The efficient functioning of any cutting tool relies heavily on its individual components and their arrangement. A comprehensive overview of these elements is essential for proper maintenance and troubleshooting. By gaining insights into how these pieces fit together, users can ensure optimal performance and longevity of their equipment.

In this section, we will explore the intricate details of the assembly, highlighting the role of each component in the overall mechanism. This knowledge empowers users to make informed decisions when it comes to repairs or replacements, enhancing their operational efficiency.

Whether you are a seasoned professional or a weekend enthusiast, familiarizing yourself with the layout and interaction of the various elements will greatly enhance your experience. Understanding these relationships not only aids in maintenance but also boosts confidence in handling your tools effectively.

Understanding the Stihl 017 Chainsaw

This section aims to provide insight into a specific model of a power tool widely used for cutting tasks. Recognizing its features and components is crucial for effective operation and maintenance.

Key characteristics include:

- Lightweight design for ease of handling

- Efficient engine for reliable performance

- Durable materials for extended longevity

Understanding the core elements enhances the user experience. Key components to consider are:

- Engine assembly

- Cutting chain

- Guide bar

- Air filter

Familiarity with these aspects will ultimately lead to better usage and maintenance practices.

Importance of Parts Diagrams

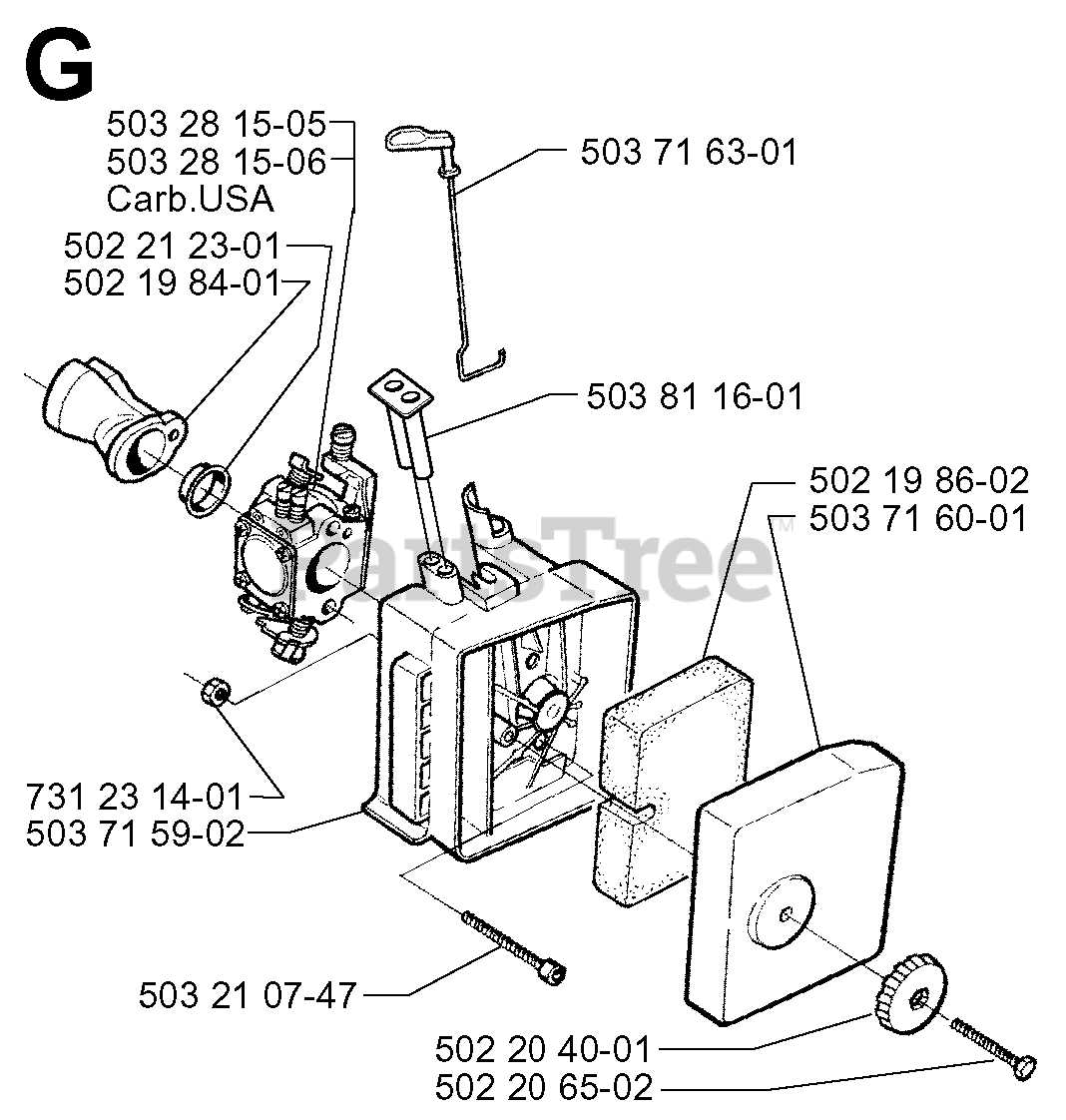

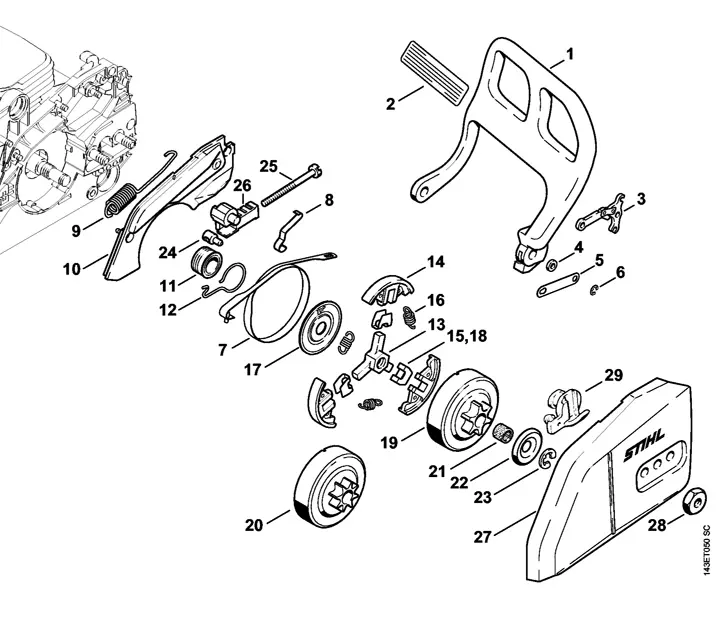

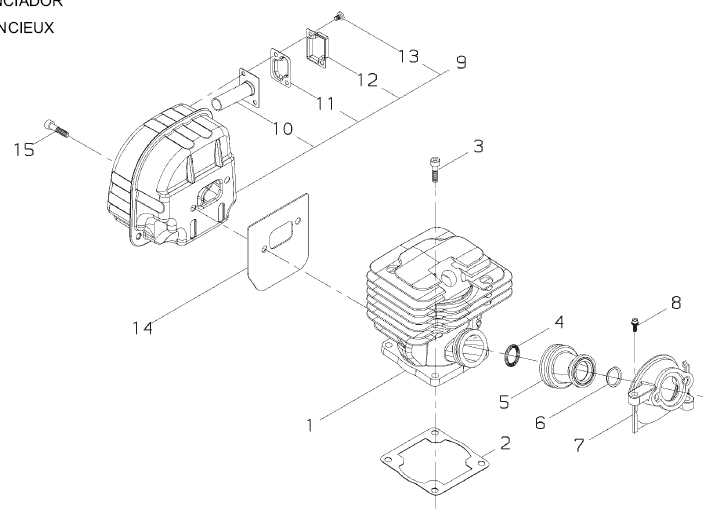

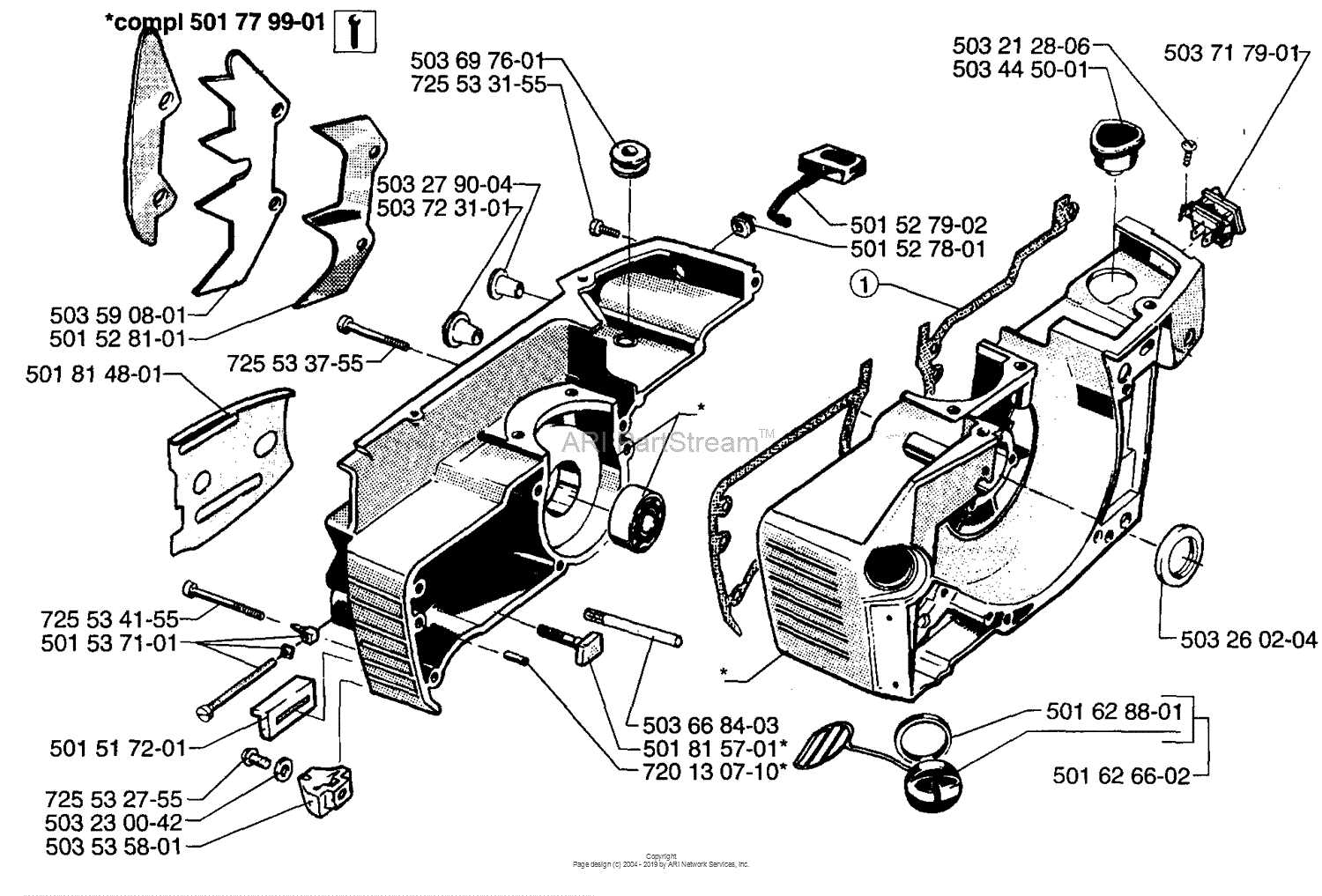

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations of components provide crucial insights that facilitate troubleshooting and enhance the overall efficiency of the equipment. These illustrations serve as a valuable resource for both novice and experienced users, guiding them through the assembly and disassembly processes with clarity.

Detailed visuals assist in identifying individual elements, ensuring that every piece is accounted for during maintenance tasks. This clarity helps in preventing errors that could arise from misidentifying components or overlooking critical parts. Furthermore, having access to such resources promotes a deeper understanding of how various elements interact within the machinery, ultimately leading to more informed decisions regarding repairs and upgrades.

Additionally, these visual aids often come with annotations and descriptions that provide context for each component’s function. This added layer of information empowers users to address issues more confidently, reducing the reliance on external expertise. As a result, possessing a comprehensive understanding of the machinery not only enhances user satisfaction but also extends the lifespan of the equipment.

Key Components of Stihl 017

Understanding the essential elements of this chainsaw is crucial for effective maintenance and optimal performance. Each component plays a vital role in ensuring the machine operates smoothly and efficiently, making it important for users to familiarize themselves with these parts.

The power unit, which includes the engine, provides the necessary force to drive the saw chain. The cutting system, comprising the guide bar and chain, is responsible for executing the cutting action. Proper lubrication of the chain is facilitated by the oil pump, ensuring longevity and reduced friction during operation.

The ignition system, including the spark plug and coil, is fundamental for starting the engine and maintaining its operation. Additionally, the air filter prevents debris from entering the engine, enhancing its performance and durability. The fuel system, which consists of the fuel tank and carburetor, is vital for mixing the right amounts of air and fuel for combustion.

Finally, the safety features, such as the chain brake and throttle lock, are critical for user protection. Each of these components works together harmoniously, contributing to the overall functionality and reliability of the tool.

How to Access the Diagram

Understanding the layout of components is essential for effective maintenance and repairs. By obtaining a visual representation, users can easily identify the parts and their arrangement, facilitating smoother servicing. This section will guide you through the steps to access this valuable resource.

Online Resources

The internet offers various platforms where you can find the necessary illustrations. Here are some popular websites that provide detailed layouts:

| Website | Description |

|---|---|

| Manufacturer’s Site | Official website offering comprehensive guides and visuals. |

| Repair Forums | Community-driven platforms with shared diagrams and insights. |

| Online Retailers | Sites selling components often include visuals in their listings. |

Local Repair Shops

Visiting a local service center can also provide direct access to physical copies or digital resources. Technicians often have access to manufacturer materials and can assist in locating the right visual aids for your needs.

Common Replacement Parts Needed

Regular maintenance of your equipment is essential for optimal performance and longevity. Over time, certain components may wear out or require replacement to ensure smooth operation. Here are some frequently needed items that owners should keep in mind.

- Chains: Essential for cutting, these components can become dull or damaged and may need replacement periodically.

- Sprockets: These gears work in tandem with the chains and can wear down, affecting efficiency.

- Filters: Air and fuel filters are crucial for maintaining clean operation and should be replaced as needed.

- Plugs: Spark plugs can wear out, leading to starting issues or decreased performance.

- Fuel Lines: Over time, these can become brittle or cracked, causing leaks that need to be addressed promptly.

Staying on top of these common replacements will help maintain the functionality of your machinery and prolong its lifespan.

Identifying Parts by Diagram

Understanding the components of your equipment is essential for effective maintenance and repairs. Visual representations can significantly aid in recognizing and locating each element, ensuring a smooth workflow during tasks. By leveraging these illustrations, users can become more proficient in managing their tools and addressing any issues that arise.

Benefits of Visual References

Utilizing graphical aids allows for quicker identification of individual elements, reducing the time spent troubleshooting. It also enhances the accuracy of replacements, as users can match old components with their new counterparts, ensuring compatibility and functionality.

How to Use Illustrations Effectively

To maximize the benefits of these visuals, start by familiarizing yourself with the layout. Take note of labeled sections and corresponding parts, and refer to the diagram regularly during maintenance to reinforce your understanding. This approach will ultimately lead to a more efficient and effective repair process.

Maintenance Tips for Stihl 017

Proper upkeep is essential for ensuring optimal performance and longevity of your equipment. Regular attention to various components can prevent potential issues and enhance efficiency. Adopting a systematic approach to maintenance will lead to smoother operation and reduced wear over time.

Regular Cleaning

Keep your machine clean by removing debris after each use. This prevents build-up that can lead to overheating and mechanical failures. Use a soft brush or compressed air to clear away dirt from air filters and cooling fins.

Inspection of Components

Regularly inspect essential parts for signs of wear or damage. Pay close attention to the chain, bar, and spark plug. Replacing worn-out components promptly will help maintain peak functionality. Lubrication is also crucial; ensure that moving parts are adequately greased to prevent friction-related issues.

Where to Find Genuine Parts

Finding authentic components for your outdoor power equipment is essential for maintaining optimal performance and longevity. Genuine items ensure compatibility and reliability, reducing the risk of malfunction and enhancing the overall user experience. Below are some effective avenues to explore when searching for original replacements.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealers. These establishments typically offer:

- Wide selection of original components

- Expert advice from knowledgeable staff

- Warranty protection on purchased items

Online Retailers

Numerous online platforms specialize in outdoor equipment components. When shopping online, consider the following:

- Look for reputable websites that guarantee authenticity.

- Read customer reviews to assess reliability.

- Check for return policies to safeguard your purchase.

Utilizing these sources will help ensure you obtain the quality components necessary for your machinery.

Comparison with Other Stihl Models

This section explores how a specific model stacks up against its counterparts in the same brand lineup. By examining features, performance metrics, and usability, users can make informed decisions based on their individual needs and preferences.

Performance and Features

When comparing various models, it’s essential to consider key aspects such as engine power, weight, and operational capabilities. Here are some notable comparisons:

- Engine Power: The selected model typically offers a robust engine suited for both light and heavy-duty tasks, while others may focus on efficiency or portability.

- Weight: Many options differ in weight, affecting maneuverability and user comfort during extended use.

- Cutting Efficiency: Blade designs and chain speed can vary, impacting overall cutting performance.

Usability and Maintenance

Ease of use and maintenance are crucial factors for many users. Here’s how different models compare:

- Ergonomics: Some models are designed with enhanced grip and balance, reducing fatigue during operation.

- Maintenance Requirements: While some require frequent servicing, others boast features that simplify upkeep.

- User-Friendliness: Variations in controls and features may cater to both novice and experienced users differently.

Tools Required for Repairs

Proper maintenance and restoration of equipment necessitate a specific set of instruments. Having the right tools at hand not only facilitates the repair process but also ensures safety and efficiency while working. A well-equipped workspace can make a significant difference in achieving successful outcomes.

Essential Instruments

Basic tools such as screwdrivers, wrenches, and pliers are fundamental for any repair task. Additionally, a torque wrench can provide the ultimate precision needed for reassembling components. Ensuring you have a variety of sizes will allow you to tackle different challenges effectively.

Specialized Equipment

For more intricate repairs, consider investing in specialized instruments like chain saw files and spark plug sockets. These tools enhance your ability to delve deeper into complex issues, ensuring thorough examination and accurate adjustments. The right equipment not only simplifies repairs but also prolongs the life of your machinery.

Safety Precautions During Repairs

When undertaking maintenance or repair tasks on any mechanical equipment, it is essential to prioritize safety. Proper precautions not only protect the individual performing the work but also help prevent damage to the equipment itself. Understanding the potential hazards and taking proactive steps can significantly reduce the risk of accidents and injuries.

Always wear appropriate personal protective equipment, such as gloves, safety goggles, and sturdy footwear. This gear serves as a first line of defense against sharp objects, flying debris, and accidental contact with moving parts. Additionally, ensure that the workspace is well-lit and free of clutter to minimize the risk of tripping or other mishaps.

Before beginning any repair, disconnect the power source to eliminate the possibility of unexpected starts. Familiarize yourself with the specific components and mechanisms of the equipment to avoid incorrect handling. Utilizing the right tools and following manufacturer guidelines can prevent unnecessary accidents.

Finally, it is advisable to work in pairs or have someone nearby in case assistance is needed. By adhering to these safety measures, you can create a secure environment that allows for effective and efficient repairs.

Frequently Asked Questions About Stihl 017

This section addresses common inquiries regarding a specific model of power equipment, providing clarity and useful insights for users and enthusiasts alike. Below are some frequently asked questions that can help guide your understanding and maintenance of this tool.

General Information

- What type of fuel is recommended for optimal performance?

- How often should I perform routine maintenance?

- Are there any specific safety precautions to consider?

Troubleshooting

- What should I do if the engine won’t start?

- How can I address issues with the cutting chain?

- What are common signs of wear and tear?