In the world of agricultural equipment, the intricacies of machinery play a crucial role in ensuring optimal performance and longevity. Each element is designed to work in harmony, allowing operators to maintain efficiency while managing their tasks. Among these components, the focus often falls on those that facilitate directional control, essential for navigating fields and completing work effectively.

The examination of these mechanical elements reveals their significance in the overall functionality of tractors and similar vehicles. Proper maintenance and a clear understanding of these components can lead to improved operational safety and enhanced productivity. When one delves into the specifics, it becomes evident how crucial these pieces are for smooth maneuverability and responsiveness.

This section aims to provide a detailed overview of the various components that contribute to directional guidance in agricultural machines. By exploring the layout and relationships between these elements, operators can better appreciate their machinery and ensure they remain in top condition for years to come.

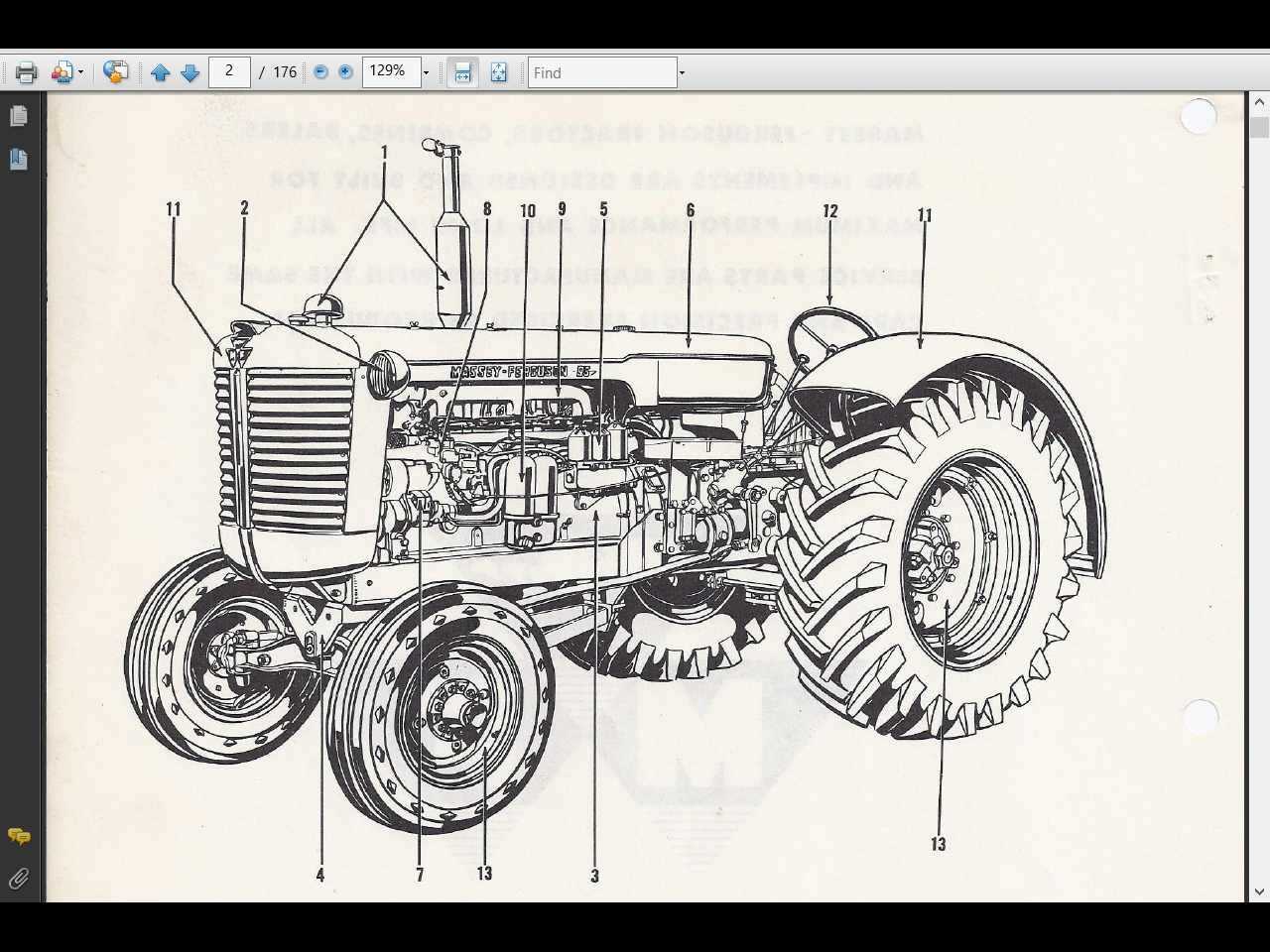

Understanding Massey Ferguson 135 Mechanics

The intricacies of agricultural machinery play a crucial role in enhancing productivity and efficiency in farming operations. Understanding the fundamental components and their interrelations is essential for optimal performance. This section delves into the mechanics of a well-known tractor model, exploring its core systems and how they contribute to its functionality.

Key Mechanical Systems

Several vital systems work in tandem to ensure smooth operation. Here are some of the primary components:

- Engine: The heart of the machine, providing the necessary power.

- Transmission: This system transmits power from the engine to the wheels, allowing for speed and torque adjustments.

- Hydraulic System: Enables the lifting and control of implements, providing essential support for various tasks.

- Chassis: The framework that supports all other components, ensuring stability and durability.

Importance of Maintenance

Regular upkeep is critical for sustaining the longevity and performance of the machinery. Here are some maintenance tips:

- Routine checks on fluid levels to prevent overheating and mechanical failures.

- Inspecting belts and hoses for wear to avoid sudden breakdowns.

- Cleaning air filters to ensure optimal engine performance.

- Lubricating moving parts to reduce friction and prolong service life.

By understanding these mechanical elements and their functions, operators can make informed decisions about maintenance and repairs, leading to enhanced operational efficiency.

Key Features of Steering Systems

Effective maneuverability is crucial for vehicles, influencing their overall performance and user experience. Several components work in harmony to ensure precise control and stability.

- Responsiveness: Systems should provide immediate feedback to driver inputs, enhancing control.

- Durability: High-quality materials and design contribute to longevity, reducing maintenance needs.

- Precision: Accurate alignment and calibration are essential for optimal handling.

- Hydraulic Assistance: Many modern mechanisms utilize fluid power to ease operation, especially in larger vehicles.

- Safety Features: Innovations such as electronic stability control enhance safety during sharp turns or sudden maneuvers.

Understanding these elements can help in maintaining and optimizing vehicle functionality for various applications.

Importance of Proper Steering Maintenance

Maintaining the directional control system of any vehicle is crucial for safe and efficient operation. Regular upkeep ensures that components function harmoniously, preventing potential failures that could lead to accidents or costly repairs.

Benefits of Regular Maintenance

- Enhances safety by providing reliable control.

- Improves overall performance and maneuverability.

- Extends the lifespan of essential components.

- Reduces repair costs over time.

Key Maintenance Practices

- Regularly check for fluid levels and leaks.

- Inspect for wear and tear on all components.

- Ensure proper alignment and calibration.

- Replace worn parts promptly to avoid further damage.

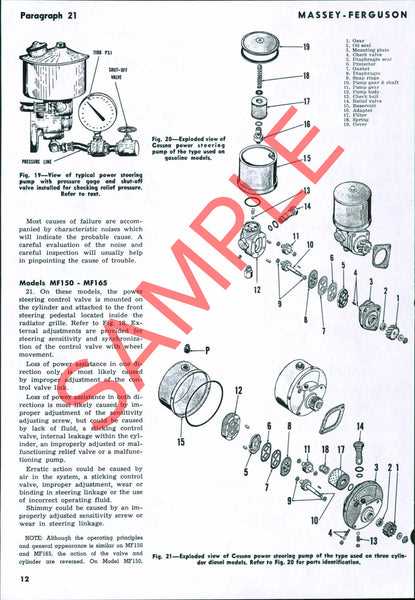

Common Issues with Steering Components

In the realm of agricultural machinery, the control mechanisms play a crucial role in operational efficiency. Over time, various elements within these systems can experience wear and tear, leading to a range of complications that affect handling and maneuverability. Recognizing and addressing these problems promptly can help maintain optimal performance and prevent further damage.

Common Symptoms of Wear

Operators may notice several indicators that suggest underlying issues with the control assembly. These signs can range from unusual noises to difficulty in turning. Identifying these symptoms early is essential for effective maintenance.

| Symptom | Possible Cause |

|---|---|

| Unresponsive handling | Fluid leaks or air in the system |

| Excessive play in control | Worn bushings or joints |

| Grinding noises | Damaged gears or bearings |

| Pulling to one side | Misalignment or uneven tire pressure |

Maintenance Tips

Regular inspections and maintenance can mitigate many of the issues mentioned. Keeping components clean and properly lubricated is essential for ensuring longevity. Additionally, replacing worn parts before they cause significant damage can save both time and resources.

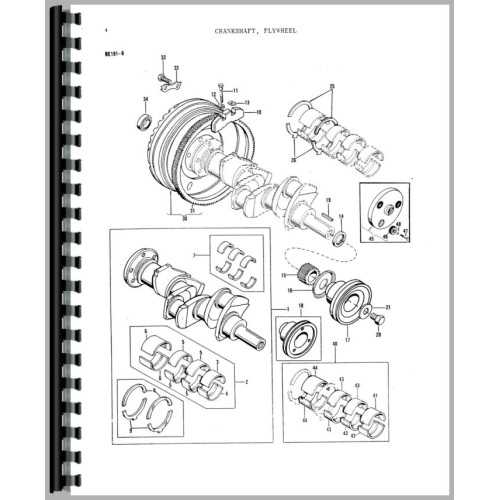

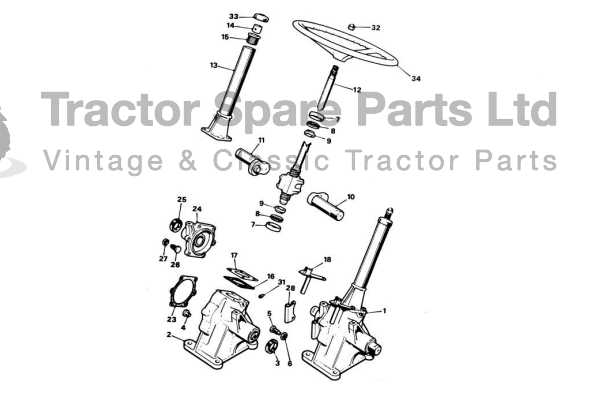

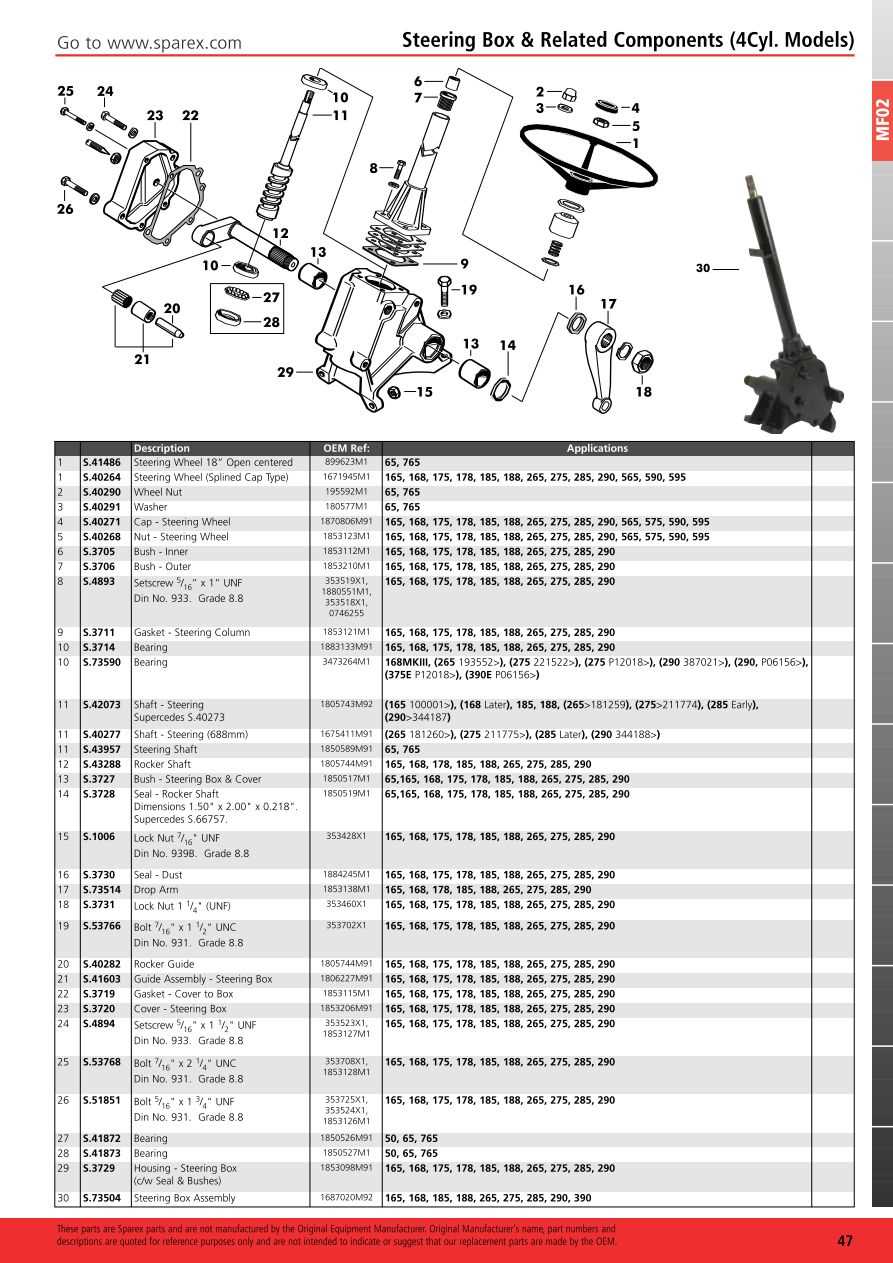

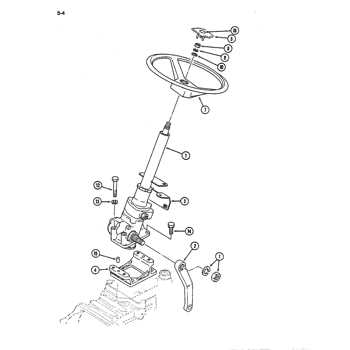

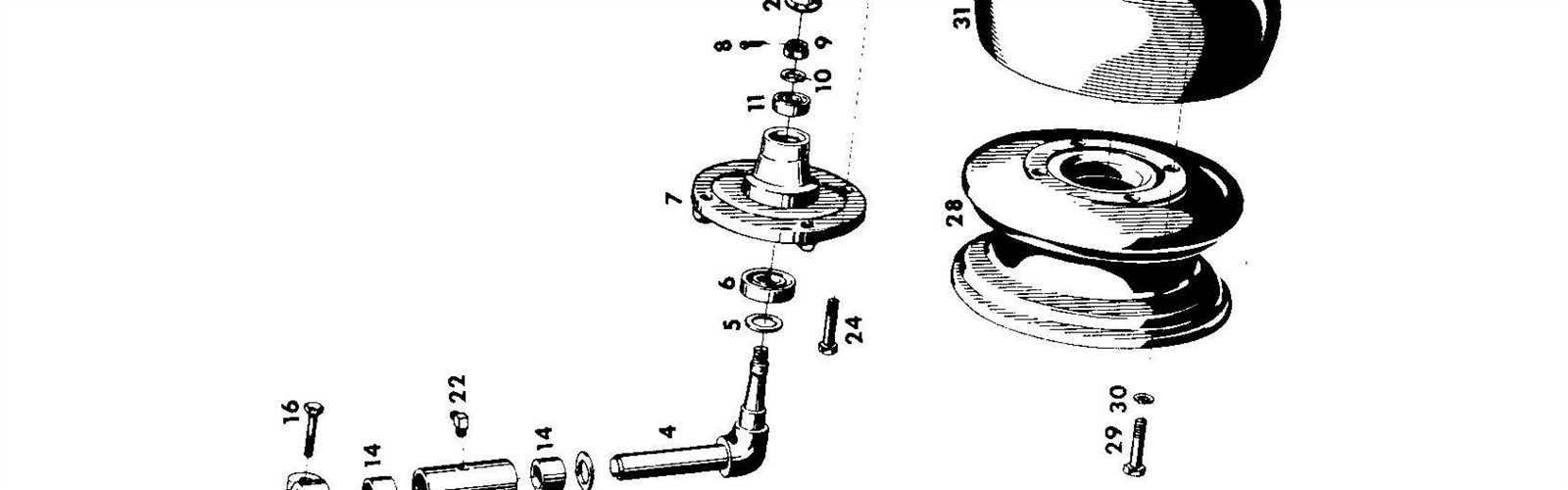

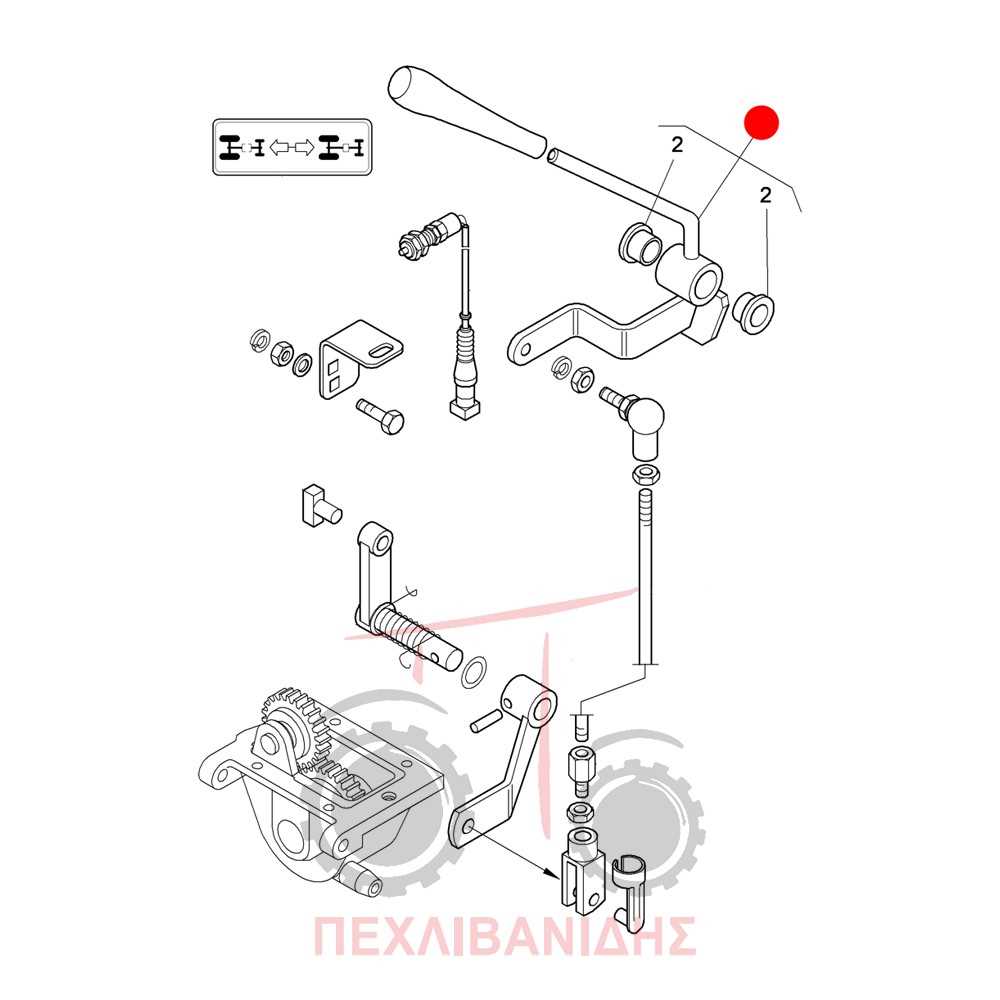

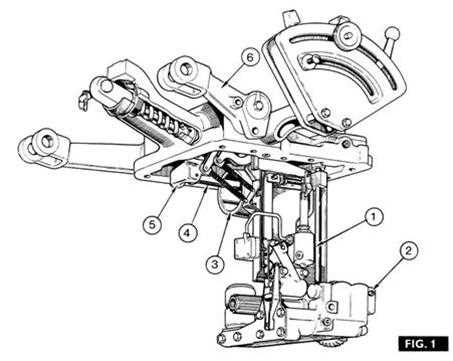

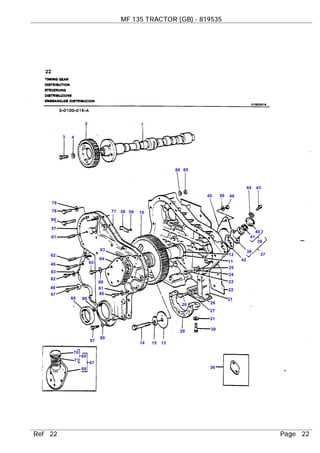

Detailed Parts Diagram Explanation

This section aims to provide a comprehensive understanding of the components involved in a particular mechanical system. By exploring the layout and relationship between various elements, one can appreciate how each contributes to overall functionality and performance.

Understanding Component Relationships

Each element within the layout serves a unique role, ensuring smooth operation and effective interaction with other parts. Recognizing how these components connect and function together is essential for maintenance and troubleshooting.

Importance of Accurate Representation

An accurate representation of the assembly allows users to identify specific items easily, making repairs or replacements more efficient. This clarity not only aids in understanding but also enhances the ability to delve into more complex issues that may arise.

How to Identify Steering Problems

Recognizing issues with your vehicle’s maneuverability is crucial for ensuring safe operation and longevity. Various signs can indicate that your handling mechanism requires attention. Being aware of these symptoms will help you diagnose problems early and maintain optimal performance.

Common Symptoms

Unusual noises, such as clunks or grinding, during turns can signal internal wear or damage. Additionally, if the control feels loose or unresponsive, it may suggest a problem with the connection between components. Difficulty in turning the wheel, or the need for excessive force, indicates potential issues that should not be ignored.

Visual Inspection

Regularly examining the external elements can reveal significant wear or damage. Look for signs of leaks around hydraulic systems or frayed cables that may affect function. Checking for proper alignment of the various components can also highlight potential concerns before they develop into more serious issues.

Early detection and maintenance can prevent costly repairs, ensuring your vehicle operates smoothly and safely.

Replacement Parts for Massey Ferguson

When it comes to maintaining agricultural machinery, having access to high-quality components is essential. Whether for repairs or upgrades, the right elements ensure optimal performance and longevity of your equipment. This section explores various replacement components that are crucial for keeping your machinery running smoothly.

Types of Components Available

A wide range of elements is available for machinery maintenance. From hydraulic systems to transmission components, each plays a vital role in the overall functionality. By choosing the appropriate replacements, you can enhance efficiency and reduce downtime, making your tasks more manageable.

Benefits of Quality Replacements

Investing in quality replacements not only improves performance but also extends the lifespan of your equipment. Durability and reliability are key factors that ensure your machinery can withstand rigorous use. With the right components, you can maintain productivity and ensure that your operations run without a hitch.

Tools Needed for Steering Repairs

When undertaking repairs related to the directional control of machinery, having the right tools is essential for efficiency and safety. A well-equipped workspace enhances the ability to address various mechanical issues effectively.

Wrenches: A set of adjustable and socket wrenches is crucial for loosening and tightening bolts and nuts.

Screwdrivers: Both flathead and Phillips screwdrivers are necessary for accessing different components.

Pliers: Needle-nose and regular pliers aid in gripping and manipulating small parts.

Torque Wrench: Ensuring bolts are tightened to the manufacturer’s specifications prevents damage and enhances performance.

Jack and Stands: Lifting the equipment safely provides better access to the undercarriage and other hard-to-reach areas.

Diagnostic Tools: Instruments for testing alignments and wear can help pinpoint issues quickly and accurately.

Utilizing these essential tools not only streamlines the repair process but also ensures that the machinery remains in optimal working condition.

Step-by-Step Steering Repair Guide

This guide provides a comprehensive approach to restoring the control system of your agricultural machinery. Following these instructions will ensure that your equipment operates smoothly and efficiently, enhancing its overall performance and longevity.

Preparation and Tools

Before starting the repair, gather all necessary tools, including wrenches, pliers, and lubrication supplies. Ensure you have a clean workspace and access to the service manual for reference. Proper preparation is essential for a successful repair process.

Disassembly and Inspection

Begin by carefully disassembling the control mechanism. Inspect each component for wear or damage, making notes of any parts that require replacement. This thorough examination is crucial to identify underlying issues that may affect functionality.

Safety Tips for Tractor Maintenance

Proper upkeep of agricultural machinery is essential for ensuring both safety and efficiency. Neglecting maintenance can lead to hazardous situations and equipment failure. Adhering to safety protocols during maintenance can prevent accidents and enhance the longevity of the machinery.

1. Wear Protective Gear: Always use appropriate personal protective equipment, including gloves, safety glasses, and steel-toed boots, to shield yourself from potential hazards.

2. Secure the Equipment: Before starting any maintenance tasks, ensure the machinery is turned off and secured against accidental start-up. Use wheel chocks and engage the parking brake.

3. Follow the Manual: Consult the manufacturer’s manual for specific maintenance procedures and safety guidelines tailored to your equipment.

4. Maintain a Clean Workspace: Keeping your work area tidy reduces the risk of slips and falls. Remove any unnecessary tools or materials from the vicinity.

5. Use Proper Tools: Always utilize the right tools for the job. Improvised tools can lead to injuries or damage to the equipment.

6. Inspect Regularly: Conduct routine inspections of your machinery to identify any potential issues early on, which can prevent more serious problems later.

7. Get Professional Help: When in doubt, seek assistance from qualified technicians to ensure that repairs and maintenance are performed correctly.

Resources for Massey Ferguson Owners

For those who own vintage agricultural machinery, having access to quality resources is essential for maintenance and repair. This section aims to provide helpful tools and information that can assist operators in keeping their equipment running smoothly and efficiently.

Manuals and Guides

- Owner’s Manuals: Comprehensive guides for understanding the functionality and maintenance of your machinery.

- Service Manuals: Detailed instructions for troubleshooting and repairing specific issues.

- Parts Catalogs: Lists of components, including diagrams that facilitate ordering and replacement.

Online Communities

- Forums: Engaging platforms where enthusiasts share experiences, tips, and solutions.

- Social Media Groups: Active communities on platforms like Facebook where members post questions and advice.

- YouTube Channels: Channels dedicated to repairs, modifications, and restoration projects for vintage equipment.

Utilizing these resources can enhance your ownership experience and extend the life of your machinery.