In the realm of winter maintenance, the efficiency of your machinery plays a crucial role in managing snow and ice. A comprehensive grasp of the internal elements of such devices is essential for optimal performance and longevity. This guide aims to illuminate the various components that contribute to the overall functionality of your equipment, ensuring that you are well-equipped to tackle the challenges posed by harsh winter conditions.

Every piece of machinery consists of a multitude of interconnected mechanisms, each serving a specific purpose. By exploring these individual components, users can better appreciate how their device operates and what maintenance practices are necessary to keep it running smoothly. A thorough examination will reveal not only the primary functions but also how these elements work in harmony to deliver effective results.

Moreover, understanding the layout and interaction of these components can significantly enhance troubleshooting capabilities. When issues arise, having a clear picture of how everything fits together enables you to pinpoint problems swiftly and efficiently. This knowledge empowers operators to perform timely repairs, ultimately extending the lifespan of their equipment and improving performance in adverse conditions.

Understanding Pronovost Snowblower Components

The efficient operation of any outdoor clearing machinery relies on a comprehensive understanding of its individual elements. Each component plays a crucial role in ensuring optimal performance and longevity. Familiarity with these parts not only aids in maintenance but also empowers users to troubleshoot and enhance their machine’s capabilities.

Key Components: A central element is the mechanism responsible for the propulsion of materials, which works in conjunction with other features to achieve desired outcomes. Additionally, the control system allows users to manipulate functions, tailoring operations to specific requirements. Proper care of these mechanisms is vital, as wear and tear can significantly impact efficiency.

Maintenance Considerations: Regular inspections and prompt replacements of worn-out elements are essential for maintaining functionality. Users should pay particular attention to components that endure the most stress during operation. Knowledge of each part’s function can facilitate more effective troubleshooting, leading to quicker resolutions of any issues that arise.

In summary, a thorough comprehension of each element within the machinery not only ensures efficient performance but also extends its lifespan. By recognizing the significance of these components, operators can make informed decisions regarding maintenance and upgrades.

Importance of Replacement Parts

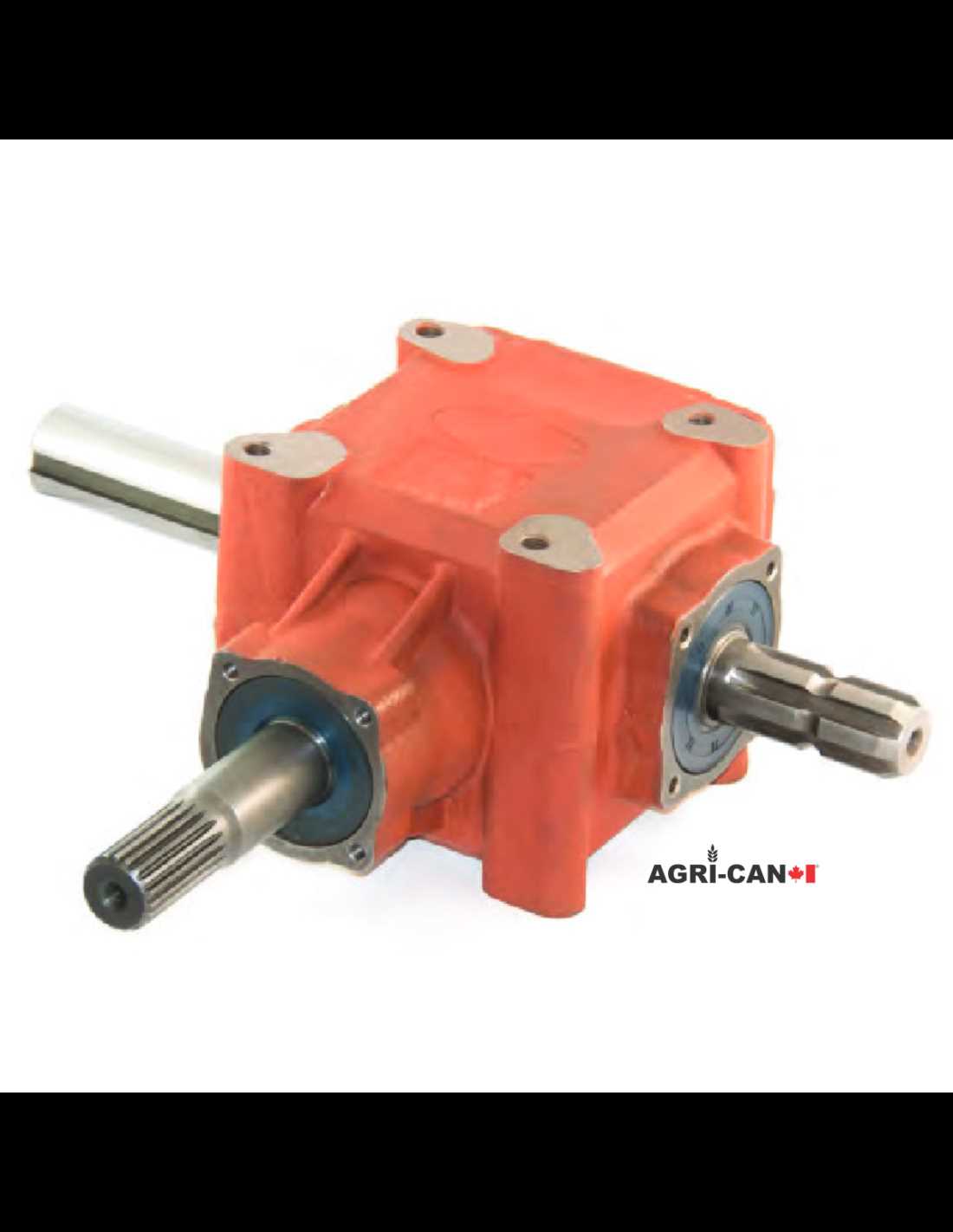

Maintaining equipment in optimal condition is crucial for ensuring longevity and performance. When components become worn or damaged, it can significantly impact the overall efficiency and functionality. Utilizing high-quality replacements is essential not only for restoring operations but also for enhancing safety and reliability. This section highlights the significance of utilizing appropriate replacements in equipment maintenance.

Benefits of High-Quality Replacements

Investing in superior replacements provides several advantages. First, they help restore functionality, ensuring that machinery operates at peak efficiency. Second, quality replacements contribute to safety by minimizing the risk of malfunctions that could lead to accidents. Finally, they often enhance the overall performance, leading to greater productivity.

Choosing the Right Components

Selecting the correct components is vital for effective maintenance. Factors to consider include compatibility, material quality, and manufacturer recommendations. Making informed choices can prevent future issues and ensure the equipment performs reliably.

| Factor | Importance |

|---|---|

| Compatibility | Ensures proper fit and function |

| Material Quality | Affects durability and performance |

| Manufacturer Recommendations | Guides in selecting the best options |

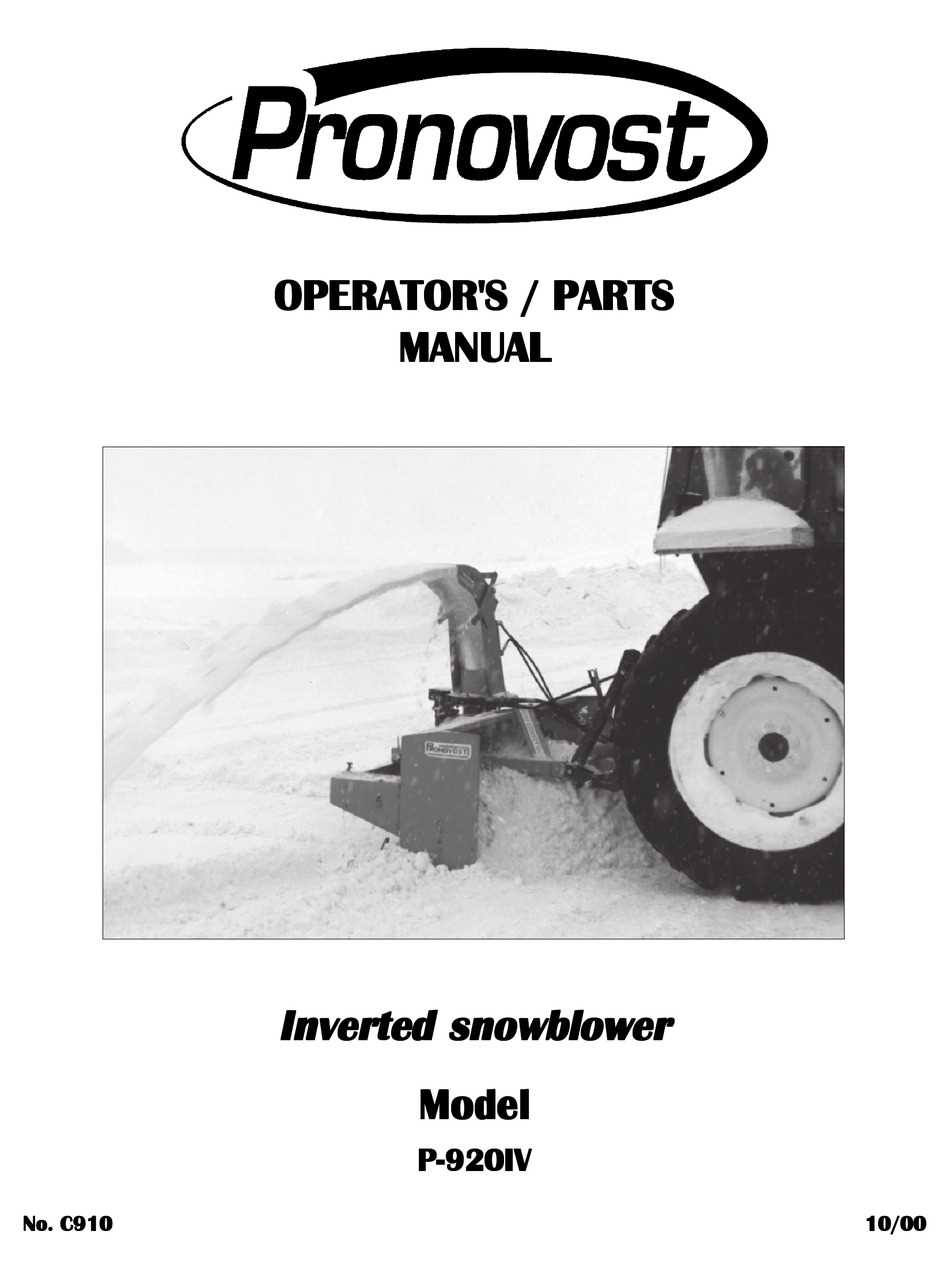

Identifying Snowblower Model Variations

Understanding the different variations of equipment is essential for efficient maintenance and optimal performance. Each version may possess unique features that cater to specific user needs or environmental conditions. By recognizing these differences, operators can ensure they are equipped with the right tools and components for their specific model, leading to enhanced functionality and longevity.

Key Features to Consider

When examining distinct models, it’s crucial to focus on several key characteristics. Engine type and power output can vary significantly, impacting the machine’s efficiency in various snow conditions. Additionally, the design of the housing, auger, and chute can influence how effectively the equipment performs its task. Identifying these elements can guide users in selecting the correct model for their specific requirements.

Model Identification Techniques

One effective approach to differentiating models is to refer to the manufacturer’s identification number, typically located on the machine itself. This number often contains valuable information regarding the model type and year of manufacture. Furthermore, consulting the user manual or official website can provide insights into the variations available, ensuring users can find the appropriate components and accessories tailored to their specific machinery.

Common Issues with Snowblower Parts

During the harsh winter months, machinery designed for clearing snow can encounter various challenges that affect their performance. Understanding these common problems can aid users in maintaining their equipment and ensuring efficient operation. Regular inspections and timely interventions can prevent minor issues from escalating into significant repairs.

1. Clogged Mechanisms: One of the most frequent complications involves blockages in the clearing mechanism. Heavy, wet snow can lead to buildup, impairing the device’s ability to function effectively. Clearing any debris immediately after use can mitigate this issue.

2. Deteriorating Belts: Over time, belts can wear out or become loose, impacting the overall efficiency of the machinery. Regularly checking the tension and condition of belts ensures optimal performance and prevents unexpected breakdowns.

3. Electrical Failures: Components reliant on electrical systems may encounter malfunctions, such as dead batteries or faulty connections. Ensuring all connections are secure and the battery is charged can prevent this problem.

4. Insufficient Lubrication: Proper lubrication of moving parts is crucial for smooth operation. Without adequate grease, components can wear down quickly, leading to premature failure. Regular maintenance schedules should include lubrication checks to avoid these complications.

5. Ineffective Fuel System: The performance of fuel systems can be hampered by stale fuel or clogged filters. Utilizing fresh fuel and changing filters periodically can maintain efficient operation and prevent engine issues.

By addressing these common issues proactively, users can extend the lifespan of their equipment and ensure reliable performance throughout the winter season.

Where to Find Pronovost Diagrams

Locating detailed schematics for your equipment can significantly enhance your maintenance and repair efforts. Whether you are searching for technical illustrations, assembly layouts, or operational guides, several resources can help you access these essential documents. Understanding where to look will ensure you have the necessary information at your fingertips to keep your machinery in optimal condition.

Online Resources

The internet hosts a wealth of information, making it one of the most accessible places to find technical illustrations. Manufacturer websites often provide downloadable resources, including manuals and schematics for various models. Additionally, forums and community groups dedicated to machinery maintenance may also share valuable insights and documents.

Local Dealers and Repair Shops

Your local equipment dealers and repair shops can be invaluable resources when searching for technical illustrations. These establishments often maintain archives of documents related to the products they sell and service. Establishing a relationship with these professionals can lead to further support and assistance in locating the specific information you need.

Steps for Proper Maintenance

Maintaining outdoor equipment is essential for ensuring its longevity and optimal performance. By following a few straightforward practices, users can avoid costly repairs and enhance the efficiency of their machinery. Regular care not only keeps the equipment running smoothly but also ensures safety during operation.

Here are the essential steps to maintain your equipment:

-

Clean the Equipment:

- Remove any debris, dirt, or snow after each use.

- Wipe down surfaces to prevent rust and corrosion.

-

Inspect Components:

- Check belts and cables for signs of wear or fraying.

- Examine the blades for dullness or damage.

-

Change Fluids:

- Replace engine oil as recommended by the manufacturer.

- Check and refill fuel and hydraulic fluids regularly.

-

Sharpen and Replace Blades:

- Regularly sharpen the blades to ensure efficient cutting.

- Replace blades if they are beyond repair.

-

Store Properly:

- Keep the equipment in a dry, sheltered location to avoid weather damage.

- Use a cover to protect it from dust and moisture.

By incorporating these practices into your routine, you can prolong the life of your equipment and ensure it performs effectively when needed. Regular maintenance is an investment that pays off in the long run.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance and repairs offers numerous advantages that enhance performance and longevity. By opting for these original items, users can ensure optimal functionality and reliability, ultimately leading to a more efficient operation.

One significant benefit of authentic components is the assurance of quality and compatibility. These items are specifically designed to work seamlessly with the equipment, reducing the risk of malfunction or damage. In contrast, aftermarket alternatives may not meet the same standards, leading to potential failures or increased wear and tear.

| Advantage | Description |

|---|---|

| Quality Assurance | Original components are manufactured under strict quality controls, ensuring they meet industry standards. |

| Optimal Performance | These items are designed to enhance the efficiency of the machinery, leading to better performance. |

| Extended Lifespan | Using authentic components can significantly increase the lifespan of the equipment by minimizing risks of breakdowns. |

| Warranty Protection | Utilizing original components often keeps warranties intact, providing peace of mind for the user. |

In summary, investing in genuine items for maintenance and repairs not only safeguards the machinery but also promotes efficiency and reliability, ultimately leading to cost savings and improved performance over time.

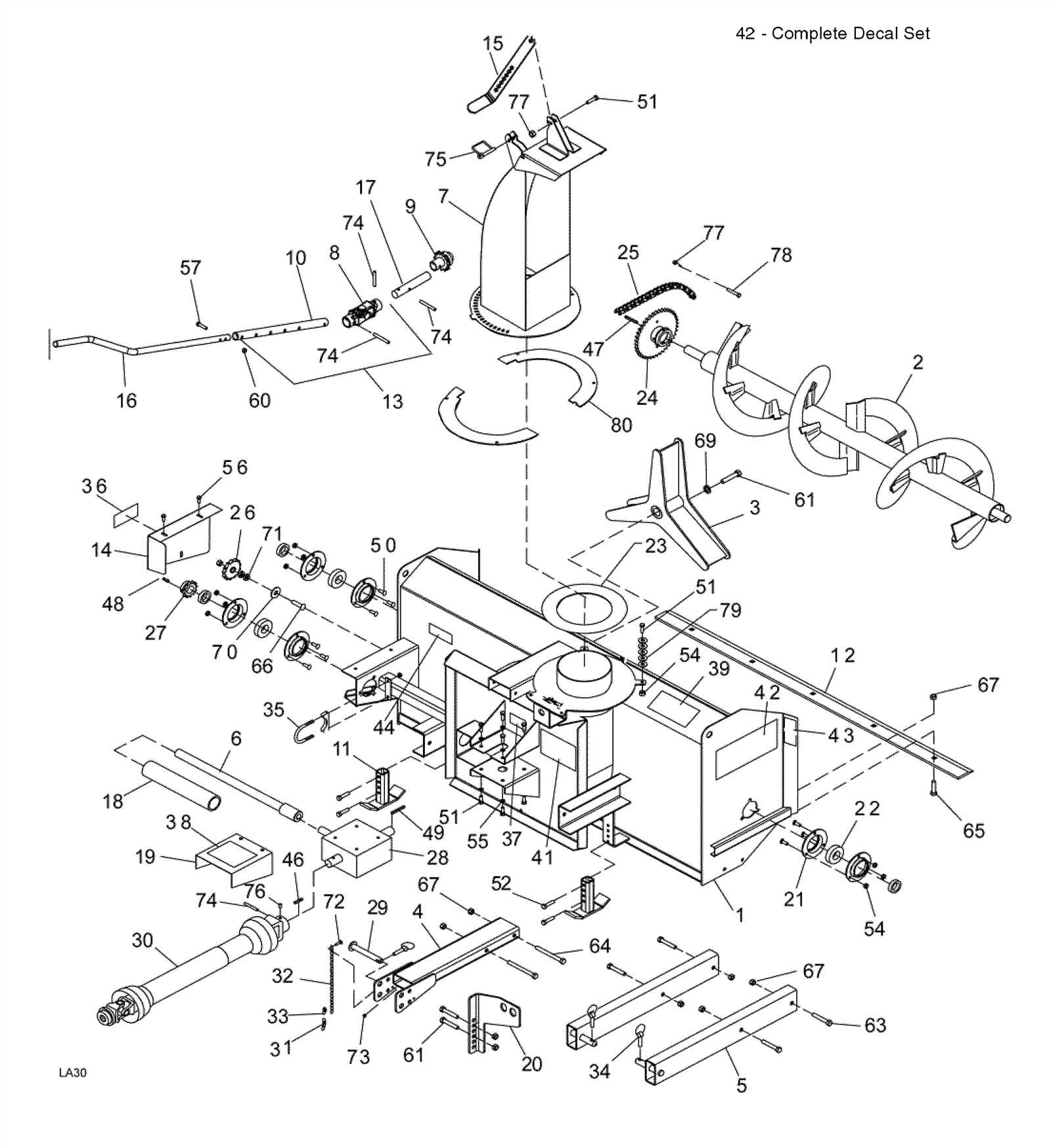

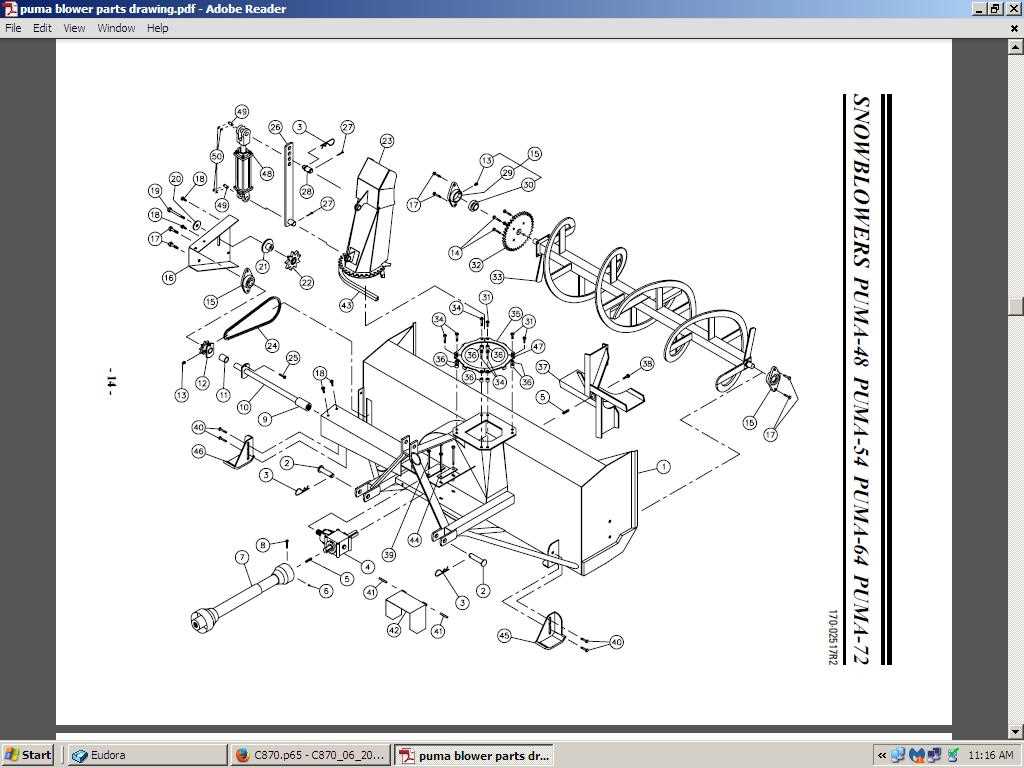

How to Read Parts Diagrams

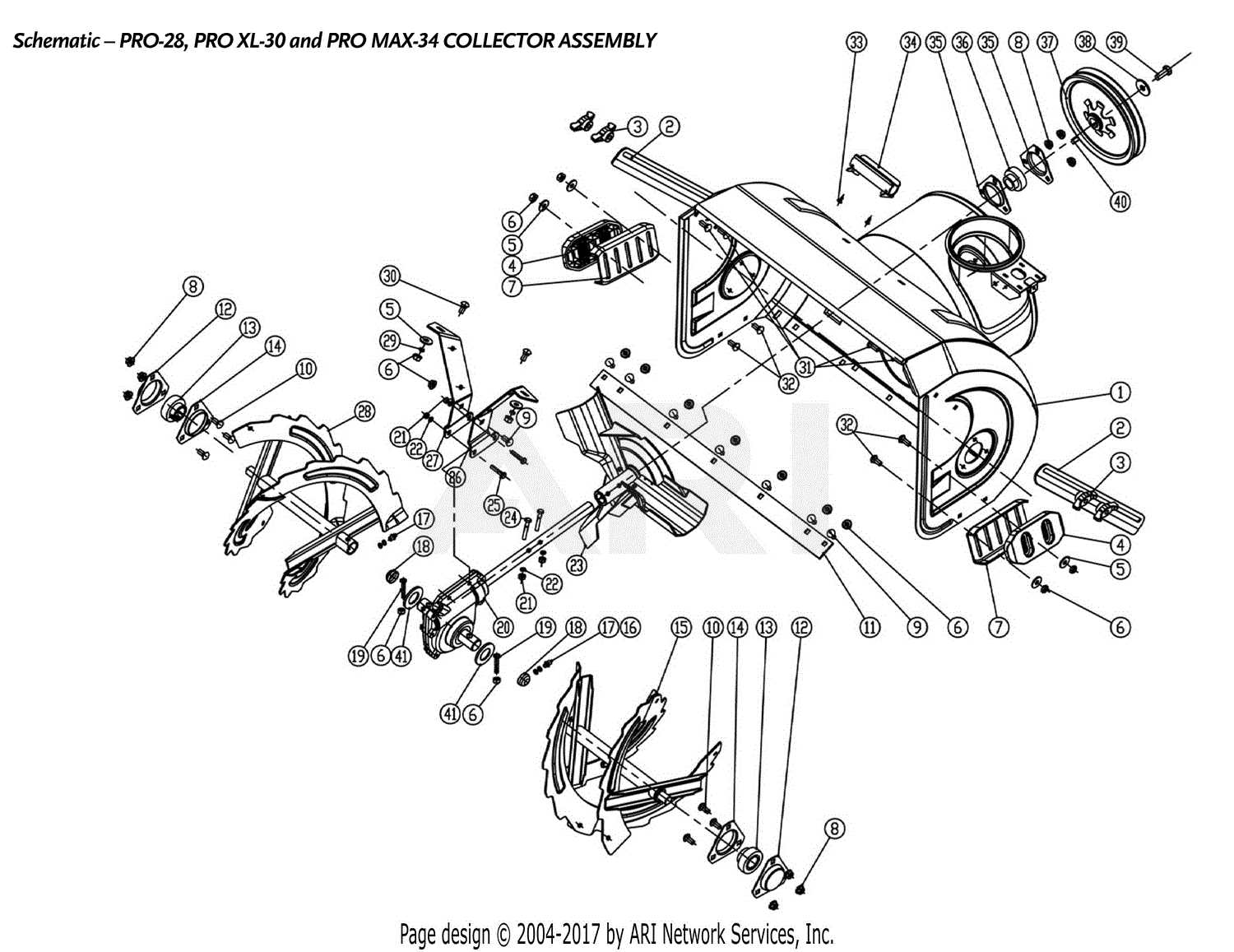

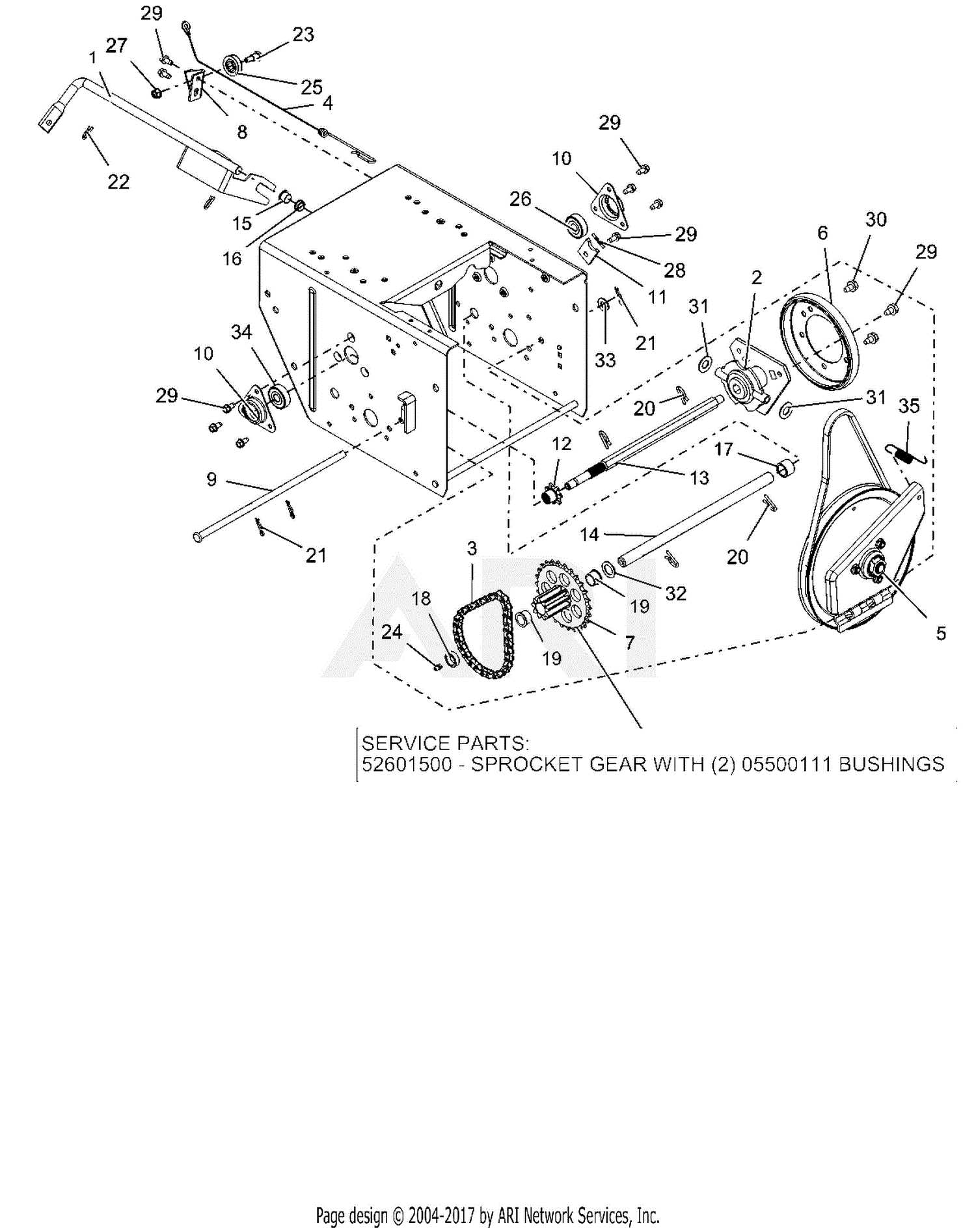

Understanding visual representations of components is crucial for efficient maintenance and repair tasks. These illustrations serve as guides, allowing users to identify and locate individual elements of a machine or tool. By interpreting these visuals correctly, one can ensure proper assembly and disassembly, ultimately enhancing performance and longevity.

Begin by familiarizing yourself with the layout. Most representations will include a key or legend that provides a reference for symbols and labels used throughout the image. Take note of the numbering system, as each element is usually accompanied by a corresponding reference number, which can be found in the accompanying list or index.

Pay attention to the scale of the illustration, as it indicates the relative size of components. This information can be essential when determining whether a specific part fits correctly within the assembly. Additionally, observe the relationship between elements. Understanding how different parts interact can help in troubleshooting issues and facilitate smoother repairs.

Finally, consult the accompanying documentation or resources for additional context. This material often contains valuable details on installation procedures, maintenance tips, and troubleshooting techniques. By leveraging all available information, you can confidently navigate the complexities of your machinery.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right instruments on hand is essential for a successful repair process. Proper tools not only facilitate efficient work but also ensure that tasks are completed safely and effectively. Familiarizing yourself with the necessary equipment can save time and effort, making the repair experience much smoother.

Essential tools typically include wrenches and socket sets, which are crucial for loosening and tightening various fasteners. Screwdrivers of different types and sizes will also be necessary to access components that require adjustments or replacements. Additionally, pliers can provide extra grip for handling small parts or wires, while a hammer might be useful for tapping stubborn elements back into place.

Moreover, safety gear should not be overlooked. Gloves will protect your hands from sharp edges and debris, while safety glasses will shield your eyes from any flying particles during the repair process. Investing in a well-organized toolbox to keep everything readily available can further enhance your efficiency and help you tackle any issues that arise.

Guidelines for Seasonal Storage

Proper seasonal storage of outdoor equipment is essential for maintaining its longevity and ensuring optimal performance when needed. Following a few key practices can prevent damage and reduce maintenance costs, allowing for a smoother transition between seasons.

Preparation Steps

Begin by cleaning the equipment thoroughly to remove dirt, debris, and any residues that could cause corrosion or mold. Inspect all components for wear and tear, and replace any damaged parts as necessary. Ensure that fluids, such as fuel and oil, are drained or stabilized to prevent deterioration during storage.

Storage Environment

Select a dry, cool place for storage, ideally indoors to shield the equipment from harsh weather conditions. Utilize protective covers to prevent dust accumulation and provide an extra layer of defense against moisture. Organize the storage area to allow easy access to the equipment, facilitating maintenance checks and quick retrieval when the season changes.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and repair of outdoor machinery. Whether you’re a seasoned user or new to the equipment, understanding essential components and their functions can enhance your experience and efficiency.

What are the most common issues faced with outdoor equipment?

Users often report problems such as poor performance, difficulty starting, and uneven operation. Regular maintenance can help mitigate these issues.

How can I identify a malfunctioning component?

Signs of malfunction may include unusual noises, leaking fluids, or visible wear. Regular inspections are crucial to identifying potential issues before they escalate.

Where can I find replacement items for my machinery?

Replacement items are typically available through authorized dealers or online retailers specializing in outdoor machinery. Ensure to verify compatibility with your model.

What maintenance tasks should be performed regularly?

Routine tasks include checking oil levels, cleaning filters, and inspecting belts. Following the manufacturer’s guidelines will ensure optimal performance and longevity.

How can I improve the efficiency of my equipment?

Regularly servicing your machinery, using the right fuel, and maintaining proper tire pressure can significantly enhance efficiency and extend its lifespan.

Resources for Troubleshooting

When faced with issues related to your equipment, having the right tools and resources at hand can significantly simplify the diagnostic process. Understanding the components and their functions is crucial for efficient problem-solving. This section highlights valuable materials that can aid in identifying and resolving common challenges.

- User Manuals: Comprehensive guides that provide detailed information on operation, maintenance, and troubleshooting procedures.

- Online Forums: Communities where users share experiences, tips, and solutions to similar problems. Engaging with others can provide insights that may not be found in official documentation.

- Video Tutorials: Visual aids available on platforms like YouTube that demonstrate repair processes step-by-step, making it easier to follow along.

- Technical Support: Contacting customer service for expert advice tailored to your specific issues can be invaluable.

Utilizing these resources can streamline the troubleshooting process, helping you to quickly identify the root cause of the malfunction and implement effective solutions.