When it comes to operating a reliable cutting tool, knowing its internal structure is essential for optimal performance and maintenance. Each mechanism plays a vital role in ensuring the smooth operation and longevity of the equipment. Familiarity with these elements can greatly enhance the user experience and efficiency during tasks.

In this section, we will explore the various elements that make up a high-performance cutting device. From the engine to the cutting mechanism, each part is designed with precision to deliver powerful results. Understanding how these components interact will empower users to make informed decisions regarding upkeep and repairs.

By examining the intricacies of the device’s design, users can develop a deeper appreciation for the technology involved. Moreover, recognizing the specific roles of individual elements can facilitate effective troubleshooting when issues arise. This knowledge not only aids in enhancing operational efficiency but also ensures safety during usage.

Key Components of the Chainsaw

Understanding the essential elements of a cutting tool is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance and durability during usage. Familiarity with these parts can enhance your ability to troubleshoot and repair the tool when necessary.

Power Unit: This is the heart of the equipment, providing the energy required for operation. It can be either electric or powered by gasoline, each offering unique advantages in terms of power and mobility.

Guide Bar: The elongated metal strip serves as the track for the cutting chain. Its length and width vary based on the tool’s design and intended use, impacting the efficiency and speed of cutting.

Cutting Chain: Comprised of sharp links, this component is responsible for the actual cutting action. Its design affects how effectively it can slice through materials, and it requires regular sharpening and maintenance to ensure optimal performance.

Chain Tensioner: This mechanism allows for the adjustment of the cutting chain’s tension, ensuring that it fits snugly against the guide bar. Proper tension is vital for safety and effective cutting.

Handle and Safety Features: Designed for ease of use and safety, the handle often includes triggers or switches for controlling the tool’s operation. Safety features, such as chain brakes, help prevent accidents during operation.

Awareness of these essential components fosters better care and handling of the equipment, ultimately extending its lifespan and enhancing performance.

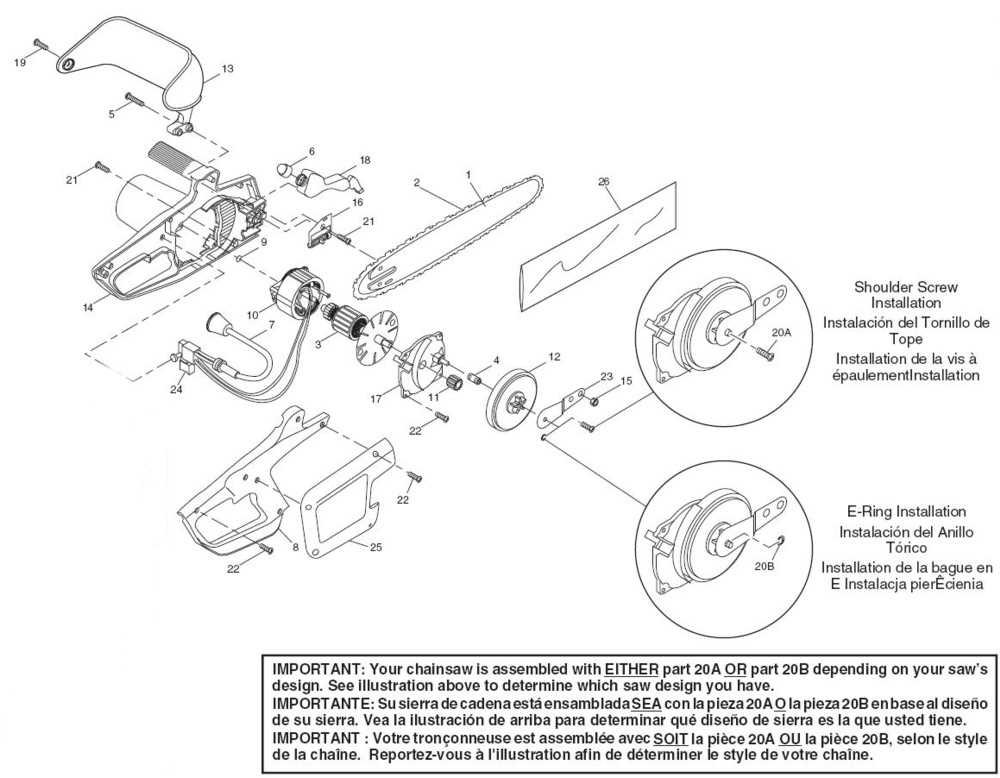

Understanding the Parts Diagram

The illustration of components serves as a crucial reference for users seeking to familiarize themselves with their equipment. It provides a visual representation of each element, highlighting their interconnections and functionality. Grasping this layout can significantly enhance maintenance and repair processes, ensuring efficient operation.

Benefits of Familiarity with Component Layout

- Improved maintenance knowledge

- Easier troubleshooting of issues

- Streamlined assembly and disassembly

- Better understanding of functionality

Key Elements to Observe

- Labeling of each part for identification

- Connections indicating how components interact

- Groupings that suggest assembly sequences

- Color coding or symbols that denote specific functions

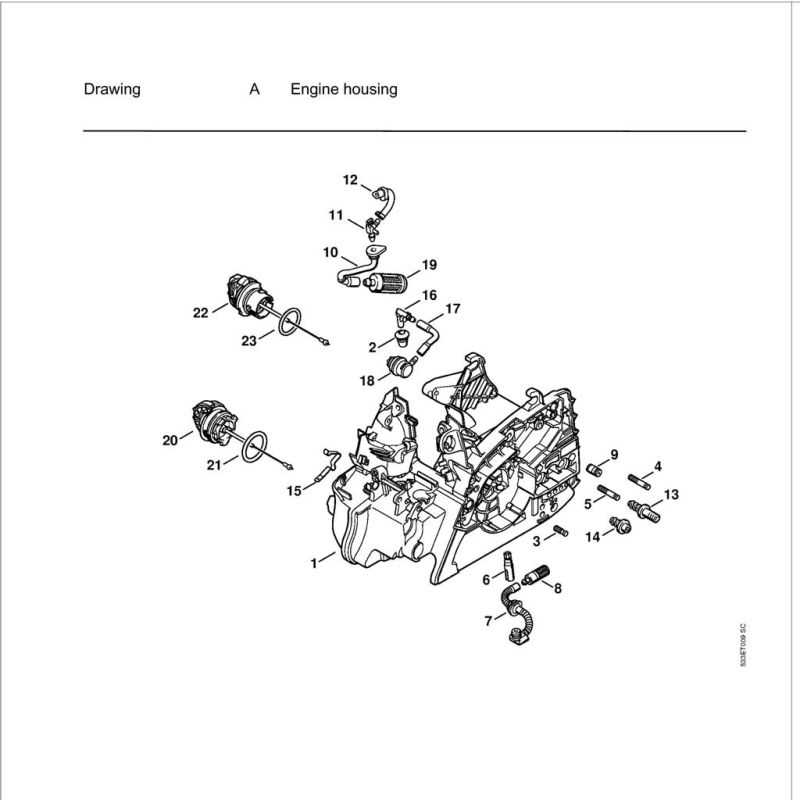

Engine and Fuel System Details

The power unit and fuel arrangement play a crucial role in the overall performance and efficiency of the device. Understanding the components involved in these systems allows users to maintain and troubleshoot effectively, ensuring optimal operation. Key elements such as the combustion chamber, fuel delivery mechanisms, and air intake systems work in harmony to deliver the necessary power for cutting tasks.

Fuel Delivery Mechanism

The fuel delivery system is responsible for transporting fuel from the tank to the engine. This process typically involves a fuel pump, which ensures a steady flow of fuel to the combustion chamber. Various filters may be included to prevent contaminants from entering the engine, maintaining its longevity and performance. Proper maintenance of these components is essential for preventing clogs and ensuring efficient fuel usage.

Combustion Chamber Dynamics

The combustion chamber is where the magic happens, as it is the site of the fuel-air mixture ignition. The design of this area is critical for achieving efficient combustion, leading to better power output and lower emissions. Regular inspection and cleaning of spark plugs and related components can help optimize engine performance, ensuring a smooth and powerful operation.

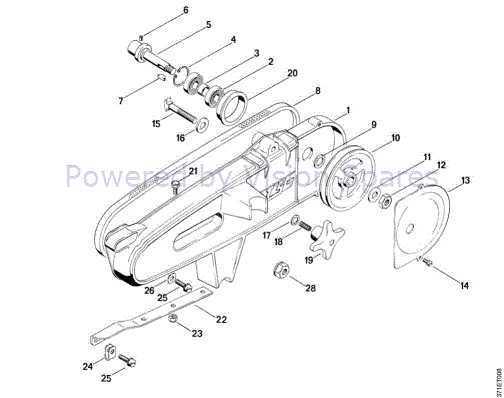

Bar and Chain Specifications

The performance of cutting equipment heavily relies on the specifications of the bar and chain used. Understanding these details is crucial for optimal operation and maintenance. This section will provide insights into the dimensions, types, and materials commonly associated with these components.

Bar Length: The length of the guide bar significantly influences the cutting capacity. It is essential to select a length that matches the intended applications, as longer bars can handle larger tasks, while shorter ones offer greater maneuverability.

Chain Type: Various chain types exist, each designed for specific cutting tasks. For instance, some chains excel in producing fine cuts, while others are tailored for faster, rougher work. Understanding these differences helps users choose the right option based on their needs.

Pitch and Gauge: The pitch refers to the distance between the chain’s drive links, while the gauge denotes the thickness of the links. These measurements are vital for ensuring compatibility with the bar and maintaining safe operation. Mismatched specifications can lead to inefficient performance or even damage.

Material Considerations: The materials used for both the bar and chain play a significant role in durability and performance. High-quality steel or alloys are typically preferred for their strength and longevity, making them suitable for demanding tasks.

In summary, a thorough understanding of bar and chain specifications enhances the effectiveness and longevity of cutting equipment. By selecting the appropriate components, users can ensure optimal performance tailored to their specific tasks.

Safety Features of the Model

This model incorporates various safety mechanisms designed to protect the user during operation. These features enhance safety and minimize the risk of accidents, ensuring a secure working environment.

Key safety aspects include:

- Chain Brake: Automatically engages in case of kickback, preventing injuries.

- Throttle Lock: Requires intentional action to operate, reducing the chance of accidental activation.

- Vibration Dampening: Minimizes operator fatigue and discomfort, allowing for better control.

- Safety Guards: Shield vulnerable areas from debris and accidental contact.

- Ergonomic Design: Promotes a comfortable grip, reducing strain and improving handling.

These features collectively contribute to a safer experience, allowing users to focus on their tasks with confidence. Regular maintenance and adherence to safety guidelines are essential for optimal protection.

Common Maintenance Practices

Regular upkeep is essential for ensuring optimal performance and longevity of your cutting tool. Implementing a consistent maintenance routine can prevent unexpected breakdowns and enhance efficiency during operation. This section outlines fundamental practices that can help maintain your equipment in excellent condition.

Cleaning and Inspection

Keeping the machinery clean and regularly inspecting its components are crucial steps in maintenance. Here are some key tasks to consider:

- Remove debris and dirt after each use to prevent buildup.

- Inspect the exterior for any signs of wear or damage.

- Check all moving parts for proper functioning and lubrication.

Regular Lubrication

Proper lubrication minimizes friction and wear, significantly extending the lifespan of various parts. Follow these guidelines:

- Use appropriate lubricants recommended for your specific equipment.

- Apply lubricant to all necessary components regularly.

- Ensure that the lubrication points are clean before application.

Troubleshooting Common Issues

Understanding and addressing typical problems is essential for maintaining optimal performance and longevity of your outdoor power equipment. This section provides insights into frequent challenges users may encounter and offers practical solutions to resolve them effectively.

Here are some common issues and their possible causes:

- Engine Won’t Start:

- Check if the fuel tank is filled with fresh fuel.

- Inspect the spark plug for wear or carbon buildup.

- Examine the ignition system for faults.

- Overheating:

- Ensure the air filter is clean and unobstructed.

- Verify that the cooling fins are free from debris.

- Look for proper lubrication levels in the engine.

- Uneven Cutting:

- Check the sharpness of the cutting blade.

- Inspect the alignment of the cutting components.

- Ensure that the equipment is held at the correct angle during operation.

- Excessive Vibration:

- Examine for loose or damaged components.

- Check the balance of the cutting blade.

- Look for wear on vibration dampening elements.

By systematically investigating these common issues, users can restore functionality and enhance the efficiency of their equipment, ensuring a more productive experience.

Replacement Parts and Compatibility

When maintaining and servicing your cutting tool, understanding the options for replacement components is crucial. Identifying compatible alternatives ensures optimal performance and longevity of the equipment.

Key considerations for selecting appropriate replacements include:

- Compatibility with the specific model and design of the device.

- Quality and durability of the replacement components.

- Availability of aftermarket versus original equipment manufacturer (OEM) options.

It is essential to consult the manufacturer’s specifications or trusted resources to verify the compatibility of any replacement items. Here are some common categories of components to consider:

- Engine components such as cylinders and pistons.

- Cutting attachments including blades and guides.

- Fuel systems, including filters and lines.

- Electrical components like ignition coils and switches.

By ensuring that all replacement items are compatible, you can enhance the efficiency and safety of your tool, ultimately prolonging its lifespan.

Assembly and Disassembly Instructions

This section provides essential guidance on how to efficiently assemble and disassemble your equipment. Understanding the correct procedures is crucial for maintaining optimal functionality and ensuring safety during the process. Proper handling of components will facilitate smooth operation and prolong the life of your device.

Tools Required

- Flathead screwdriver

- Phillips screwdriver

- Wrench set

- Safety gloves

- Protective eyewear

Disassembly Steps

- Ensure the machine is turned off and unplugged to prevent accidental activation.

- Remove the cover by unscrewing the screws using the appropriate screwdriver.

- Carefully detach the components in the following order:

- Fuel tank

- Air filter

- Bar and chain

- Inspect each part for wear and damage before proceeding with assembly.

Assembly Steps

- Start by attaching the bar and chain securely, ensuring proper alignment.

- Reinstall the air filter, making sure it fits snugly in place.

- Reconnect the fuel tank and tighten all screws adequately.

- Finally, replace the cover and check that all components are secure.

Following these instructions will help ensure that your equipment functions effectively and safely. Regular maintenance and proper assembly are key to prolonging the lifespan of your device.

Upgrades and Modifications Available

Enhancing the performance and versatility of your equipment can significantly improve its efficiency and lifespan. Various upgrades and modifications can be implemented to optimize functionality, increase power output, and tailor the tool to specific tasks. Whether you are looking to boost cutting efficiency or enhance user comfort, there are numerous options to consider.

Performance Enhancements

One of the most popular modifications involves upgrading the engine components. Replacing standard parts with high-performance alternatives can lead to noticeable improvements in power and torque. Additionally, fine-tuning the carburetor settings can help achieve better fuel efficiency and responsiveness.

Comfort and Usability Improvements

Enhancing the comfort and usability of your equipment can greatly improve the user experience. Consider adding vibration-dampening handles or adjustable grips to reduce fatigue during extended use. Another option is to install lightweight materials to improve maneuverability without sacrificing durability.

| Upgrade/Modification | Description | Benefits |

|---|---|---|

| High-Performance Carburetor | Replaces standard carburetor for improved fuel delivery. | Increases power and efficiency. |

| Vibration-Dampening Handles | Handles designed to minimize vibrations during operation. | Enhances comfort and reduces fatigue. |

| Lightweight Materials | Utilizes advanced materials to reduce overall weight. | Improves maneuverability and ease of use. |

| Chain and Bar Upgrade | Switching to a premium chain and bar for better cutting performance. | Increases cutting efficiency and durability. |

Where to Find Original Parts

When seeking authentic components for your equipment, it is essential to know the best sources to ensure quality and compatibility. Utilizing trusted suppliers not only guarantees that you receive genuine items but also provides peace of mind regarding performance and durability.

Authorized Dealers

One of the most reliable places to purchase genuine items is through authorized dealers. These distributors are certified to sell authentic merchandise and often have knowledgeable staff who can assist you in finding the right components for your needs. They may also offer warranty support and assistance with installation.

Online Retailers

Numerous online platforms specialize in genuine equipment components. It’s vital to choose reputable websites that focus on authentic merchandise. Look for customer reviews and ratings to gauge the reliability of the retailer. Many of these sites also provide detailed descriptions and specifications, making it easier to find exactly what you need.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Guaranteed authenticity, expert advice | May have higher prices |

| Online Retailers | Convenience, often competitive pricing | Need to verify authenticity |

| Local Repair Shops | Knowledgeable technicians, potential for installation help | Limited stock |