The intricacies of marine control mechanisms play a vital role in ensuring smooth navigation and maneuverability on watercraft. These systems consist of various components that work in harmony, allowing for precise handling and responsive movements. Familiarity with these elements is essential for anyone involved in the operation or maintenance of marine vessels.

In this section, we will explore the essential components that contribute to the functionality of marine directional systems. A comprehensive overview will provide insight into how each element interacts within the overall framework, enabling users to better understand their roles and significance. Whether for troubleshooting, maintenance, or enhancement purposes, knowledge of these components is invaluable.

Through detailed representations and clarifications, readers will gain a deeper appreciation for the engineering behind these control systems. Recognizing how individual elements contribute to the collective operation will enhance one’s ability to engage with marine technology effectively. This understanding fosters improved safety and efficiency while navigating various aquatic environments.

Components of Hynautic Steering Systems

The effective functionality of marine navigation relies on a complex interplay of various elements designed to ensure precision and reliability. Each component plays a vital role in maintaining control, enabling the operator to maneuver effortlessly through different conditions. Understanding these essential elements is crucial for anyone involved in the maintenance or operation of marine vessels.

| Component | Description |

|---|---|

| Control Head | This unit serves as the interface between the operator and the system, allowing for intuitive command input. |

| Hydraulic Cylinders | These devices convert hydraulic pressure into mechanical force, enabling smooth and responsive maneuverability. |

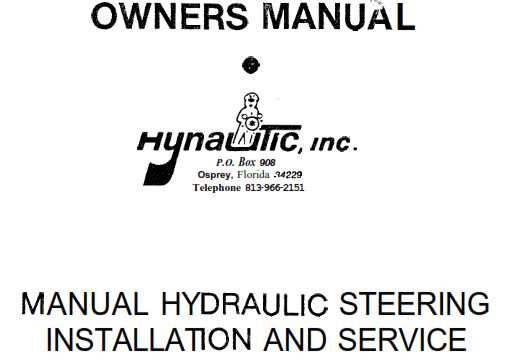

| Fluid Reservoir | A storage container for hydraulic fluid, essential for maintaining system pressure and performance. |

| Flexible Hoses | These conduits transport hydraulic fluid between components, ensuring uninterrupted functionality. |

| Valves | Critical for regulating fluid flow and pressure, these components ensure that the system operates efficiently. |

How to Read Hynautic Diagrams

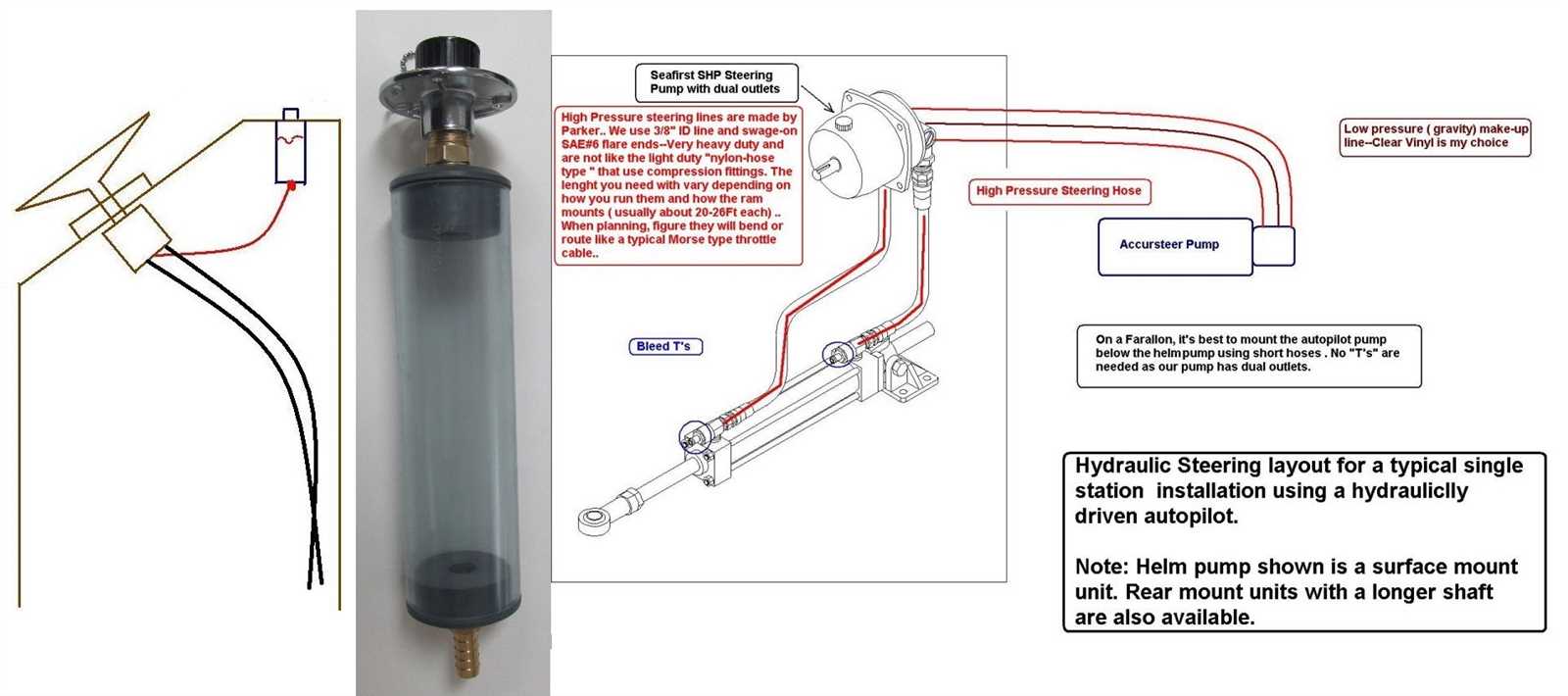

Understanding technical illustrations is essential for anyone working with marine control systems. These visuals provide valuable information about the components and their relationships, enabling efficient troubleshooting and maintenance. Familiarizing oneself with the symbols, lines, and notations used in these illustrations is crucial for effective interpretation.

To begin, identify the symbols representing various elements. Each symbol corresponds to a specific function or component, so a legend or key is often included for reference. Familiarize yourself with common representations, such as valves, pumps, and actuators, to build a foundational understanding.

Next, pay attention to the lines connecting the symbols. Solid lines typically indicate physical connections, while dashed lines may represent flow paths or control signals. Understanding these connections helps in visualizing the flow of information or hydraulic fluid throughout the system.

Additionally, note any directional arrows or annotations that provide further context. These notations often indicate the flow direction or specific operational instructions, enhancing your comprehension of how the system operates as a whole.

Lastly, practice by analyzing different illustrations. As you gain experience, you will become more adept at quickly interpreting the information presented, allowing you to diagnose issues and implement solutions effectively.

Common Issues with Steering Parts

Various components involved in directional control systems can experience a range of challenges that affect their performance and reliability. Understanding these issues is crucial for ensuring safety and efficiency in operation. Below are some frequent concerns that users may encounter.

1. Wear and Tear

Over time, many elements of directional control mechanisms undergo natural degradation due to continuous use. This can lead to:

- Decreased responsiveness

- Increased friction

- Potential failure of critical components

2. Fluid Leaks

Leaks in hydraulic systems are a common issue that can compromise functionality. Possible causes include:

- Damaged seals and gaskets

- Punctured hoses

- Corroded connections

These leaks can result in a significant loss of fluid, leading to inefficient operation and possible failure of the mechanism.

Regular maintenance and inspections can help identify these issues early, prolonging the life of the system and ensuring smooth operation.

Maintenance Tips for Hynautic Systems

Regular upkeep of your vessel’s control mechanisms is essential for ensuring optimal performance and longevity. Proper maintenance not only enhances safety but also improves the overall efficiency of your equipment. Adopting a systematic approach to care can help prevent costly repairs and extend the life of your apparatus.

1. Routine Inspections: Conduct periodic checks of all components to identify signs of wear or damage. Look for fraying cables, leaks, or corrosion that may compromise functionality. Addressing these issues promptly can prevent more significant problems later.

2. Fluid Levels: Regularly monitor and maintain the fluid levels in your system. Ensure that the appropriate type of fluid is used, as this directly affects the responsiveness and reliability of the controls. Refill or replace fluids as necessary to keep the system operating smoothly.

3. Cleaning: Keep all exposed areas free of dirt, salt, and debris. Regular cleaning prevents buildup that could hinder movement or cause corrosion. Use mild cleaners and avoid abrasive materials that could damage surfaces.

4. Lubrication: Apply lubricant to moving parts as specified in the manufacturer’s guidelines. Proper lubrication minimizes friction and wear, ensuring smooth operation. Pay attention to any areas that may require more frequent lubrication due to exposure to harsh conditions.

5. Professional Servicing: Schedule periodic professional inspections to ensure all systems are functioning as intended. Experts can identify potential issues that may not be visible during routine checks and provide necessary repairs or adjustments.

6. Documentation: Keep a detailed maintenance log to track inspections, repairs, and replacements. This record can be invaluable for identifying patterns of wear and predicting future maintenance needs, helping to keep your system in peak condition.

By implementing these maintenance strategies, you can ensure that your control mechanisms remain reliable and efficient, enhancing the overall safety and enjoyment of your boating experience.

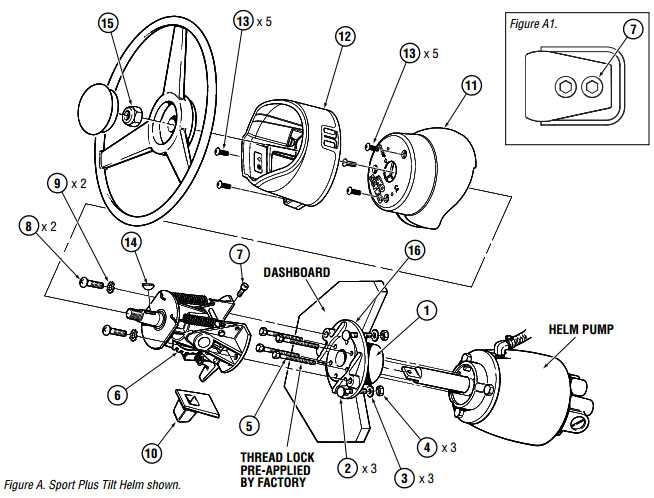

Identifying Steering Components Visually

Recognizing the various elements of a control system is essential for effective maintenance and troubleshooting. Familiarity with the appearance and function of these components can greatly enhance the efficiency of operations. This section will provide insights into how to visually distinguish among different elements, facilitating a more comprehensive understanding of their roles within the overall mechanism.

Common Components and Their Characteristics

Several key components are typically found in a control mechanism. Helms, for example, are often characterized by their circular shape and grip surface, designed for user comfort and control. Linkages can be identified by their elongated forms and pivot points, which allow for flexible movement. Observing the connection between these elements provides critical clues about their functionality and interrelations.

Visual Cues for Maintenance

When conducting inspections, pay close attention to wear and tear on the visible surfaces. Discoloration, fraying, or unusual movement can indicate the need for replacement or adjustment. Additionally, understanding the typical layout of these components within the assembly can help identify any misplaced or misaligned parts. Regular visual assessments are crucial for maintaining optimal performance and safety.

Installation Guide for Hynautic Parts

This guide provides essential information for the proper assembly and installation of marine control components. Understanding the structure and functionality of these mechanisms is crucial for achieving optimal performance and safety on the water. Following the outlined steps will ensure a seamless integration of the components into your vessel.

Preparation Steps

Before commencing the installation, gather all necessary tools and equipment. Familiarize yourself with the components and their respective functions. It is advisable to review the user manual for specific guidelines related to your model. Ensure that the workspace is clean and organized to prevent any components from becoming misplaced during the process.

Installation Process

Begin by securely mounting the control unit in the designated area. Make sure to use appropriate fasteners to avoid any movement during operation. Next, connect the associated cables and hoses, ensuring that all fittings are tight and leak-free. It is vital to follow the recommended torque specifications to avoid damaging the components. After the initial connections, double-check all work before proceeding to the final adjustments and tests.

Comparing Hynautic with Other Systems

This section aims to provide an insightful comparison between a specific marine control mechanism and its competitors. By examining various technologies and approaches, we can identify their strengths and weaknesses, ultimately assisting users in making informed choices based on their unique requirements.

Performance and Efficiency

Different control systems offer varying levels of performance and efficiency. Some mechanisms may provide quicker response times, while others focus on durability and low maintenance. Understanding these differences is crucial for selecting the most appropriate option for your vessel.

Installation and Maintenance

Installation ease and ongoing maintenance play significant roles in the selection process. Some systems require specialized tools and expertise, while others boast user-friendly designs that simplify setup and upkeep. Evaluating these factors can help potential users save time and resources in the long run.

| Feature | System A | System B | System C |

|---|---|---|---|

| Response Time | Fast | Moderate | Slow |

| Durability | High | Moderate | Low |

| Ease of Installation | Simple | Complex | Moderate |

| Maintenance Frequency | Low | High | Moderate |

Upgrading Your Steering Mechanism

Enhancing your control system can significantly improve the overall performance and handling of your vessel. By investing in modern technologies and components, you can achieve smoother navigation, better responsiveness, and increased durability. This guide will explore key considerations and options for upgrading your system to optimize your marine experience.

Benefits of Modernization

Upgrading your control mechanism brings numerous advantages. First, newer technologies often feature advanced materials that reduce wear and tear, extending the lifespan of the equipment. Additionally, improved designs can enhance precision, allowing for more accurate movements and greater safety during operation. A modern setup can also provide easier maintenance, ensuring that your vessel remains in top condition for longer periods.

Key Components to Consider

When planning an upgrade, focus on essential elements that can make a substantial difference. Here are some critical components to consider:

| Component | Description | Benefits |

|---|---|---|

| Hydraulic Systems | Advanced hydraulic mechanisms for smooth operation. | Improved responsiveness and control. |

| Electronic Controls | State-of-the-art electronic interfaces for precision. | Enhanced accuracy and ease of use. |

| Durable Materials | High-strength materials to withstand harsh conditions. | Longer lifespan and reduced maintenance. |

| Rudders | Redesigned rudders for optimized flow and handling. | Better maneuverability and stability. |

Choosing the right components and technologies can transform your control system into a more efficient and enjoyable experience, ensuring your time on the water is as safe and pleasant as possible.

FAQs about Hynautic Steering Parts

This section addresses common inquiries regarding the components of a hydraulic control system used in marine applications. Understanding these elements is crucial for both maintenance and effective operation, ensuring a smooth experience on the water.

What are the main components of a hydraulic control system?

The primary elements include the helm unit, hydraulic cylinders, hoses, and fittings. Each plays a vital role in transferring and controlling the fluid needed to achieve precise movements.

How can I identify if a component is faulty?

Signs of wear or malfunction may include leaks, unusual noises, or resistance when turning the wheel. Regular inspections can help catch issues early before they lead to more significant problems.

Is it necessary to use specific fluid types?

Yes, using the recommended fluid type is essential for optimal performance. Always refer to the manufacturer’s guidelines for specifications to avoid damage and ensure longevity.

Can I perform maintenance myself?

While some basic maintenance tasks can be handled independently, such as checking fluid levels, it’s advisable to consult a professional for more complex repairs to avoid compromising system integrity.

What should I do if I experience difficulty in maneuvering?

Difficulty in handling could indicate a variety of issues, including air in the system or low fluid levels. It’s important to troubleshoot the problem or seek professional assistance to ensure safety while operating.

How often should I inspect the components?

Regular inspections are recommended, ideally before each boating season. Additionally, consider checking them periodically during use, especially after prolonged operation or exposure to harsh conditions.

Resources for Further Learning

Exploring the intricacies of marine control systems can enhance your understanding and proficiency in nautical technology. This section offers a collection of valuable materials that can broaden your knowledge base and provide practical insights into the components and mechanisms involved in marine navigation and handling.

Whether you’re a novice seeking foundational information or an experienced enthusiast looking to deepen your expertise, these resources cover a wide range of topics. From instructional manuals to detailed technical guides, they cater to different learning styles and preferences.

| Resource Type | Title | Link |

|---|---|---|

| Book | Understanding Marine Systems | Read More |

| Online Course | Advanced Nautical Mechanics | Enroll Now |

| Video Tutorial | Basics of Control Mechanisms | Watch Here |

| Technical Manual | Comprehensive Guide to Marine Equipment | Download |