In the world of outdoor machinery, a thorough grasp of individual elements and their organization is crucial for optimal performance and maintenance. Whether you are a seasoned professional or a novice, familiarity with the intricate layout of each unit can significantly enhance your operational efficiency.

Comprehending the structure allows users to pinpoint issues quickly and undertake necessary repairs with confidence. A detailed overview of the key components provides insights into their functionality and interrelation, ultimately leading to a more effective troubleshooting process.

Moreover, exploring these assemblies can serve as a valuable resource for those looking to upgrade or replace specific segments. By delving into the various configurations, you can make informed decisions that will prolong the life and enhance the efficiency of your machinery.

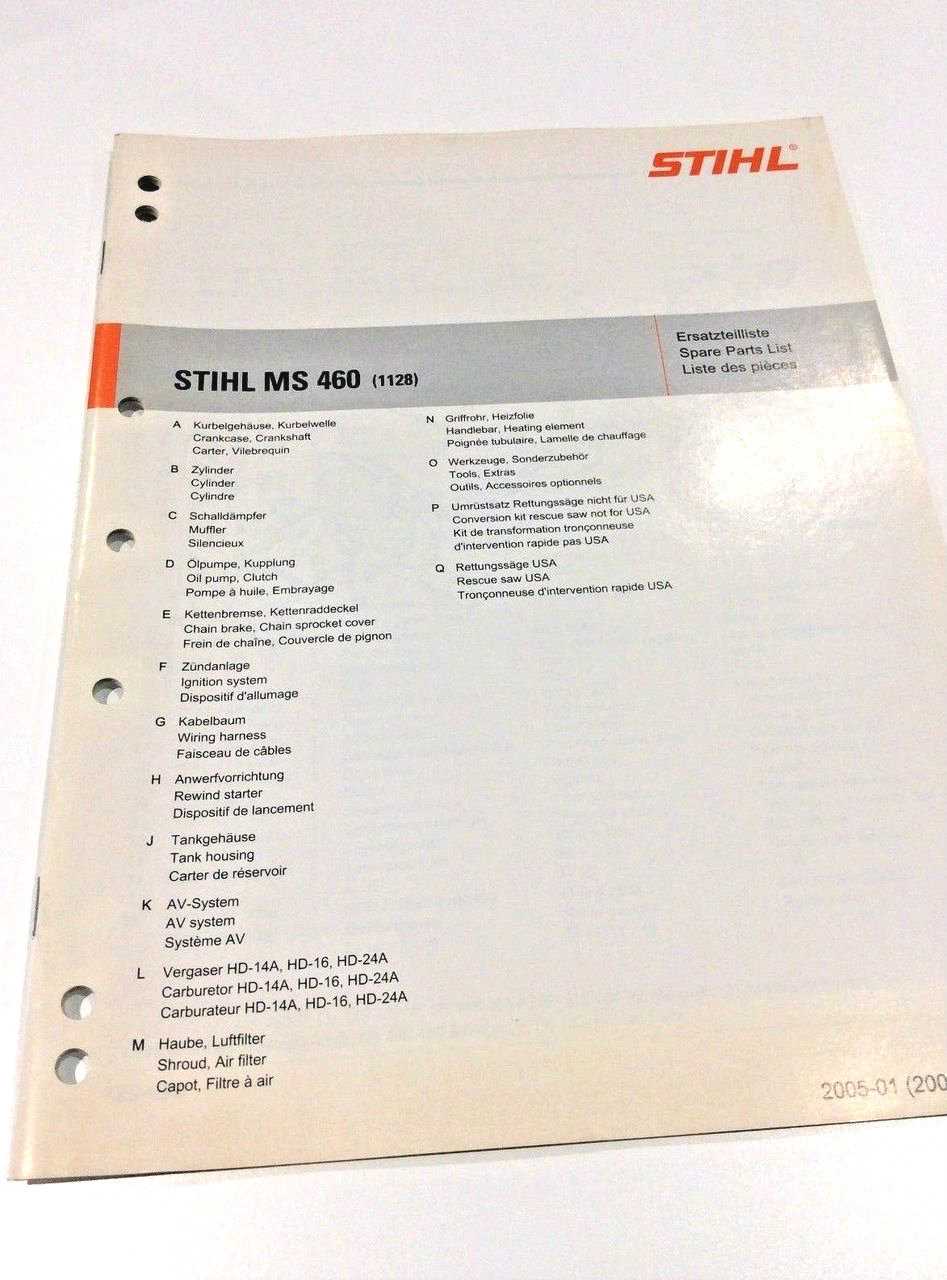

Understanding Stihl 460 Chainsaw Components

The effective functioning of a cutting tool relies on its various integral elements, each playing a crucial role in performance and safety. By comprehending these components, users can ensure optimal operation and maintenance, enhancing longevity and reliability.

Engine: The heart of the tool, providing the necessary power for cutting through tough materials. A well-maintained engine ensures efficiency and effectiveness during operation.

Bar: This essential piece determines the depth and breadth of your cuts. Selecting the right size is vital for achieving desired results in different applications.

Chain: The teeth on this component do the heavy lifting, so understanding the type and sharpness is critical for effective performance. Regular sharpening and replacement can significantly affect cutting speed and precision.

Handle: Designed for comfort and control, the handle plays a significant role in user safety and maneuverability. Ergonomic designs help reduce fatigue during extended use.

Safety Features: Modern tools come equipped with various safety mechanisms, such as chain brakes and anti-vibration systems. Familiarizing oneself with these features is essential to ensure a safe operating environment.

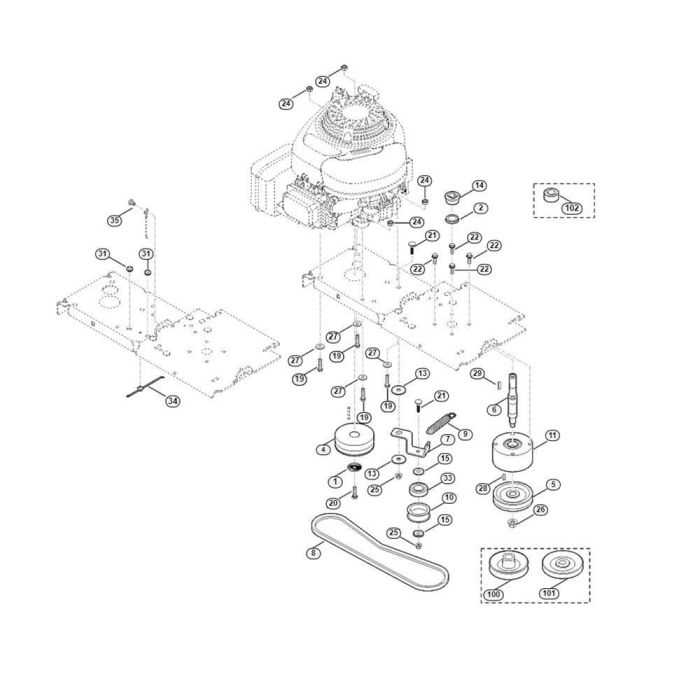

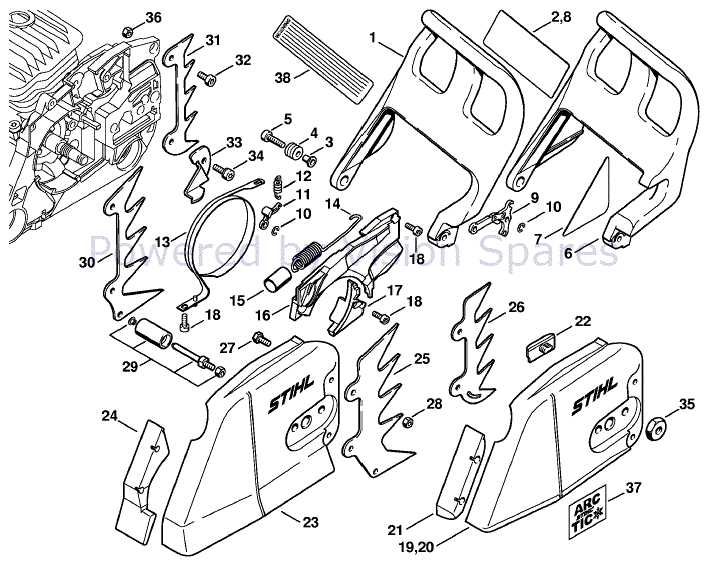

Importance of Accurate Parts Diagrams

Clear and precise representations of components are crucial for effective maintenance and repair tasks. They serve as essential tools for technicians, enabling them to identify specific elements and understand their relationships within the machinery. By having reliable visual guides, users can streamline their workflow and enhance their troubleshooting capabilities.

Understanding components becomes significantly easier with accurate illustrations. Users can quickly pinpoint the parts needed for repairs or replacements, reducing the risk of errors and improving efficiency. This ultimately leads to a smoother operational experience.

Moreover, detailed schematics contribute to the longevity of equipment. By following the correct assembly and disassembly procedures, users minimize the chances of damaging sensitive parts during maintenance. This not only saves time and resources but also enhances the overall performance of the machinery.

Common Stihl 460 Repair Issues

Understanding the frequent challenges associated with a popular outdoor power tool can greatly assist in maintenance and repairs. This section highlights typical problems users may encounter, enabling timely interventions and prolonging the lifespan of the equipment.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Starting Difficulties | Engine fails to start, excessive pull on the starter cord | Check spark plug, fuel quality, and air filter condition |

| Overheating | Smoke from the engine, unusual smells | Inspect cooling fins, clean air intake, and check fuel mixture |

| Chain Stopping | Chain does not rotate or stops abruptly | Examine chain tension, lubricate bar, and check for blockages |

| Vibrations | Excessive shaking during operation | Check for loose components, inspect the clutch and bearings |

| Fuel Leaks | Puddles of fuel under the unit | Inspect fuel lines and connections for wear or damage |

How to Identify Stihl 460 Parts

Understanding the components of your outdoor power equipment is essential for effective maintenance and repair. Proper identification of individual elements not only ensures optimal performance but also simplifies troubleshooting and replacement processes. This section provides a comprehensive guide to recognizing and categorizing the various components of your machinery.

1. Consult the Manual: The first step in identifying components is to refer to the user manual. This document typically includes a comprehensive list of all elements, along with descriptions and part numbers. Familiarizing yourself with this information can significantly streamline the identification process.

2. Visual Inspection: Conduct a thorough examination of the machine. Look for markings, labels, or any distinct features on each part. Many components have specific shapes or colors that can aid in their identification. Taking clear photographs can also help you cross-reference parts later.

3. Online Resources: Numerous online platforms offer extensive databases and forums where enthusiasts and professionals share knowledge. These resources can be invaluable for comparing your findings with detailed images and descriptions provided by other users.

4. Seek Expert Assistance: If you encounter difficulties in identifying any component, consider reaching out to a professional. Authorized service centers or knowledgeable retailers can provide accurate information and guidance tailored to your specific model.

By following these steps, you can effectively identify the necessary elements of your machinery, ensuring its longevity and performance.

Benefits of Using OEM Parts

Utilizing original components ensures optimal performance and longevity of your equipment. These items are specifically designed to fit and function perfectly, providing a seamless integration that enhances efficiency.

Quality Assurance

- Manufactured to meet exact specifications

- High durability and reliability

- Extensive testing for performance standards

Warranty and Support

- Maintains the manufacturer’s warranty

- Access to customer support and resources

- Potential for higher resale value

Step-by-Step Parts Replacement Guide

This guide provides a comprehensive approach to replacing components in your equipment. By following these steps, you can ensure that the process is efficient and minimizes the risk of errors. Each phase is broken down clearly for ease of understanding and execution.

-

Gather Necessary Tools and Materials:

- Screwdrivers (flathead and Phillips)

- Wrenches

- Replacement components

- Safety gloves

- Work surface or bench

-

Ensure Safety First:

- Disconnect the equipment from any power source.

- Wear safety gloves to protect your hands.

- Clear the workspace of any unnecessary items.

-

Identify the Component to Replace:

- Consult the manual for specific guidance.

- Locate the exact position of the part within the assembly.

-

Remove the Old Component:

- Unscrew any fasteners securing the part.

- Carefully detach the component from its housing.

-

Install the New Component:

- Align the new part with the mounting points.

- Secure it using the previously removed fasteners.

-

Test the Installation:

- Reconnect the power source.

- Perform a test run to ensure proper functionality.

-

Final Inspection:

- Check for any loose connections.

- Ensure that the new part is secure and functioning as expected.

Following these steps will help you successfully replace components, ensuring your equipment runs smoothly and efficiently.

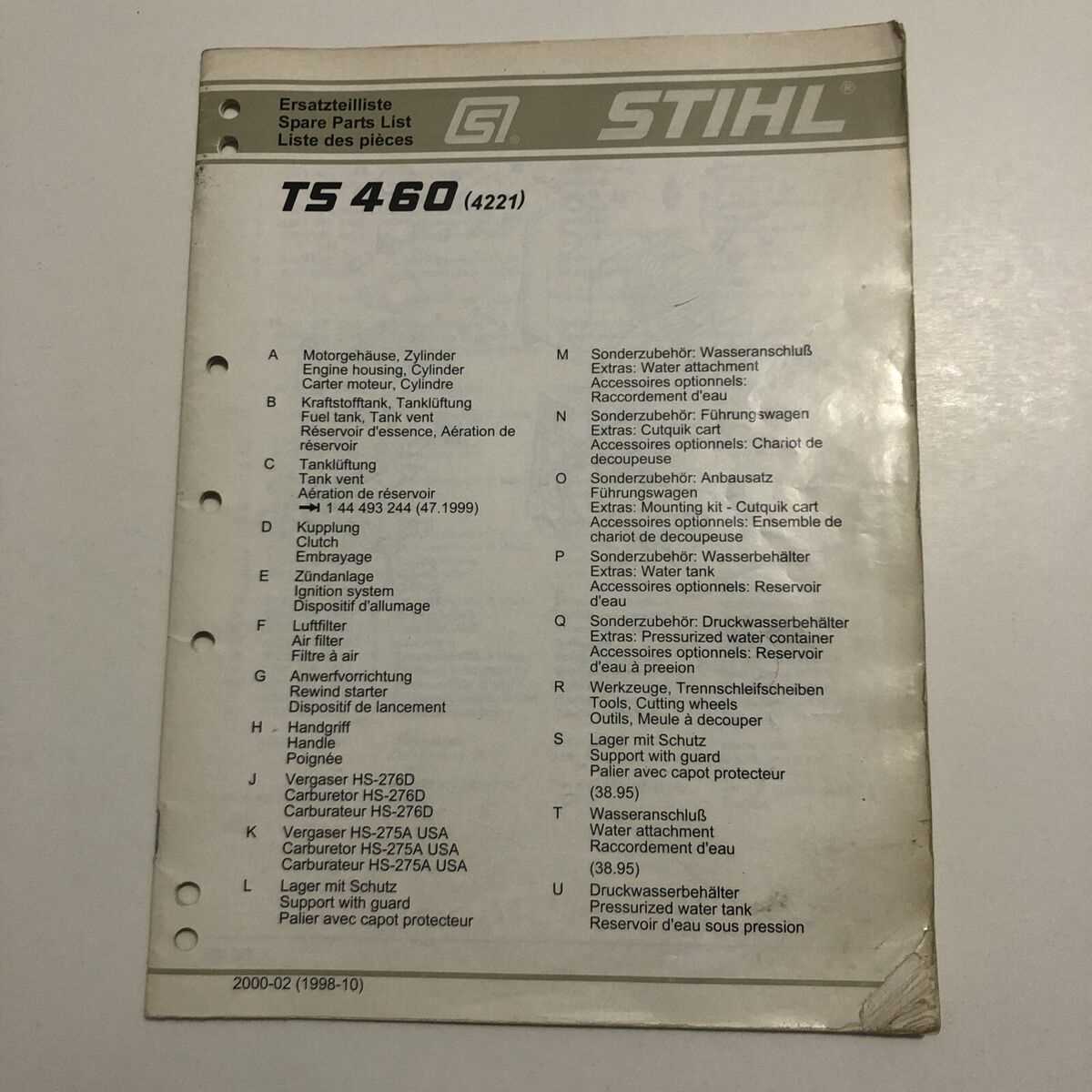

Where to Find Stihl 460 Diagrams

Finding accurate schematics for equipment can significantly enhance maintenance and repair efforts. Various resources are available, both online and offline, to help locate these valuable visual aids. Whether you’re a professional or a hobbyist, knowing where to search can save time and ensure that you have the correct information at hand.

Online Resources

The internet is a treasure trove of information. Official websites often provide downloadable manuals that include comprehensive visuals. Additionally, various forums and community websites dedicated to machinery enthusiasts frequently share links to detailed drawings and user experiences. A simple search can yield numerous results, making it easier to find what you need.

Local Dealers and Repair Shops

Local retailers and service centers can also be excellent sources of information. Many have access to manufacturer databases that include schematics. Don’t hesitate to ask for assistance, as professionals are often willing to share their knowledge and resources. Moreover, they can offer insights into common issues and best practices for upkeep.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular upkeep and attention to detail. By following a systematic maintenance routine, you can prevent issues and enhance the overall functionality of your machinery.

- Regular Cleaning: Keep the exterior and internal components clean to prevent debris buildup.

- Check Filters: Replace or clean air and fuel filters regularly to maintain airflow and performance.

- Inspect Blades: Ensure that blades are sharp and free from damage to improve cutting efficiency.

Additionally, consider the following practices:

- Oil Levels: Regularly check and change the oil to ensure proper lubrication.

- Fuel Quality: Use high-quality fuel to prevent engine issues and enhance performance.

- Storage Conditions: Store equipment in a dry, protected area to prevent rust and corrosion.

By incorporating these maintenance strategies, you can achieve the ultimate performance and extend the lifespan of your machinery.

Common Accessories for Stihl 460

When it comes to enhancing the performance and usability of your cutting equipment, a variety of attachments and tools can make a significant difference. These additions not only improve efficiency but also ensure safety and comfort during operation.

Safety Gear

Essential safety equipment includes helmets, gloves, and chaps designed to protect users from potential hazards. Investing in high-quality protective gear is crucial for any operator to maintain safety while working in various environments.

Maintenance Tools

Regular maintenance is vital for optimal performance. Accessories such as chain sharpeners, cleaning kits, and fuel mixing bottles help keep your equipment in top shape, extending its lifespan and enhancing functionality.

Comparing Stihl 460 with Other Models

This section explores the distinctions and similarities between a specific powerful machine and its counterparts in the market. Understanding these differences can help users make informed choices based on their needs and preferences.

Key areas of comparison include:

- Performance: Analyze engine power, cutting capacity, and efficiency.

- Weight: Consider portability and ease of use.

- Durability: Evaluate the materials used and the expected lifespan.

- Features: Look at unique functionalities offered by each model.

- Price: Compare cost-effectiveness in relation to features.

By examining these aspects, users can delve deeper into the ultimate choice that best suits their operational needs.

Tips for Troubleshooting Your Chainsaw

When your power tool isn’t functioning as expected, it can be frustrating. Understanding common issues and knowing how to address them can save you time and ensure optimal performance. This guide provides practical advice for diagnosing and resolving frequent problems.

Common Issues and Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Chainsaw won’t start | Fuel issues | Check fuel quality and ensure it is properly mixed. |

| Engine stalling | Clogged air filter | Clean or replace the air filter. |

| Poor cutting performance | Dull chain | Sharpen or replace the chain. |

| Excessive vibration | Loose components | Tighten all screws and bolts. |

| Leaking fuel | Damaged fuel lines | Inspect and replace any damaged lines. |

Regular Maintenance Tips

Performing routine upkeep can prevent many issues. Regularly check the chain tension, clean the guide bar, and ensure all components are lubricated. Keeping your tool in optimal condition will enhance performance and prolong its lifespan.