When it comes to maintaining your winter machinery, having a comprehensive visual reference can significantly enhance your experience. A detailed representation of the various components allows users to better grasp the structure and functionality of their equipment, ultimately leading to more effective troubleshooting and maintenance practices.

In this section, we will explore the intricate assembly of your winter tool, focusing on each individual element and its role within the larger system. By delving into these components, you’ll gain insight into how they work together to ensure optimal performance during the harshest of conditions.

Whether you’re a seasoned user or a newcomer, understanding the layout and relationship between parts can empower you to tackle repairs with confidence. This knowledge not only streamlines maintenance but also enhances your overall proficiency with the machinery, making winter tasks more manageable.

Understanding Manual MTD Snowblower Parts

This section aims to clarify the essential components of a snow-clearing machine, providing insights into their functions and significance. A comprehensive grasp of these elements can enhance maintenance and troubleshooting efforts, ensuring optimal performance during winter operations.

Key Components and Their Functions

Familiarity with the main components aids in efficient usage and repair. Each part plays a crucial role in the overall functionality, from the engine to the control mechanisms.

| Component | Function |

|---|---|

| Engine | Drives the machine and powers all operations. |

| Auger | Collects and moves snow towards the discharge chute. |

| Chassis | Provides the structural framework for stability and support. |

| Controls | Allow the operator to navigate and adjust settings easily. |

Maintenance Tips

Regular inspection of each component is vital for longevity. Addressing minor issues promptly can prevent more significant problems, ensuring reliable operation when it matters most.

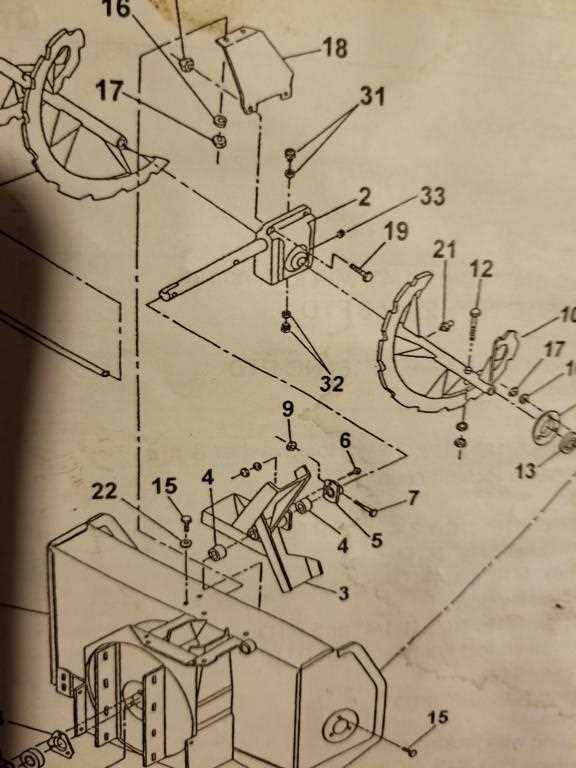

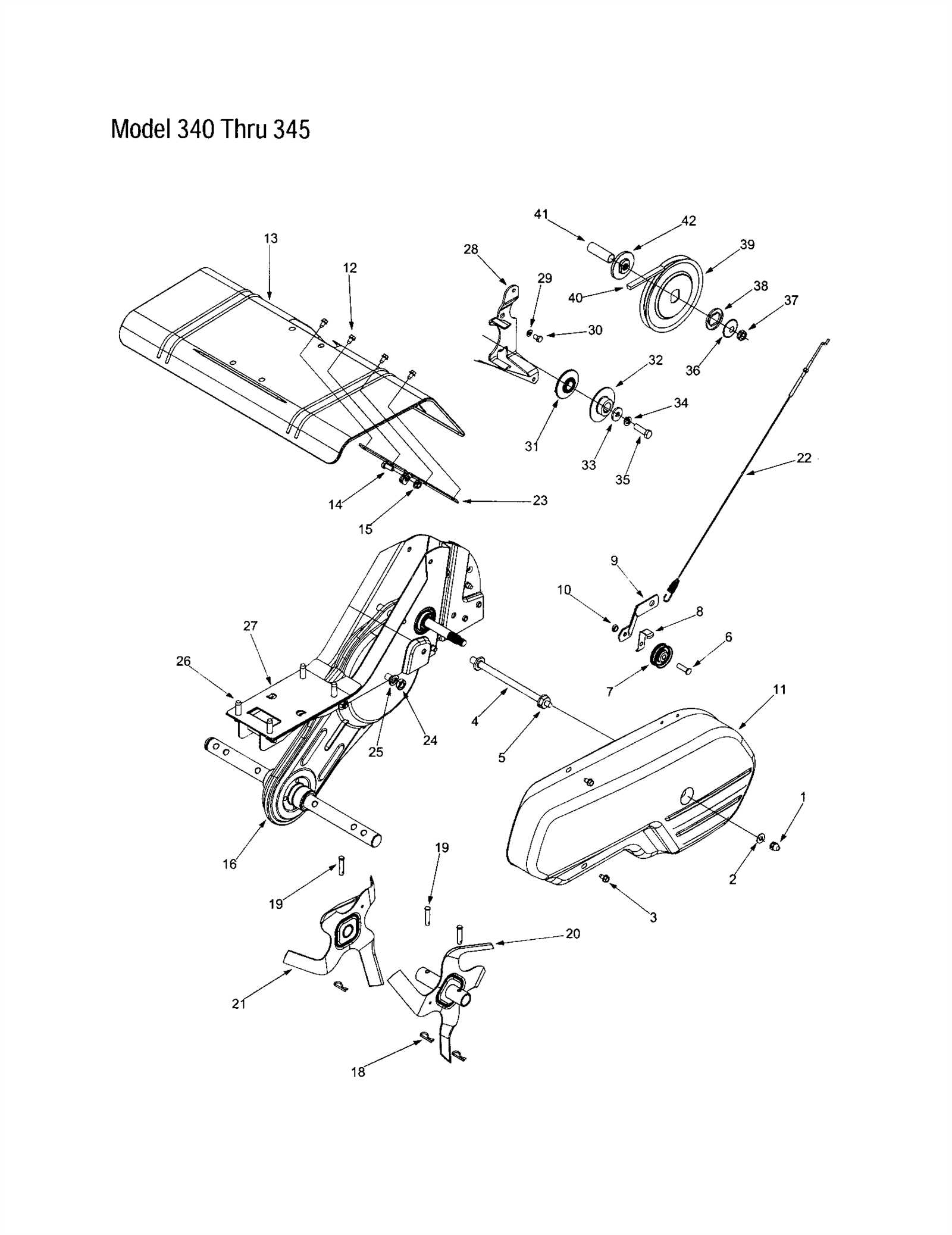

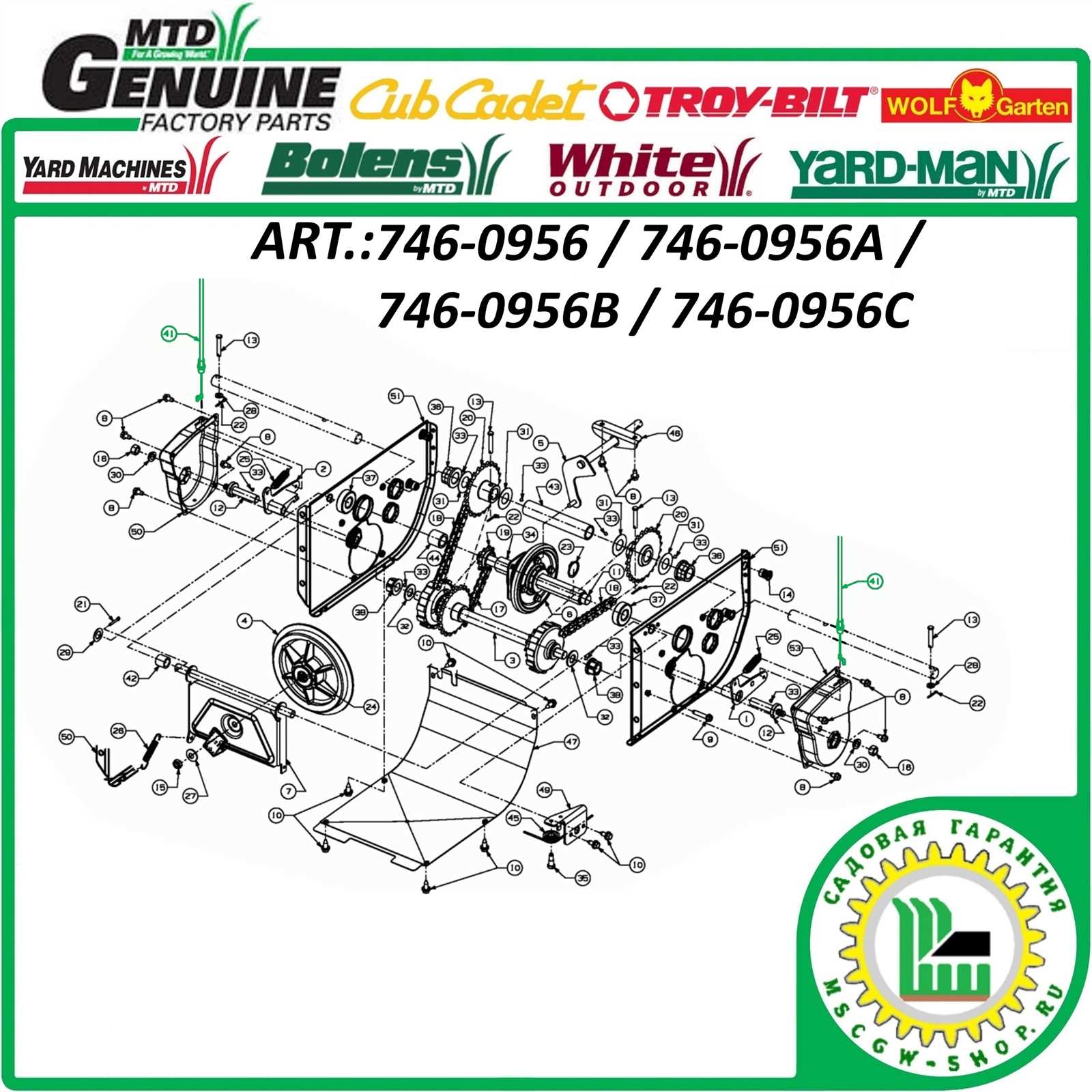

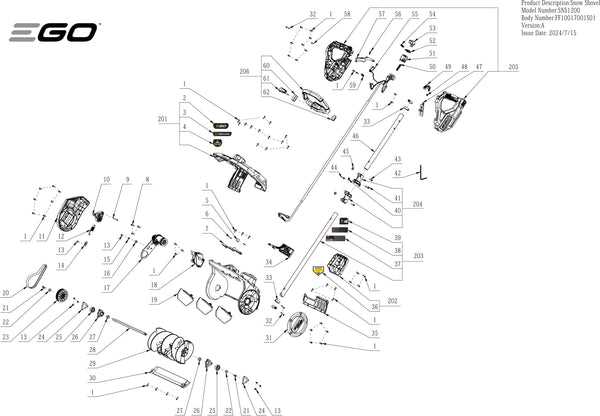

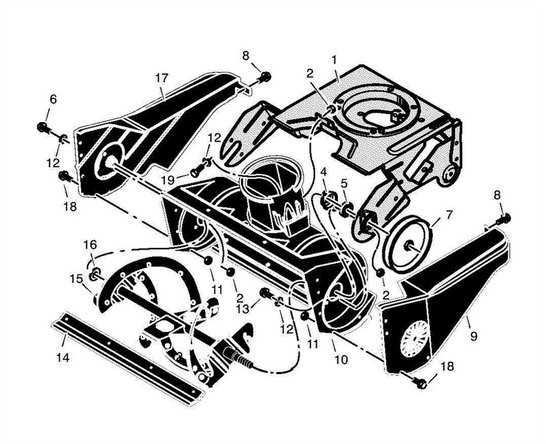

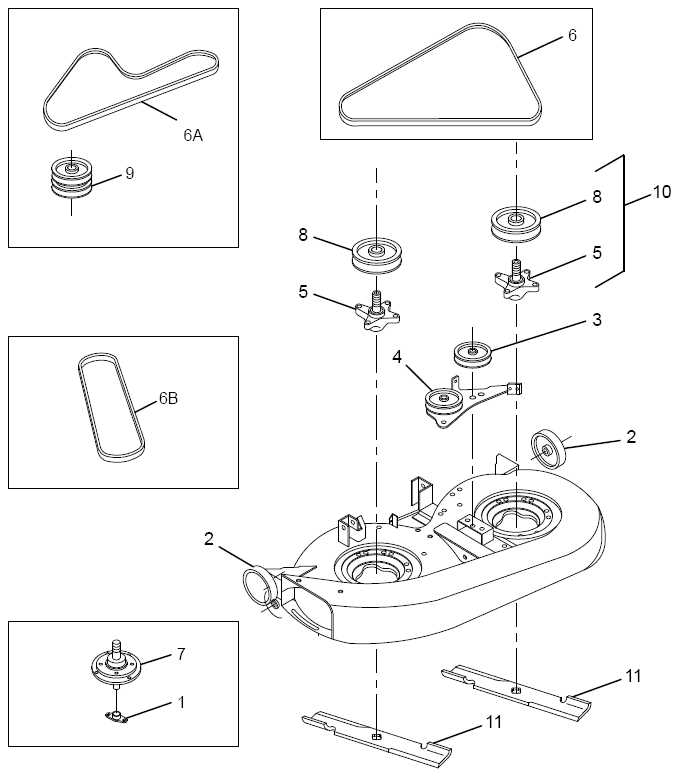

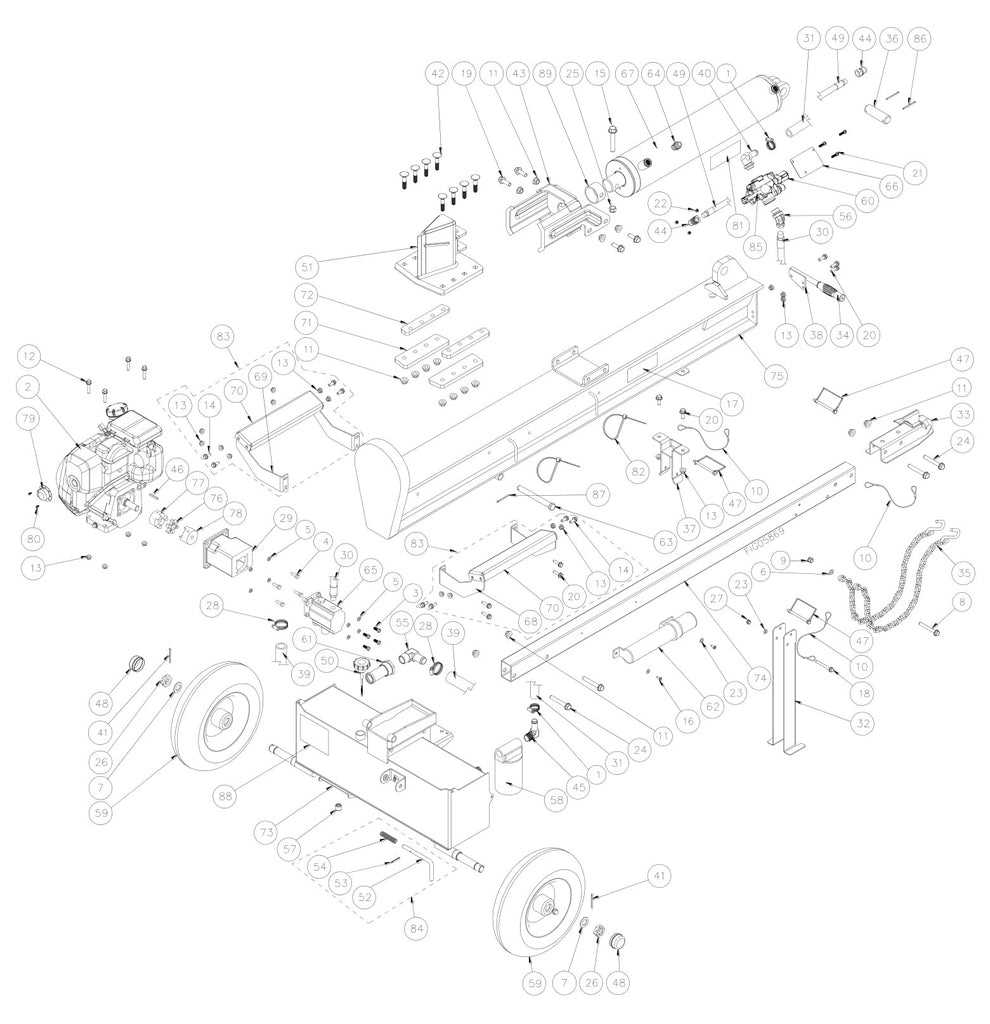

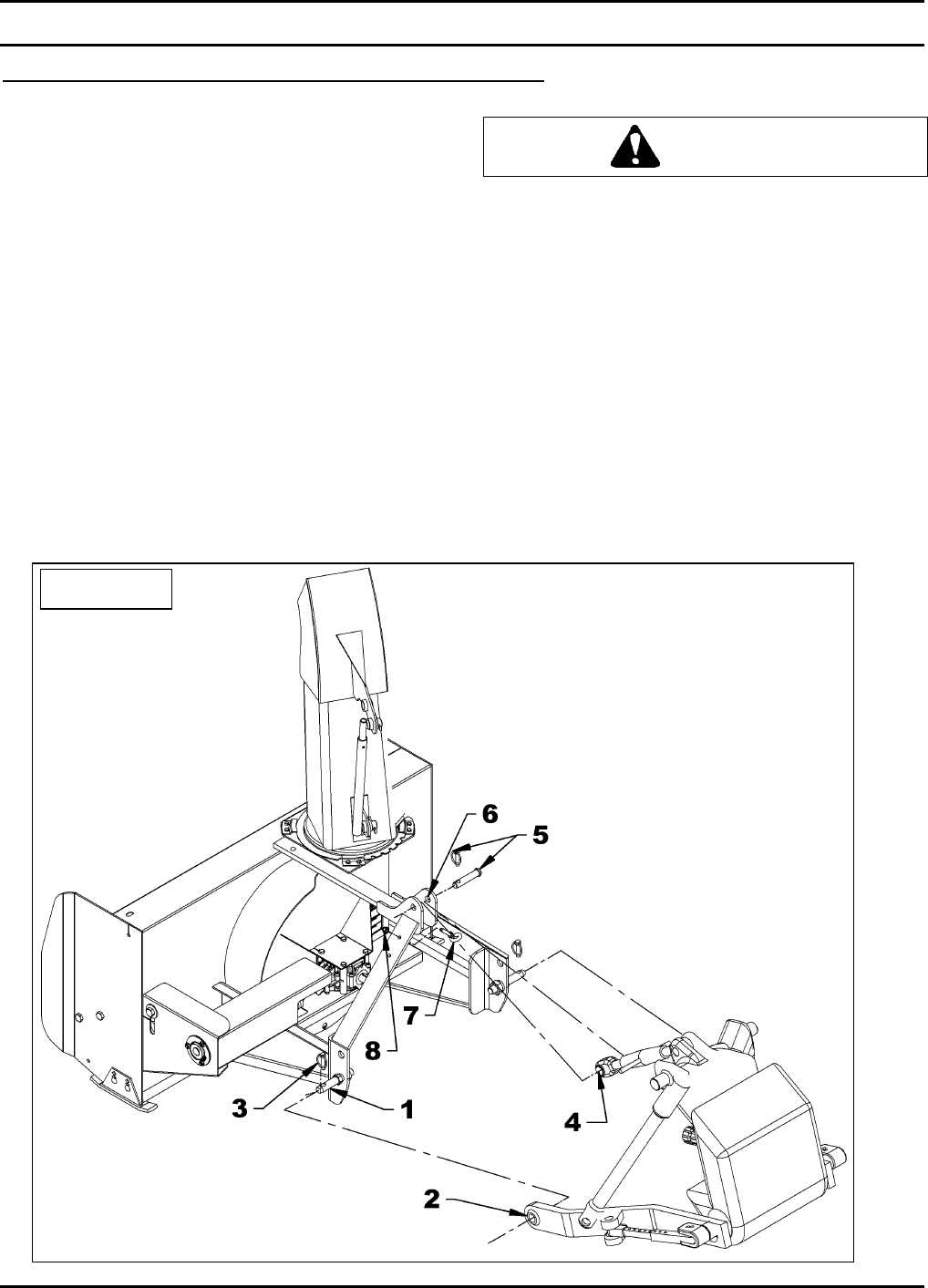

Importance of Parts Diagrams

Understanding the layout and components of a machine is crucial for effective maintenance and repair. Visual representations provide clarity, ensuring users can easily identify each element and its function. This knowledge not only enhances efficiency but also minimizes the risk of errors during servicing.

Furthermore, these illustrations serve as invaluable resources for troubleshooting, allowing users to quickly pinpoint issues. When individuals are well-acquainted with the structure, they can address problems proactively, ultimately prolonging the equipment’s lifespan.

In addition, detailed visuals foster confidence among users, empowering them to tackle repairs independently. This self-sufficiency can lead to significant savings in service costs, making a compelling case for the necessity of such representations in any maintenance toolkit.

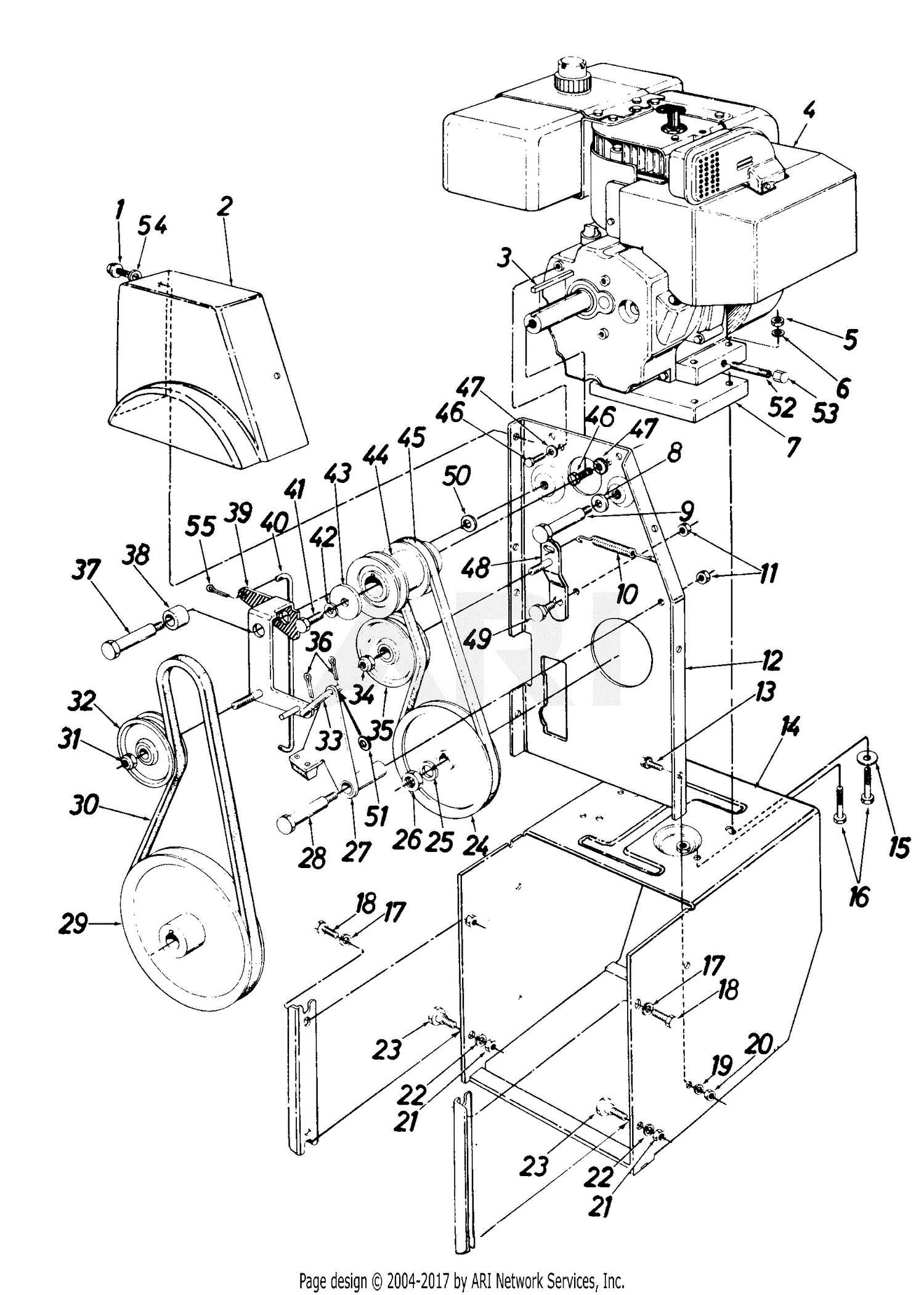

Key Components of Snowblowers

The efficiency of winter clearing machines relies on several essential elements that work in harmony to ensure optimal performance. Understanding these components is crucial for proper maintenance and effective operation during the snowy season.

Engine and Power System

The heart of any clearing device is its engine, which provides the necessary power to operate all functions. Different models may feature gas or electric engines, each with distinct advantages. The power system directly influences the machine’s capability to tackle varying snow conditions.

Auger and Impeller

These components are vital for the movement and expulsion of snow. The auger gathers snow and feeds it into the machine, while the impeller propels it out through the chute. Their design and efficiency greatly affect the clearing process, making them integral to the overall functionality.

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to maintain and repair machinery. These illustrations provide a structured overview of various elements, helping users identify individual pieces and their relationships within the overall system. Mastering the art of interpreting these visuals can save time and reduce frustration during maintenance tasks.

Key Elements to Identify

When examining these visuals, focus on several essential aspects:

| Element | Description |

|---|---|

| Labels | Most visuals include labels that correspond to specific components, facilitating easy identification. |

| Numbers | Numeric codes often link to a list, providing detailed information about each component’s specifications. |

| Lines and Arrows | Connections between components are often indicated with lines and arrows, showing how parts fit together. |

Steps for Effective Interpretation

To effectively decode these illustrations, follow these steps:

- Start with the overall view to get a sense of the layout.

- Identify and note the labeled components.

- Cross-reference with accompanying lists to understand specifications.

- Pay attention to connections indicated by lines and arrows for assembly insights.

Common MTD Snowblower Issues

During winter operations, various challenges can arise with outdoor machines designed for clearing snow. Understanding these frequent complications can aid in timely resolutions and enhance performance.

Starting Difficulties

One of the most prevalent problems encountered is trouble initiating the engine. This may stem from fuel issues, spark plug failures, or battery malfunctions, which can hinder efficiency and prolong clearing tasks.

Auger and Chassis Problems

Another common concern involves the auger and housing. Blockages or wear can diminish functionality, leading to inefficient snow removal. Regular inspections can help mitigate these issues and ensure optimal operation.

Finding Replacement Parts Easily

Locating suitable components for your outdoor equipment can often feel overwhelming. However, with the right approach, you can streamline the process and ensure you find what you need without unnecessary hassle.

Key Strategies

- Utilize online marketplaces for a wide selection.

- Check local retailers that specialize in garden equipment.

- Visit forums and community groups for recommendations.

Helpful Tips

- Keep a record of your equipment model and specifications.

- Take advantage of comparison tools to find the best prices.

- Contact manufacturers directly for guidance and availability.

Tools Needed for Repairs

Proper equipment is essential for effective maintenance and repair tasks. Having the right tools not only enhances efficiency but also ensures safety and precision during the process. Whether tackling minor fixes or significant overhauls, a well-equipped toolkit is crucial for achieving optimal results.

Essential Hand Tools

A variety of hand tools are indispensable for any repair job. Wrenches, screwdrivers, and pliers are fundamental for disassembling and reassembling components. Additionally, a good set of sockets can provide the versatility needed for different fasteners, while a sturdy hammer can assist with adjustments and fittings.

Power Tools and Equipment

For more complex tasks, power tools can greatly accelerate the process. A reliable drill, for example, is useful for creating holes or driving screws with ease. An angle grinder may also be beneficial for cutting or grinding metal parts, ensuring that repairs are completed efficiently and effectively.

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring its longevity and optimal performance. By following a few simple practices, you can extend the life of your machine and maintain its efficiency throughout the years.

- Regular Cleaning: Keep the exterior free from debris and dirt. After each use, wipe down surfaces to prevent buildup.

- Fluid Checks: Regularly inspect and replace fluids as needed. This includes checking oil levels and replacing fuel when necessary.

- Inspect Belts and Cables: Look for signs of wear or fraying. Replace any damaged components to prevent further issues.

By adhering to these guidelines, you can help ensure that your equipment remains in peak condition, ready for use when you need it most.

- Sharpen Blades: Keep blades sharp for efficient operation. Dull blades can strain the motor and reduce effectiveness.

- Battery Care: If your machine has a battery, ensure it is charged properly and maintained according to the manufacturer’s recommendations.

- Storage Practices: When not in use, store the equipment in a dry, sheltered area to protect it from the elements.

Implementing these maintenance practices will not only improve performance but also save you time and money in the long run.

Where to Purchase Authentic Parts

Finding reliable components for your outdoor equipment is crucial for maintaining optimal performance. Sourcing genuine replacements ensures durability and compatibility, which ultimately prolongs the life of your machinery. Here are some trusted avenues for obtaining authentic items.

Authorized Retailers

Visiting authorized dealers is one of the best ways to ensure you are getting legitimate replacements. These retailers often carry a comprehensive selection of original items and can provide expert advice tailored to your specific needs. Additionally, purchasing through an authorized source often comes with a warranty, adding an extra layer of security.

Online Marketplaces

Numerous online platforms specialize in selling quality components. When shopping online, always check for customer reviews and ratings to gauge the reliability of the seller. Look for platforms that offer a return policy, which can be helpful if the item does not meet your expectations. Consider websites that specifically focus on your equipment type for a better selection.

Comparing Aftermarket Options

When it comes to enhancing your outdoor equipment, exploring alternative components can offer significant advantages. These replacements may provide cost savings, improved performance, or specific features that cater to your needs.

Here are some key factors to consider when evaluating these alternatives:

- Quality: Assess the materials and construction methods used in the replacements. Higher quality often leads to better durability.

- Compatibility: Ensure that the parts are designed to fit your equipment model accurately. Incompatibility can lead to performance issues.

- Price: Compare costs with original components. While savings can be substantial, be cautious of options that seem too cheap.

- Warranty: Check if the replacements come with a warranty. A good warranty can provide peace of mind regarding your investment.

- Reviews: Look for customer feedback on the aftermarket products. Insights from other users can guide your decision-making process.

By taking these factors into account, you can make a well-informed choice that meets your operational needs and budget while ensuring your equipment runs smoothly.

Repair vs. Replacement: Making Decisions

When faced with a malfunctioning piece of equipment, one of the most critical choices is whether to repair the existing unit or to invest in a new one. This decision can significantly impact both your finances and the longevity of your operations. Analyzing various factors can help streamline this process.

- Cost Analysis: Evaluate the expenses associated with both options. Consider the cost of repairs versus the price of a new unit.

- Age of the Equipment: Determine how long you have had the current unit. Older models may be more prone to issues.

- Frequency of Repairs: If the equipment requires frequent maintenance, replacement might be a more viable option.

Weighing the pros and cons is essential to making an informed decision. A thoughtful approach will ensure that you choose the best path forward.

- Assess Condition: Look for visible signs of wear or damage that may indicate a need for replacement.

- Research Alternatives: Explore newer models and their features that may offer enhanced performance or efficiency.

- Consider Downtime: Factor in the time needed for repairs versus the immediate availability of a new unit.

Ultimately, the choice between fixing or replacing hinges on a careful evaluation of these elements. Prioritizing long-term value over short-term solutions will lead to better outcomes.

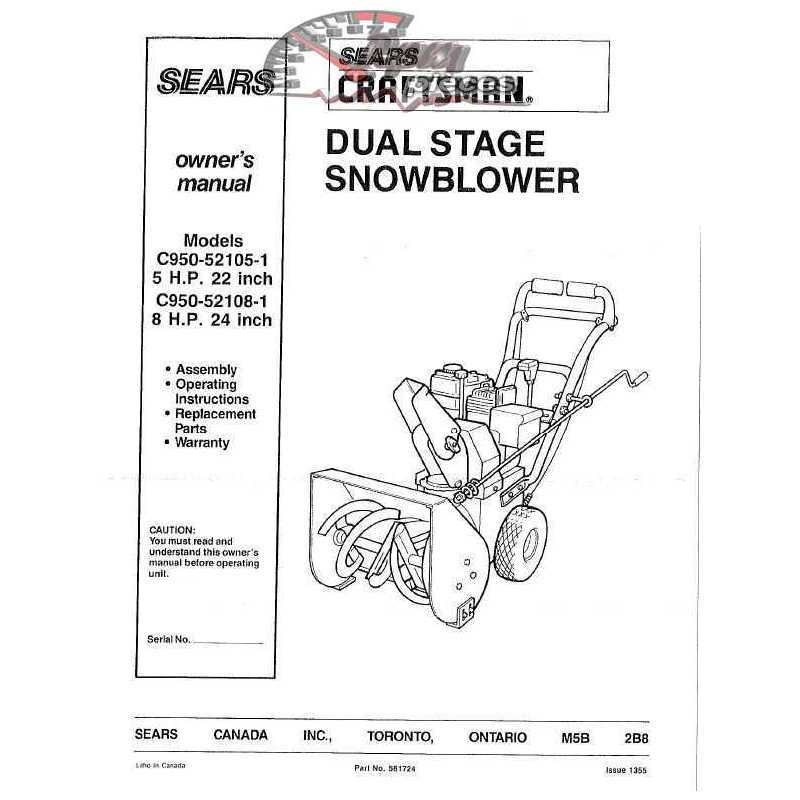

Owner Manuals and Their Usefulness

Owner guides serve as essential resources for individuals seeking to maximize the performance and longevity of their equipment. These documents provide critical information on maintenance, safety procedures, and operational techniques, ensuring users can navigate their machines effectively.

Understanding the contents of these guides enables users to troubleshoot common issues, perform routine upkeep, and make informed decisions regarding repairs or upgrades. By having a thorough grasp of the information presented, owners can delve into the specifics of their equipment, enhancing both efficiency and safety.

In essence, these resources empower users to take full advantage of their investment, fostering a deeper connection with the machinery while ultimately leading to better performance outcomes.

Customer Support Resources Available

When it comes to maintaining your equipment, having access to reliable assistance can make all the difference. Understanding the various avenues for support ensures that you can resolve any issues efficiently and get the most out of your investment.

Online Portals provide a wealth of information, including troubleshooting guides, FAQs, and community forums where users can exchange tips and experiences. These resources are invaluable for quick fixes and gaining insights from fellow enthusiasts.

Customer Service is readily available through multiple channels. You can reach out via phone or email for direct assistance from knowledgeable representatives who can guide you through complex problems or provide recommendations tailored to your needs.

Documentation is often available in digital format, allowing you to easily download and access user guides, installation instructions, and service tips at your convenience. Having this information at your fingertips can streamline the maintenance process.

In addition to these options, many brands also offer video tutorials that visually demonstrate various procedures, making it easier for users to follow along and perform necessary tasks themselves. These resources enhance your ability to troubleshoot and maintain your machinery effectively.

By leveraging these support resources, you can ensure optimal performance and longevity for your equipment while gaining confidence in your maintenance skills.