When it comes to maintaining and optimizing your outdoor machinery, a comprehensive grasp of its internal structure is essential. Familiarity with each component’s role can significantly enhance both performance and longevity. Whether you are a professional or an enthusiast, knowing how everything fits together is crucial.

Exploring the intricate layout of your machinery allows for informed decisions during repairs and upgrades. By dissecting the various elements, users can identify common issues and understand how to resolve them efficiently. This knowledge is not just beneficial; it is ultimately empowering.

In this article, we will delve into the specific configurations and arrangements that make up your equipment. Armed with this understanding, you will be better equipped to tackle any maintenance challenges that arise.

Understanding Stihl 064 AV Parts

Grasping the components of a chainsaw model is essential for effective maintenance and optimal performance. Each element plays a crucial role in ensuring the machine operates smoothly, and familiarity with these elements can enhance troubleshooting skills. This section delves into the various integral components that contribute to the overall functionality of the equipment.

From the engine assembly to the cutting mechanism, each section serves a specific purpose and requires careful attention. Knowing how these parts interact can assist in both repairs and upgrades, leading to improved efficiency. It is important to understand the function of the fuel system, ignition, and chain drive, among other key elements.

Additionally, recognizing wear indicators on various components can help in timely replacements, minimizing downtime. Regular inspections and knowledge of how each part contributes to the operation can significantly prolong the lifespan of the device. This awareness not only benefits the user but also enhances safety during operation.

Overview of the Stihl 064 AV

This section provides an insight into a well-regarded model in the realm of outdoor power equipment, known for its robust performance and reliability. Ideal for both professional and amateur users, this tool showcases an impressive combination of power and ease of use, making it a popular choice for various applications in forestry and landscaping.

With a history of engineering excellence, this model features advanced technology that enhances its operational efficiency. Its design reflects a commitment to durability, ensuring that it can withstand the rigors of demanding tasks while maintaining user comfort and control.

| Feature | Description |

|---|---|

| Engine Type | Two-stroke engine for high power output |

| Weight | Lightweight construction for ease of handling |

| Fuel Capacity | Generous tank size for extended use |

| Safety Features | Includes chain brake and anti-vibration system |

| Applications | Suitable for felling, limbing, and bucking |

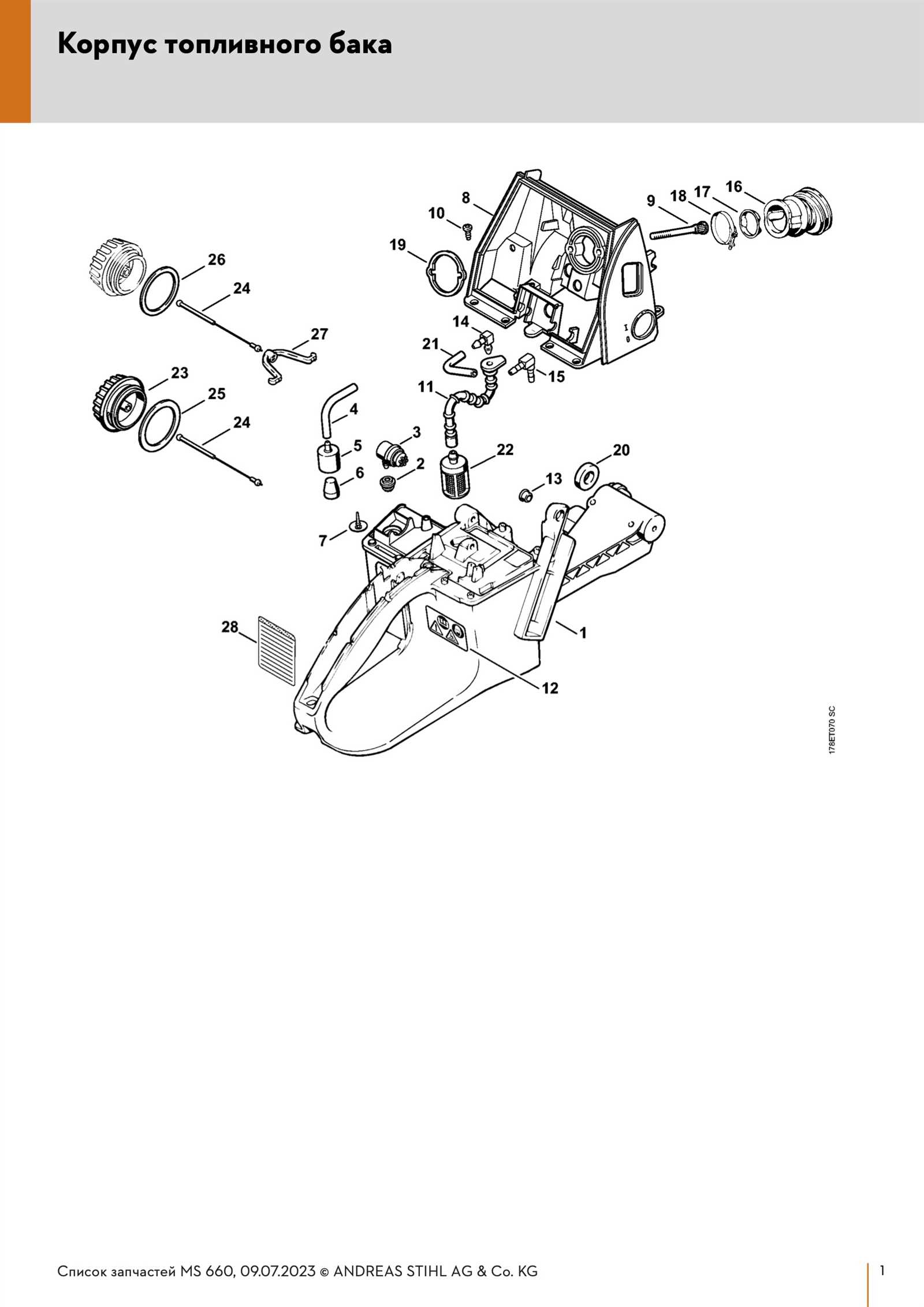

Importance of a Parts Diagram

A visual representation of components is essential for understanding the assembly and maintenance of equipment. It provides clarity and simplifies complex structures, making repairs and modifications more manageable.

Here are some key benefits:

- Enhanced Understanding: Visual aids help users grasp the relationships between different elements.

- Streamlined Repairs: Knowing where each component fits can expedite troubleshooting and repair processes.

- Accurate Replacements: Identifying the correct components ensures that replacements are precise and effective.

- Efficiency in Maintenance: Regular upkeep becomes easier with a clear overview of necessary parts and their locations.

Ultimately, having a well-illustrated reference serves as a valuable tool for both novice and experienced users, facilitating a smoother operational experience.

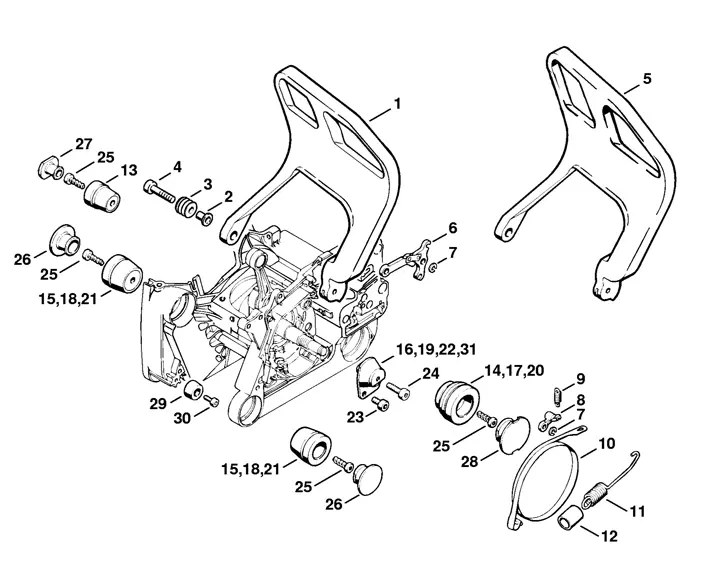

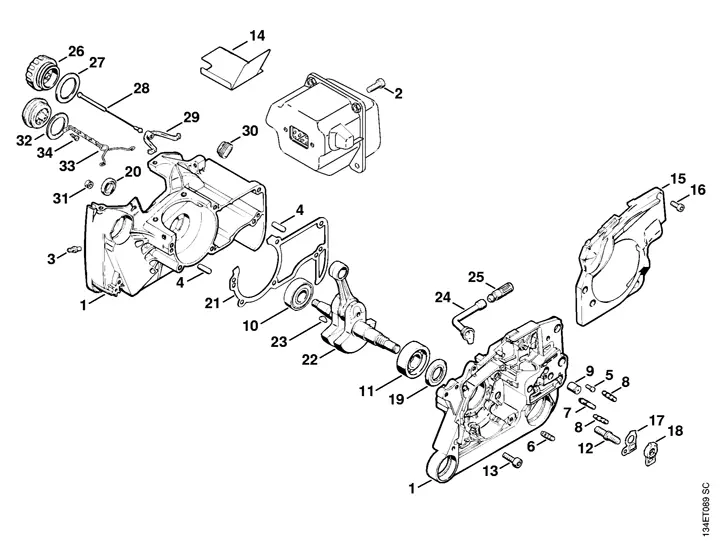

Identifying Key Components

Understanding the essential elements of any machinery is crucial for effective maintenance and repair. By recognizing these components, users can ensure optimal performance and longevity. Each part plays a specific role, contributing to the overall functionality of the equipment.

Engine: The heart of the system, providing the necessary power for operation.

Fuel System: Comprising the tank, filter, and lines, this system ensures proper fuel delivery.

Ignition: Vital for starting the engine, this component generates the necessary spark.

Cylinder and Piston: These work together to compress the fuel-air mixture, enabling combustion.

Exhaust System: Responsible for expelling gases produced during combustion, this component is key to efficiency.

Air Filter: Essential for protecting the engine from dirt and debris, promoting clean operation.

By delving into these key parts, users can identify potential issues and take preventive measures, leading to the ultimate performance of the machine.

How to Use the Diagram

Utilizing a visual representation of components can significantly enhance your understanding of machinery assembly and maintenance. This guide will help you navigate through the illustration effectively, allowing you to identify each element and its function within the overall system.

Step-by-Step Navigation

Start by familiarizing yourself with the layout of the visual aid. Break down the sections into manageable parts and focus on one area at a time. By doing this, you can delve into the specifics without feeling overwhelmed.

Identifying Components

As you study the illustration, pay attention to labels and reference numbers associated with each piece. This will ensure you have the ultimate clarity when sourcing replacements or conducting repairs. Cross-referencing with your manual can also provide additional insights into compatibility and installation procedures.

Common Issues with Stihl 064 AV

When operating a popular model of outdoor power equipment, users may encounter several common problems that can hinder performance. Understanding these issues can aid in maintenance and ensure optimal functionality. Below are some frequent concerns associated with this particular tool.

Engine Performance Problems

One of the most prevalent issues is related to engine performance. Users often report difficulties that may manifest as:

- Poor acceleration

- Difficulty starting

- Stalling during operation

These problems can be attributed to various factors, including fuel quality, air filter condition, and spark plug effectiveness. Regular checks can prevent these issues from escalating.

Chain and Bar Issues

Another area of concern involves the cutting mechanism. Users frequently experience:

- Chain slipping off the bar

- Uneven cutting

- Excessive wear on the guide bar

Such issues may arise from improper tensioning, lack of lubrication, or using a dull chain. Maintaining the cutting components is essential for efficient operation.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for maximizing the lifespan of your outdoor equipment. By implementing a few simple strategies, you can ensure that your machine remains efficient and reliable over the years. This section delves into key practices that will help you maintain your device effectively.

Routine Inspections

Conducting regular checks can prevent minor issues from escalating into major problems. Inspect all components, including filters, spark plugs, and chains. Look for signs of wear and tear, and address any concerns promptly to avoid costly repairs.

Cleaning and Lubrication

Keeping your equipment clean is crucial. Remove debris and buildup after each use. Additionally, ensure that all moving parts are adequately lubricated. This not only enhances performance but also reduces friction, leading to prolonged durability. Investing time in maintenance will yield ultimate benefits in the long run.

Where to Find Replacement Parts

When seeking components for your equipment, it’s essential to explore reliable sources to ensure quality and compatibility. Whether you’re conducting routine maintenance or repairing specific issues, knowing where to look can save time and effort.

Online Retailers

The internet offers a plethora of options for sourcing components. Here are some popular platforms:

- Specialty websites focused on outdoor equipment

- Major e-commerce platforms with extensive inventories

- Manufacturer’s official website for authentic items

Local Suppliers

In addition to online options, local shops can be invaluable resources:

- Authorized dealers for genuine components

- Hardware stores with a selection of compatible items

- Repair shops that may offer refurbished or aftermarket solutions

By utilizing these avenues, you can find the necessary components to keep your equipment running smoothly and efficiently.

Comparing Parts with Other Models

This section aims to explore the similarities and differences between components of various models, highlighting key features and compatibility considerations. Understanding these aspects can aid in maintenance and enhance performance.

When comparing components, consider the following factors:

- Design Features: Look for unique attributes that may affect functionality.

- Material Quality: Different models may use varying materials impacting durability.

- Compatibility: Some elements may interchange between models, while others may not.

Key models to examine for comparison include:

- Model A: Known for its efficiency and lightweight design.

- Model B: Features robust construction ideal for heavy-duty tasks.

- Model C: Offers advanced technology for enhanced performance.

In conclusion, by analyzing these aspects, users can make informed decisions about selecting and replacing components across different models.

DIY Repair Guide for Beginners

Engaging in repairs can be both rewarding and educational. For novices, tackling maintenance tasks on machinery can seem daunting, but with the right approach and resources, it can become an enjoyable experience. This guide aims to provide essential tips and techniques to help you successfully navigate the repair process.

Before diving into repairs, consider the following steps:

- Gather Information: Research the specific model you are working on. Understanding its components and functions is crucial.

- Acquire Necessary Tools: Ensure you have the right tools for the job. Common tools include wrenches, screwdrivers, and pliers.

- Establish a Workspace: Create a clean, organized area where you can work safely and efficiently.

Once you’re prepared, follow these fundamental steps for any repair task:

- Assessment: Identify the issue. Look for visible damage or signs of wear.

- Disassembly: Carefully take apart the machine, noting how components fit together. Keep screws and small parts in labeled containers.

- Replacement: If parts are damaged, source replacements that match your model. Check compatibility before purchasing.

- Reassembly: Reassemble the machine, following your notes or photos to ensure proper configuration.

- Testing: Once reassembled, perform a test to ensure everything functions as expected.

Remember, patience is key. Don’t rush the process; take your time to understand each step. With practice, your skills will improve, making future repairs easier and more enjoyable.

Tools Needed for Repairs

To effectively carry out maintenance and repairs on equipment, having the right tools is essential. These instruments not only enhance efficiency but also ensure that tasks are completed safely and accurately. Understanding the specific tools required can significantly streamline the repair process.

Essential implements often include wrenches, screwdrivers, and pliers, each serving a unique purpose in disassembly and reassembly. Additionally, specialty tools may be necessary for more complex repairs, allowing for precise adjustments and configurations. A reliable toolbox with a variety of sizes and types will prepare you for any repair challenge.

Finally, safety equipment such as gloves and goggles should always be on hand to protect against potential hazards during the repair process. With the right tools and precautions, tackling maintenance tasks becomes a manageable and effective endeavor.

Understanding Warranty Policies

When investing in high-quality outdoor equipment, it’s essential to comprehend the protection offered by manufacturers. These guarantees ensure that customers are supported in case of defects or performance issues, promoting confidence in their purchases.

Types of Coverage

Typically, warranties can vary in duration and scope, covering parts and labor or just specific components. It’s crucial to read the fine print to understand what is included and excluded, ensuring that your equipment remains in optimal condition.

Claim Process

To initiate a warranty claim, owners usually need to provide proof of purchase and details of the issue. Understanding the steps involved can facilitate a smoother experience, helping users navigate any potential challenges effectively.

Resources for Further Learning

Exploring additional resources can significantly enhance your understanding of machinery and their components. A variety of platforms and materials are available to deepen your knowledge and improve your practical skills. Engaging with these resources will provide valuable insights and help you troubleshoot effectively.

Online forums and communities dedicated to equipment enthusiasts offer a wealth of shared experiences and solutions. Participating in discussions can lead to discovering best practices and innovative approaches from fellow users.

Video tutorials are another excellent way to visually grasp assembly techniques and maintenance procedures. Many content creators specialize in machinery repair and can guide you step-by-step through complex processes.

Books and manuals focusing on mechanical engineering or specific equipment can serve as comprehensive references. These texts often cover fundamental principles, technical specifications, and troubleshooting tips that are invaluable for both beginners and seasoned users.

Finally, workshops and local classes provide hands-on experience under the guidance of experts. Engaging in practical exercises not only solidifies your knowledge but also connects you with a network of like-minded individuals.