In the realm of outdoor equipment, a comprehensive grasp of the various elements that make up a well-engineered machine is essential for both enthusiasts and professionals alike. Recognizing how each part functions and interconnects enhances the overall performance and longevity of the device. This knowledge not only empowers users to maintain their equipment effectively but also to troubleshoot issues with greater confidence.

Exploring the intricate assembly of a particular model unveils a wealth of information about its design and operation. By delving into the specifics of its construction, one can appreciate the engineering prowess that contributes to its reliability and efficiency. Each component plays a pivotal role, and understanding these roles can lead to more informed decisions regarding repairs and upgrades.

Furthermore, visual representations of these elements can greatly aid in this understanding. Clear illustrations highlight the relationships between different sections, making it easier to identify where improvements or replacements are needed. Such resources are invaluable for those looking to optimize their tools, ensuring they remain in peak condition for years to come.

Understanding the Stihl 051 Chainsaw

This section explores the intricacies of a renowned cutting tool designed for efficiency and durability. Whether for professional or personal use, grasping its components and functionality can enhance performance and maintenance. A deeper understanding fosters better handling and longevity.

Key Features

Equipped with a powerful engine, this device boasts excellent cutting capabilities. Its lightweight design ensures ease of maneuverability, while advanced safety features provide peace of mind during operation. Additionally, the ergonomic handle contributes to user comfort, making it suitable for extended use.

Maintenance Tips

Regular upkeep is essential for optimal performance. Keep the chain sharp and clean, and routinely check the fuel mixture. Understanding the machine’s requirements not only improves efficiency but also extends its lifespan. Investing time in maintenance can yield significant long-term benefits.

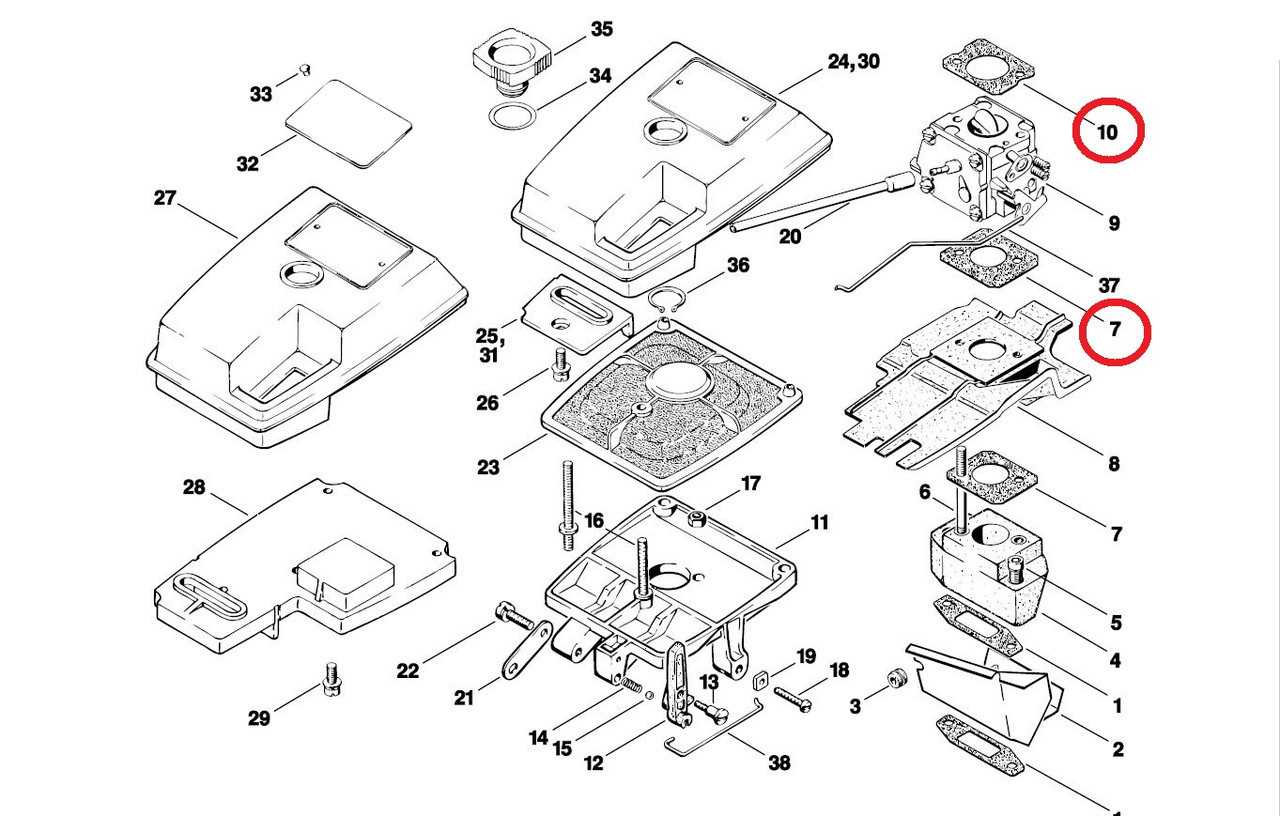

Parts Breakdown for Stihl 051

This section provides a comprehensive overview of the various components that make up the tool. Understanding these elements is essential for effective maintenance, repair, and overall performance enhancement.

Essential Components

- Engine Assembly

- Fuel System

- Ignition System

- Chain Mechanism

- Bar and Chain

Maintenance Tips

- Regularly inspect the fuel system for leaks and clogs.

- Keep the chain sharp for optimal cutting performance.

- Check ignition components for wear and replace as necessary.

- Clean the air filter frequently to ensure proper airflow.

By familiarizing yourself with these crucial elements, you can ensure that your equipment operates efficiently and lasts longer.

Essential Components of the Chainsaw

Understanding the crucial elements of a cutting tool is vital for effective maintenance and operation. Each part plays a specific role, contributing to the overall functionality and efficiency of the device. A well-functioning unit relies on the seamless interaction of these components, ensuring optimal performance during use.

Key Elements

The following table outlines the primary components found in a typical cutting machine, along with their functions:

| Component | Function |

|---|---|

| Engine | Powers the tool and drives the cutting mechanism. |

| Bar | Provides support and guides the chain during operation. |

| Chain | Interacts with the bar to cut through wood. |

| Throttle Trigger | Controls the speed of the engine and chain movement. |

Maintenance and Care

Regular upkeep of these essential parts is crucial for longevity and reliability. Ensuring that each component is in good working condition will enhance performance and safety during operation.

Maintenance Tips for Stihl 051

Regular upkeep is essential for ensuring optimal performance and longevity of your outdoor power equipment. By adhering to a few fundamental practices, you can keep your machinery in top shape, minimizing the risk of breakdowns and enhancing efficiency.

Here are some effective maintenance suggestions to consider:

| Task | Frequency | Description |

|---|---|---|

| Air Filter Cleaning | Every 10 hours | Remove the filter and clean it to prevent dust accumulation, which can hinder engine performance. |

| Chain Oil Check | Before each use | Ensure that the oil reservoir is filled to maintain proper lubrication for the cutting mechanism. |

| Spark Plug Inspection | Every 25 hours | Check for wear and replace if necessary to guarantee reliable ignition. |

| Fuel System Cleaning | Every season | Flush the fuel system and replace old fuel to prevent clogging and ensure smooth operation. |

| Blade Sharpening | As needed | Keep blades sharp for efficient cutting and to reduce strain on the motor. |

By implementing these straightforward practices, you can significantly extend the life of your equipment and enhance its performance. Consistent care not only safeguards your investment but also ensures safety during use.

Common Issues with Stihl 051 Parts

When working with outdoor power equipment, various components may present challenges over time. Understanding these issues can help users maintain optimal performance and longevity of their tools. Below are some frequent concerns that arise with specific elements of these machines.

Frequent Problems

- Fuel System Blockages

- Worn-Out Gaskets and Seals

- Ignition Failures

- Chain Tensioner Malfunctions

- Excessive Vibration

Maintenance Tips

- Regularly check and clean the fuel filter.

- Inspect gaskets and seals for wear and replace if necessary.

- Test the ignition system periodically to ensure reliable starting.

- Adjust the chain tension frequently to prevent damage.

- Balance the equipment to minimize vibration issues.

Addressing these common problems through routine checks and proper maintenance can significantly enhance the efficiency and lifespan of the machinery.

Where to Find Replacement Parts

When it comes to maintaining your outdoor equipment, sourcing quality components is essential for optimal performance. Fortunately, there are several avenues to explore for acquiring the necessary items that can restore functionality and extend the lifespan of your machinery.

Authorized Dealers: One of the most reliable options is to visit authorized dealers. These establishments typically offer genuine components, ensuring compatibility and durability. Additionally, their staff can provide valuable insights and assistance in selecting the right parts for your specific model.

Online Retailers: The internet has opened up a vast marketplace for purchasing components. Numerous websites specialize in outdoor equipment and supply a wide range of items. Always check customer reviews and ratings to ensure the reliability of the seller.

Local Repair Shops: Visiting local repair shops can be advantageous. Many of these businesses maintain a stock of commonly needed components and can often order specific items if they are not readily available. Plus, they might offer expert advice on installation and maintenance.

Second-hand Market: For those on a budget, exploring the second-hand market can yield significant savings. Online platforms and local classifieds often feature listings for used components. Just be sure to assess the condition and functionality before making a purchase.

Whether you opt for authorized dealers, online platforms, local shops, or second-hand options, ensuring you find high-quality items will help keep your equipment running smoothly for years to come.

Upgrading Your Stihl 051 Features

Enhancing the capabilities of your chainsaw can significantly improve its performance and longevity. By implementing strategic upgrades, you can optimize efficiency, increase power output, and enhance user experience. This section explores various modifications that can elevate your tool to meet your specific needs.

Consider replacing the existing cutting chain with a high-performance variant to achieve faster cutting speeds. Additionally, upgrading the air filter and carburetor can result in better fuel efficiency and increased power. Exploring options for vibration dampening systems can also provide a more comfortable operation.

Another avenue for improvement is to invest in a more robust guide bar, which can enhance durability during heavy usage. Accessorizing with advanced safety features will not only protect you but also prolong the lifespan of your equipment. Ultimately, focusing on these upgrades can transform your experience and elevate the tool’s overall effectiveness.

Identifying Original Stihl Components

Recognizing authentic components is crucial for maintaining the efficiency and longevity of your machinery. Original elements are designed specifically for optimal performance, ensuring safety and reliability during use. Understanding how to differentiate between genuine and counterfeit parts can significantly impact the functionality of your equipment.

Key Features of Authentic Components

When examining components, several characteristics can help in identifying originals. Look for consistent branding, precise measurements, and high-quality materials. Additionally, packaging should reflect the manufacturer’s standards, often including serial numbers or authenticity labels.

Comparison Table of Features

| Feature | Original Components | Counterfeit Components |

|---|---|---|

| Branding | Clear and consistent logos | Poorly printed or missing logos |

| Quality | Durable materials | Fragile or inconsistent quality |

| Packaging | Standardized packaging with details | Generic or unmarked packaging |

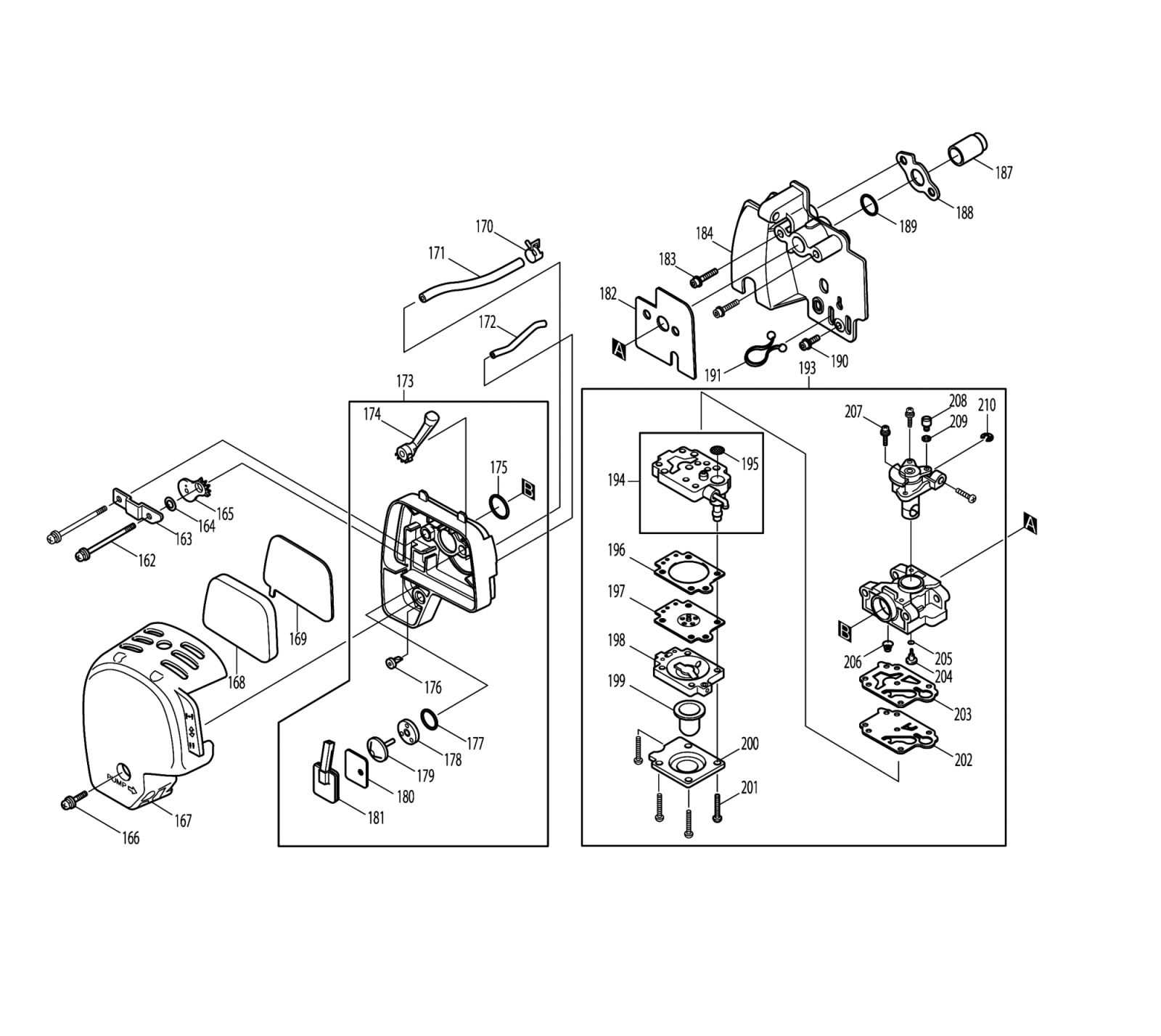

DIY Repair for Stihl 051 Chainsaw

Maintaining and fixing your outdoor power equipment can save you time and money while ensuring optimal performance. With the right knowledge and tools, even complex repairs can be tackled effectively at home. This section will guide you through essential steps to restore your chainsaw, enabling you to keep it running smoothly for all your cutting tasks.

Understanding Common Issues

Before diving into repairs, it’s crucial to identify the typical problems that may arise. Common issues include difficulty starting, erratic idling, and reduced cutting power. These symptoms often point to fuel system blockages, ignition failures, or wear and tear on components.

Essential Tools and Materials

Having the right tools is vital for any repair project. Ensure you have a basic toolkit that includes screwdrivers, wrenches, pliers, and safety equipment like gloves and goggles. Additionally, having replacement parts on hand can expedite the repair process.

Step-by-Step Repair Guide

Start by examining the air filter and fuel lines. Cleaning or replacing a clogged air filter can significantly improve performance. Next, inspect the spark plug for wear; replacing it can often resolve starting issues. If problems persist, check the carburetor for blockages or wear, as this can affect fuel delivery.

Final Tips

Always refer to your equipment’s manual for specific repair guidelines. Regular maintenance, such as cleaning and lubricating moving parts, will help extend the life of your chainsaw. Embrace the challenge of DIY repairs, as they can enhance your understanding of your equipment and improve its longevity.

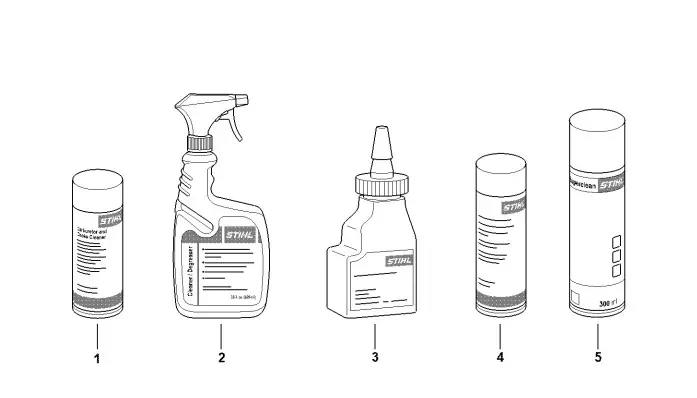

Tools Needed for Stihl Maintenance

Proper upkeep of your outdoor power equipment requires a selection of essential tools. These implements ensure that your machines operate efficiently and last longer, making regular maintenance a straightforward task. Knowing what tools to have on hand can streamline the process and help prevent any potential issues.

Essential Hand Tools

Having the right hand tools is critical for effective maintenance. Commonly used items include wrenches, screwdrivers, and pliers, which are necessary for tightening, loosening, and adjusting various components.

Specialized Equipment

In addition to standard tools, specialized equipment can be beneficial for specific tasks. These may include torque wrenches, diagnostic tools, and cleaning kits designed for outdoor machinery.

| Tool Type | Purpose |

|---|---|

| Wrench | Tightening and loosening bolts and nuts |

| Screwdriver | Adjusting screws in various components |

| Pliers | Gripping and manipulating small parts |

| Torque Wrench | Ensuring proper tightness of bolts |

| Cleaning Kit | Maintaining cleanliness of air filters and spark plugs |

| Diagnostic Tool | Identifying issues and monitoring performance |

Safety Precautions When Using Chainsaws

Using a power saw can be hazardous if proper precautions are not taken. Awareness of potential risks and adherence to safety measures is essential for preventing accidents and ensuring a safe working environment. Understanding how to operate equipment correctly and recognizing the importance of protective gear can significantly reduce the likelihood of injury.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as helmets, eye protection, gloves, and chainsaw chaps. These items are crucial for safeguarding against flying debris and accidental contact with the cutting chain. Ensuring that your clothing fits properly and is free from loose ends can also help prevent entanglement.

Operational Guidelines

Before using the equipment, inspect it for any damage or wear. Make sure that the chain is properly tensioned and lubricated. Familiarize yourself with the controls and always maintain a firm grip while operating. Avoid working in adverse weather conditions and keep bystanders at a safe distance to minimize risks during cutting operations.