For those working with outdoor equipment, it’s essential to have a clear understanding of how various elements fit together. The efficient functioning of any machine relies on the correct assembly and condition of its individual parts. In this guide, we’ll explore the essential components, helping you ensure everything operates as intended.

By identifying the correct layout and knowing the role each piece plays, you can easily maintain and repair your equipment. This overview will help you navigate through the most important elements, ensuring smooth and uninterrupted operation for your tasks.

Additionally, this guide provides insights into

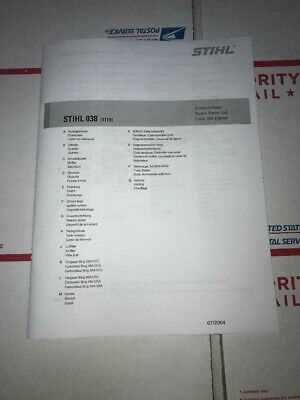

Comprehensive Guide to Stihl 038 Magnum Components

Understanding the key elements of a powerful cutting tool is essential for ensuring optimal performance and longevity. This guide covers the most crucial components that work together to maintain the efficiency and reliability of the machine. Whether you’re handling maintenance or just looking to better understand its mechanisms, each part plays a significant role in smooth operation.

Engine Assembly is the heart of the machine, converting fuel into mechanical energy. Proper upkeep of this system ensures consistent power output and extended service life.

The starter mechanism initiates the operation, allowing the

Essential Parts for Smooth Operation

For effective and reliable performance, it is crucial to focus on key components that ensure the machine runs smoothly. These vital elements work together, guaranteeing durability and precision during operation. Regular attention to these aspects helps maintain functionality and avoids unexpected breakdowns.

| Component | Function | Maintenance Tips | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Housing | Protects internal mechanisms and supports heat dissipation. |

| Component | Function | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | Provides the power necessary to drive the system, converting fuel into energy. | ||||||||||||||

How to Identify Common Wear Parts

Regular maintenance of any cutting tool involves recognizing the signs of wear in its essential components. Understanding which elements are prone to wear and tear ensures that replacements are made in time, improving the longevity and performance of the equipment. Examine the Cutting Teeth: One of the most critical components to monitor is the set of cutting edges. Dullness, chipped edges, or uneven surfaces are clear indicators that it’s time for sharpening or replacement. Check the Drive Links: The connecting links that facilitate the smooth rotation of the chain Crucial Sections for Regular MaintenanceEnsuring the longevity and efficient operation of your equipment relies heavily on routine upkeep. Identifying essential areas for regular care can significantly enhance performance and prevent potential malfunctions. This section outlines the vital components that require attention during maintenance tasks. Key Components for CareRegularly inspecting and servicing critical elements can prevent unexpected breakdowns and ensure optimal functionality. Focus on the following sections:

Importance of Consistent MaintenanceRegular attention to these crucial areas not only extends the life of your equipment but also enhances safety during operation. Consistent upkeep can lead to more efficient performance, reducing the likelihood of costly repairs in the long run. Optimizing Chainsaw Performance with Proper ComponentsEnhancing the efficiency of a cutting tool significantly relies on the selection and maintenance of its various elements. Each component plays a crucial role in ensuring optimal functionality and longevity. Understanding how to choose and care for these parts can lead to improved performance and a more satisfying user experience. Key Components to Consider

Maintenance Practices for Longevity

Replacing Vital Components for LongevityEnsuring the durability and optimal performance of a mechanical device relies heavily on the timely replacement of its essential elements. By addressing wear and tear promptly, users can significantly enhance the lifespan and efficiency of their equipment. This practice not only promotes reliability but also reduces the likelihood of unexpected failures during operation. Identifying Key Elements for ReplacementIt is crucial to recognize which components are vital for sustained functionality. Elements such as the cutting mechanism, drive system, and power unit play significant roles in overall performance. Regular inspection can help in identifying any signs of damage or degradation, allowing for proactive maintenance. Benefits of Timely Component ReplacementReplacing worn or damaged components not only improves performance but also contributes to safety. A well-maintained unit operates more efficiently, consuming less energy and producing better results. Furthermore, regular updates to critical parts can prevent costly repairs and extend the operational life of the equipment. Tips for InspectingRegular examination of your cutting tool is essential for ensuring optimal performance and longevity. By conducting routine inspections, you can identify potential issues before they escalate, thereby maintaining the efficiency and safety of your equipment. Visual AssessmentBegin by performing a thorough visual check of the exterior components. Look for signs of wear, damage, or accumulation of debris. Ensure that all parts are securely attached and free from cracks or breaks that could affect operation. Functional TestingAfter the visual inspection, proceed with functional testing. Start the equipment and observe its performance closely. Listen for unusual noises and watch for any irregular movements that may indicate underlying problems. Addressing these concerns promptly can prevent further complications and ensure reliable operation. |