The functionality of outdoor machinery relies heavily on its steering mechanisms, which play a vital role in ensuring smooth and precise navigation. An in-depth look at the various elements involved can aid users in maintaining and repairing their equipment efficiently.

Identifying the components that contribute to the steering system is essential for effective troubleshooting and enhancements. Knowledge of how these parts interact can empower operators to perform necessary adjustments and replacements, thus prolonging the lifespan of the equipment.

By familiarizing oneself with the layout and connections of these essential elements, users can confidently approach maintenance tasks. This understanding not only facilitates problem-solving but also enhances overall operational efficiency.

Key Parts of the Steering System

The steering mechanism of a vehicle is crucial for ensuring precise maneuverability and control. Understanding its essential components helps in maintaining and diagnosing issues that may arise during operation.

Below are the primary elements that contribute to the functionality of this mechanism:

- Wheel Assembly: The component that allows the driver to turn the vehicle by rotating the steering wheel.

- Column: The shaft that connects the steering wheel to the mechanism, providing stability and support.

- Linkage: A series of rods and joints that transmit the driver’s input from the wheel to the wheels themselves.

- Gearbox: This converts the rotational motion of the wheel into linear motion, enabling smoother turns.

- Control Arms: These components help in maintaining the alignment of the wheels and provide a connection point to the suspension system.

By familiarizing oneself with these crucial components, users can better understand how the system operates and identify potential problems that may affect performance.

Importance of Proper Steering Alignment

Maintaining accurate directional alignment is crucial for the overall performance and safety of any vehicle. When the wheels are correctly positioned, it enhances maneuverability and reduces the risk of accidents. Proper alignment ensures that the vehicle tracks straight, minimizes tire wear, and improves fuel efficiency.

When alignment is neglected, several issues can arise. Misalignment can lead to uneven tire wear, which not only shortens the lifespan of the tires but also compromises traction and handling. Additionally, it can cause undue strain on the suspension system, leading to costly repairs. Regular checks and adjustments help in preventing these problems and ensure a smooth driving experience.

Moreover, correct alignment contributes to driver comfort by providing a stable and predictable response to steering inputs. This is particularly important for maintaining control during high-speed maneuvers or on uneven terrain. Thus, investing time and resources in alignment checks is essential for optimal vehicle operation and safety.

Common Issues with Steering Parts

Proper functioning of the control system is crucial for the overall performance of a vehicle. However, certain complications can arise, leading to decreased efficiency and safety concerns. Understanding these issues can help in timely maintenance and repair.

Frequent Complications

- Wear and Tear: Over time, components can degrade due to regular use, resulting in reduced responsiveness.

- Misalignment: Improper adjustment can cause difficulty in maneuvering, making the vehicle harder to control.

- Fluid Leaks: Loss of hydraulic fluid can lead to a lack of assistance, affecting handling capabilities.

- Corrosion: Rust and other forms of corrosion can weaken structural integrity, posing risks during operation.

Signs of Trouble

- Unusual noises when turning or adjusting direction.

- Difficulty in maintaining a straight line while driving.

- Increased resistance when attempting to turn.

- Visible leaks or puddles under the vehicle.

Steps to Diagnose Steering Problems

Identifying issues with the directional control mechanism of your vehicle requires a systematic approach. This process involves evaluating various components to determine the source of any malfunction. By following a structured method, you can effectively isolate the problem and implement the necessary repairs.

1. Visual Inspection: Begin with a thorough examination of the surrounding components. Look for any visible signs of wear, damage, or misalignment. Pay close attention to the connections and ensure that nothing is loose or corroded.

2. Check Fluid Levels: Assess the levels of hydraulic fluid, as insufficient fluid can lead to operational difficulties. If the fluid appears dirty or contaminated, it may need to be replaced.

3. Test Movement: Operate the vehicle slowly and observe the behavior of the directional control system. Note any unusual sounds or resistance when turning. These observations can provide insights into underlying issues.

4. Examine Linkages: Inspect all linkages and attachments for signs of damage or excessive play. Ensure that all joints are functioning smoothly and that no components are binding or sticking.

5. Consult a Professional: If the problem persists after these evaluations, consider seeking the expertise of a qualified technician. They can perform more advanced diagnostics and recommend appropriate solutions.

How to Replace Steering Components

Replacing the control mechanisms in your machine is essential for ensuring optimal performance and safety. This process involves identifying the faulty elements and following a systematic approach for replacement. Below are the general steps to guide you through this procedure.

- Gather Necessary Tools and Materials:

- Wrenches

- Screwdrivers

- Replacement components

- Lubricants

- Safety gear

- Disconnect the Power Source:

Before starting any work, ensure that the machine is powered off and disconnected to prevent accidents.

- Remove the Old Components:

Carefully detach the worn-out parts by following these steps:

- Locate the screws and bolts securing the elements.

- Use the appropriate tools to remove them.

- Set the old parts aside for disposal or recycling.

- Install New Components:

Once the old parts are removed, follow these steps to install the new ones:

- Align the new components with the mounting brackets.

- Secure them in place using screws and bolts.

- Ensure everything is tightly fastened to avoid future issues.

- Test the Installation:

After installation, it is crucial to check the functionality of the new components:

- Reconnect the power source.

- Perform a test run to ensure everything operates smoothly.

- Look for any unusual noises or movement.

Following these steps will help you effectively replace the control mechanisms in your equipment, enhancing its performance and reliability.

Maintenance Tips for Steering Systems

Proper upkeep of directional control mechanisms is essential for ensuring optimal performance and longevity. Regular inspection and maintenance help identify potential issues before they escalate, thus providing a smoother and safer experience.

1. Regular Inspections: Schedule frequent evaluations of the components involved in directional control. Look for signs of wear, such as loose connections or frayed cables, and address them promptly.

2. Lubrication: Keep the moving elements well-lubricated to reduce friction and prevent premature wear. Utilize appropriate lubricants and follow the manufacturer’s guidelines for application.

3. Cleaning: Dirt and debris can accumulate in the mechanism, causing potential malfunctions. Regularly clean the surfaces and components to ensure smooth operation.

4. Alignment Checks: Misalignment can lead to uneven wear and handling difficulties. Perform periodic checks to ensure that all elements are properly aligned and make adjustments as necessary.

5. Consult Professional Help: If you encounter persistent issues, it’s advisable to seek assistance from qualified technicians. They can provide expert analysis and recommendations for repairs or replacements.

Tools Needed for Steering Repairs

Repairing the directional control mechanism requires a selection of specialized tools. Having the right equipment ensures that the process is efficient and successful, enabling proper adjustments and replacements where necessary.

The essential tools for this type of maintenance include:

- Wrenches: Various sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types to access screws in different configurations.

- Socket set: For working with nuts and bolts in tight spaces.

- Pliers: Useful for gripping and twisting components.

- Jack and jack stands: To safely elevate the vehicle for better access.

- Torque wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Ball joint separator: Essential for disconnecting ball joints without damage.

- Grease gun: For lubricating parts to reduce wear and tear.

In addition to these primary tools, a few safety items are also recommended:

- Safety glasses: Protect your eyes from debris.

- Gloves: Provide grip and protect your hands from sharp edges.

Having these tools on hand will facilitate a smoother repair process and enhance the durability of the directional control system.

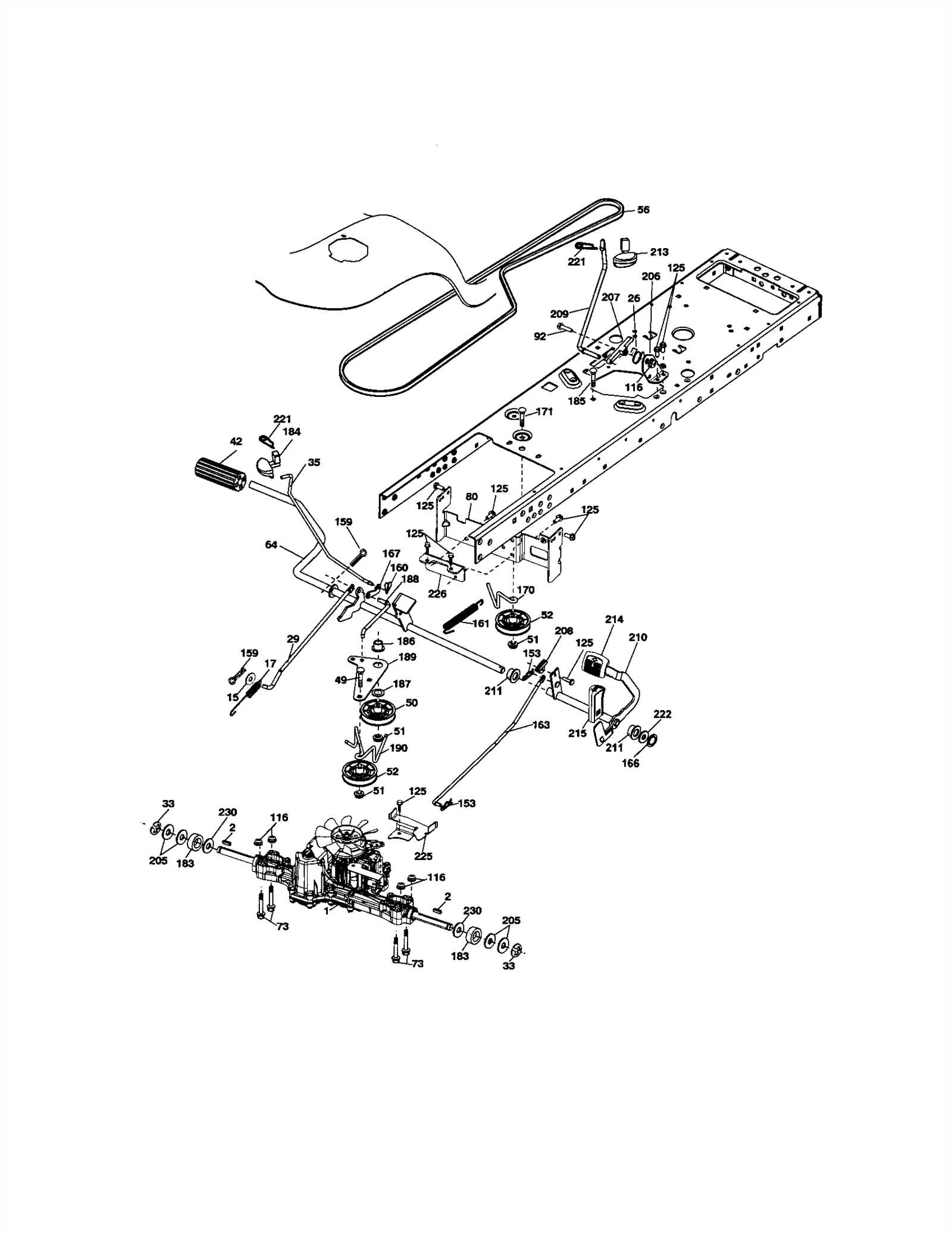

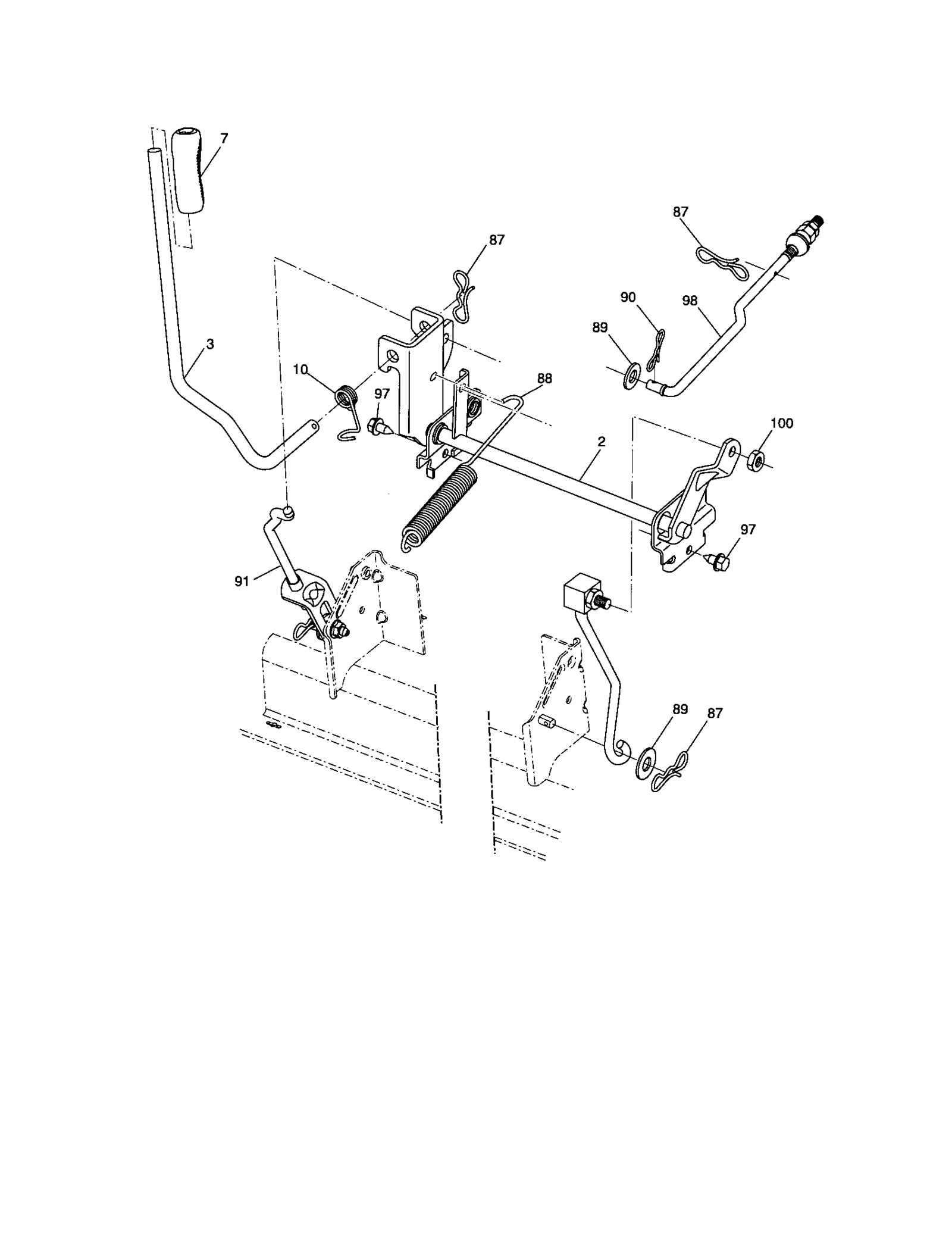

Visual Guide to Steering Assembly

This section provides an illustrative overview of the components involved in the directional control mechanism of a riding mower. Understanding the layout and functionality of these elements is crucial for effective maintenance and troubleshooting. A well-functioning control system ensures smooth navigation and optimal performance during operation.

Key Components: The assembly consists of various elements that work together to facilitate movement. These include the wheel assemblies, connecting rods, and linkages that transmit force and allow for precise maneuvering. Each part plays a vital role in maintaining stability and responsiveness.

Maintenance Tips: Regular inspections and upkeep of the components are essential. Look for signs of wear and tear, such as frayed cables or loose connections, which can impact the overall functionality. Keeping these parts in good condition not only enhances performance but also prolongs the lifespan of the equipment.

By familiarizing yourself with the configuration and maintenance of the control system, you can ensure a safe and efficient operation of your mower.

Choosing Quality Replacement Parts

When it comes to maintaining machinery, selecting high-grade components is essential for ensuring optimal performance and longevity. Using reliable replacements can significantly affect the efficiency of your equipment, providing smoother operation and reducing the likelihood of future breakdowns.

Quality components should be sourced from reputable manufacturers known for their commitment to excellence. Look for options that offer durability and compatibility with your specific machinery. It’s also advisable to consider components that have received positive reviews from other users, as this can be an indicator of their reliability.

Additionally, evaluating the material quality is crucial. Parts made from robust materials tend to withstand wear and tear better, thereby prolonging their lifespan. Investing in superior replacements may incur a higher initial cost but can lead to savings in the long run through reduced maintenance and improved functionality.

Understanding Steering Geometry Basics

Mastering the fundamental principles of directional control is essential for achieving optimal handling and performance in vehicles. These principles encompass the relationships between various components that influence maneuverability, stability, and response during operation. A thorough comprehension of these aspects is vital for both enthusiasts and professionals in the field.

Key Concepts in Directional Control

Several critical concepts form the foundation of directional control. These include caster, camber, and toe, each playing a unique role in how a vehicle behaves on the road. Understanding these terms helps in diagnosing issues and improving overall vehicle dynamics.

Impact of Geometry on Performance

The geometric configuration directly affects how a vehicle reacts to driver inputs. Adjustments in the alignment can significantly enhance performance, ensuring better traction and stability. Proper setup contributes to an enjoyable driving experience and prolongs component life.

| Concept | Description |

|---|---|

| Caster | The angle of the steering axis, influencing stability during forward motion. |

| Camber | The tilt of the wheels, affecting cornering grip and tire wear. |

| Toe | The alignment of the wheels relative to the centerline of the vehicle, impacting handling responsiveness. |

Safety Precautions When Working

Ensuring safety while engaging in maintenance or repair tasks is essential for preventing accidents and injuries. Adhering to proper guidelines and employing suitable safety measures can significantly reduce risks during any hands-on activities.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. This includes gloves, goggles, and sturdy footwear to safeguard against potential hazards. Always inspect your PPE for any damage before starting work.

Work Area Organization

Maintaining a clean and organized workspace minimizes the chances of accidents. Ensure that all tools are in good condition and stored properly after use. Keep the area free of clutter to allow for safe movement and easy access to necessary equipment.

Remember: Safety should always be a priority when performing any mechanical tasks. Following these precautions can help create a safer environment for yourself and others.

Resources for Further Learning

Expanding your knowledge about equipment maintenance and repair can be highly beneficial. Numerous resources are available to help enthusiasts and professionals alike understand the intricacies of various mechanisms and enhance their skills. Here are some valuable materials to consider for deepening your expertise.

Books and Manuals

- Repair Manuals: Detailed guides provide comprehensive insights into maintenance procedures and troubleshooting.

- Technical Handbooks: These resources offer in-depth explanations of components and their functionalities.

- DIY Repair Books: A variety of publications cater to enthusiasts seeking to enhance their hands-on skills.

Online Resources

- Educational Websites: Numerous sites focus on machinery repair and maintenance, offering tutorials and articles.

- Video Platforms: Visual demonstrations can aid in understanding complex repairs and techniques.

- Online Forums: Engaging with communities can provide valuable tips and shared experiences from other users.