When it comes to maintaining your all-terrain vehicle, having a clear understanding of its various components is essential. This knowledge not only facilitates effective repairs but also enhances the overall riding experience. By familiarizing yourself with each element’s function and location, you can ensure your vehicle operates smoothly and efficiently.

Exploring the intricacies of your vehicle’s assembly can uncover valuable insights. Identifying and recognizing individual elements allows for informed decision-making during maintenance tasks. Whether you are a seasoned enthusiast or a novice, understanding the layout and connectivity of these parts will empower you in keeping your machine in top condition.

With an organized reference to the various components, you’ll be equipped to tackle repairs confidently. This comprehensive guide will serve as a vital tool, enabling you to approach any mechanical issue with assurance and precision. Prepare to enhance your knowledge and elevate your skills in maintaining your all-terrain vehicle.

Overview of Polaris Sportsman 500 HO

This segment delves into the attributes and functionalities of a renowned all-terrain vehicle that has captured the attention of enthusiasts. Recognized for its versatility and durability, this model is designed to excel in various environments, catering to both recreational and utilitarian needs.

Equipped with a robust engine, the vehicle promises impressive power and reliability. Its design features a balanced structure that enhances stability while navigating rough terrains, making it an ideal choice for outdoor adventures.

| Feature | Description |

|---|---|

| Engine Type | Four-stroke engine known for efficiency and torque |

| Transmission | Automatic system providing smooth gear shifts |

| Suspension | Independent suspension enhancing comfort on uneven surfaces |

| Payload Capacity | Significant load capacity suitable for various tasks |

This model stands out due to its blend of performance and comfort, making it a popular choice among both hobbyists and professionals alike.

Essential Components of the ATV

All-terrain vehicles (ATVs) comprise several crucial elements that contribute to their overall functionality and performance. Understanding these components is essential for maintenance and ensuring optimal operation. Each part plays a specific role, from providing power to enhancing stability, making them indispensable for adventurous rides across various terrains.

Engine and Transmission

The heart of any ATV is its engine, which generates the necessary power for movement. Paired with a reliable transmission system, it ensures smooth acceleration and efficient power transfer to the wheels. The synergy between these components is vital for achieving desired speeds and handling characteristics.

Suspension System

A well-designed suspension system enhances comfort and control by absorbing shocks from uneven surfaces. This system not only supports the vehicle’s weight but also allows for better traction and stability during challenging rides. Proper maintenance of the suspension is crucial for maintaining performance and safety on rugged terrains.

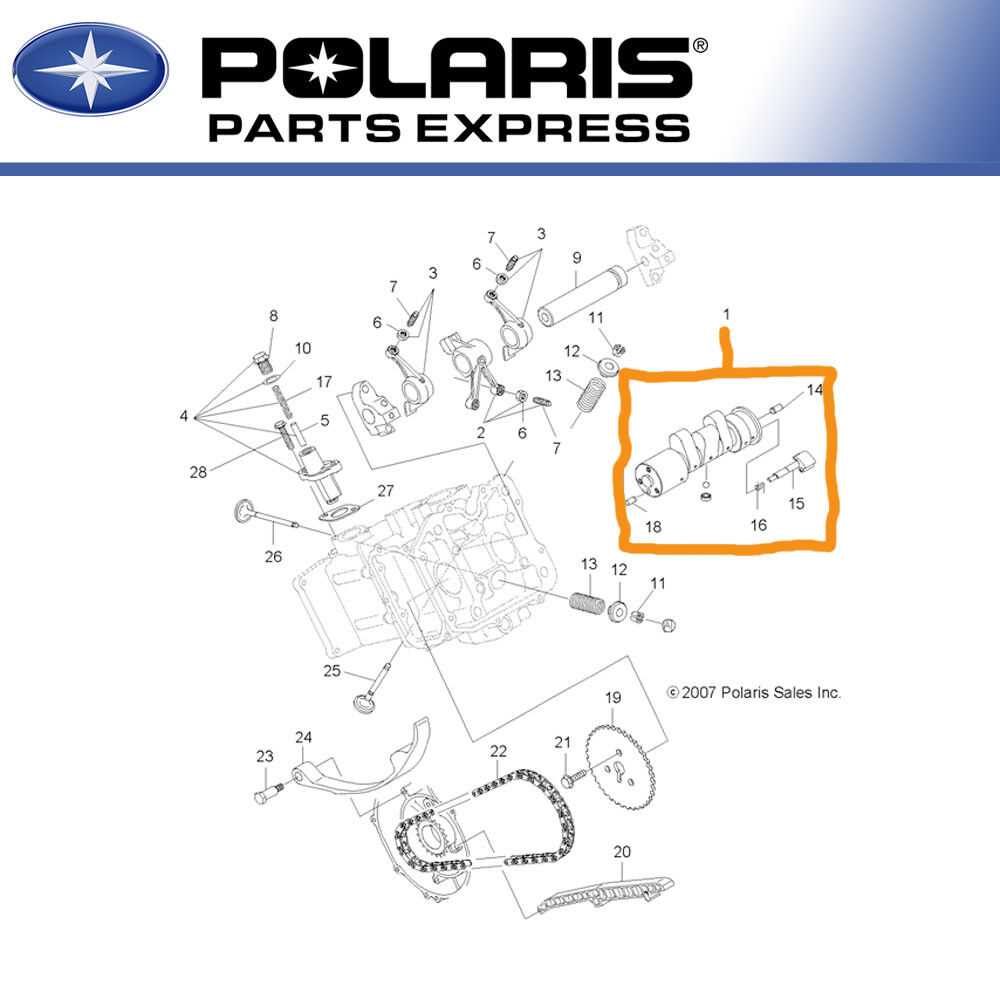

Importance of Parts Diagrams

Understanding the layout and components of a vehicle is crucial for maintenance and repairs. Visual representations of various sections offer clarity and guidance, helping owners identify each element’s function and placement. This knowledge simplifies the process of troubleshooting and enhances the efficiency of any repair task.

Enhanced Maintenance Efficiency

Using visual schematics streamlines the maintenance process. When individuals can easily pinpoint specific components, they save time and reduce the likelihood of errors during repairs. This efficiency is particularly beneficial when sourcing replacements, ensuring that the correct items are procured without unnecessary delays.

Facilitating Repairs and Modifications

Clear illustrations support not only routine upkeep but also modifications. Enthusiasts can use these resources to customize their vehicles effectively. By understanding how each part interacts with others, they can make informed decisions about upgrades or alterations, enhancing performance and personalizing the ride.

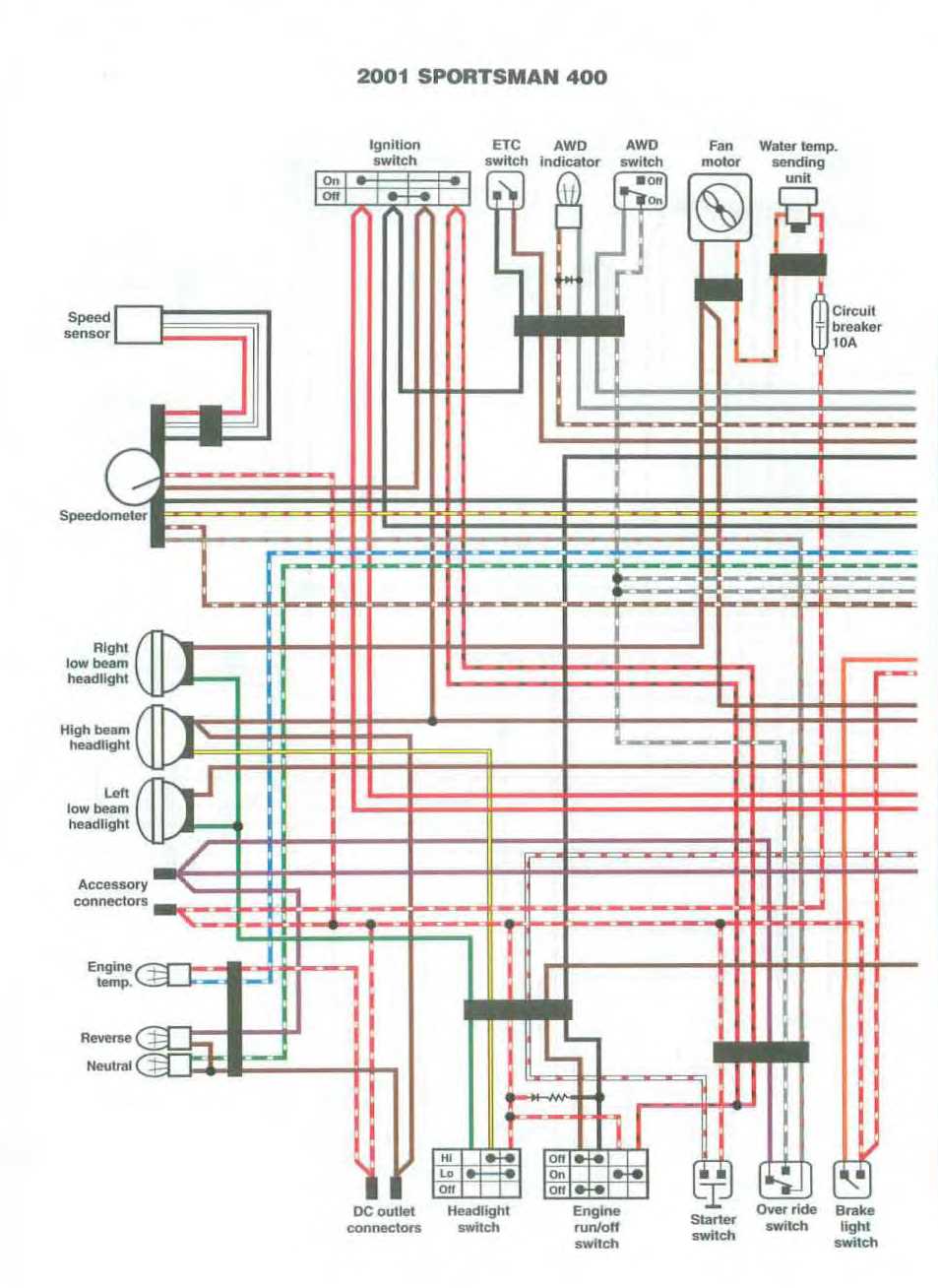

Understanding the Wiring Layout

The electrical configuration of an all-terrain vehicle plays a crucial role in its overall functionality and reliability. A clear grasp of the wiring setup not only aids in maintenance but also ensures effective troubleshooting of any electrical issues that may arise.

This layout typically consists of various components, including connectors, fuses, and switches, all working together to facilitate the vehicle’s operations. Understanding each part’s location and function can significantly enhance the owner’s ability to diagnose problems and implement repairs efficiently.

Moreover, familiarizing oneself with the wiring structure contributes to better performance, as it allows for optimized modifications or upgrades, enhancing the riding experience. Proper knowledge of the wiring layout empowers users to make informed decisions regarding repairs and enhancements, ensuring their vehicle remains in peak condition.

Engine Specifications and Parts

This section delves into the vital components and characteristics of the engine, highlighting its performance metrics and essential features. Understanding these elements is crucial for maintenance and enhancement.

The engine is designed with a robust cubic capacity that ensures reliable power output. Featuring a four-stroke configuration, it provides a balanced combination of efficiency and torque. This design facilitates smooth operation, making it suitable for various terrains.

Key components include the cylinder head, which plays a pivotal role in the combustion process, and the piston assembly, essential for generating power. The intricate fuel delivery system ensures optimal performance by regulating fuel flow and mixture. Regular inspection of these components is advised to maintain peak functionality.

Transmission and Drive System Insights

The transmission and drive mechanism play a pivotal role in the overall performance of all-terrain vehicles. These systems are designed to transfer power from the engine to the wheels, ensuring efficient movement across diverse terrains. Understanding the intricacies of these components can enhance maintenance practices and improve operational reliability.

Key Components of this system include gears, belts, and differentials. Each element contributes to the seamless operation of the vehicle, allowing for smooth acceleration and optimal handling. Regular checks on these parts can prevent wear and enhance longevity.

Maintenance Tips: It’s essential to perform routine inspections and fluid changes. Keeping the drive components clean and lubricated not only reduces friction but also improves responsiveness. Additionally, monitoring for unusual noises can help identify potential issues early.

Suspension System and Components

The suspension system plays a vital role in enhancing the performance and comfort of an off-road vehicle. This intricate assembly ensures a smooth ride by absorbing shocks and maintaining tire contact with the terrain. Understanding its various elements is crucial for effective maintenance and optimal operation.

At the heart of the suspension is the shock absorber, which dampens the impact of uneven surfaces, preventing excessive bounce and instability. Alongside this component, springs provide the necessary support, allowing the vehicle to adapt to different loads and conditions. Together, these parts work harmoniously to create a balanced and controlled driving experience.

Another essential aspect is the suspension arms, which connect the chassis to the wheels. These arms are designed to pivot, enabling the wheels to move independently over obstacles. Additionally, linkages facilitate the alignment and coordination between various components, contributing to overall vehicle handling and responsiveness.

Regular inspection and maintenance of the suspension system are crucial to ensure safety and performance. Over time, wear and tear can affect the functionality of these components, leading to reduced handling capabilities and comfort. Keeping the system in top condition enhances both the durability of the vehicle and the enjoyment of the ride.

Braking Mechanism Explained

The braking system is a crucial component in ensuring safety and control during operation. This system enables the operator to slow down or halt the movement effectively, providing a stable experience in various terrains.

Components of the Braking System

Understanding the essential elements of the braking mechanism helps in comprehending its functionality. The primary components include:

- Brake Pads: These provide the friction needed to slow down the wheels.

- Brake Discs: These are the surfaces against which the pads press to create stopping power.

- Hydraulic Lines: These transfer the force from the brake lever to the brake pads.

- Master Cylinder: This component generates the hydraulic pressure needed to activate the brakes.

How the System Works

The operation of the braking system involves several steps:

- When the operator applies the brake lever, it activates the master cylinder.

- This action generates hydraulic pressure, which travels through the hydraulic lines.

- The pressure pushes the brake pads against the discs, creating friction.

- As a result, the wheels slow down or come to a complete stop.

Regular maintenance and understanding of these components ensure optimal performance and longevity of the braking mechanism, enhancing overall safety during operation.

Maintenance Tips for Longevity

Ensuring the extended life of your all-terrain vehicle involves a combination of regular upkeep and attentive care. By implementing a systematic maintenance routine, you can prevent wear and tear, enhance performance, and ultimately enjoy countless adventures.

Regular checks of critical components can significantly impact the reliability and efficiency of your vehicle. Below is a table outlining essential maintenance tasks and their recommended frequency:

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 50 hours of operation |

| Air Filter Inspection | Every 25 hours of operation |

| Tire Pressure Check | Monthly |

| Brake System Check | Every 50 hours of operation |

| Battery Maintenance | Monthly |

Adhering to these practices will not only enhance performance but also ensure a safer and more enjoyable riding experience.

Common Issues and Solutions

This section addresses frequent challenges encountered with an all-terrain vehicle and offers practical remedies. Understanding these typical problems can enhance maintenance and prolong the lifespan of the machine.

Regular inspections and timely interventions are essential to ensure optimal performance. Below are some common issues along with their respective solutions:

| Issue | Solution |

|---|---|

| Engine won’t start | Check the battery and connections. Ensure the fuel system is primed and inspect spark plugs for wear. |

| Overheating | Verify coolant levels and inspect the radiator for blockages. Ensure the fan is functioning correctly. |

| Poor handling | Inspect tire pressure and tread condition. Check the suspension system for wear or damage. |

| Unusual noises | Identify the source of the noise. Check for loose components or abnormal wear on belts and chains. |

Where to Find Replacement Parts

Locating the necessary components for your all-terrain vehicle can enhance its performance and longevity. There are various avenues to explore for acquiring these essential elements, ensuring you have reliable options at your disposal.

Online Retailers

The internet offers a plethora of websites dedicated to off-road vehicle accessories. Many platforms specialize in aftermarket and original equipment options, providing detailed specifications and user reviews to aid in your selection process.

Local Dealerships

Your local dealership often serves as a valuable resource for acquiring authentic components. These establishments typically maintain a comprehensive inventory and can assist in ordering any items not readily available.

| Source | Advantages | Disadvantages |

|---|---|---|

| Online Retailers | Wide selection, convenience | Shipping times, potential for incorrect items |

| Local Dealerships | Authenticity, immediate availability | Higher prices, limited stock |

Using OEM vs. Aftermarket Parts

When it comes to vehicle maintenance and repairs, choosing between original equipment manufacturer (OEM) components and aftermarket alternatives can significantly impact performance and longevity. Each option presents distinct advantages and disadvantages that cater to various preferences and budgets.

OEM components are designed and produced by the manufacturer of the vehicle, ensuring compatibility and adherence to the original specifications. These parts often come with a warranty, providing peace of mind for the consumer. However, they can be more expensive, leading some owners to consider aftermarket options.

Aftermarket components, on the other hand, are produced by third-party manufacturers and can often be found at a lower cost. While they may provide an economical solution, quality can vary widely. Some aftermarket alternatives match or even exceed OEM specifications, while others might compromise on durability and reliability.

| Aspect | OEM | Aftermarket |

|---|---|---|

| Quality | High, consistent standards | Varies widely |

| Cost | Generally higher | Often lower |

| Warranty | Usually included | Depends on manufacturer |

| Availability | Limited to manufacturer | Widely available |

Ultimately, the choice between OEM and aftermarket components hinges on individual needs, budget considerations, and desired performance outcomes. Evaluating these factors can help ensure that the right decision is made for vehicle upkeep.