Understanding the intricate elements that comprise a chainsaw is essential for both maintenance and effective operation. A well-functioning tool relies on numerous interconnected pieces, each playing a crucial role in ensuring optimal performance. By familiarizing oneself with these components, users can troubleshoot issues more effectively and enhance their overall experience.

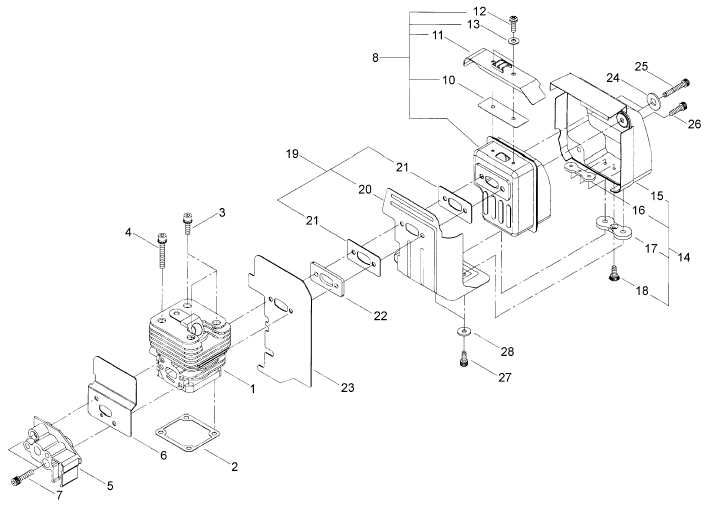

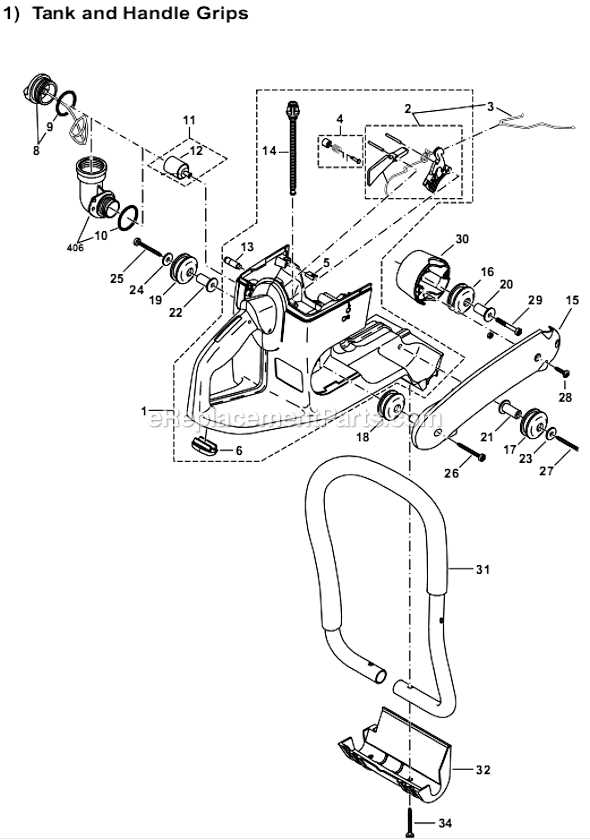

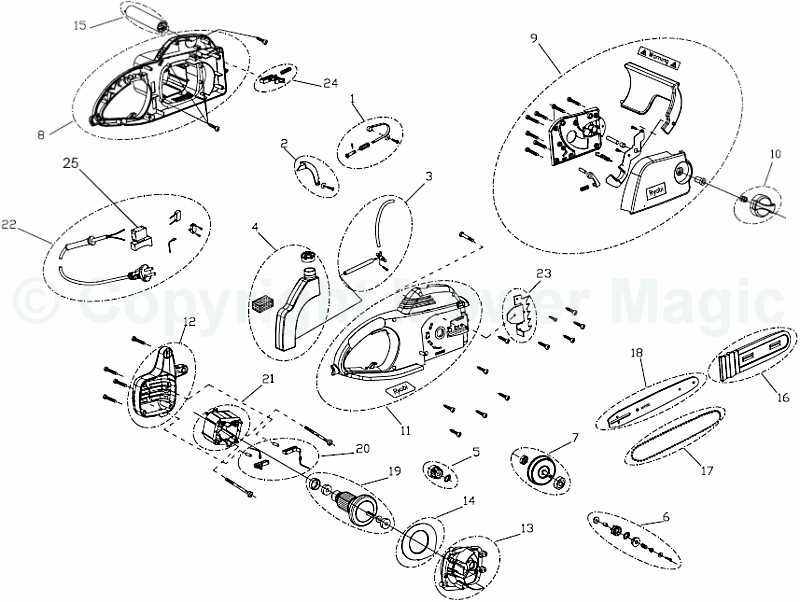

In this section, we will delve into a detailed visual representation of the various components that make up this specific type of cutting equipment. This representation will serve as a valuable resource for those looking to identify parts, facilitate repairs, or simply gain a deeper understanding of their tool. Recognizing how each element interacts will empower users to handle their equipment with greater confidence.

By examining this visual guide, enthusiasts and professionals alike can better appreciate the craftsmanship involved in the design of their chainsaw. This knowledge not only aids in routine upkeep but also fosters a stronger connection between the user and their trusted tool.

Overview of Stihl 009 Components

This section provides a comprehensive look at the essential elements that make up the machinery, focusing on their functionalities and interrelationships. Understanding these components is crucial for effective maintenance and repair, ensuring the equipment operates efficiently and reliably.

Key Elements and Their Functions

The main components play significant roles in the overall performance of the equipment. Each element is designed to contribute to the seamless operation, whether it’s the engine’s functionality, the fuel delivery system, or the cutting mechanism. A thorough grasp of these parts enables users to troubleshoot issues and optimize performance.

Maintenance and Care Tips

Regular upkeep of these essential elements is vital for longevity and efficiency. Users should periodically check for wear and tear, ensuring all components function properly. Utilizing appropriate lubricants and following recommended service intervals can significantly enhance the lifespan of the machinery.

Common Issues with Stihl 009

When working with outdoor power equipment, various challenges can arise that impact performance and reliability. Understanding these frequent problems can help users maintain their tools effectively and ensure they operate smoothly.

Engine Performance Problems

Engine-related issues are among the most common. Here are some typical symptoms:

- Difficulty starting the engine

- Unstable idle or stalling

- Excessive smoke during operation

These problems can often be attributed to fuel system issues, such as clogged filters or improper fuel mixtures.

Mechanical Failures

Mechanical components can also fail over time, leading to decreased efficiency. Common signs include:

- Unusual vibrations during use

- Difficulty in chain movement

- Visible wear on the cutting chain or bar

Regular inspections and maintenance can help mitigate these issues and extend the lifespan of the equipment.

Understanding the Parts Breakdown

The breakdown of components provides a clear view of the individual elements that make up a specific machine. By examining this schematic representation, users can gain insights into the function and interaction of each segment within the overall assembly. This understanding is crucial for effective maintenance, repair, and operation.

Each component is labeled in a way that corresponds to its location and role, allowing for easy identification and troubleshooting. This systematic approach helps users navigate through potential issues and enhances their ability to perform repairs accurately. Furthermore, familiarizing oneself with these details promotes better care practices and prolongs the lifespan of the equipment.

Knowing how different segments work together also aids in enhancing performance. Whether it’s for routine upkeep or addressing specific malfunctions, having a comprehensive grasp of the assembly encourages informed decision-making during repairs and upgrades. As a result, users can ensure that their machinery operates efficiently and reliably.

Replacement Parts for Stihl 009

Maintaining your equipment is crucial for optimal performance and longevity. When components wear out or break, sourcing suitable replacements becomes essential to ensure continued functionality. This section outlines the various alternatives available for essential components, focusing on quality and compatibility.

Key components to consider include the engine’s internal mechanisms, fuel systems, and ignition units. Each part plays a vital role in the overall operation of the machine. Ensuring that you have the right replacements can greatly enhance efficiency and reduce the risk of malfunctions.

For those seeking to restore their equipment, reputable suppliers provide a wide range of options, including aftermarket and OEM choices. It’s advisable to select high-quality alternatives to ensure durability and reliability.

Summary: Investing in proper replacement components is an investment in the longevity and reliability of your equipment. By selecting the right parts, users can ensure smooth operation and extend the lifespan of their machines.

Maintenance Tips for Stihl 009

Regular upkeep is essential for ensuring optimal performance and longevity of your outdoor equipment. Proper maintenance routines can prevent unnecessary wear and tear, ultimately saving time and resources. Here are some key practices to keep your machine running smoothly.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Air Filter Cleaning | Every 10 hours | Remove the air filter and clean it to ensure proper airflow and engine efficiency. |

| Chain Lubrication | Before each use | Apply lubricant to the chain to reduce friction and prevent damage during operation. |

| Spark Plug Replacement | Every 25 hours | Check and replace the spark plug as needed to maintain reliable ignition and performance. |

| Fuel System Inspection | Monthly | Inspect fuel lines and filters for leaks or blockages to ensure optimal fuel flow. |

| General Cleaning | After each use | Clean the exterior of the machine to prevent dirt accumulation that could affect performance. |

Tools Required for Repairs

When undertaking maintenance or repair tasks, having the right equipment is essential for achieving optimal results. Proper tools not only enhance efficiency but also ensure that the work is completed safely and effectively. This section outlines the necessary instruments that can facilitate repairs, making the process smoother and more manageable.

Basic Hand Tools

Among the fundamental items, a set of reliable hand tools is crucial. This includes screwdrivers, wrenches, and pliers, which allow for the easy assembly and disassembly of components. Having a variety of sizes can help address different fasteners that may be encountered during the repair process.

Specialized Equipment

In addition to standard tools, specialized equipment may be needed to address specific issues. Socket sets and torque wrenches are invaluable for tightening bolts to the correct specifications. Furthermore, having access to a quality cleaning kit ensures that all parts are free from debris, allowing for smoother operation and longevity.

Finding Stihl 009 Parts Online

Locating components for your equipment has become increasingly accessible through various online platforms. Many websites specialize in offering an extensive selection of spare parts, making it easy for users to find what they need without visiting physical stores. This section will explore the best strategies and resources for acquiring the necessary elements for your machine efficiently.

Utilizing Official Retailers

Official distributors often provide a comprehensive inventory of components, ensuring quality and compatibility. It is advisable to check their websites for availability and specific models. These retailers typically offer detailed catalogs, which can be very helpful when searching for the correct items.

Exploring Third-Party Websites

Numerous online marketplaces also feature a wide range of spare components. These platforms may offer competitive pricing and various shipping options. When utilizing these resources, it is essential to verify the reliability of the sellers and read customer reviews to ensure a satisfactory purchase experience.

| Website | Type | Notes |

|---|---|---|

| Official Retailer | Authorized Parts | Quality guaranteed |

| eBay | Third-Party Sellers | Varied pricing |

| Amazon | Third-Party and New | Fast shipping options |

| Local Classifieds | Used Components | Potential for bargains |

Identifying OEM vs. Aftermarket Parts

Understanding the difference between original equipment manufacturer (OEM) components and aftermarket alternatives is crucial for maintaining equipment efficiency and longevity. While both options serve similar purposes, their origins, quality, and performance can vary significantly. Making an informed choice can impact both the functionality and durability of your machinery.

Characteristics of OEM Components

- Manufactured by the original brand or a licensed company.

- Designed to meet the exact specifications of the machinery.

- Often comes with a warranty, ensuring reliability.

- Tend to be more expensive due to quality assurance.

Features of Aftermarket Alternatives

- Produced by third-party companies, not affiliated with the original brand.

- Can vary widely in quality and compatibility.

- Typically more affordable, offering a budget-friendly option.

- Some may provide enhanced performance or additional features.

Choosing between OEM and aftermarket components involves evaluating factors such as cost, quality, and intended use. Always consider the specific requirements of your equipment to ensure optimal performance.

Assembly Instructions for Stihl 009

Proper assembly of the equipment is crucial for optimal performance and safety. Following systematic steps ensures that each component fits correctly and functions effectively.

Before beginning, gather all necessary tools and components. Familiarize yourself with the parts and their designated locations.

- Prepare the Workspace:

- Clear a spacious area free from debris.

- Ensure good lighting for visibility.

- Have a clean surface for organizing components.

- Inspect Components:

- Check each part for damage or wear.

- Ensure all components are available as per the assembly list.

- Assemble the Base:

- Start with the base structure, ensuring it is stable.

- Attach the engine securely to the base using the designated fasteners.

- Install Additional Parts:

- Carefully fit the fuel tank in place, ensuring seals are tight.

- Attach the handle, making sure it is ergonomically positioned.

- Connect the exhaust system, checking for proper alignment.

- Final Checks:

- Verify that all fasteners are tightened appropriately.

- Ensure no loose components remain.

- Check fluid levels before initial operation.

Following these steps will help in achieving a well-assembled machine ready for use. Always refer to the specific instructions provided for each part for detailed guidance.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount to avoid accidents and injuries. Adhering to proper guidelines and taking necessary precautions will facilitate a secure working environment. This section highlights essential safety measures to implement before, during, and after repairs.

Preparation and Personal Protective Equipment

Before starting any repair work, it is crucial to prepare adequately. Wearing appropriate personal protective equipment (PPE) can significantly reduce the risk of injuries. The following items are recommended:

| Type of Equipment | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris and chemicals |

| Gloves | Provides hand protection from sharp edges and chemicals |

| Ear Protection | Reduces exposure to loud noise |

| Steel-Toed Boots | Protects feet from heavy objects |

Proper Workspace Setup

Establishing a clean and organized workspace is essential for safety. Ensure that tools and materials are arranged systematically to avoid hazards. Adequate lighting should be provided to enhance visibility, and any clutter should be cleared to prevent trips and falls.

Frequently Asked Questions on Parts

This section addresses common inquiries regarding components and their functionality in machinery. Understanding the various elements is essential for maintenance and repair, ensuring that users can effectively manage their equipment.

- What are the essential components of the equipment?

Essential elements include the motor, fuel system, and cutting mechanisms, each playing a vital role in performance.

- How can I identify the right components for my machine?

Refer to the manufacturer’s manual or consult authorized dealers for accurate identification.

- Are replacement components readily available?

Yes, many authorized retailers stock replacements for common elements, while specialized parts can be ordered as needed.

- What should I do if I encounter issues with a specific component?

Consult troubleshooting guides or contact customer support for assistance with any problems related to the equipment.

- Is regular maintenance necessary for optimal performance?

Yes, routine checks and servicing are crucial to extend the lifespan and efficiency of all parts.