing replacements and ensure optimal functionality.

Understanding Identifiers

Each element comes with a unique alphanumeric code that serves as its identifier. This code is essential for tracking, ordering, and ensuring compatibility with your machine.

Locating Codes

Typically, these identifiers can be found on the component itself or in the equipment’s user manual. Checking the manufacturer’s website can also provide helpful resources for verifying these numbers.

Customer Reviews on Snowblower Performance

Feedback from users provides valuable insights into the effectiveness of winter clearing equipment. Customers often share their experiences, highlighting various aspects such as efficiency, ease of use, and durability. These reviews can help prospective buyers make informed decisions based on real-world performance.

Key Performance Factors

- Power: Many users appreciate models that easily tackle heavy snow, noting the importance of a robust engine.

- Ease of Maneuverability: Reviews frequently mention the ease of steering and turning, which is crucial in tight spaces.

- Clearing Width: Customers often compare the effectiveness of different widths, with wider options receiving praise for speed and efficiency.

User Experiences

- Many customers report satisfaction with their machine’s ability to handle varying snow conditions.

- Some users express concerns about maintenance needs, especially after extended use in harsh weather.

- Positive feedback often highlights the convenience of electric start features, especially in extremely cold temperatures.

Expert Advice for DIY Repairs

When tackling repairs on your outdoor machinery, having a solid approach can make all the difference. Understanding the components and their functions is crucial for effective maintenance and troubleshooting.

- Start with the manual: Always refer to the manufacturer’s guide for detailed instructions.

- Gather your tools: Ensure you have the necessary tools on hand before beginning any repair.

- Inspect thoroughly: Examine all parts carefully for wear and damage.

Consider these steps to enhance your repair skills:

- Document the process: Take photos as you disassemble components for easier reassembly.

- Research common issues: Look for common problems associated with your equipment model.

- Test each component: After repairs, test functionality to confirm everything is working properly.

By applying these tips, you can confidently navigate repairs and maintain your equipment effectively.