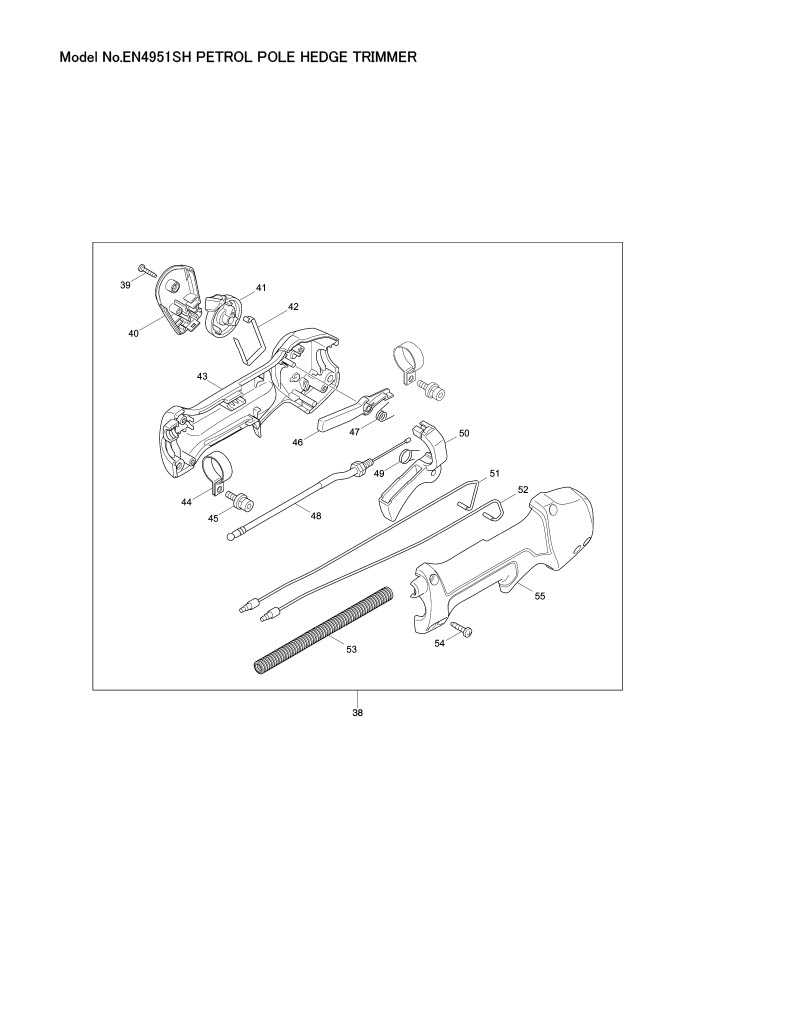

Exploring the structural blueprint of essential machinery allows for better insight into how various elements interact to ensure efficient performance. By gaining a clearer picture of the internal layout, users can more effectively maintain, troubleshoot, and repair complex equipment, keeping it running smoothly for longer periods of time.

Each segment of this blueprint serves a critical role, contributing to the overall functionality. Recognizing these individual elements and understanding their placement can empower users to address potential issues and ensure the longevity of their machine.

Accurate identification and effective organization of the core components are vital for anyone looking to keep their machinery in

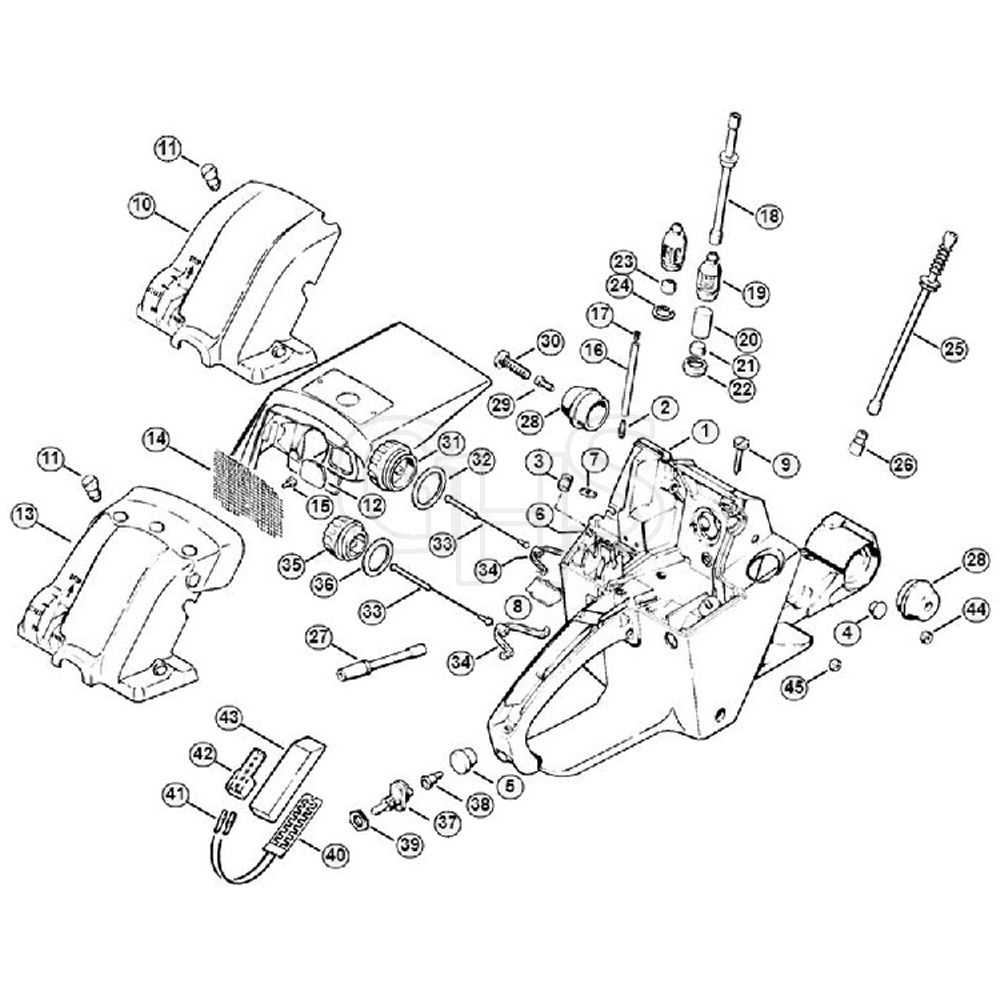

Stihl 048 Parts Diagram Overview

Understanding the layout and structure of a tool’s components is essential for proper maintenance and repairs. A clear representation of how each element fits together provides invaluable insight for anyone looking to keep their equipment in top working condition.

Component breakdowns are commonly used to illustrate the arrangement of internal and external elements, ensuring easy identification and replacement. By

Key Components of Stihl 048 Chainsaw

Understanding the main elements of a professional-grade chainsaw is essential for proper maintenance and long-lasting performance. Each piece plays a vital role in ensuring smooth operation and optimal efficiency during use. Regular inspection of these crucial parts will help extend the tool’s lifespan and improve safety.

Engine assembly is the heart of the machine, powering the blade’s movement and determining the overall cutting performance. Proper care of this part is critical for smooth functionality, especially in demanding tasks.

The chain mechanism ensures precision in cutting and relies on regular sharpening and tension adjustments. Keeping the

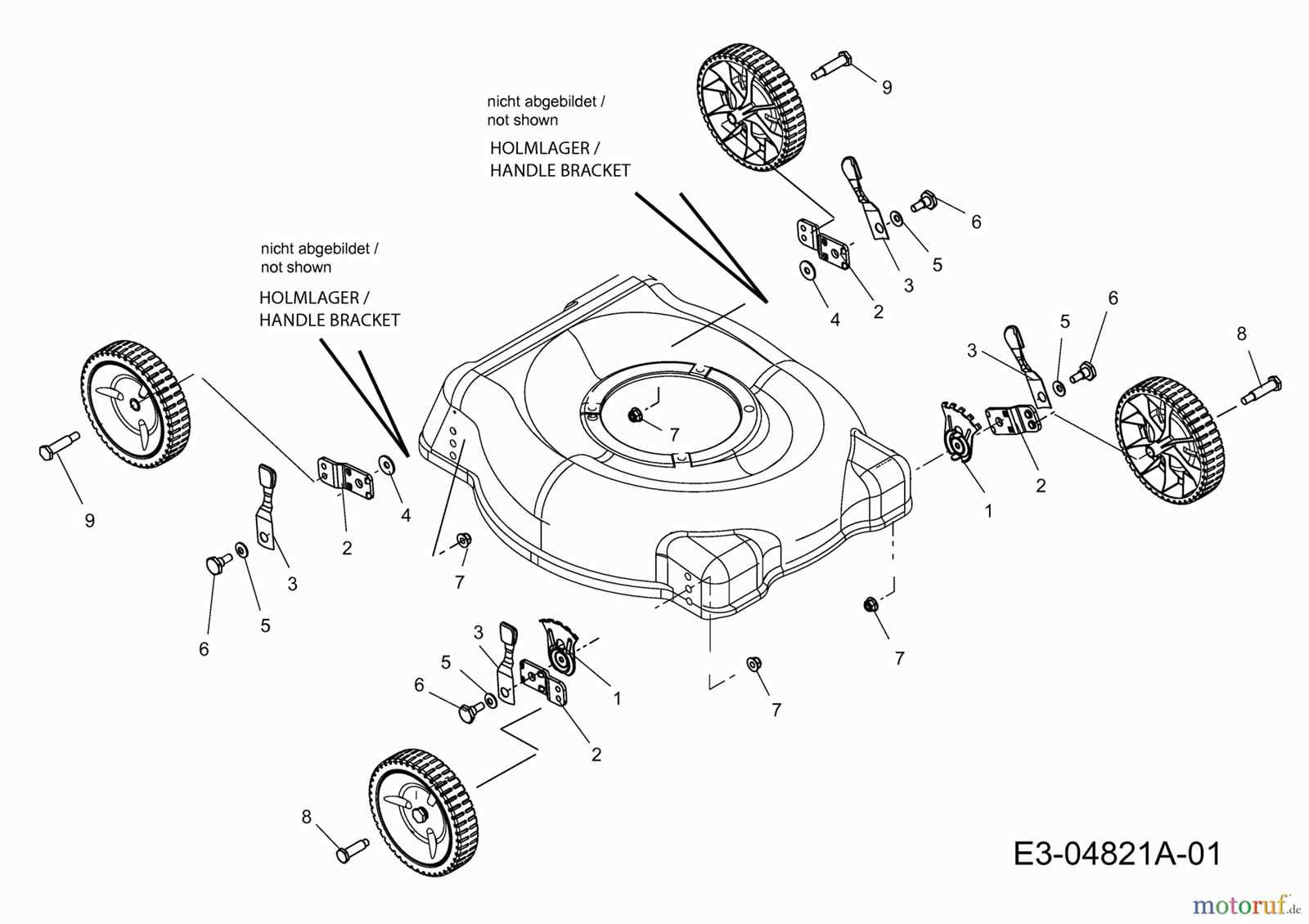

Understanding the Engine Assembly Layout

The arrangement of the engine components is crucial for the overall performance of any machine. Knowing how these elements are organized helps in maintenance and repair, ensuring efficiency and longevity. The layout provides a logical sequence, making it easier to identify and work on specific areas of the power unit.

Key Sections of the Engine

- Crankshaft and connecting rod placement

- Piston configuration and alignment

- Cooling system setup and pathways

Component Connectivity

- Fuel intake and carburetor arrangement

- Exhaust system routing

- Guide to the Ignition System Components

The ignition mechanism plays a crucial role in ensuring the proper functioning of any internal combustion engine. By generating the necessary spark at the right moment, it initiates the combustion process, powering the engine effectively. This section outlines the key elements involved in this essential system, providing a deeper understanding of their function and interaction.

Primary Components Overview

The ignition system comprises several interconnected parts. Each component contributes to delivering a consistent and reliable spark to ignite the fuel. Below is a breakdown of the most vital elements:

Component Exploring the Fuel System Diagram

The structure of the fuel delivery mechanism is key to ensuring efficient performance and reliability. By understanding its layout, users can maintain, troubleshoot, and repair their machines more effectively. The arrangement of components allows for smooth fuel flow and proper combustion, leading to optimal functionality.

Key Components of the Fuel System

Several crucial elements make up the fuel system. These include the fuel tank, filters, and the lines that connect them. Each of these

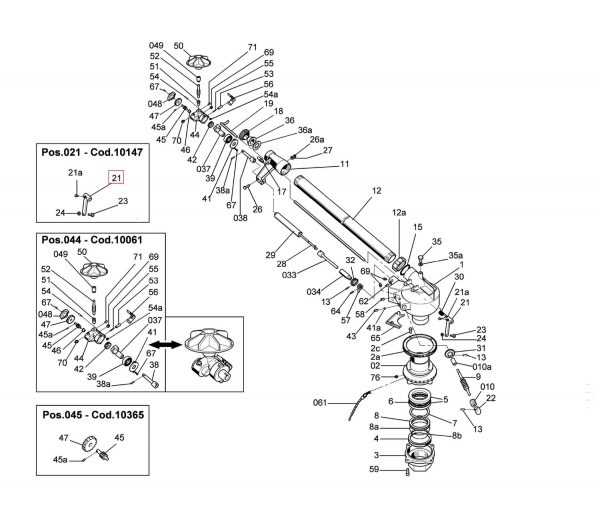

Chain and Bar Parts Breakdown

The functioning of cutting equipment relies heavily on the components that facilitate smooth operation. Understanding these essential elements is crucial for maintaining efficiency and performance during usage. This section delves into the various components associated with the cutting chain and guide bar.

Guide Bar: The guide bar serves as the foundation for the chain, allowing it to rotate and cut effectively. This elongated metal component must be durable and properly maintained to ensure optimal performance.

Cutting Chain: The cutting chain consists of interlinked segments designed to slice through wood with precision. Each segment features sharp teeth that engage with the material, enabling efficient cutting action. Regular inspection and sharpening of these teeth are vital for maintaining cutting efficiency.

Drive Links: Drive links are the elements that connect the chain to the power source. They fit into the guide bar groove and enable the chain to move smoothly around the bar. Ensuring that these links are intact and properly lubricated is essential for preventing wear and tear.

Chain Tensioner: The chain tensioner allows for the adjustment of the chain’s tightness, ensuring it operates safely and effectively. Proper tension is critical to prevent slippage or breakage during use, making this component an important aspect of equipment maintenance.

How to Identify Carburetor Parts

Understanding the various components of a fuel mixing device is crucial for effective maintenance and troubleshooting. Recognizing these elements allows for better servicing and enhances the overall performance of the engine. Each component plays a significant role in the proper functioning of the system, making identification a key skill for operators.

The following table outlines the primary components and their functions:

Component Function Float Regulates the fuel level within the chamber Jet Controls the fuel flow into the mixing chamber Diaphragm Maintains fuel pressure and regulates flow Needle Valve Stops or allows fuel flow into the chamber Throttle Valve Controls the airflow and engine speed Starter Mechanism Parts Explanation

The starter assembly is crucial for initiating the operation of outdoor power equipment. This section delves into the individual components of the mechanism, explaining their functions and how they contribute to the overall efficiency of the system. Understanding these elements is essential for effective maintenance and troubleshooting.

Key Components of the Mechanism

At the heart of the starting assembly lies the recoil spring, which provides the necessary tension to retract the starter cord after use. The starter cord itself is typically wound around a pulley, allowing for smooth operation when the user engages the handle. In addition, the pawls play a vital role in engaging the flywheel, ensuring that the engine cranks effectively.

Functionality and Maintenance Tips

Regular inspection of these components can prevent common issues such as cord breakage or failure to start. Ensuring that the recoil spring is properly tensioned and the pawls are free of debris will enhance the reliability of the mechanism. Regular maintenance not only extends the life of the starter assembly but also ensures optimal performance during operation.

Air Filter and Muffler Components

The air intake system plays a crucial role in the performance of an engine, ensuring optimal combustion by filtering out contaminants. Key elements of this system include the air filter and muffler, both of which contribute to the efficiency and longevity of the machinery.

Air filters are designed to trap dirt and debris before they can enter the engine. Maintaining a clean filter is essential for peak performance. The muffler, on the other hand, reduces noise and directs exhaust gases away from the engine, enhancing the overall functionality.

Key Components of the Air Filter

- Filter Element: The main part that captures dust and particles.

- Housing: The casing that holds the filter securely in place.

- Seals: Ensure a tight fit to prevent unfiltered air from entering.

Essential Parts of the Muffler

- Shell: The outer structure that houses the internal components.

- Sound Dampening Material: Reduces noise created by exhaust gases.

- Exhaust Inlet and Outlet: Pathways for the gases to enter and exit.

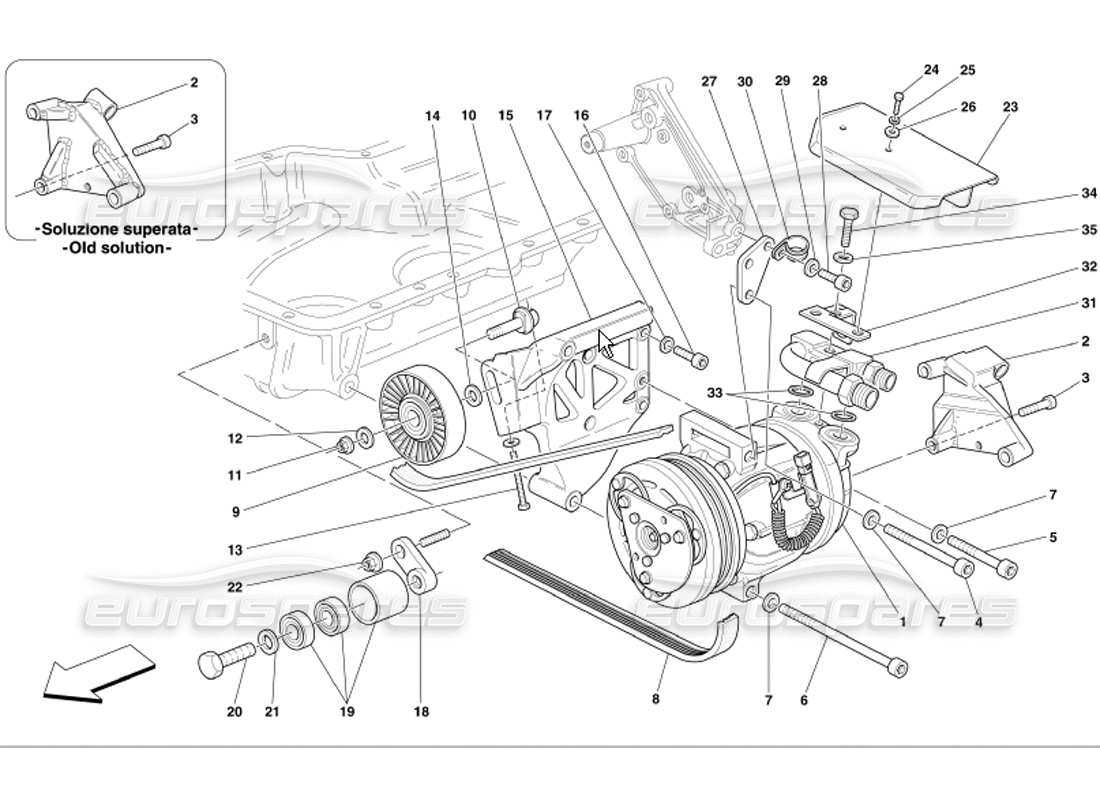

Clutch and Drive System Breakdown

The clutch and drive mechanism is essential for the effective operation of outdoor power equipment, allowing for controlled power transfer from the engine to the cutting tool. This system consists of various components working together to ensure smooth engagement and disengagement during operation.

Key Components

The primary elements of this assembly include the friction clutch, drive shaft, and associated bearings. The friction clutch is responsible for connecting and disconnecting the engine’s power to the tool, enabling precise control over the cutting action. The drive shaft transmits this power, while bearings support smooth rotation and reduce wear.

Maintenance Considerations

Regular inspection and maintenance of the clutch and drive system are crucial for optimal performance. Users should check for wear on the friction surfaces, ensure proper lubrication, and replace any damaged components promptly. Addressing these issues helps maintain efficiency and prolongs the life of the equipment.

Maintenance Tips for Stihl 048 Parts

Regular upkeep of your equipment is essential for optimal performance and longevity. Understanding the components and their care can prevent unnecessary breakdowns and enhance efficiency. By following a few straightforward practices, you can ensure that your machinery remains in excellent condition, providing reliable service for years to come.

Routine Inspections: Conduct frequent checks of all essential components to identify any wear or damage early on. Look for signs of fraying, corrosion, or loose connections, and address these issues promptly to avoid more significant problems.

Proper Lubrication: Ensure that moving parts are well-lubricated to minimize friction and wear. Using the correct type of lubricant will help maintain smooth operation and prolong the life of each component.

Cleanliness is Key: Keep the equipment clean from debris and buildup. Regularly remove dust and dirt from surfaces, as this can impede performance and lead to overheating or malfunctioning.

Follow Manufacturer Guidelines: Adhering to the recommended maintenance schedule and using appropriate replacement components will ensure that your equipment runs efficiently and safely. Refer to your manual for specific instructions related to care and upkeep.