The efficiency and performance of a well-known power tool depend significantly on its intricate components. Each part plays a vital role in ensuring that the device operates smoothly and effectively. A comprehensive understanding of these elements can aid in maintenance and troubleshooting, ultimately extending the tool’s lifespan and enhancing its reliability during use.

Familiarizing oneself with the various elements and their functions can empower users to address common issues that may arise. Recognizing how each component interacts within the mechanism will contribute to better operational efficiency. By delving into the layout of these essential features, users can gain insights that are crucial for optimal performance.

This exploration will provide a clearer picture of how each element contributes to the overall functionality of the tool. Whether for repair or enhancement purposes, knowing the specifics of the internal workings is indispensable. Users will find that such knowledge not only improves their experience but also fosters a greater appreciation for the engineering behind this powerful device.

Understanding MS 290 Chainsaw Components

The functionality of a cutting tool relies heavily on its various elements working in harmony. Each component plays a specific role, contributing to the overall efficiency and performance of the equipment. A thorough comprehension of these elements is essential for users aiming to maintain, repair, or optimize their machinery.

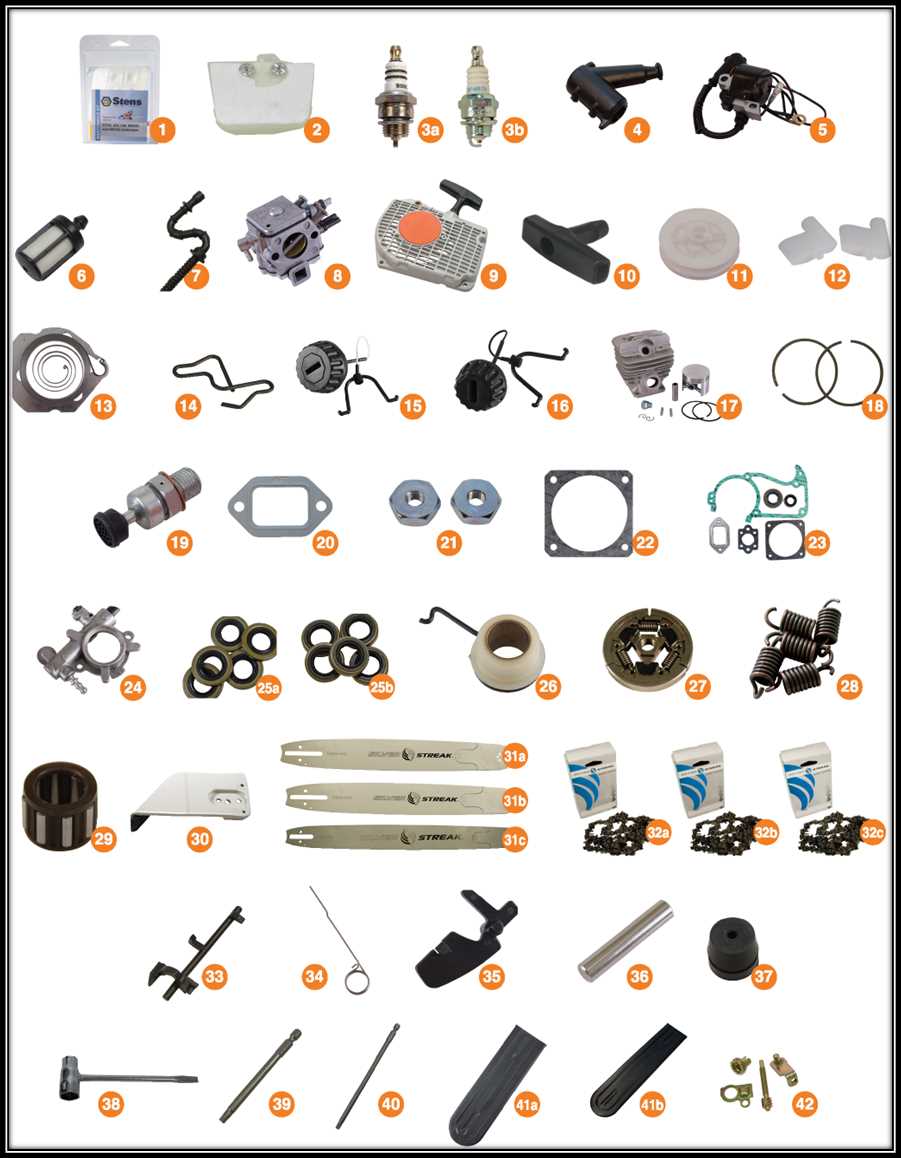

Key Elements

- Engine: This is the heart of the device, providing the necessary power for operation.

- Guide Bar: Serves as the support for the cutting chain, determining the length and cutting capacity.

- Chain: The crucial component that performs the cutting action, with sharp teeth designed for efficient wood processing.

- Fuel System: Supplies the engine with the necessary mixture of fuel and oil for optimal performance.

- Air Filter: Prevents debris from entering the engine, ensuring a clean airflow for efficient combustion.

Maintenance Considerations

- Regular Inspection: Routine checks help identify wear and tear, ensuring all components function properly.

- Cleaning: Keeping parts clean is essential to prevent buildup that can hinder performance.

- Replacement: Knowing when to replace worn-out elements can significantly extend the lifespan of the equipment.

- Lubrication: Proper lubrication of moving parts reduces friction and enhances efficiency.

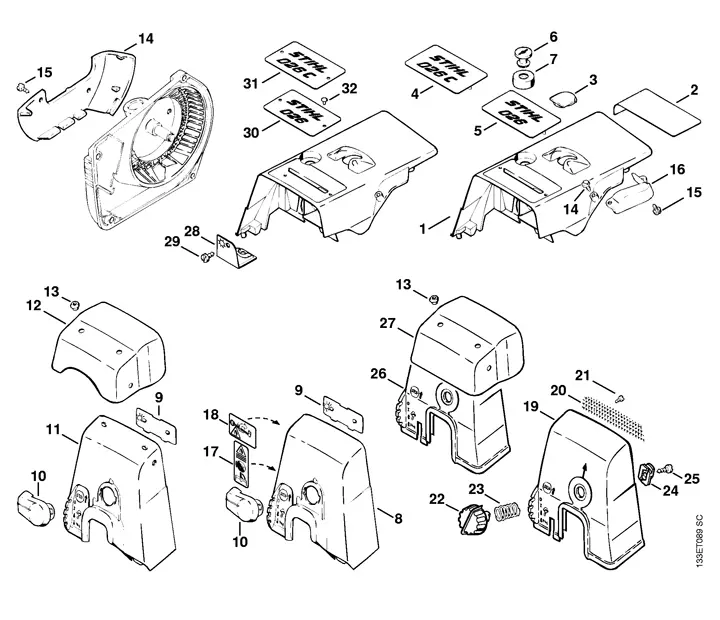

Overview of Chainsaw Assembly Parts

The assembly of a cutting tool consists of various components that work together to ensure optimal performance and efficiency. Each element plays a crucial role in the overall functionality, influencing factors such as cutting speed, safety, and ease of use. Understanding these components helps users maintain and troubleshoot their equipment effectively.

Main Components

At the heart of the mechanism lies the engine, which powers the entire system. Connected to the engine is the drive system, responsible for transferring energy to the cutting element. The cutting assembly itself includes a guide and a blade, designed for precise cutting tasks. Each of these elements must be compatible to achieve seamless operation.

Support Structures

In addition to the primary components, several support structures are essential for stability and user safety. The housing encases the engine and drive components, providing protection and contributing to the overall design. Furthermore, handles and guards are integrated to enhance user control and prevent accidents during operation. Each structural element is designed to facilitate a balance between power and safety.

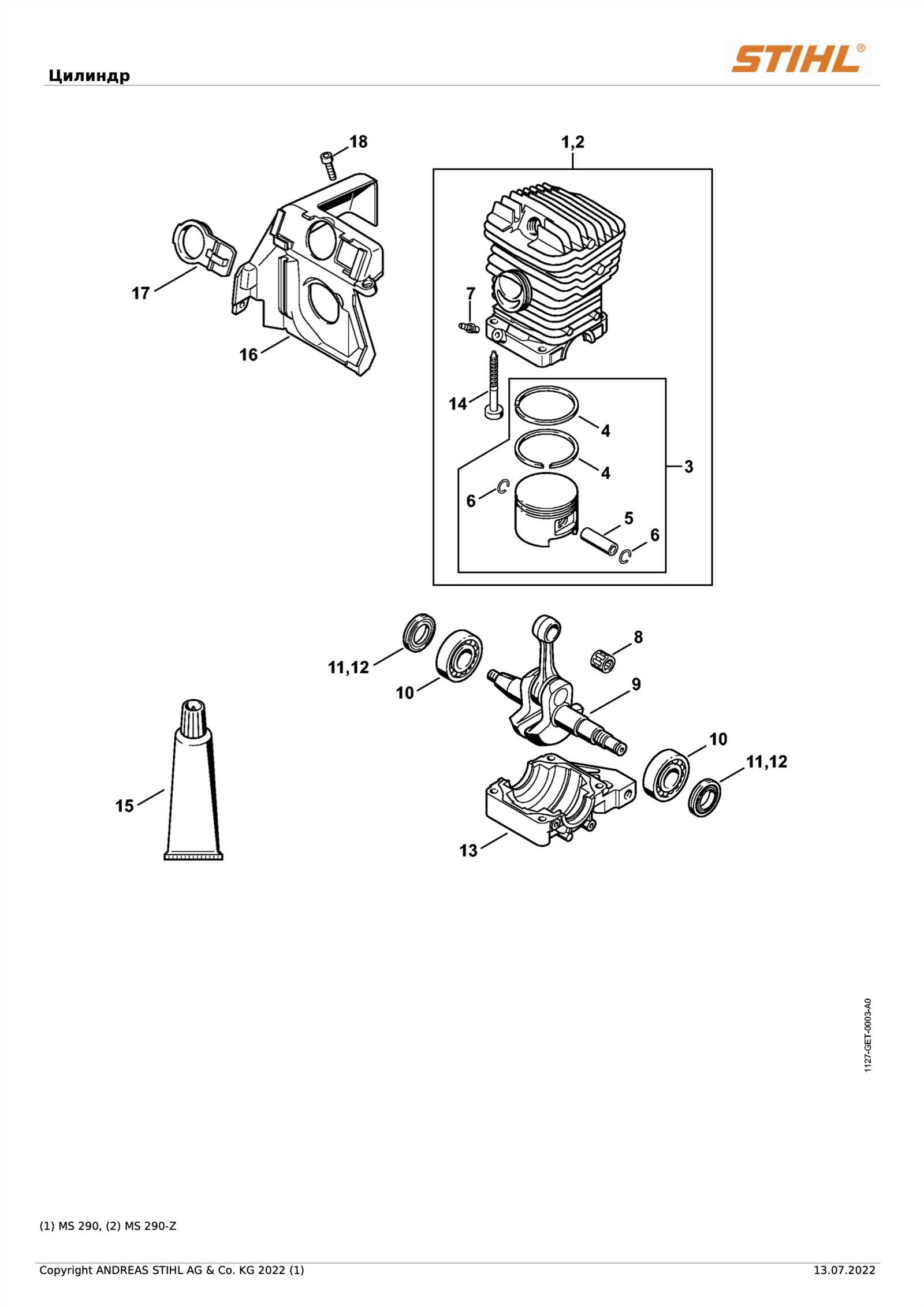

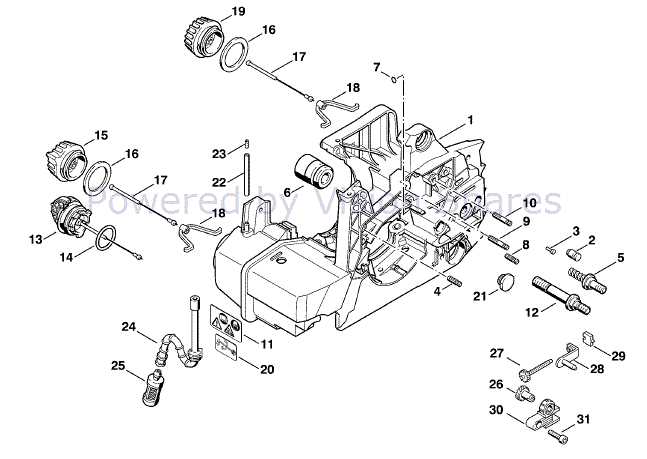

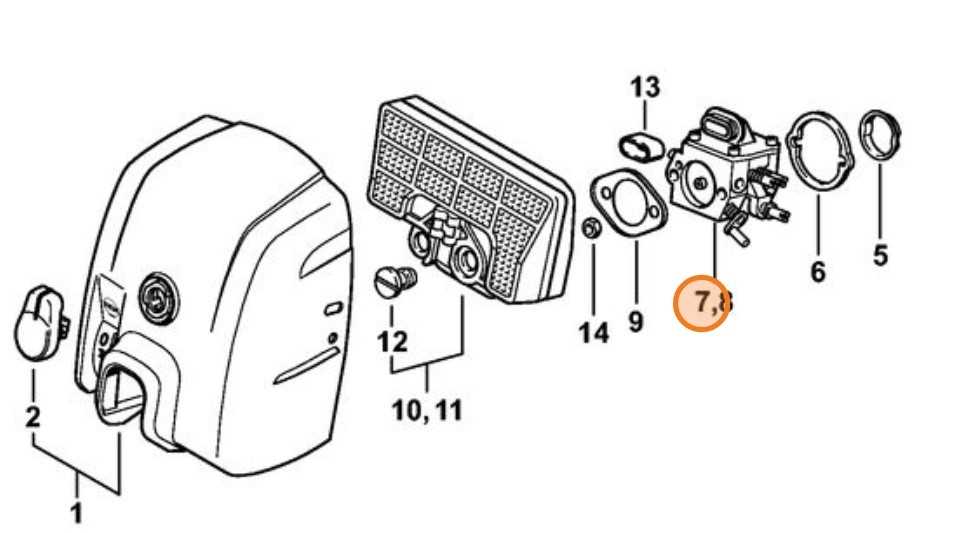

Detailed Diagram of Stihl MS 290

The intricate layout of a power tool is essential for understanding its functionality and maintenance requirements. This section delves into the various components that comprise a specific model, highlighting their arrangement and interconnections. By examining the structure, users can gain insights into the assembly and disassembly process, ensuring optimal performance and longevity of the equipment.

Key Components Overview

The machine consists of several crucial elements, each serving a distinct purpose. The engine serves as the heart, providing the necessary power for operation. The fuel system, including the tank and lines, ensures a continuous supply of energy, while the cutting mechanism is designed for efficiency and precision. Understanding these fundamental parts allows for more effective troubleshooting and repairs.

Assembly and Maintenance Tips

Proper assembly and regular maintenance are vital for the longevity of the tool. Users should familiarize themselves with the layout to ensure each component is correctly positioned during reassembly. Routine checks of the essential elements, such as the air filter and spark plug, can prevent potential issues. Regular lubrication of moving parts also enhances performance and minimizes wear.

Functionality of Key Parts Explained

This section delves into the essential components of a powerful cutting tool, illustrating how each element contributes to its overall performance and efficiency. Understanding the roles of these components enhances not only the user’s knowledge but also the ability to maintain and troubleshoot effectively.

-

Engine: The heart of the machine, responsible for generating the power needed to drive the cutting mechanism. Its design ensures optimal performance and reliability under various conditions.

-

Guide Bar: This elongated metal strip provides the path along which the cutting chain moves. Its length and profile are crucial for achieving specific cutting tasks with precision.

-

Cutting Chain: Comprised of a series of linked segments, this component executes the actual cutting action. Each link is designed for durability and effectiveness, ensuring smooth operation.

-

Clutch: This mechanism engages and disengages the cutting chain from the engine’s drive system, allowing for safe operation and control during use.

-

Fuel System: Comprising the tank, lines, and filter, this system delivers the necessary energy source to the engine, ensuring a consistent and reliable power supply.

-

Starter Mechanism: Facilitating the initial ignition of the engine, this system typically includes a pull cord and spring, providing an easy way to start the tool without excessive effort.

Each of these components plays a vital role in the overall functionality and efficiency of the equipment, making a thorough understanding of their roles essential for optimal performance and longevity.

Common Issues with MS 290 Parts

When it comes to the components of this popular outdoor tool, users often encounter a range of challenges that can affect performance and reliability. Understanding these common problems is crucial for maintenance and ensuring the longevity of the equipment.

Fuel Supply Problems: One frequent issue arises from the fuel delivery system, where clogs or leaks can disrupt the flow of fuel. This can lead to difficulty starting or inconsistent operation.

Ignition Failures: Another common concern is related to the ignition mechanism. A malfunctioning spark plug or faulty ignition coil can result in poor starting or misfires during use, diminishing overall efficiency.

Bar and Chain Wear: Over time, the cutting attachment may exhibit signs of wear, leading to reduced cutting effectiveness. Regular inspection and replacement of these components are essential to maintain optimal cutting performance.

Vibration Issues: Excessive vibrations during operation can indicate problems with the vibration dampening system. This not only affects user comfort but may also lead to faster wear of the internal components.

Air Filter Blockages: A dirty air filter can restrict airflow, resulting in reduced power output and increased fuel consumption. Cleaning or replacing the air filter regularly is vital for optimal engine performance.

How to Identify Parts Visually

Recognizing components visually is a crucial skill for anyone working with machinery. By understanding the general shapes, sizes, and characteristics of various elements, one can quickly locate the necessary pieces when performing maintenance or repairs. This process involves not only looking at the items but also familiarizing oneself with their functions and placements within the overall assembly.

Begin by examining the exterior of the equipment. Most items will have distinctive features that set them apart, such as unique shapes, colors, or markings. Documentation, like user manuals or technical guides, can provide valuable references for understanding what to look for. Pay attention to any labels or model numbers that might help identify the components more accurately.

Next, take note of the connectivity between elements. Components often connect in specific ways, whether through screws, clips, or other fastening methods. Understanding these connections can aid in determining which parts are interchangeable or need replacement. Physical comparisons with known parts can also enhance recognition, ensuring that you have the correct items for your needs.

Finally, observing the wear and tear on each item can help in identifying their functionality. Components that show signs of damage or degradation may need to be replaced. Being able to visually distinguish between functioning and non-functioning elements is vital for maintaining the efficiency of the machine.

Maintenance Tips for Optimal Performance

To ensure the longevity and efficiency of your equipment, regular upkeep is essential. Proper care not only enhances performance but also reduces the likelihood of unexpected failures. Following a systematic approach to maintenance can significantly improve your machine’s functionality and lifespan.

- Regular Cleaning: Keep the exterior and interior components free from debris. Use a soft brush and compressed air to remove dust and dirt, especially around air intakes and cooling fins.

- Chain Lubrication: Ensure that the cutting mechanism is well-lubricated. Regularly check the oil levels and refill as needed to prevent overheating and wear.

- Filter Inspection: Check and clean or replace the air and fuel filters regularly. Clogged filters can hinder performance and lead to engine problems.

- Sharpening the Blade: Maintain a sharp edge on the cutting tool for effective operation. Dull blades require more power and can cause damage.

- Fuel Quality: Use high-quality fuel and ensure it is fresh. Stale fuel can lead to starting issues and poor performance.

- Inspect Cables and Connections: Regularly check all cables and electrical connections for wear or damage. Replace any frayed wires to maintain safety and functionality.

- Storage Practices: When not in use, store your equipment in a cool, dry place. Ensure it is cleaned and serviced before long-term storage to prevent degradation.

Adhering to these maintenance guidelines will promote efficient operation and enhance the durability of your equipment, ensuring it remains reliable for all your tasks.

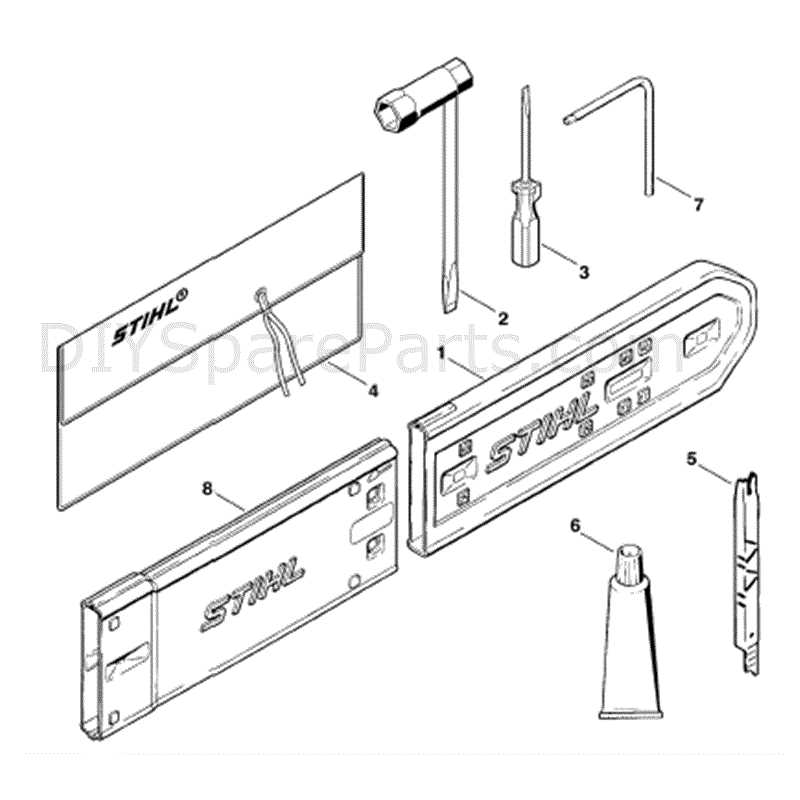

Tools Needed for Parts Replacement

When undertaking maintenance or repairs on a mechanical device, having the right tools at your disposal is essential for ensuring a smooth and efficient process. Utilizing the appropriate instruments not only facilitates the replacement of components but also helps prevent damage to the machinery. This section outlines the essential tools required to effectively carry out replacements, promoting both safety and efficiency.

Essential Hand Tools

To begin with, a set of quality hand tools is fundamental for any replacement job. Common items include screwdrivers of various sizes, pliers, and wrenches, which are necessary for loosening and tightening fasteners. Additionally, a socket set can be advantageous for accessing hard-to-reach areas and ensuring a secure fit. These basic tools form the backbone of your toolkit, enabling you to tackle most tasks with confidence.

Specialized Instruments

In some cases, specialized instruments may be required for more intricate replacements. For instance, a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications, preventing over-tightening or under-tightening. Moreover, a set of hex keys might be necessary for certain components. Having these specialized tools on hand can make a significant difference in the quality of the repair and the longevity of the device.

Where to Buy Replacement Components

Finding high-quality replacement components for your equipment is essential to maintain its efficiency and longevity. Several options are available for sourcing these elements, ensuring you can get what you need to keep your tool functioning optimally.

Authorized Dealers

One of the best places to start is with authorized dealers. These retailers are recognized by the manufacturer and often carry a complete selection of authentic components. Purchasing from them guarantees that you receive parts designed specifically for your model, ensuring compatibility and performance.

Online Retailers

The internet offers a vast array of online retailers specializing in equipment components. Websites dedicated to tool supplies often have extensive inventories, competitive pricing, and customer reviews to help guide your purchase. Make sure to check the return policy when ordering online, as it allows for exchanges in case the component does not fit or meet your expectations.

Comparing MS 290 to Other Models

This section provides a comparative analysis of a specific model against its peers in the same category, highlighting their strengths and weaknesses. Understanding these differences helps users make informed decisions based on their requirements and preferences.

Performance and Features

The performance of various models can vary significantly. When assessing their capabilities, factors such as engine power, weight, and cutting efficiency are crucial. The model in focus boasts a robust engine, which often translates to enhanced cutting speed and durability compared to lighter alternatives. Additionally, the inclusion of advanced features, such as easy starting systems and anti-vibration technology, can greatly influence user experience.

Durability and Maintenance

Longevity and ease of maintenance are essential considerations for anyone looking to invest in a reliable tool. The model under discussion is designed for heavy-duty use, making it a suitable choice for professionals and enthusiasts alike. In contrast, some other options may prioritize lightweight construction at the expense of durability. Regular maintenance requirements also differ, with certain models necessitating more frequent servicing, which can impact overall user satisfaction.

Safety Precautions During Repairs

When undertaking maintenance tasks on mechanical equipment, prioritizing safety is crucial to prevent accidents and ensure a successful repair process. Familiarizing yourself with essential safety measures helps to protect not only the individual performing the repairs but also those nearby. Adhering to proper guidelines minimizes the risk of injuries and promotes a more efficient working environment.

Essential Safety Gear

Using appropriate safety gear is vital when conducting repairs. The following items should always be worn to provide protection:

| Safety Gear | Purpose |

|---|---|

| Safety goggles | Protect eyes from flying debris |

| Gloves | Shield hands from sharp edges and chemicals |

| Hearing protection | Minimize noise exposure |

| Steel-toed boots | Prevent foot injuries from falling objects |

Work Area Safety

Creating a safe and organized workspace is essential for effective repairs. Ensuring the area is well-lit and free from clutter helps to reduce the likelihood of accidents. Additionally, having a first-aid kit readily available can provide quick assistance in case of any injuries that may occur.