When it comes to maintaining the efficiency and longevity of your equipment, understanding how the different elements work together is crucial. Whether you’re a professional or a hobbyist, knowing the internal structure of your device can help you quickly identify issues and carry out repairs. A clear overview of the core mechanisms will assist in ensuring your machine operates smoothly for years to come.

Key mechanical sections include a variety of parts that, when assembled properly, allow the tool to function at its best. Recognizing these components and their interconnections will empower users to handle routine upkeep

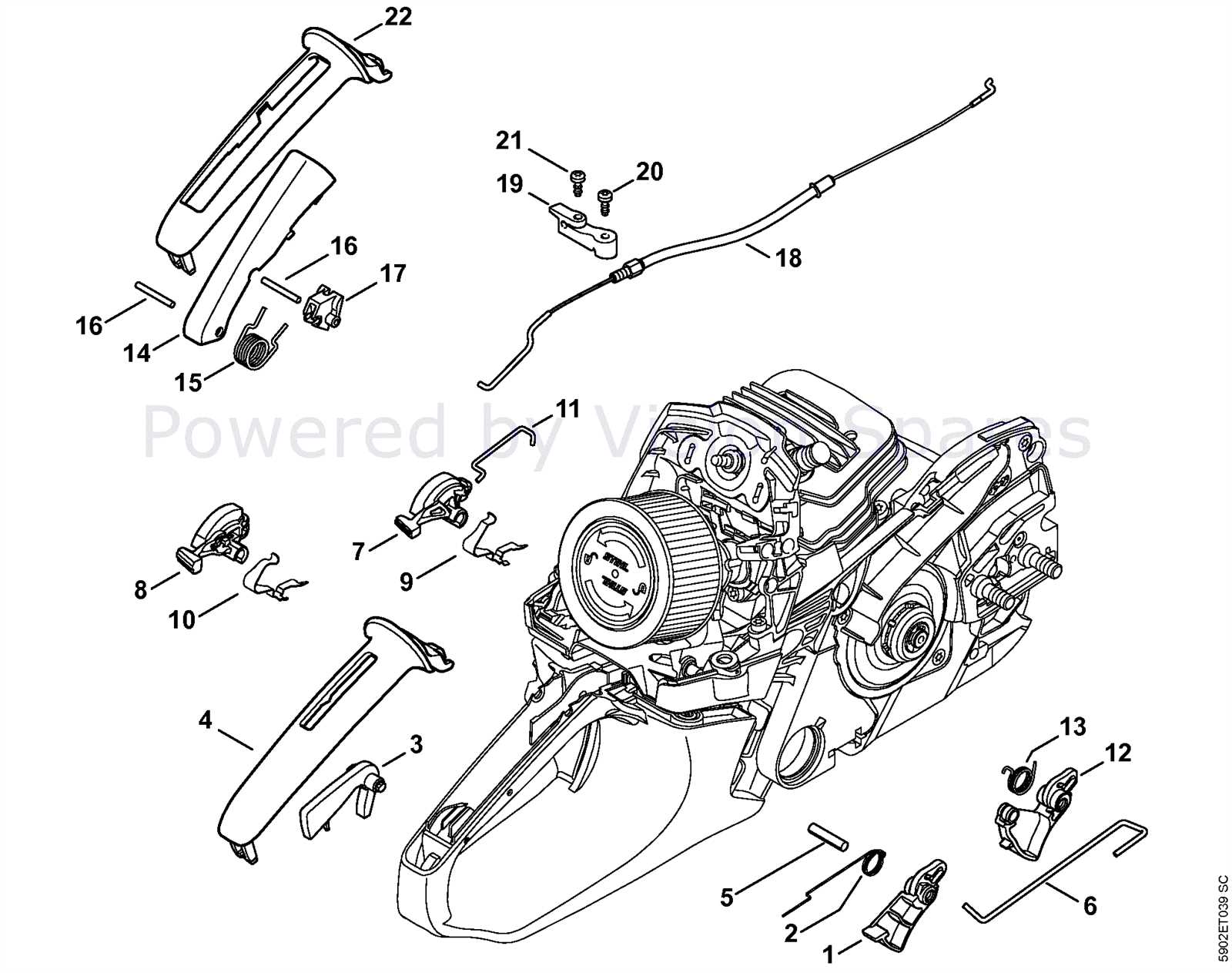

STIHL 261 Chainsaw Overview

The featured model is a powerful tool designed for both professionals and homeowners who seek reliability and performance. This saw delivers impressive cutting power while maintaining a lightweight structure, making it ideal for a wide range of tasks, from routine maintenance to more demanding operations in forestry.

Known for its durability, this chainsaw includes advanced features that enhance user comfort and safety. Equipped with a highly efficient engine, it balances fuel consumption and power output, ensuring smooth and consistent performance under various conditions.

Key characteristics of this model include an ergonomic design, which reduces fatigue during prolonged use, and easy maintenance capabilities. Whether tackling large logs or performing precise cuts, it offers the versatility and efficiency required for any cutting task

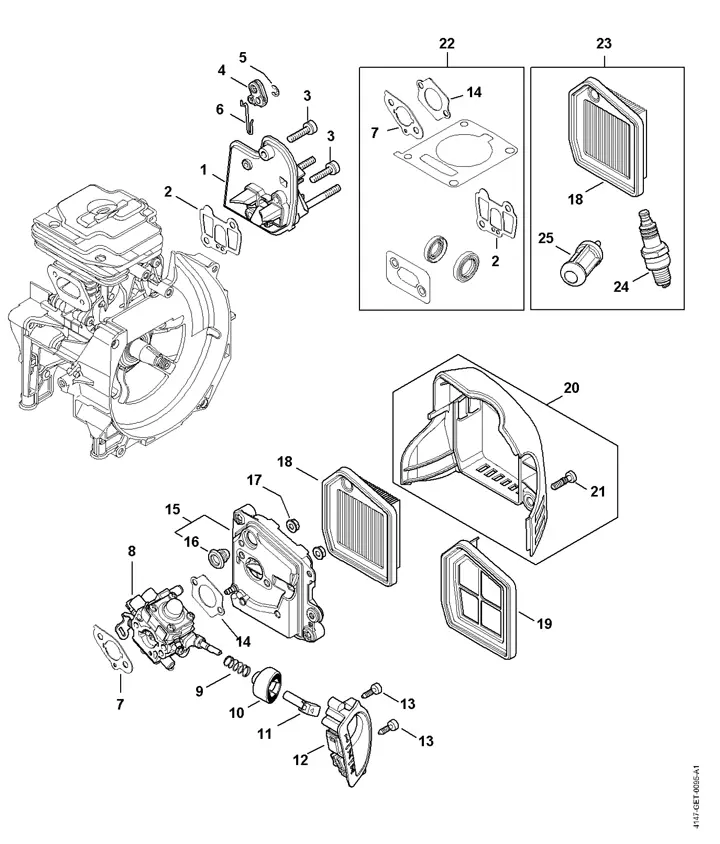

Understanding the Internal Mechanism of STIHL 261

When it comes to precision-engineered machines, understanding the inner workings is key to ensuring longevity and performance. Inside this chainsaw, a complex system of interconnected components works seamlessly to convert raw power into effective cutting force. Each part, from the motor to the chain drive, plays a crucial role in maintaining efficiency, power output, and overall balance during operation.

The core of the mechanism revolves around its combustion system. An optimized mix of fuel and air creates the necessary energy to drive the engine. As the energy is generated, it moves through a sequence of mechanical transitions, including the crankshaft and pistons,

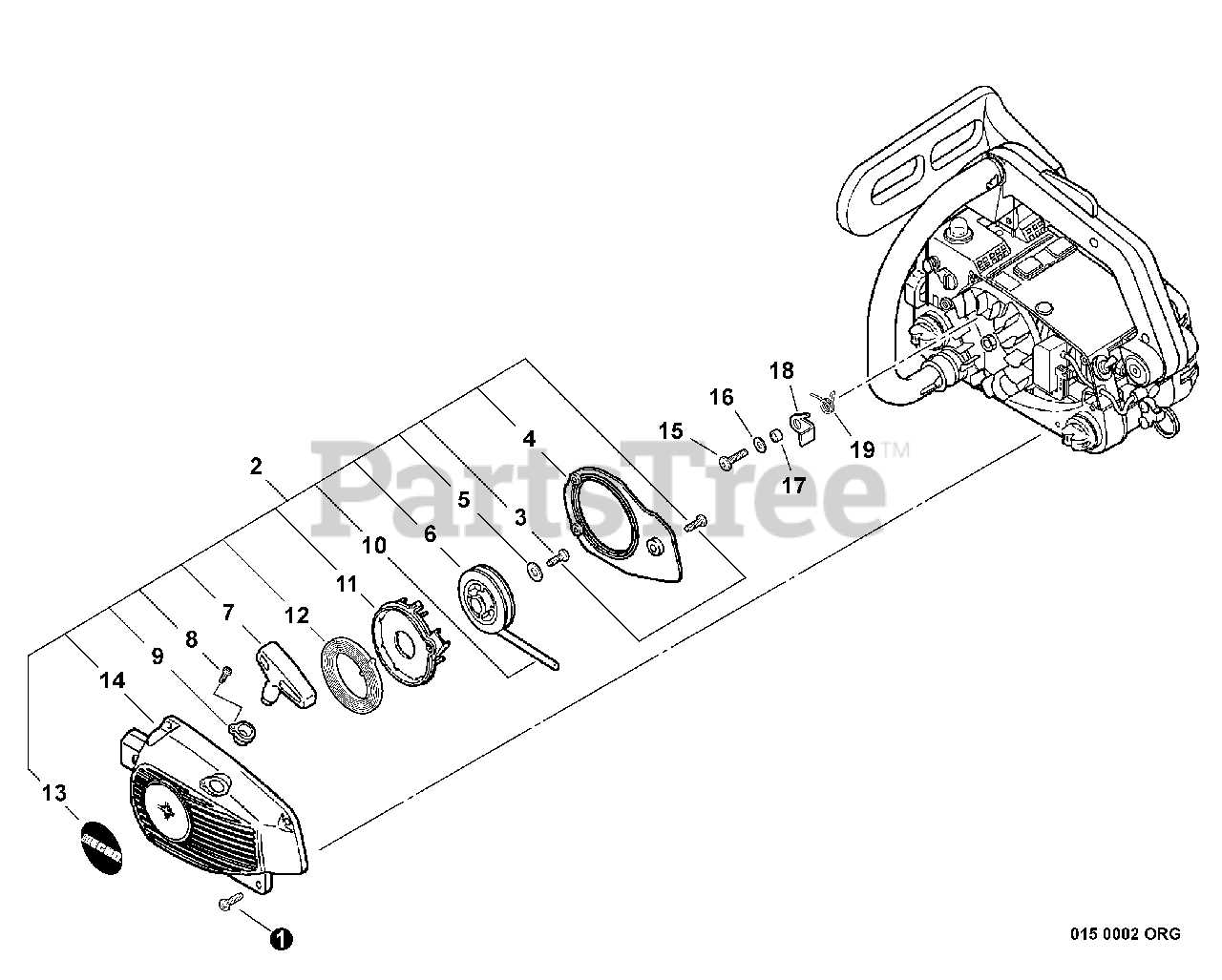

Key Components of the STIHL 261 Chainsaw

The reliability and efficiency of this chainsaw are ensured by the thoughtful design and integration of crucial mechanisms. Each element is carefully engineered to support smooth operation, enhance performance, and extend the tool’s lifespan. Understanding these essential components helps to grasp how they contribute to the machine’s overall durability and functionality.

The engine lies at the heart of the saw, driving the entire system. Coupled with the ignition module, it delivers the power necessary for high-performance cutting. The carburetor plays a key role in regulating the air and fuel mixture, ensuring the engine runs smoothly under various conditions.

The guide bar and cutting chain form the business end of

Common Issues with STIHL 261 Parts

When it comes to maintaining high-performance outdoor equipment, understanding common problems that may arise with various components is essential. Regular use can lead to wear and tear, making it crucial to identify and address potential issues before they result in costly repairs or downtime.

- Engine overheating – Frequent use can sometimes cause the motor to overheat, especially in high-demand tasks. This may be due to a clogged air filter or insufficient lubrication.

Where to Find a Reliable Parts Diagram

When searching for detailed technical illustrations, it’s essential to choose trustworthy sources. Having an accurate and clear reference is crucial for maintenance and repairs, ensuring that you can identify each component correctly. Reliable diagrams simplify the task of sourcing replacements and understanding complex assemblies, making the entire process smoother.

Official Manufacturer Websites

The best place to obtain precise technical illustrations is through official websites of the manufacturers. These platforms often provide

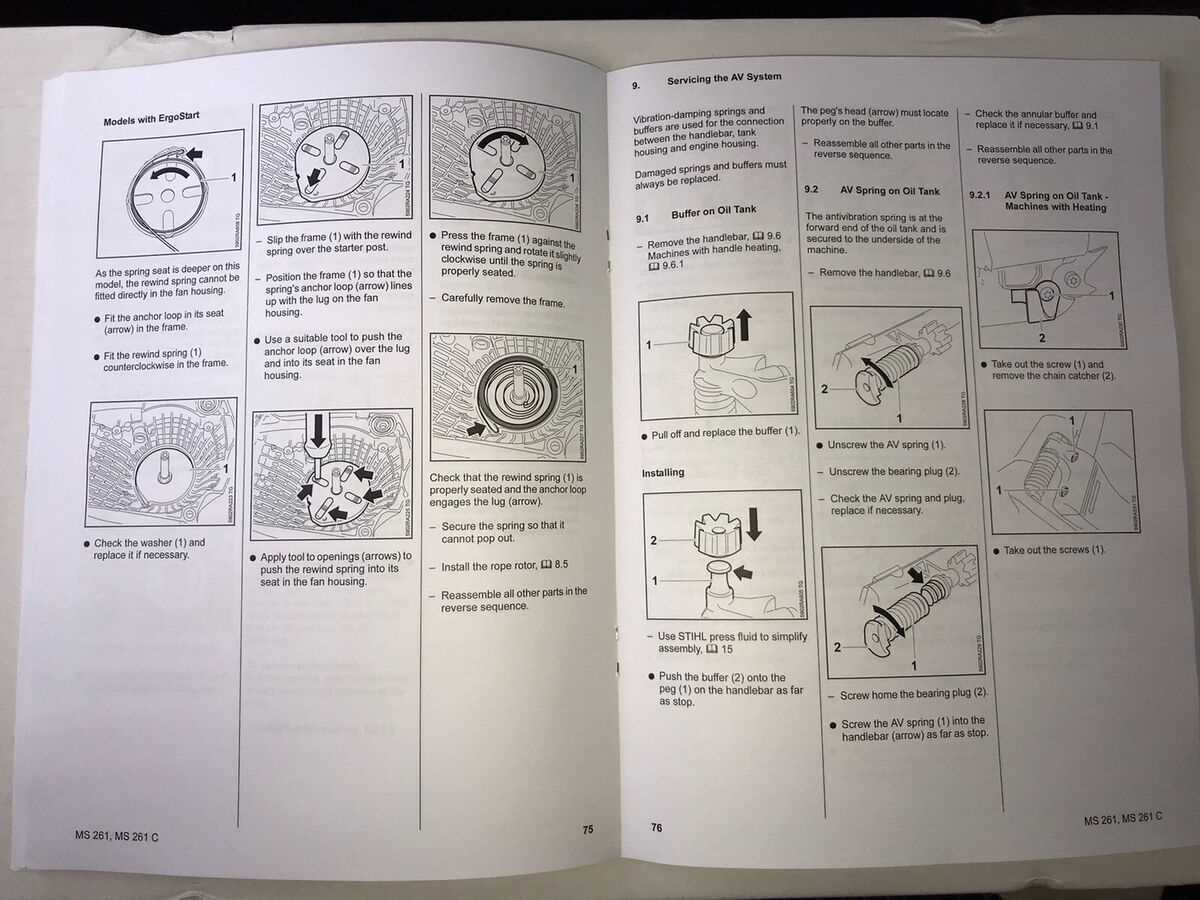

Guide to Replacing STIHL 261 Parts

Maintaining your equipment in optimal condition is essential for ensuring its longevity and performance. Whether it’s a minor adjustment or a significant repair, understanding how to effectively change components can enhance the machine’s functionality and prevent further damage. This guide will walk you through the essential steps and considerations involved in the replacement of various components, ensuring a smooth and efficient process.

Before beginning any replacement work, it’s crucial to gather all necessary tools and components. Make sure you have a clean workspace and access to the specific items needed for your task. Below is a table listing common components and their respective functions, which will aid you in identifying what needs to be replaced.

Component Function Chain Transfers power from the engine to the cutting mechanism. Bar Supports the chain and guides it during operation. Filter Prevents dirt and debris from entering the engine. Spark Plug Ignites the fuel-air mixture for engine operation. Fuel Line Delivers fuel from the tank to the engine. Following the identification of components, consult your user manual for specific instructions on how to perform the replacement. If the manual is unavailable, there are numerous online resources and forums where experienced users share their insights and techniques. Ensure all safety precautions are taken, including wearing protective gear and working in a well-ventilated area.

After successfully replacing the required parts, it’s advisable to perform a thorough inspection to confirm everything is properly secured and functioning. Regular maintenance checks can further prolong the life of your equipment, allowing you to enjoy its full capabilities without unexpected interruptions.

Importance of Using Genuine STIHL Parts

Utilizing authentic components for machinery maintenance and repair is crucial for optimal performance and longevity. These high-quality replacements ensure that the equipment operates as intended, providing reliability and efficiency for the user.

One of the primary advantages of employing original items is the assurance of compatibility. Genuine replacements are designed specifically for each model, which minimizes the risk of malfunctions and enhances overall functionality.

- Quality Assurance: Authentic components undergo rigorous testing to meet stringent standards.

- Extended Lifespan: Using original parts contributes to the durability of the equipment, reducing the need for frequent replacements.

- Warranty Protection: Many manufacturers offer warranty coverage only when genuine items are used, safeguarding your investment.

- Improved Safety: Original replacements reduce the risk of accidents or failures during operation, protecting both the user and the equipment.

In conclusion, investing in genuine components is essential for maintaining the efficiency, safety, and longevity of machinery. It not only ensures optimal operation but also provides peace of mind for users.

Maintenance Tips for STIHL 261 Chainsaw

Proper upkeep of your power tool is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances the efficiency of the machine but also promotes safety during operation. By following a few key practices, you can keep your device in excellent working condition and ready for any task at hand.

Routine Cleaning

Cleaning your equipment after each use is crucial. Remove sawdust, debris, and any residues that may accumulate on the exterior and inside components. Pay special attention to the air filter, as a clogged filter can hinder airflow and reduce engine performance. Regularly check the bar and chain for any build-up and clean them thoroughly to prevent wear.

Regular Inspections

Frequent inspections of vital components can help identify issues before they escalate. Examine the chain tension regularly to ensure it is neither too loose nor too tight, as both conditions can lead to operational problems. Additionally, inspect the spark plug, fuel lines, and bar oil level to ensure everything is functioning correctly. Replacing worn or damaged parts promptly will enhance the overall efficiency of your tool.

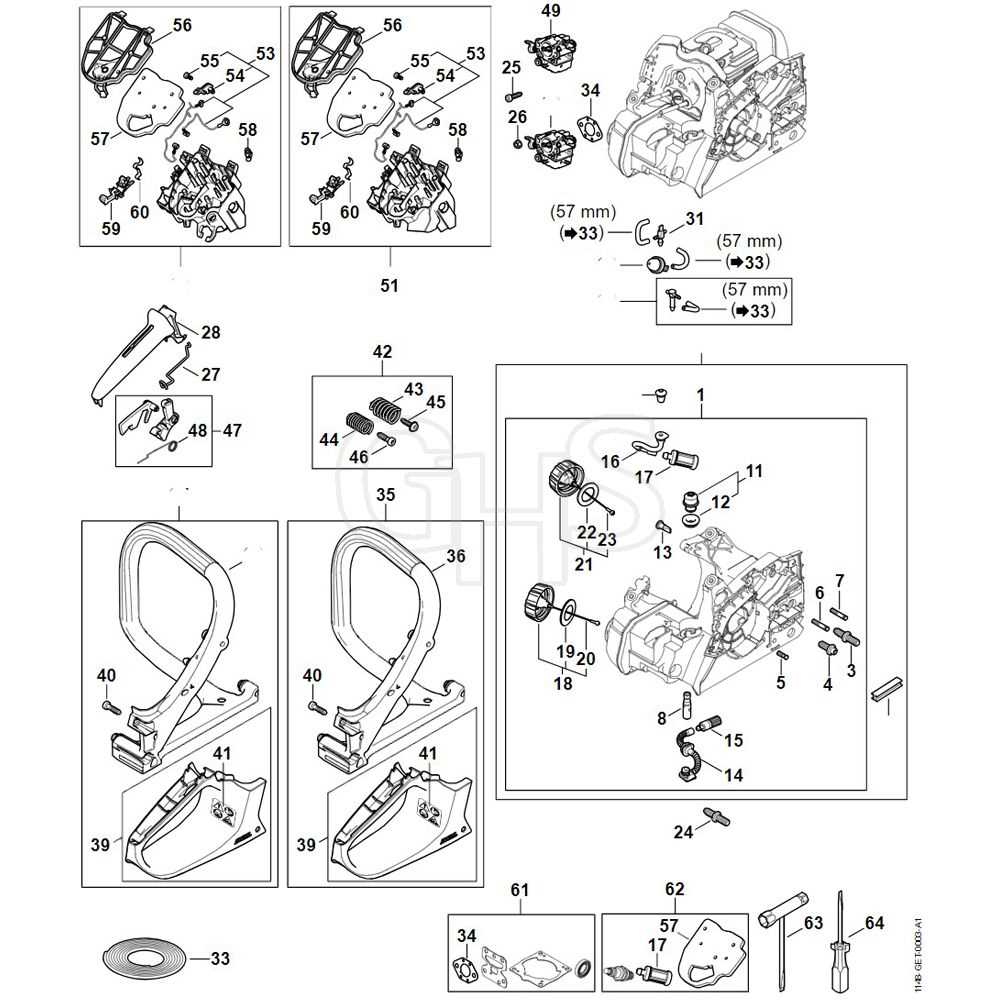

How to Interpret

Understanding the intricacies of machinery components can be essential for effective maintenance and repair. A clear representation of various elements assists users in identifying specific parts and their relationships within the system. This knowledge empowers individuals to perform repairs with confidence and efficiency.

Analyzing the Visual Representation

The graphical layout typically illustrates numerous elements, each labeled for easy reference. The arrangement often follows a logical flow, allowing for quick identification of parts and their functions. Familiarity with common symbols and notations used in these illustrations is crucial for accurate interpretation.

Utilizing Reference Tables

Supplementary reference tables are commonly included to enhance understanding. These tables provide detailed information about each component, including specifications and compatibility. By cross-referencing the visual layout with the table, users can gain comprehensive insights into the assembly.

Component Description Part Number Housing Enclosure that protects internal parts 123-456-789 Chain Drive mechanism for cutting 987-654-321 Bar Guides the chain during operation 456-789-123