Understanding the essential elements that contribute to a vehicle’s navigation system is crucial for ensuring smooth operation. Each component plays a vital role in maintaining direction and control during movement, making it important to familiarize yourself with their individual functions and how they work together.

In this section, we will explore the various elements involved in guiding the mechanism responsible for direction. By examining each component’s role, you will gain a deeper appreciation for the precision and engineering behind the smooth operation of your equipment. This guide will help you identify and maintain these crucial elements, ensuring optimal performance over time.

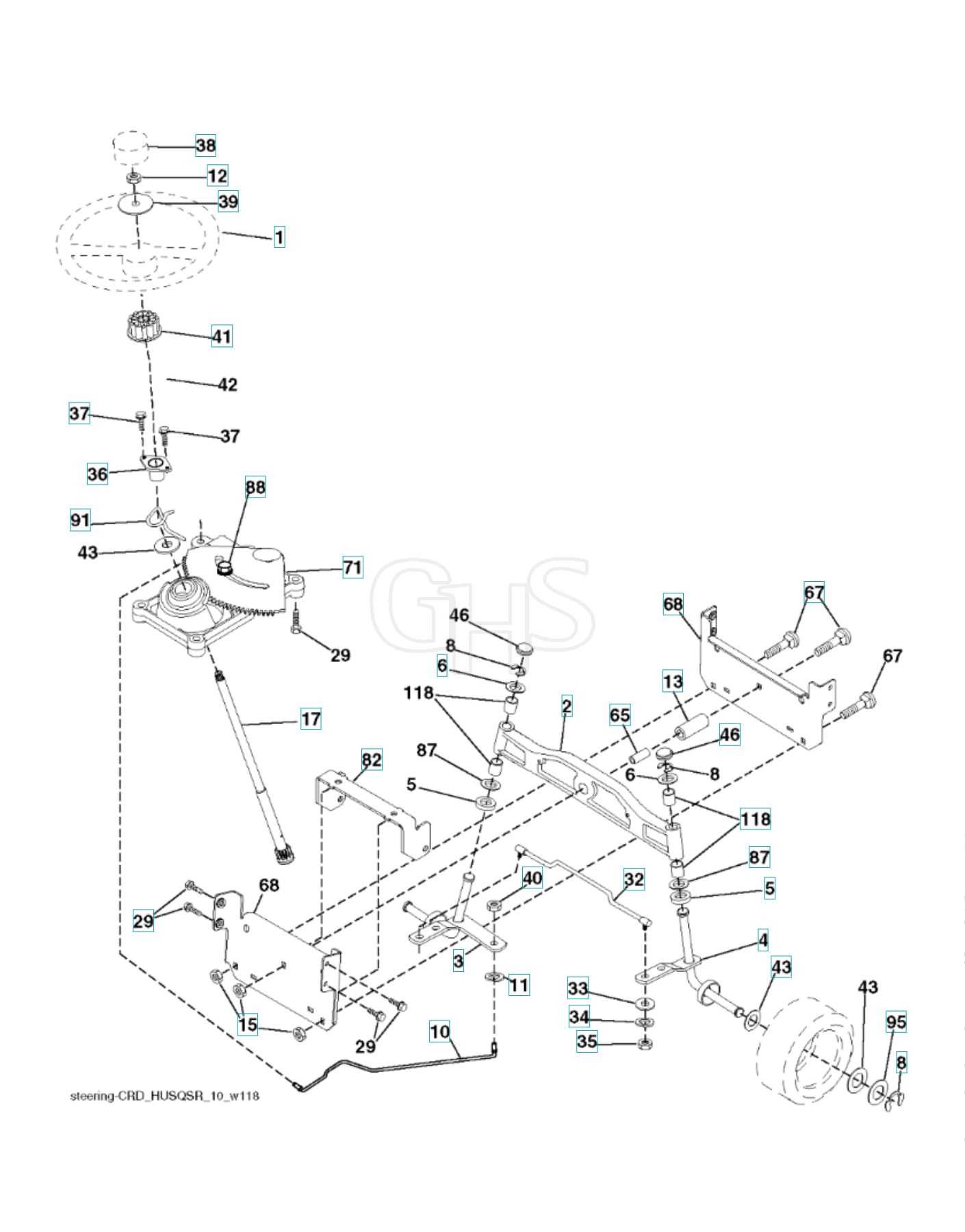

Overview of Husqvarna Steering System Components

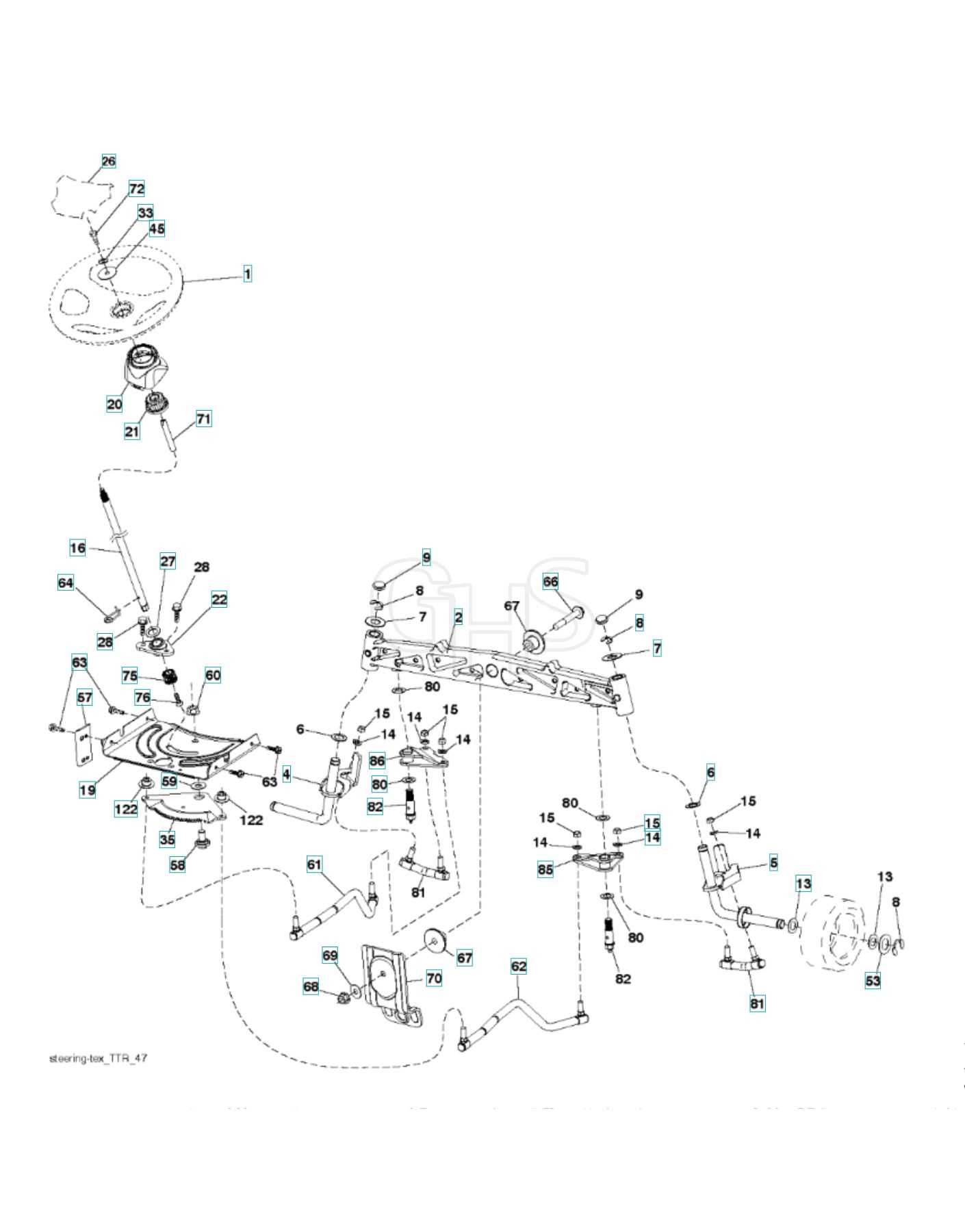

The control mechanism of any riding machine plays a critical role in ensuring smooth maneuverability and efficient direction changes. Understanding the different elements involved in this system can help in maintaining optimal performance and preventing issues that may arise over time.

Main Elements of the Control Mechanism

- Control Wheel: The primary component used to guide the movement of the machine, allowing for precision in handling.

- Linkage Components: These connectors relay the movements from the control wheel to other critical parts, ensuring seamless transitions in direction.

- Support Axle: A crucial part that helps to balance the machine while providing the structural support necessary for accurate direction changes.

Additional Supporting Components

- Adjustment Rods: These elements allow for fine-tuning, ensuring that all directional inputs result in the desired movements without delay.

- Bearings: Key components that reduce friction, making the entire system more responsive and extending the longevity of the mechanism.

Key Functions of Steering Mechanism

The navigation system plays a crucial role in determining the direction and control of the vehicle. Its main purpose is to ensure smooth movement, allowing precise control while maintaining balance. The mechanism works in coordination with other components to enhance stability and performance, ensuring effective maneuverability under various conditions.

Control and Stability

The control system allows the operator to direct the vehicle effortlessly. This is achieved through the interaction of several elements that respond to inputs, adjusting the path of movement based on the driver’s actions. Stability is ensured by maintaining consistent coordination between these elements, even during sharp turns or uneven terrain.

Adjustment and Responsiveness

One of the key aspects is its ability to adjust quickly to various operating conditions. The mechanism responds to external factors such as terrain and speed, allowing for smooth transitions and immediate corrections. This adaptability enhances the overall performance and safety of the vehicle.

| Function | Description |

|---|---|

| Direction Control | Enables the vehicle to change its course based on operator inputs. |

| Stability Maintenance | Ensures balanced and smooth movement even under challenging conditions. |

| Adaptability | Adjusts to various terrain types and speed variations, improving performance. |

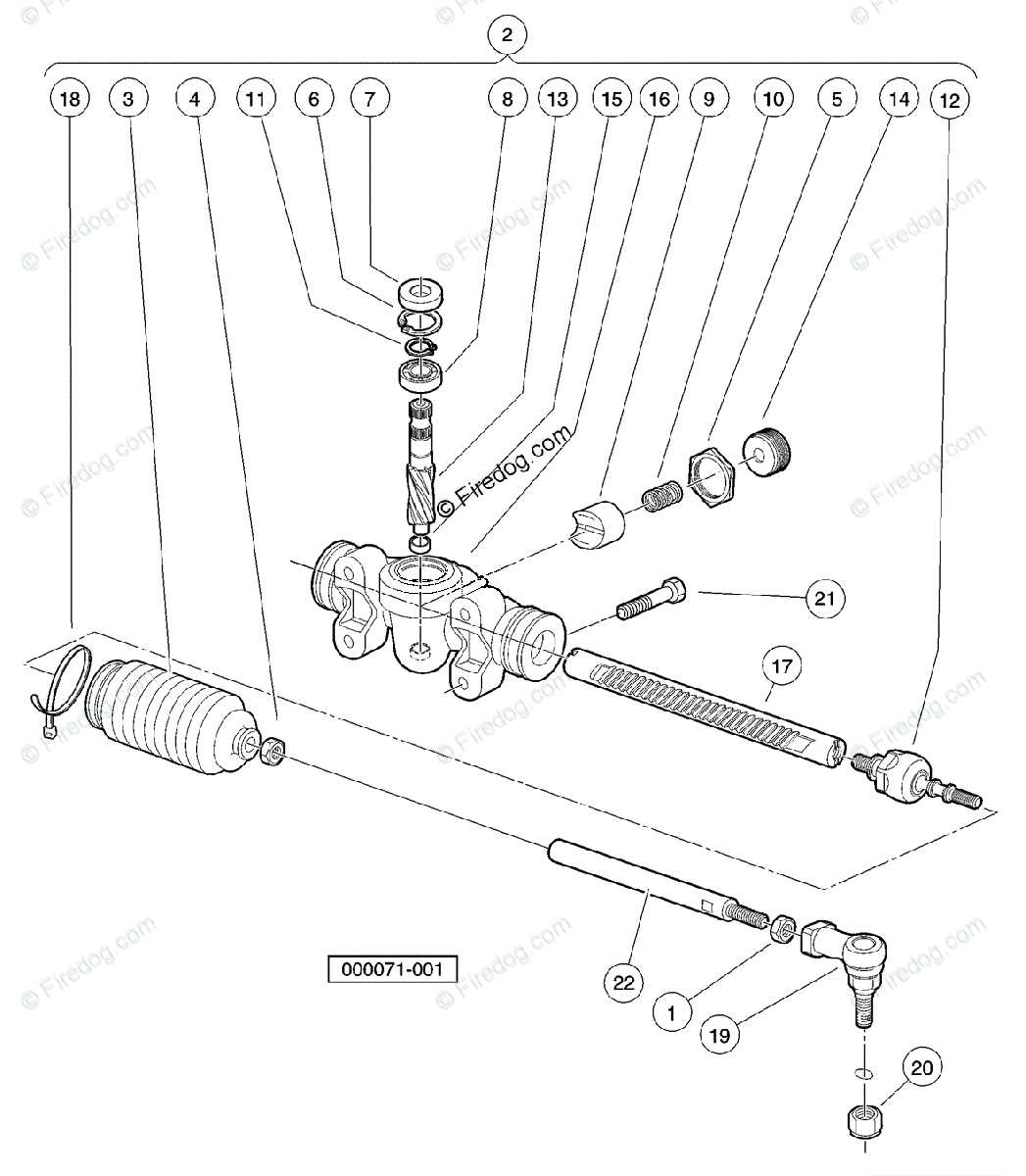

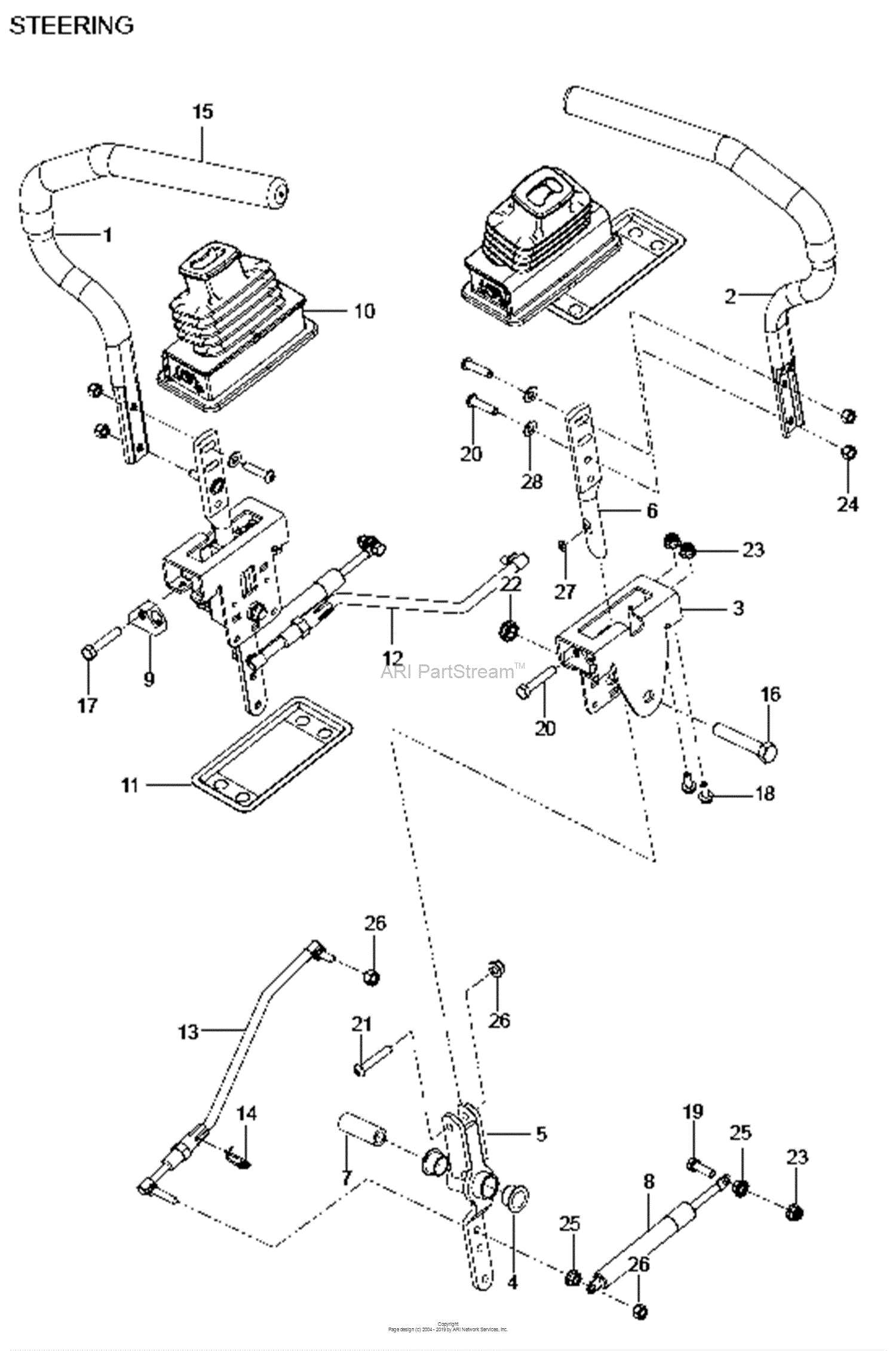

How to Identify Steering Linkage Parts

Understanding how different components of a machine’s control system connect can greatly improve your ability to maintain or repair it. These elements work together to ensure smooth directional changes and control of the equipment. Knowing the functions of each part helps in identifying issues or replacing them when necessary.

Connecting Rods are essential for transmitting the force required for movement. They link the control mechanism with the wheels, ensuring precise direction changes.

Control Arms provide stability and support during movement. They connect to the system to maintain alignment and allow smooth transitions during operation.

Pivots serve as key points where movement occurs. They allow the directional control components to move flexibly and responsively.

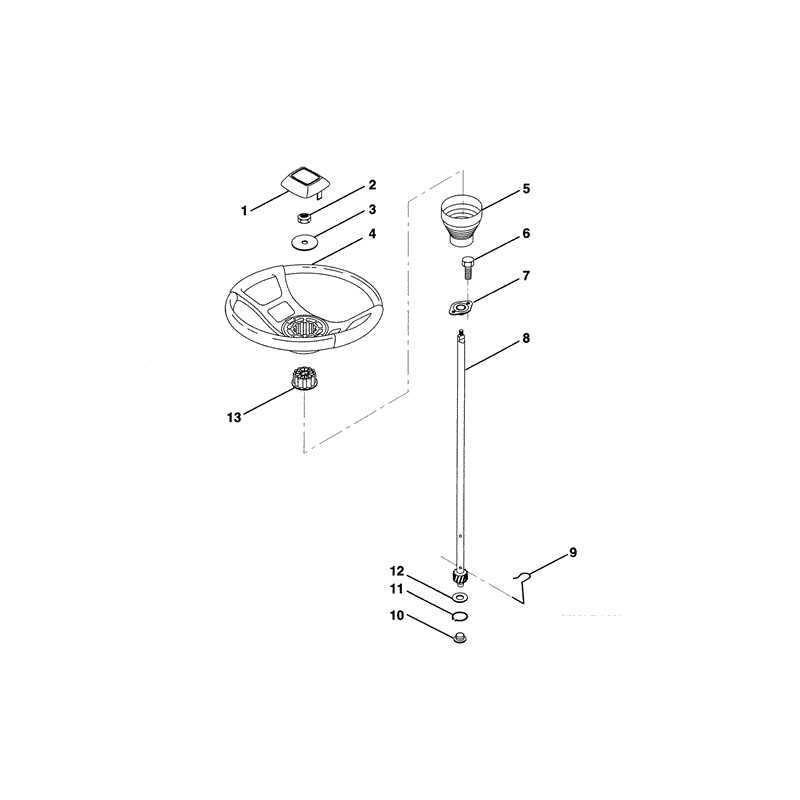

Understanding Husqvarna Steering Column Design

The column structure is a crucial component in ensuring smooth control and handling of the machine. This system connects the operator’s input to the front wheels, enabling precise maneuverability. Its design influences responsiveness and overall driving experience, playing a pivotal role in performance.

- Structural integrity: The column must withstand significant forces, maintaining stability during operation.

- Adjustment mechanism: Some models include features allowing the user to modify the angle or position, enhancing comfort and control.

- Connection points: Key joints and pivots link the column to other essential mechanisms, ensuring fluid movement and efficient power transfer.

Common Steering Wheel Parts and Their Role

The control system of a vehicle’s direction relies on a combination of components that work together to ensure smooth handling. Each element plays a vital part in maintaining the vehicle’s maneuverability, responsiveness, and overall safety during operation. Understanding these elements helps to grasp how they influence the overall driving experience.

Column Mechanism

The central shaft acts as the link between the wheel and the vehicle’s turning system. It transmits motion from the wheel to the rest of the mechanism, allowing the driver to control the vehicle’s path effectively. This mechanism also often includes tilt and telescoping features for comfort.

Joints and Linkages

These connections ensure that the input from the operator is accurately transferred to the system. Joints allow flexibility and smooth movements, while linkages ensure that every rotation is translated into precise adjustments, enabling the vehicle to follow the desired path.

Troubleshooting Issues in Steering Assemblies

When navigating challenges related to directional control systems, it is essential to identify common malfunctions and their underlying causes. This section aims to provide guidance on diagnosing issues that may arise, ensuring smooth operation and optimal performance of your machinery.

Common Symptoms and Their Causes

Users may experience various symptoms, such as difficulty in maneuverability or unusual noises during operation. These can stem from several factors, including improper alignment, worn components, or inadequate lubrication. Regular inspections can help pinpoint the specific areas needing attention.

Steps for Effective Diagnosis

To effectively address issues, begin by visually inspecting the assembly for any visible damage or misalignment. Next, check all connections and ensure that they are secure. Finally, testing the system under controlled conditions can help isolate the problem, allowing for targeted repairs or adjustments.

Maintenance Tips for Steering System Components

Regular upkeep of the maneuvering system elements is essential for ensuring optimal performance and longevity. Adopting a systematic approach to maintenance can help prevent potential issues and enhance the overall functionality of the machinery.

Here are some key recommendations for maintaining the components:

| Task | Frequency | Description |

|---|---|---|

| Inspect connections | Monthly | Check all connections for wear or looseness to ensure a secure fit. |

| Lubricate joints | Every 3 months | Apply appropriate lubricant to all pivot points to reduce friction. |

| Examine for wear | Every 6 months | Look for signs of wear on the system elements and replace if necessary. |

| Clean components | Monthly | Remove dirt and debris from all parts to prevent buildup and ensure smooth operation. |

| Check alignment | Annually | Ensure that all components are properly aligned to avoid strain during operation. |

Replacing Worn Out Steering Components

Maintaining optimal functionality in your machinery requires regular attention to its essential mechanisms. Over time, certain elements may wear down, affecting performance and safety. Identifying these components and knowing when to replace them is crucial for ensuring a smooth operation.

Identifying Worn Components

Signs of deterioration in essential mechanisms can include unusual noises, reduced responsiveness, or visible wear. Regular inspections are vital for spotting these issues early, allowing for timely replacements. If any parts show signs of damage or excessive play, they should be evaluated and replaced as necessary.

Replacement Process

When it’s time to replace old components, following a systematic approach can help ensure proper installation. First, gather all necessary tools and new components. Carefully remove the worn parts, taking note of their configuration for accurate reinstallation. Next, install the new elements according to the manufacturer’s specifications, ensuring everything is secure.

| Component | Symptoms of Wear | Replacement Frequency |

|---|---|---|

| Linkage | Play or looseness | Every 2-3 years |

| Bearings | Grinding noise | As needed |

| Bolts | Corrosion | Check annually |

Steering Shaft and its Importance

The element responsible for direction control in various machinery plays a crucial role in ensuring smooth maneuverability. This component connects different sections, allowing operators to navigate with precision and efficiency. Its design and functionality directly impact the overall performance and safety of the equipment.

Key Functions of the Component

This critical element facilitates the transfer of movement from the operator to the wheels or blades. It allows for precise adjustments, enabling the equipment to respond accurately to user inputs. Proper functioning of this mechanism is vital for achieving optimal performance and maintaining operational safety.

Impact on Overall Machinery Performance

Without a reliable connection, the machinery’s effectiveness may diminish significantly. A malfunctioning component can lead to erratic movements, posing risks to both the user and the equipment itself. Regular maintenance and timely replacement of worn parts ensure that the mechanism continues to perform at its best, thereby enhancing the longevity of the entire system.

Guide to Steering Gear Adjustments

Proper calibration of the directional mechanism is essential for ensuring optimal handling and maneuverability of your machine. Adjustments may be required over time due to wear and tear, environmental factors, or changes in performance. Understanding how to effectively manage these settings will enhance your overall experience and prolong the lifespan of the equipment.

Tools and Preparation

Before beginning any adjustments, gather the necessary tools, including wrenches, screwdrivers, and a level. Ensure the machine is parked on a flat surface and that you have access to the adjustment points. Familiarize yourself with the specific areas that require modification to enhance responsiveness and stability.

Adjustment Process

Begin by inspecting the current setup for any visible wear. Tighten or loosen the adjusting mechanisms according to the specifications outlined in your manual. Make small changes and test the functionality after each adjustment to ensure that you achieve the desired effect. Always prioritize safety when making these changes to avoid any potential hazards during operation.

Best Practices for Steering System Inspection

Regular evaluation of the directional control mechanism is essential for maintaining vehicle safety and performance. Implementing a systematic approach during inspections can help identify potential issues before they lead to significant problems.

Firstly, ensure the vehicle is on a level surface and securely supported to facilitate a thorough examination. Begin by visually assessing the condition of the control components for signs of wear or damage, such as cracks, corrosion, or excessive play. This initial observation can reveal underlying issues that require immediate attention.

Next, check the functionality of the mechanism by turning the wheel through its full range of motion. Listen for any unusual sounds and feel for resistance or stiffness that may indicate internal problems. Smooth operation is crucial for effective maneuverability.

In addition to the visual and functional checks, it is important to inspect the fluid levels and condition if applicable. Low or contaminated fluids can significantly affect performance, leading to erratic behavior. Make sure to refill or replace fluids according to the manufacturer’s recommendations.

Finally, document all findings and address any identified issues promptly. Keeping a record of inspections not only helps in maintaining the vehicle but also assists in future evaluations, ensuring optimal performance and safety.